Professional Documents

Culture Documents

ITP For Boiler Erection

Uploaded by

Umair AwanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP For Boiler Erection

Uploaded by

Umair AwanCopyright:

Available Formats

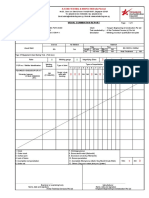

INSPECTION AND TEST PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: Erection of Boiler MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

CMEC (QC Inspector) TUV Austria Engro

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

1 Documentation

1.1 Approval of Drawings ASME Section 1 Drawings R

1.2 Weld Matrix/Weld Map ASME Sec. IX, Drawings Weld Matrix/Weld Map H/R

1.3 WPS/PQR ASME Sec. IX, Drawings WPS/PQR H/R

1.4 Welder's Qualifications ASME Sec. IX WPQ/WOPQ H/R

1.5 NDE Procedure ASME Sec. V NDE Procedure H/R

List of Qualified Welders and NDE ASME SEC-V ASME NDE Procedures

1.6 H/R

Personnel SEC-IX WPQ/WOPQ

ASME SEC II PART C, Consumable Control

1.7 Consumable control Procedure ASME SEC I Procedure

H/R

2 MATERIAL INSPECTION AND CONTROL

Inspection of raw material (Pipe, tubes, MTC & Material

2.1 ASME SEC II PART A H/R

plates) Inspection Report

ASME SEC II PART-C/ MTC & Material

2.2 Inspection of consumables ASME SEC IX Inspection Report

H/R

ASME SEC II PART-C/

2.3 Electrode Baking Consumable Control Electrode Baking Log H/R

Procedure

CALIBRATION AND CONTROL OF

3

EQUIPMENT

©ONTROLLED, ©ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 1 of 6

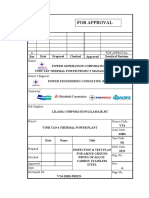

INSPECTION AND TEST PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: Erection of Boiler MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

CMEC (QC Inspector) TUV Austria Engro

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

Calibration of inspection and measuring

3.1 Calibration Procedure Claibration Ceritifcates H/R

tools and equipment (IMTE's)

3.2 Calibration of Welding Machines Calibration Procedure Claibration Ceritifcates H/R

ALLIGNMENT OF DRUMS,TUBES &

4

HEADERS

ITP / Pre-Installation

4.1 Allignment of steam drum Drawings

Report

H

ITP / Pre-Installation

4.2 Allignment of front wall tubes Drawings

Report

H

ITP / Pre-Installation

4.3 Allignment of side wall tubes Drawings

Report

H

ITP / Pre-Installation

4.4 Allignment of back wall tubes Drawings

Report

H

ITP / Pre-Installation

4.5 Allignment of front wall header Drawings

Report

H

ITP / Pre-Installation

4.6 Allignment of side wall header Drawings

Report

H

ITP / Pre-Installation

4.7 Allignment of Back wall header Drawings

Report

H

©ONTROLLED, ©ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 2 of 6

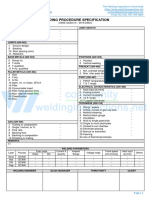

INSPECTION AND TEST PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: Erection of Boiler MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

CMEC (QC Inspector) TUV Austria Engro

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

ITP / Pre-Installation

4.8 Allignment of super heater header Drawings

Report

H

5 Fit-UP INSPECTION

ITP / Fit-up Inspection

5.1 Fit of tube to tube (water walls) Drawings

Report

H

ITP / Fit-up Inspection

5.2 Fit-up of tubes with front wall header Drawings

Report

H

ITP / Fit-up Inspection

5.3 Fit-up of tubes with side wall header Drawings

Report

H

ITP / Fit-up Inspection

5.4 Fit-up of tubes with back wall header Drawings

Report

H

ITP / Fit-up Inspection

5.5 Fit-up of tubes with super heater header Drawings

Report

H

ITP / Fit-up Inspection

5.6 Fit-up of tubes with economiser header Drawings

Report

H

ITP / Fit-up Inspection

5.7 Fit-up of downcomers header Drawings

Report

H

ITP / Fit-up Inspection

5.8 Fit-up of downcomers with steam drum Drawings

Report

H

ITP / Fit-up Inspection

5.9 Fit-up of tubes with air chamber Drawings

Report

H

ITP / Fit-up Inspection

5.10 Fit-up of connections with headers Drawings

Report

H

ITP / Fit-up Inspection

5.11 Fit-up of tubes with cooling screen headers Drawings

Report

H

ITP / Fit-up Inspection

5.12 Fitup of down-comers/risers Drawings

Report

H

©ONTROLLED, ©ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 3 of 6

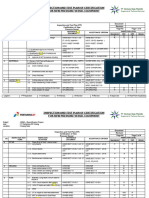

INSPECTION AND TEST PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: Erection of Boiler MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

