Professional Documents

Culture Documents

Oxidation Stability of Biodiesel

Uploaded by

Ramnarayan MeenaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oxidation Stability of Biodiesel

Uploaded by

Ramnarayan MeenaCopyright:

Available Formats

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X,

PP 77-83

www.iosrjournals.org

Bio-Diesel Production from Mahua (Madhuca Indica) and its

Characterization through a TLC Analysis

Ramnarayan Meena1, Mukesh Tak2, Akash Nukani3

1

(Department of Mechanical Engineering, U. V. Patel College of Engineering, Ganpat University, India)

2

(Department of Mechanical Engineering, U. V. Patel College of Engineering, Ganpat University, India)

Abstract: In search of a suitable fuel alternative to fast depleting fossil fuel and oil reserves and in serious

consideration of the environmental issues associated with the extensive use of fuels based on petrochemicals,

research work is in progress worldwide, Non edible mahua oil was also used as a SGBF candidate in the

present study. Double stage transesterification was used for Non Edible Mahua Oil. Through a TLC analysis is

found that the FFA and TG are totally converted in to the FAME. The optimum combinations for reducing the

acid level of mahua oil to less than 1% after pretreatment was 0.32% v/v methanol to oil ratio, 1.24% v/v

H2SO4, catalyst and 1.26 hours reaction time at 65 C. After the pretreatment of mahua oil, transesterification

reaction was carried out with 0.25 v/v methanol to oil ratio (6:1 molar ratio) and 0.7% w/v KOH as an alkaline

catalyst to produce biodiesel. The fuel properties of mahua biodiesel so obtained compiled the requirements of

both the ASTM and EN standards for biodiesel.

Keywords: Alternative fuel, Bio-Diesel, mahua oil, TLC Analysis, Transesterification.

I. Introduction

Bio fuels are drawing increasing attention worldwide as substitutes for petroleum-derived

transportation fuels to address energy cost, energy security and global warming concerns associated with liquid

fossil fuels. The term bio fuel is used here to mean any liquid fuel made from plant material that can be used as

a substitute for petroleum-derived fuel. Second-generation fuels are generally those made from non-edible

lignocellulosic biomass, either non-edible residues of food crop production (e.g. corn stalks or rice husks) or

non-edible whole plant biomass (e.g. grasses or trees grown specifically for energy) or waste product of refinery

oil industry. Biodiesel is defined by ASTM International as a fuel composed of monoalkyl esters of long-chain

fatty acidsderived from renewable vegetable oils or animal fats meeting the requirements of ASTM D6751

(ASTM 2008a). Vegetable oils and animal fats are principally composed of triacylglycerols (TAG) consisting of

longchain fatty acids chemically bound to a glycerol (1, 2,3- propanetriol) backbone. The chemical process by

which biodiesel is prepared is known as the transesterification reaction.

II. Materials And Method

Mahua oil is obtained from the kernel of mahua tree (Madhuca indica), which is a medium to large tree

found in most parts of India. Mahua seed contain 30-40 percent fatty oil called mahua oil. Mahua oil was

obtained from Agrawal oil mills near Udaipur, Rajasthan, India. Before preparation of bio diesel the property of

oil likes chemical composition of oil, acid value, iodine value and FFA etc should be known for establishing

procedure for bio diesel. Mahua biodiesel was prepared using two step processes, in which initial step is acid

esterification process and second one is transesterification process. Experiments were conducted in a laboratory-

scale setup. All chemicals including methanol (99.5%) and sulfuric acid (99% pure) were of analytical reagent

(AR) grade. The KOH in pellet form was used as a base catalyst for transesterification reaction. Crude unrefined

mahua oil was brownish yellow in colour. This oil had an initial acid value of 20.34 mg KOH/gm of oil

corresponding to a FFA level of 10.17%.

III. Preperation And Chracterrization

"Biodiesel is defined as mono-alkyl ester of long chain fatty acid derived from vegetable oil or animal

fats.” Non edible Mahua oil and acid oil (waste product) from ground nut oil industry is used as a second

generation bio fuel. Mahua biodiesel was prepared using two step processes. Crude unrefined mahua oil was

brownish yellow in colour. This oil had an initial acid value of 20.34 mg KOH/gm of oil corresponding to a

FFA level of 10.17%.

Innovation in engineering science and technology (NCIEST-2015) 77 | Page

JSPM’S Rajarshi Shahu College Of Engineering,Pune-33,Maharashtra ,India

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X,

PP 77-83

www.iosrjournals.org

3.1 Transesterification process:

a) Preheating of esterified oil:

b) Transesterification process using alkaline catalysis

c) Separation of Glycerol from Transesterified oil (FAME)

d) Neutralizing Transesterified oil (FAME)

3.2 Acid esterification:

a) Preheating of raw oil

b) Esterification process using acid catalysis

c) Separation of Methanol from Esterifies oil

d) Neutralized Esterifies oil

Pre-heated raw mahua oil mixed with methanol (0.32% v/v) using H2SO4 as catalyst (1.24% v/v) for 1.45 hours

reaction at 65⁰ C temperature.