CMEC (QC Inspector) TUV Austria Engro

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

ITP / Fit-up Inspection

5.13 Fitup of Cyclone Drawings

Report

H

ITP / Fit-up Inspection

5.14 Fit-up of tubes with tubes Drawings

Report

H

6 WELDING INSPECTION

Welding of tubes inside the steam drum ITP / Welding

6.1 ASME Sec 1/IX W

after expansion Inspection Report

Welding of tubes inside the water drum ITP / Welding

6.2 ASME Sec 1/IX W

after expansion Inspection Report

ITP / Welding

6.3 welding of tubes with front wall header ASME Sec 1/IX

Inspection Report

W

ITP / Welding

6.4 welding of tubes with side wall header ASME Sec 1/IX

Inspection Report

W

ITP / Welding

6.5 welding of tubes with back wall header ASME Sec 1/IX

Inspection Report

W

©ONTROLLED, ©ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 4 of 6

INSPECTION AND TEST PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: Erection of Boiler MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

CMEC (QC Inspector) TUV Austria Engro

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

ITP / Welding

6.6 welding of tubes with super heater header ASME Sec 1/IX

Inspection Report

W

ITP / Welding

6.7 Welding of down-comers/risers ASME Sec 1/IX

Inspection Report

W

ITP / Welding

6.8 Welding of Cyclone ASME Sec 1/IX

Inspection Report

W

ITP / Welding

6.9 Welding of tubes with tubes ASME Sec 1/IX

Inspection Report

W

QIP / Inspection

ASME SEC-V , ASME Request /

7 NDE SEC-I Dimensional

Inspection Report,

ASME SEC-V , ASME

7.1 100% RT of all Butt joints SEC-1

ITP / RT REPORT H/R

ASME SEC-V , ASME

7.2 Random DPT of bevel of non-RT welding SEC-1

ITP / DPT REPORT H/R

ASME SEC-V , ASME

7.3 PMI of super heater coils SEC-1

ITP / PMI REPORT H/R

8 PWHT ASME SEC-1 PWHT Report H

PWHT of super heater coil & header (if

8.1 ASME SEC-1 PWHT Chart & Report H/R

required)

9 Final Inspection H

Dimensional inspection as per last revision

9.1 Drawings Dimensional Report H/R

of drawing

©ONTROLLED, ©ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 5 of 6

INSPECTION AND TEST PLAN

JOB NO: PROJECT NAME: CLIENT: DATE:

DRAWING No: _ DESCRIPTION: Erection of Boiler MANUFACTURER'S SERIAL NO.: QIP NO.: REV. No.: 0

H:Hold W:Witness point S:Surveillance Inspection R:Review of Record

CMEC (QC Inspector) TUV Austria Engro

Acceptance

Sr. No. Description of Inspection & Test Verifying Document Remarks

Criteria Check Check Check

Sign Sign Sign

Point Point Point

9.2 Hydrostatic test ASME SEC 1 Hydro test Report H/R

Note: After the final hydrostatic test Boiler shall Air Cleaning Inspection

9.3 be dried and cleaned completely. Report

H/R

10 SURFACE PREPARATION H

ITP / Surface Cleaning

10.1 Cleaning / Burushing SA 2 &1/2

Inspection Report

H

ITP/ Painting Inspection

10.2 Painting Manufacturer data sheet

Report

H

11 Review of Inspection Data Manual. H

12 NON CONFORMANCE (IF ANY) ASME SEC 1 NCR H

NAME: NAME: NAME:

DATE: DATE: DATE:

SIGNATURE: SIGNATURE: SIGNATURE:

©ONTROLLED, ©ONFIDENTIAL @ IKAN Engineering Services (Pvt) Ltd.-------------------------------------------- Page 6 of 6

You might also like

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Inspection and Test Plan - Pressure Vessel Fabrication (ITP)Document9 pagesInspection and Test Plan - Pressure Vessel Fabrication (ITP)Senthil Kumaran100% (2)

- ITP Heat ExchangerDocument3 pagesITP Heat ExchangerĐỗ Thị Huyền100% (3)

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisNo ratings yet

- Exhibit No.34 - Welding Consumables Receiving Inspection RecordDocument1 pageExhibit No.34 - Welding Consumables Receiving Inspection RecordMohammed KamalNo ratings yet

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDocument7 pages005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- 3-Piping Repair Weld Procedure - PR003Document5 pages3-Piping Repair Weld Procedure - PR003mohd as shahiddin jafriNo ratings yet

- Sample ITP BoilerDocument6 pagesSample ITP Boilerintolscrib100% (1)

- QIR 101 Welder Qualification CertificateDocument1 pageQIR 101 Welder Qualification CertificateSamer BayatiNo ratings yet

- Inspection Test Plan For Pipeline JobsDocument6 pagesInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNo ratings yet

- Marine Facilities Work Egyptian LNG Project-Idku Work Instruction FOR Handling of Consuamable MaterialsDocument6 pagesMarine Facilities Work Egyptian LNG Project-Idku Work Instruction FOR Handling of Consuamable Materialszaki fadlNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Welding Consumables Handling Procedure.Document5 pagesWelding Consumables Handling Procedure.Mohammed Kamal78% (23)

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- Procedure For Calibration of Machines Welding PDFDocument3 pagesProcedure For Calibration of Machines Welding PDFravi00098100% (1)

- NDT Map Itp Pressure VesselDocument4 pagesNDT Map Itp Pressure VesselSYED FADZIL SYED MOHAMEDNo ratings yet

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Assessment Procedure Welding Report FormDocument23 pagesAssessment Procedure Welding Report Formssierro100% (1)

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- Fit Up Report Format-1Document1 pageFit Up Report Format-1BalkishanDyavanapellyNo ratings yet

- Welding Consumable and Storage ProcedureDocument10 pagesWelding Consumable and Storage Procedurehasan_676489616100% (1)

- ITP For Piping WorksDocument91 pagesITP For Piping Workshasan_676489616100% (1)

- Dimensional Inspection ReportDocument2 pagesDimensional Inspection Reportrize1159No ratings yet

- Inspection and Test Plan For Water Tube BoilerDocument13 pagesInspection and Test Plan For Water Tube BoilerVinh Do Thanh100% (1)

- Attachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Document44 pagesAttachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Ali Hajirassouliha100% (1)

- ITPDocument7 pagesITPSyed Mahmud Habibur Rahman83% (6)

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Document24 pagesItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Vaccum Box Test Procedure For All TanksDocument6 pagesVaccum Box Test Procedure For All Tanksויליאם סן מרמיגיוסNo ratings yet

- Hydrotest ProcedureDocument12 pagesHydrotest Procedurealex_feryando42100% (1)

- HRSG ITP (Rev E)Document5 pagesHRSG ITP (Rev E)rvsreddysena100% (5)

- Inspection and Test Plan For Pressure VesselDocument4 pagesInspection and Test Plan For Pressure VesselNurul Amirah Princesza100% (3)

- Hydrotest Check ListDocument1 pageHydrotest Check ListSaut Maruli Tua SamosirNo ratings yet

- Quality Audit Checklist For Flange ManagementDocument3 pagesQuality Audit Checklist For Flange ManagementjksankarNo ratings yet

- Dimensional Inspection Report: Sample Production Lot/BatchDocument1 pageDimensional Inspection Report: Sample Production Lot/BatchAndi Yanuar0% (1)

- Alignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / DateDocument6 pagesAlignment Inspection Report (Vertical Equipment) : - Sign / Date Sign / Date Owner Sign / Dateคุณพ่อน้อง บิ๊กบอส100% (1)

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriNo ratings yet

- PQR Wps WPQ FormatDocument12 pagesPQR Wps WPQ FormatessnelsonNo ratings yet

- Test PackDocument17 pagesTest PackMuhammad Bilal Arif100% (3)

- 5.a. Piping Fabrication PlanDocument15 pages5.a. Piping Fabrication PlanOkeyman100% (5)

- Check List For Installation of Local Instruments.Document1 pageCheck List For Installation of Local Instruments.Jaya SeelanNo ratings yet

- Inspection and Test Plan For New Pressure VesselDocument2 pagesInspection and Test Plan For New Pressure VesselCak Nhass0% (1)

- PWHTDocument103 pagesPWHTChetan B KapadiaNo ratings yet

- PWHT Procedure PDFDocument9 pagesPWHT Procedure PDFAbhishek AnandNo ratings yet

- Flow Chart Test PackageDocument1 pageFlow Chart Test PackagejajakaNo ratings yet

- WPS Format For Asme Ix - Wps - GtawDocument1 pageWPS Format For Asme Ix - Wps - GtawThe Welding Inspections Community50% (2)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- QIP of Boiler For ErectionDocument6 pagesQIP of Boiler For ErectionUmair Awan100% (2)