Fig. 1 Pre-heating of Raw oil Fig. 2 Esterification Process Using Acid Catalysis

After esterification process 94.14% reduction in acid value of mahua oil which is suitable for the main

transesterification reaction.

Fig. 3 Transesterification process Fig. 4 Neutralized Esterified Oil

Alkaline-catalyzed transesterification was run using a pre-treated sample that had an acid value of 1.19

mg KOH/gm of oil. A 0.25 %v/v methanol-to-oil and an alkaline catalyst (0.5% w/v KOH) were used for the

reaction for 45 minute.

Innovation in engineering science and technology (NCIEST-2015) 78 | Page

JSPM’S Rajarshi Shahu College Of Engineering,Pune-33,Maharashtra ,India

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X,

PP 77-83

www.iosrjournals.org

Fig.5 Separation of Methanol from Esterifies Oil Fig.6 Neutralizing Transesterified Oil (FAME)

IV. Tlc Analysis Of Bio Diesel With Respect To Mahua Oil

TLC (Thin Layer chromatography) is commonly used for qualitative analysis. It is fast and effective,

and also can be used to verify the conversion of the oil during the reaction. Some solvent systems and detecting

reagents commonly used for evaluation of starting material conversion during the reaction are shown below.

Solvent systems and detecting reagents parameters by (%v/v/v) for TLC [15]:

(a) Hexane: ethyl acetate: acetic acid (90:10:1) iodine vapour

(b) Iso hexane: diethyl ether: acetic acid (80:20:1) ultraviolet light

(c) Chloroform: petroleum ether (1:3)

(d) Petroleum ether: diethyl ether: acetic acid (85:15:1) iodine vapour

(e) Hexane: ethyl acetate: acetic acid (90:10:1) sulphuric acid: methanol 1:1

Fig. 7 TLC results of product composition at different reaction point for transesterified mahua oil.

The results analyzed by TLC for neat mahua oil were shown in figure 7. The changes in product

compositions with reaction during the transesterification of the oils and the distribution of various components

in the reaction system can be clearly seen. In above figure point A and B is consider as a reference point and

point a show initial mahua oil point, b indicates after esterification point.

Innovation in engineering science and technology (NCIEST-2015) 79 | Page

JSPM’S Rajarshi Shahu College Of Engineering,Pune-33,Maharashtra ,India

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X,

PP 77-83

www.iosrjournals.org

Fig 8. Raw Mahua Oil and Mahua Oil Bio Diesel

V. Characterisation of second generation bio diesel

5.1 Acid value

A value indicating the amount of free acid present in a substance, equal to the number of milligrams of

potassium hydroxide needed to neutralize the free fatty acids present in one gram of fat or oil also called acid

number. Figure 9-10 shows acid value of different Oils and biodiesel.

AV = (v - b) x N x 56.1 / w

Where, v is the titration volume in ml

b is the blank in ml

N is the normality of the KOH solution

w is the weight of sample in gm

Fig. 9 Acid Value of different Oils and biodiesel

5.2 Free fatty acid (FFA)

Figure FFA of different Oils and biodiesel. FFA% is the weight to weight ratio of FFA found in an oil

sample. The weight of an oil sample divided into the weight of the FFA in that sample. To calculate FFA% from

an acid value the formula is:

AV = 1.99 FFA%

Innovation in engineering science and technology (NCIEST-2015) 80 | Page

JSPM’S Rajarshi Shahu College Of Engineering,Pune-33,Maharashtra ,India

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X,

PP 77-83

www.iosrjournals.org

Fig. 10 FFA of different Oils and biodiesels

5.3 Kinematic Viscosity

For present work Viscosity is measure with help of redwood viscometer which shows on figure 11-12.

In red wood viscometer cup is fill up to oil and which is surrounded by water bath. Kinematic viscosity is

measure at a 400C. With the help of heater water is heated and reached temperature around 40-450C. Oil was

stop through needle in cup pin hole when temperature is reached 400C needle is remove from the pin hole and

collect in to collector for 50 ml and time was measured with the help of stop watch.

Fig. 11 Red wood Viscometer

The viscosity of an engine fuel is one of the most critical fuel features. It plays a dominant role in the

fuel spray, mixture formation and combustion process. The high viscosity interferes with the injection process

and leads to insufficient fuel atomization. Moreover, the mean diameter of the fuel droplets from the injector

and their penetration increases with increasing fuel viscosity. The inefficient mixing of fuel with air contributes

to incomplete combustion in the engine. In addition to all these, high viscosity can cause early injection due to

high line pressure, which moves the combustion of the fuel closer to top dead centre, increasing the maximum

pressure and temperature in the combustion chamber. Figure 3-22 shows kinematic viscosity of different oils

and biodiesel obtained in our laboratory.

Innovation in engineering science and technology (NCIEST-2015) 81 | Page

JSPM’S Rajarshi Shahu College Of Engineering,Pune-33,Maharashtra ,India

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X,

PP 77-83

www.iosrjournals.org

Fig. 12 Kinematics Viscosity of different Oils and biodiesels

Viscosity of any fuel is related to its chemical structure. Viscosity increases with the increase in the chain length

and decreases with the increase in the number of double bonds (un-saturation level) [20].

VI. Conclusions

Biodiesel from Mahua oil was obtained by two stage transesterification process. In order to synthesize

acid oil no standardize method was available in the literature. The conventional method fails to form ester using

acid oil as its FFA value is too high. A suitable solid acid catalyst was developed with the help of chemistry

department to successfully synthesize the acid oil for biodiesel formation. It is important to note that acid oil is

much cheaper as compared to any other available feedstock for biodiesel and is generally considered as a waste

product of oil refinery. In view of increased cost of first generation biofuel and also some non-edible oil

candidate like Pongamia and Jatropha, the waste product of oil industry i.e. acid oil which is available at much

cheaper cost and its utility as a biofuel for CI engine promises better prospectus for biodiesel industry. Mahua

oil biodiesel too have better prospectus as its tree has abundant seeds and oil seed yield is also very high.

References

[1]. Anca Diana Barbu, Ricardo Fernandez, Ann Gardiner, Ayla Uslu and James Greenleaf., Energy and environment report 2008, EEA

Report No 6, 2008.

[2]. L.B. Klyashtorin & A.A. Lyubushin., ‘On the Coherence between Dynamics of the World Fuel Consumption and Global

Temperature Anomaly’, Energy & Environment, volume 14, No.06, 2003.

[3]. Sandip D. Shah., A Study of the Physical and Chemical Properties of Exhaust Emissions from Heavy- Duty Diesel Engines, Ph.D.

Thesis, Dept. of Chemical and Environment Engineering, University of California, Dec 2004

[4]. Agarwal A.K., Bio fuels (alcohols and biodiesel) applications as fuels for internal combustion engines, Progress in Energy and

Combustion Science, 2007, 33, 233-71.

[5]. Poonam Singh Nigam, Anoop Singh., Production of liquid bio-fuels from renewable resources: A review, Progress in Energy and

Combustion Science, 2011, 37, 52-68.

[6]. S.N. Naik, Vaibhav V. Goud, Prasant K. Rout, Ajay K. Dalai., ‘Production of first and second generation bio fuels: A

comprehensive review’ Renewable and Sustainable Energy Reviews, 2010, 14, 578–597.

[7]. International Energy Agency (IEA), From First to Second-Generation Bio fuel Technologies.

http://www.iea.org/publications/free/new/Desc. Pdf, 2008.

[8]. Larson ED., Biofuel production technologies: status, prospects and implications for trade and development, Report No.

UNCTAD/DITC/TED/2007/10.

[9]. Stevens DJ, Worgetten M, Saddler J., Biofuels for transportation: an examination of policy and technical issues, IEA Bioenergy

Task 39, Liquid Biofuels Final Report 2001-2003.

[10]. Srivastava, A., Prasad R., ‘Triglycerides-based diesel fuels’, Renew. Sustain. Energy Rev., 2000, 4, 111–133.

[11]. B M Kulkarni, B G Pujar & S Shanmukhappa, Investigation of acid oil as a source of biodiesel, Indian Journal of Chemical

Technology, September 2008, Vol. 15, 467-471.

[12]. Vishwanath Patil, Khanh-Quang Tran, Hans Ragnar Giselrod, Towards Sustainable Production of Biofuels from Microalgae,

International Journal of Molecular Sciences, 2008, 9, 1188-1195.

Innovation in engineering science and technology (NCIEST-2015) 82 | Page

JSPM’S Rajarshi Shahu College Of Engineering,Pune-33,Maharashtra ,India

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE)

e-ISSN: 2278-1684,p-ISSN: 2320-334X,

PP 77-83

www.iosrjournals.org

[13]. A.L. Ahmad, N.H. Mat Yasin, C.J.C. Derek, J.K. Lim., Microalgae as a sustainable energy source for biodiesel production: A

review, Renewable and Sustainable Energy Reviews, 2011, 15, 584–593.