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- Draft ITP PV NEW PEP ScrubberDocument4 pagesDraft ITP PV NEW PEP Scrubberinspectionzona11No ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument10 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Qa-R-01 List of Measuring Equipment and Calib. DueDocument2 pagesQa-R-01 List of Measuring Equipment and Calib. DuevinothNo ratings yet

- Inspection and Test Plan For Storage TankDocument8 pagesInspection and Test Plan For Storage TankAndreas AlexanderNo ratings yet

- Qa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Document3 pagesQa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Ali Haider100% (1)

- ITP ManifoldDocument7 pagesITP ManifoldvinothNo ratings yet

- ITP For PipingDocument5 pagesITP For PipingAldeline SungahidNo ratings yet

- Inspection Test Plan: Fabrication and Instalation of PipingDocument3 pagesInspection Test Plan: Fabrication and Instalation of PipingRejoy babyNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Solved Passed Paper FCPS Part-1 DaleepDocument20 pagesSolved Passed Paper FCPS Part-1 DaleepUmair AwanNo ratings yet

- Part 1: Summary of The Entire SessionDocument4 pagesPart 1: Summary of The Entire SessionmarufNo ratings yet

- Part 1: Summary of The Entire SessionDocument3 pagesPart 1: Summary of The Entire SessionDYNOOO GAMEINGNo ratings yet

- Part 1: Summary of The Entire SessionDocument4 pagesPart 1: Summary of The Entire SessionUmair AwanNo ratings yet

- Part 1: Summary of The Entire SessionDocument5 pagesPart 1: Summary of The Entire Sessionmaruf100% (1)

- Part 1: Summary of The Entire Session:: Light FormsDocument7 pagesPart 1: Summary of The Entire Session:: Light FormsUmair AwanNo ratings yet

- Solved Passed Paper FCPS Part-2 DaleepDocument20 pagesSolved Passed Paper FCPS Part-2 DaleepUmair AwanNo ratings yet

- Part 1: NUMBER: Dream Worldwide Unit 1Document9 pagesPart 1: NUMBER: Dream Worldwide Unit 1DYNOOO GAMEINGNo ratings yet

- Part 1: Summary of The Entire SessionDocument3 pagesPart 1: Summary of The Entire SessionDYNOOO GAMEINGNo ratings yet

- Part 1: NUMBER: Dream Worldwide Unit 1Document9 pagesPart 1: NUMBER: Dream Worldwide Unit 1DYNOOO GAMEINGNo ratings yet

- Pair Group:: PART 2: Notes On Light & Heavy StatusDocument4 pagesPair Group:: PART 2: Notes On Light & Heavy StatusDYNOOO GAMEINGNo ratings yet

- PART 1: Summary of The Entire Session: in EnglishDocument4 pagesPART 1: Summary of The Entire Session: in EnglishUmair AwanNo ratings yet

- Part 1: Three Kinds of Words in ArabicDocument5 pagesPart 1: Three Kinds of Words in Arabicesma baharNo ratings yet

- Part 1: Three Kinds of Words in ArabicDocument5 pagesPart 1: Three Kinds of Words in Arabicesma baharNo ratings yet

- Factory Acceptance Test For PRVDocument4 pagesFactory Acceptance Test For PRVUmair AwanNo ratings yet

- Pair Group:: PART 2: Notes On Light & Heavy StatusDocument4 pagesPair Group:: PART 2: Notes On Light & Heavy StatusDYNOOO GAMEINGNo ratings yet

- Taking Ownership - Optimizing ProductivityDocument29 pagesTaking Ownership - Optimizing ProductivityUmair AwanNo ratings yet

- Taking Control of Your Career: Sandra Haase & Catherine Steele Centre For People at WorkDocument19 pagesTaking Control of Your Career: Sandra Haase & Catherine Steele Centre For People at WorkUmair AwanNo ratings yet

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- Introduction To Petroleum Refinery OperationsDocument12 pagesIntroduction To Petroleum Refinery Operationsvinhlhd83% (6)

- AlignmentDocument27 pagesAlignmentdax100% (2)

- Factory Acceptance Test For RDDocument3 pagesFactory Acceptance Test For RDUmair Awan100% (1)

- GEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceDocument20 pagesGEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceUmair Awan100% (1)

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVDocument2 pagesTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanNo ratings yet

- Section PF - Heating & VentilationDocument8 pagesSection PF - Heating & VentilationUmair AwanNo ratings yet

- 20140718042050137Document11 pages20140718042050137bkprodhNo ratings yet

- ................................. DIVISION OFFICE 1999 Inspection Guide (Metric Version) Major Structures - Steel ErectionDocument4 pages................................. DIVISION OFFICE 1999 Inspection Guide (Metric Version) Major Structures - Steel ErectionYohannes GebreNo ratings yet