[14]. Shashikant Vilas Ghadge, Hifjur Raheman., Process optimization for biodiesel production from mahua (Madhuca indica) oil using

response surface methodology, Bio resource Technology, 2006, 97, 379–384.

[15]. Angelo C. Pinto, Lilian L. N. Guarieiro, Michelle J. C. Rezende, Núbia M. Ribeiro, Ednildo A. Torresb, Wilson A. Lopes, Pedro A.

de P. Pereirac and Jailson B. de Andrade., Biodiesel: An Overview, J. Braz. Chem. Soc., 2005, Vol. 16, No. 6B, 1313-1330.

[16]. D.Y.C. Leung ,Y. Guo., Transesterification of neat and used frying oil: ptimization for biodiesel production, Fuel Processing

Technology, 2006, 87, 883–890.

[17]. Rafael Guzatto, Diego Defferrari, Quelen Bülow Reiznautt, Ígor Renz Cadore, Dimitrios Samios., Transesterification double step

process modification for ethyl ester biodiesel production from vegetable and waste oils, Fuel, 2012, 92, 197–203.

[18]. D. Samios , F. Pedrotti, A. Nicolau, Q.B. Reiznautt, D.D. Martini, F.M. Dalcin.’ ‘A Transesterification Double Step Process - TDSP

for biodiesel preparation from fatty acids triglycerides’, Fuel Processing Technology, 2009, 90, 599–605.

[19]. Michael J. Haas, Paul J. Michalski, Stan Runyon, Alberto Nunez, and Karen M. Scott., Production of FAME from Acid Oil, a By-

product of Vegetable Oil Refining, JAOCS, 2003, Vol. 80, no. 1.

[20]. M. Canakci · H. Sanli., Biodiesel production from various feedstocks and their effects on the fuel properties, J Ind Microbiol

Biotechnol, 2008, 35, 431–441.

[21]. Ali Y, Hanna MA, Cuppett SL., Fuel properties of tallow and soybean oil esters, J Am Oil Chem Soc, , 1995, 72, 1557–1564.

[22]. Lee I, Johnson LA, Hammond EG., Use of branched-chain esters to reduce the crystallization temperature of biodiesel, J Am Oil

Chem Soc, 1995, 72, 1155–1160.

Innovation in engineering science and technology (NCIEST-2015) 83 | Page

JSPM’S Rajarshi Shahu College Of Engineering,Pune-33,Maharashtra ,India

You might also like

- TIWARI Et Al., 2007Document7 pagesTIWARI Et Al., 2007Patrick MoliveiraNo ratings yet

- Experimental Study of Using Hybrid Vegetable Oil Blends in Diesel EngineDocument4 pagesExperimental Study of Using Hybrid Vegetable Oil Blends in Diesel EngineSerenityNo ratings yet

- Biodiesel Production From Residual Oils Recovered From Spent Bleaching EarthDocument6 pagesBiodiesel Production From Residual Oils Recovered From Spent Bleaching EarthCamilo Andres Picon Prada100% (1)

- Fuel Processing Technology: Umer Rashid, Farooq Anwar, Gerhard KnotheDocument7 pagesFuel Processing Technology: Umer Rashid, Farooq Anwar, Gerhard KnothejoanitanakamuraNo ratings yet

- Transesterification of Neat and Used Frying Oil: Optimization For Biodiesel ProductionDocument8 pagesTransesterification of Neat and Used Frying Oil: Optimization For Biodiesel ProductionCristiNo ratings yet

- Optimization and Standardisation of Waste Cooking Oil Into BioDieselDocument3 pagesOptimization and Standardisation of Waste Cooking Oil Into BioDieselInternational Organization of Scientific Research (IOSR)No ratings yet

- 3 Preparation and CharactersationDocument26 pages3 Preparation and Charactersationsindhnayak48No ratings yet

- Comparative study of jatropha and karanja biodiesel performance and emissions in diesel engineDocument0 pagesComparative study of jatropha and karanja biodiesel performance and emissions in diesel engineatulsemiloNo ratings yet

- Renewable Energy: Pedro J. García-Moreno, Mohriam Khanum, Antonio Guadix, Emilia M. GuadixDocument7 pagesRenewable Energy: Pedro J. García-Moreno, Mohriam Khanum, Antonio Guadix, Emilia M. GuadixIka SulistyaningtiyasNo ratings yet

- Non-Edible Seed Oils as Biodiesel FeedstocksDocument6 pagesNon-Edible Seed Oils as Biodiesel FeedstocksUMA MAHESHNo ratings yet

- Optimization of Biodiesel Production From Manilkara Zapota (L.) Seed OilDocument7 pagesOptimization of Biodiesel Production From Manilkara Zapota (L.) Seed OilMaria Mihaela100% (1)

- Kinetic Study of Methanolysis of Jatropha Curcas-Waste Food Oil MixtureDocument10 pagesKinetic Study of Methanolysis of Jatropha Curcas-Waste Food Oil MixtureCeciNo ratings yet

- Attacus Ricinii (Eri) Pupae Oil As An Alternative Feedstock For The Production of BiofuelDocument3 pagesAttacus Ricinii (Eri) Pupae Oil As An Alternative Feedstock For The Production of BiofuelWARP-World Academy of Research and PublicationNo ratings yet

- PDF/ajeassp 2011 130 132Document3 pagesPDF/ajeassp 2011 130 132Jorge Sergio CondeNo ratings yet

- Synthesis of Biolubricants From Non Edible OilsDocument5 pagesSynthesis of Biolubricants From Non Edible OilsAnonymous kw8Yrp0R5rNo ratings yet

- Optimising Palm Fatty Acid EsterificationDocument9 pagesOptimising Palm Fatty Acid EsterificationNo NameNo ratings yet

- Biodiesel Production by Enzymatic Transesterification of Papaya Seed Oil and Rambutan Seed OilDocument5 pagesBiodiesel Production by Enzymatic Transesterification of Papaya Seed Oil and Rambutan Seed OilNilmar NasaanNo ratings yet

- Transesterification and Physical Properties of Fatty Acid Methyl Ester From Rubber Seed Oil.Document7 pagesTransesterification and Physical Properties of Fatty Acid Methyl Ester From Rubber Seed Oil.hanifahNo ratings yet

- CURRENT PROBLEMS. Alternative Fuels: Use of Baru Oil (Dipteryx Alata Vog.) TO PRODUCDocument4 pagesCURRENT PROBLEMS. Alternative Fuels: Use of Baru Oil (Dipteryx Alata Vog.) TO PRODUCAntonio Carlos Flash BatistaNo ratings yet

- Process Optimization of Crude Palm Oil Biodiesel Production by Response Surface MethodologyDocument8 pagesProcess Optimization of Crude Palm Oil Biodiesel Production by Response Surface MethodologyRuzi Falahi KautsarNo ratings yet

- Modeling, Analysis and Optimization For The Biodiesel Production Process From Waste Cooking OilDocument10 pagesModeling, Analysis and Optimization For The Biodiesel Production Process From Waste Cooking OilAdhisya Salma KhairunnisaNo ratings yet

- Preparation and Research On Properties of Castor Oil As A Diesel Fuel AdditiveDocument8 pagesPreparation and Research On Properties of Castor Oil As A Diesel Fuel Additivezin berNo ratings yet

- Sustainable Production of Biodiesel From Tallow, Lard and Poultry Fat and Its Quality EvaluationDocument6 pagesSustainable Production of Biodiesel From Tallow, Lard and Poultry Fat and Its Quality EvaluationNidia CaetanoNo ratings yet

- Production of Biodiesel From Waste Cooking OilDocument5 pagesProduction of Biodiesel From Waste Cooking OilIJMERNo ratings yet

- Acid-Catalyzed Transesterification Reaction of Beef Tallow For Biodiesel Production by Factor VariationDocument4 pagesAcid-Catalyzed Transesterification Reaction of Beef Tallow For Biodiesel Production by Factor VariationAJER JOURNALNo ratings yet

- Modeling, Analysis and Optimization For The Biodiesel Production Process From Waste Cooking OilDocument10 pagesModeling, Analysis and Optimization For The Biodiesel Production Process From Waste Cooking Oilkivumbi AchileoNo ratings yet

- MS Spectroscopy StudyDocument13 pagesMS Spectroscopy StudyPerseaNo ratings yet

- Tetrahydrofuran-Assisted Transesterification Biodiesel From Waste Cooking OilDocument5 pagesTetrahydrofuran-Assisted Transesterification Biodiesel From Waste Cooking OilromaniaturismNo ratings yet

- Particle SizeDocument7 pagesParticle SizeyohannesNo ratings yet

- Heliyon: Adewale Johnson Folayan, Paul Apeye Lucky AnaweDocument11 pagesHeliyon: Adewale Johnson Folayan, Paul Apeye Lucky AnaweNadiah NadiahNo ratings yet

- Methanolysis of Triglycerides Using Jatropha Oil and Koh CatalystDocument9 pagesMethanolysis of Triglycerides Using Jatropha Oil and Koh Catalysttoesin1No ratings yet

- International Journal of Chemtech Research: Prajakt S Charhate, Madhura Bhalerao, Vijay Y KaradbhajneDocument10 pagesInternational Journal of Chemtech Research: Prajakt S Charhate, Madhura Bhalerao, Vijay Y KaradbhajneNo NameNo ratings yet