- Minimum Quality Requirements For Epc Contractors PDFDocument47 pagesMinimum Quality Requirements For Epc Contractors PDFUmair Awan100% (2)

- Gb6654-1996 Steel Plate For PVDocument14 pagesGb6654-1996 Steel Plate For PVsiens2304No ratings yet

- BalancingDocument40 pagesBalancingdax100% (2)

- Updated Summary of Alignment Soils Mpemba-Isongole Road From CML - 03102012Document35 pagesUpdated Summary of Alignment Soils Mpemba-Isongole Road From CML - 03102012david karasilaNo ratings yet

- Hydraulics - Civil Engineering Questions and Answers Page 3Document6 pagesHydraulics - Civil Engineering Questions and Answers Page 3umairNo ratings yet

- Howard B (1) - Petroleum Engineers Handbook, Part 4Document331 pagesHoward B (1) - Petroleum Engineers Handbook, Part 4yayNo ratings yet

- SB 1803 R2 Operating TBO & HSI FrequencyDocument22 pagesSB 1803 R2 Operating TBO & HSI FrequencyDade Sobarna100% (4)

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Document255 pagesD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- I-Beam Girder ComputionsDocument10 pagesI-Beam Girder ComputionsMark Christopher Del RosarioNo ratings yet

- Easa Ar100 2006 PDFDocument33 pagesEasa Ar100 2006 PDFChecho Buenaventura100% (1)

- Hydro Power PlantsDocument7 pagesHydro Power PlantsKyambadde FranciscoNo ratings yet

- Belt Drive Numerical 1Document6 pagesBelt Drive Numerical 1Prateek ridersNo ratings yet

- NDT Important QuestionsDocument2 pagesNDT Important QuestionsSaffan ahmed KhanNo ratings yet

- A Review On Battery Thermal Management System of Electric VehicleDocument5 pagesA Review On Battery Thermal Management System of Electric VehiclePrafull ShindeNo ratings yet

- 001-008 Camshaft: InstallDocument6 pages001-008 Camshaft: InstallNaing Min HtunNo ratings yet

- Entropy of Mixing PDFDocument16 pagesEntropy of Mixing PDFrupaliroyNo ratings yet

- PTSC MC-Piping Design Training-Basic Piping-LATESTDocument31 pagesPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- NATCO TurbulatorDocument2 pagesNATCO TurbulatorshansalNo ratings yet

- A Brief Review of Recent Results in Vortex Induced VibrationsDocument23 pagesA Brief Review of Recent Results in Vortex Induced VibrationsAkshay DeshpandeNo ratings yet

- Bircosir - NW 150: Stability and DiversityDocument5 pagesBircosir - NW 150: Stability and Diversityjagath2005ukNo ratings yet

- 9792 PHYSICS: MARK SCHEME For The May/June 2010 Question Paper For The Guidance of TeachersDocument14 pages9792 PHYSICS: MARK SCHEME For The May/June 2010 Question Paper For The Guidance of TeachersbobNo ratings yet

- ME3252 Chapter 2 NotesDocument5 pagesME3252 Chapter 2 NotesAsffaq MuhdNo ratings yet

- Ce353 CH7 PDFDocument19 pagesCe353 CH7 PDFDarlene Mae ZaraNo ratings yet

- Qip (Iit Indore) - Steel-Concrete Composite StructuresDocument33 pagesQip (Iit Indore) - Steel-Concrete Composite StructuresLong LothaNo ratings yet

- FRR 500 - 500S Igm0087 - 6-CylDocument4 pagesFRR 500 - 500S Igm0087 - 6-CylMarvin White0% (1)

- Lecture2 PDFDocument9 pagesLecture2 PDFPriyam NayakNo ratings yet

- Skoda Fabia 1.4Document2 pagesSkoda Fabia 1.4wnsdNo ratings yet

- MCL 311 Lab 4 PDFDocument29 pagesMCL 311 Lab 4 PDFAditya SheoranNo ratings yet

- Exploded View of WEBER 32-36 DGV 5A GBPDocument3 pagesExploded View of WEBER 32-36 DGV 5A GBPJannie CoetzeeNo ratings yet

- 05-Vl996 Vista Series-A4 2010 Intl Application GuideDocument4 pages05-Vl996 Vista Series-A4 2010 Intl Application GuideJuan SuarezNo ratings yet

- High-Mn Steel Weldment Mechanical Properties at 4.2 KDocument9 pagesHigh-Mn Steel Weldment Mechanical Properties at 4.2 K3834saldNo ratings yet

- Local Checks 1Document85 pagesLocal Checks 1Alphyl BalasabasNo ratings yet