- Determination of Physico-Chemical Properties of Castor Biodiesel A PotentialDocument7 pagesDetermination of Physico-Chemical Properties of Castor Biodiesel A PotentialIAEME PublicationNo ratings yet

- Characterization and Transesterification of Iranian Bitter Almond OilDocument5 pagesCharacterization and Transesterification of Iranian Bitter Almond OilJames VeraNo ratings yet

- Fatty Acid Methyl Esters Characteristic and Esterification of Some Vegetable Oils For P Roduction of BiodieselDocument4 pagesFatty Acid Methyl Esters Characteristic and Esterification of Some Vegetable Oils For P Roduction of BiodieselresearchinventyNo ratings yet

- Simulation of biodiesel production via transesterificationDocument9 pagesSimulation of biodiesel production via transesterificationTaslinNo ratings yet

- Chapter 3: Hydrolysis of Vegetable Oils and Animal FatDocument27 pagesChapter 3: Hydrolysis of Vegetable Oils and Animal FatSamiNo ratings yet

- Experimental Studies On The Combustion and Emission Characteristics of A Diesel Engine Fuelled With Used Cooking Oil Methyl Ester and Its Diesel BlendsDocument7 pagesExperimental Studies On The Combustion and Emission Characteristics of A Diesel Engine Fuelled With Used Cooking Oil Methyl Ester and Its Diesel BlendsAshokNo ratings yet

- Saka, Et Al. (2) Without Using Any Catalyst. An Experiment Has Been Carried Out in The Batch-TypeDocument16 pagesSaka, Et Al. (2) Without Using Any Catalyst. An Experiment Has Been Carried Out in The Batch-TypeVinaya NaralasettyNo ratings yet

- 2009 Tint Tint Kywe - Production of Biodiesel From Jatropha Oil. - IntroducciionDocument7 pages2009 Tint Tint Kywe - Production of Biodiesel From Jatropha Oil. - IntroducciionArceo A HenryNo ratings yet

- Transesterification For The Preparation of Biodies PDFDocument6 pagesTransesterification For The Preparation of Biodies PDFmelvin ekboteNo ratings yet

- YOGA ManualDocument9 pagesYOGA Manual12mchc07No ratings yet

- Fatty Acid CompositionDocument5 pagesFatty Acid CompositionAnonymous MhTaJsNo ratings yet

- Bio DieselDocument29 pagesBio DieselkiransideasNo ratings yet

- Paper 7Document6 pagesPaper 7Tiên PhạmNo ratings yet

- Bioresource Technology: María Jesús Ramos, Carmen María Fernández, Abraham Casas, Lourdes Rodríguez, Ángel PérezDocument8 pagesBioresource Technology: María Jesús Ramos, Carmen María Fernández, Abraham Casas, Lourdes Rodríguez, Ángel PérezJames VeraNo ratings yet

- Parameters in Transesterification ReactionsDocument6 pagesParameters in Transesterification Reactionsniquee9nerNo ratings yet

- 2 131 Acpi 2 (1) 2012 PDocument7 pages2 131 Acpi 2 (1) 2012 PBreKB MéndezNo ratings yet

- Research PaperDocument4 pagesResearch PaperSiddharthBhatNo ratings yet

- Biodiseal Cooked OilDocument4 pagesBiodiseal Cooked OildineshlathiaNo ratings yet

- AD Patil Sir SynopsisDocument13 pagesAD Patil Sir SynopsissumitNo ratings yet

- Renewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuDocument7 pagesRenewable Energy: Jerekias Gandure, Clever Ketlogetswe, Abraham TemuLacramioara Iuliana VladulescuNo ratings yet

- The Optimization of The Esterification Reaction in BiodieselDocument12 pagesThe Optimization of The Esterification Reaction in BiodieselPablo PaganiNo ratings yet

- PluginDocument8 pagesPluginFeri TariganNo ratings yet

- Biodiesel Production From Jatropha CurcaDocument7 pagesBiodiesel Production From Jatropha CurcaManharsinh DodiyaNo ratings yet

- Venkatesh and BhaghaviDocument10 pagesVenkatesh and BhaghavilarryNo ratings yet

- Imp 2Document8 pagesImp 2Shivam PandyaNo ratings yet

- Biodiesel As An Alternative Fuel A StateDocument24 pagesBiodiesel As An Alternative Fuel A Statepadam0088No ratings yet

- Esterification of High Free Fatty Acid Crude Palm Kernel Oil As Feedstock For Base-Catalyzed Transesterification ReactionDocument5 pagesEsterification of High Free Fatty Acid Crude Palm Kernel Oil As Feedstock For Base-Catalyzed Transesterification ReactionInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Trait-Modified Oils in FoodsFrom EverandTrait-Modified Oils in FoodsFrank T. OrthoeferNo ratings yet

- Session 4 Percentage and AgesDocument14 pagesSession 4 Percentage and AgesRamnarayan MeenaNo ratings yet

- Session 11 Clocks, Permutations and CombinationDocument13 pagesSession 11 Clocks, Permutations and CombinationRamnarayan MeenaNo ratings yet

- Session 8: Problems On Simple Interest and Compound InterestDocument11 pagesSession 8: Problems On Simple Interest and Compound InterestRamnarayan MeenaNo ratings yet

- Session 2 Decimal Fraction and SimplificiationDocument49 pagesSession 2 Decimal Fraction and SimplificiationRamnarayan MeenaNo ratings yet

- Session 9 Area Volume and SurfaceDocument12 pagesSession 9 Area Volume and SurfaceRamnarayan MeenaNo ratings yet

- Session 3 Exponents Roots and AverageDocument17 pagesSession 3 Exponents Roots and AverageRamnarayan MeenaNo ratings yet

- Session 7: Problems On Trains Boats and StreamsDocument11 pagesSession 7: Problems On Trains Boats and StreamsRamnarayan MeenaNo ratings yet

- Session 12 Height and Distance, Odd Man Out and SeriesDocument22 pagesSession 12 Height and Distance, Odd Man Out and SeriesRamnarayan MeenaNo ratings yet

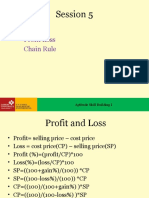

- Session 5 Profit Loss and Chain RuleDocument13 pagesSession 5 Profit Loss and Chain RuleRamnarayan MeenaNo ratings yet

- Session 10: Problems On Races and Games of Skill and CalendarDocument9 pagesSession 10: Problems On Races and Games of Skill and CalendarRamnarayan MeenaNo ratings yet

- Session 6 Time and Work & Time and DistanceDocument20 pagesSession 6 Time and Work & Time and DistanceRamnarayan MeenaNo ratings yet

- Bridge Course On Aptitude Skill Building: Prepared By: Prof. Ravi Raval (701650137) Prof. Hitesh Rajput (9824474595)Document7 pagesBridge Course On Aptitude Skill Building: Prepared By: Prof. Ravi Raval (701650137) Prof. Hitesh Rajput (9824474595)Ramnarayan MeenaNo ratings yet

- Review of Efficient High Productivity Solar StillsDocument24 pagesReview of Efficient High Productivity Solar StillsRamnarayan MeenaNo ratings yet

- Machine Design by S K MondalDocument81 pagesMachine Design by S K Mondalreyrey19No ratings yet

- Solar D DryerDocument50 pagesSolar D DryerRamnarayan MeenaNo ratings yet

- Psychrometry and Hvac: Psychrometry (Hygrometry) : Science of Moist Air HVAC: Heating, Ventilating, and Air-ConditioningDocument38 pagesPsychrometry and Hvac: Psychrometry (Hygrometry) : Science of Moist Air HVAC: Heating, Ventilating, and Air-Conditioningbenedict policarpioNo ratings yet

- Reduction of No in Diesel EngineDocument43 pagesReduction of No in Diesel EngineDevesh RajputNo ratings yet

- Learning Psychrometric Chart and Measurement of T and RHDocument31 pagesLearning Psychrometric Chart and Measurement of T and RHRamnarayan MeenaNo ratings yet

- AES L2 Solar Collectors 2017Document77 pagesAES L2 Solar Collectors 2017MuhammadNo ratings yet

- Solar Collector ClassificationDocument6 pagesSolar Collector Classification06l01a0224No ratings yet

- Ec & Us Manual PDFDocument111 pagesEc & Us Manual PDFRamnarayan MeenaNo ratings yet

- Algae Derived Biodiesel Using Nanocatalytic 2017Document39 pagesAlgae Derived Biodiesel Using Nanocatalytic 2017Ramnarayan MeenaNo ratings yet

- Solar Radiation CalculationDocument49 pagesSolar Radiation CalculationOrlando DunstNo ratings yet

- 171P00480 PDFDocument3 pages171P00480 PDFRamnarayan MeenaNo ratings yet

- 1 1 B Basic Solar GeometryDocument28 pages1 1 B Basic Solar GeometryjhdmssNo ratings yet

- Solar Geometry ExplainedDocument13 pagesSolar Geometry ExplainedParimal BhambareNo ratings yet

- Manual PDFDocument126 pagesManual PDFRamnarayan MeenaNo ratings yet

- Battery Bank Knowledge PDFDocument16 pagesBattery Bank Knowledge PDFamir uddinNo ratings yet

- Renewable Vs Nonrenewable ResourcesDocument13 pagesRenewable Vs Nonrenewable ResourcesRamnarayan MeenaNo ratings yet

- Isolation Identification and Analysis of PhytoconstituentsDocument30 pagesIsolation Identification and Analysis of PhytoconstituentsMurugan MNo ratings yet

- Bitter-Orange-epicarp and Mesocarp TinctureDocument2 pagesBitter-Orange-epicarp and Mesocarp TinctureNikotiano TobacumNo ratings yet

- Silverman 2015Document7 pagesSilverman 2015lunosicaNo ratings yet

- Experiment On Paper ChromatographyDocument8 pagesExperiment On Paper ChromatographyCarla Louise Bulacan BayquenNo ratings yet

- Module 4: TLC Analysis of Plant ExtractsDocument7 pagesModule 4: TLC Analysis of Plant ExtractsARMAN AKRAM BIN OMAR / UPMNo ratings yet

- Extraction and Separation of Plant PigmentsDocument4 pagesExtraction and Separation of Plant PigmentsJade EncarnacionNo ratings yet

- Thin Layer Chromatographi Thin Layer Chromatographi PT. Abadi Nusa UsahasemestaDocument43 pagesThin Layer Chromatographi Thin Layer Chromatographi PT. Abadi Nusa UsahasemestafebyanzNo ratings yet

- Analysis of Amino AcidsDocument3 pagesAnalysis of Amino AcidsRinaldi SukarnoNo ratings yet

- Shrinathji Institute of Pharmacy Upali Oden, NathdwaraDocument8 pagesShrinathji Institute of Pharmacy Upali Oden, NathdwaraPatel AmeeNo ratings yet

- 2mtblts Extraction2Document28 pages2mtblts Extraction2Vijay KumarNo ratings yet

- Synthesis and Characterization of Schiff Base From Aromatic Amine and Aromatic P Nitro BenzaldehydeDocument4 pagesSynthesis and Characterization of Schiff Base From Aromatic Amine and Aromatic P Nitro BenzaldehydeEditor IJTSRDNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2004/0143126A1Document5 pagesPatent Application Publication (10) Pub. No.: US 2004/0143126A1SmokeNo ratings yet

- 4.12 F. Y. B. Sc. ChemistryDocument18 pages4.12 F. Y. B. Sc. ChemistryJonnyJamesNo ratings yet

- Article PDFDocument8 pagesArticle PDFNovara RahmatNo ratings yet

- Determining Compound Rf Values Using TLCDocument5 pagesDetermining Compound Rf Values Using TLCRizki AuNo ratings yet

- Preparative HPLCDocument4 pagesPreparative HPLCottoilariNo ratings yet

- Stereospecific Synthesis of AmphetaminesDocument7 pagesStereospecific Synthesis of Amphetaminesgeovani2No ratings yet

- Unit 1 Pharmaceutical Analysis - Defination and ScopeDocument45 pagesUnit 1 Pharmaceutical Analysis - Defination and ScopeAnis SayyedNo ratings yet

- Official Paper Chromatography ProcedureDocument13 pagesOfficial Paper Chromatography ProcedureCarla Luna MinucheNo ratings yet

- DestyRestiaet AlDocument8 pagesDestyRestiaet AlBlokV 19No ratings yet

- PharmacognosyDocument67 pagesPharmacognosyAbdul Manan90% (29)

- Formal Report Extraction of Total Lipids From Chicken Egg Yolk and ColumnDocument4 pagesFormal Report Extraction of Total Lipids From Chicken Egg Yolk and ColumnNorjem Villanueva88% (8)

- Novel+Synthesis+of+1.5dibenzalacetone+Using+NaOH - ZrO2-.IJCAS .Document5 pagesNovel+Synthesis+of+1.5dibenzalacetone+Using+NaOH - ZrO2-.IJCAS .Arturo CamañoNo ratings yet

- Origani HerbaDocument3 pagesOrigani HerbaArtem KulikovNo ratings yet

- Extraction of Wax From Plants For Possible Commercial Application (24 Pages) PDFDocument24 pagesExtraction of Wax From Plants For Possible Commercial Application (24 Pages) PDFOlly GayagayaNo ratings yet

- Pcog Lab Ex 1,2,3Document8 pagesPcog Lab Ex 1,2,3Cyril Leigh Santos EstrellasNo ratings yet

- Chromatography NotesDocument25 pagesChromatography NotesGeetha AnjaliNo ratings yet

- PETCT L11 Quality Control WEBDocument22 pagesPETCT L11 Quality Control WEBLatgiangNo ratings yet