Professional Documents

Culture Documents

Finite Element Analysis of Different Types of FRP On Beam Column Joint IJERTV7IS050232

Uploaded by

Syed Abdul QuddusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Finite Element Analysis of Different Types of FRP On Beam Column Joint IJERTV7IS050232

Uploaded by

Syed Abdul QuddusCopyright:

Available Formats

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 05, May-2018

Finite Element Analysis of Different Types of FRP

on Beam-Column Joint

Arindom Bora1 Tejaswini M.L.2 Kiran S.M.3

th Assistant Professor, Civil Assistant Professor, Mechanical

4 sem, M.Tech. Structural

Engineering Engineering Dept. Engineering Dept.

MVJ College of Engineering MVJ College of Engineering, MVJ College of Engineering,

Bengaluru, Karnataka, India Bengaluru, Karnataka, India Bengaluru, Karnataka, India

Abstract— In any type of building the most crucial element is Types of Fiber Reinforced Polymer used in this study:

the beam-column joint. In this study, the beam-column joint

analysis is done using ANSYS. The design is first carried out in • Carbon Fiber Reinforced Polymer.

ETABS and using the design data it is analysed in ANSYS. The • Glass Fiber Reinforced Polymer.

equivalent stresses and the total deformation generated in the • Basalt Fiber Reinforced Polymer.

beam-column joint is calculated. Due to the bad effects of • Aramid Fiber Reinforced Polymer

environmental changes, pollution, carbonation, corrosion

occurring in a structural element due to which the building is II. ANALYSIS

likely to collapse. The failure in the beam-column joint can occur A. Analysis in ETABS

due to these reasons and also due to lack of proper reinforcement For the analysis of the structure using ETABS 2016, a

in the joint region. While experiencing seismic activity with frame structure is taken into consideration. The frame structure

inadequate reinforcement the beam-column joint will fail. This

has the dimension of 15m*19m having a storey height of 3.5m

project aims in introducing FRP in the beam column joints which

are likely to fail by retrofitting it. The failure can be identified by

at first floor and 3.2m for the subsequent 4 floors. A depth of

observing cracks or carrying out NDT tests to find out the region 1.5m is assumed for the foundation below the ground level.

of cracks and the amount of reinforcement corroded. In this Material properties used:

study different types of FRP is introduced to the beam-column Grade of Concrete= M30

joint in ANSYS. It is7analysedfand then the equivalent stresses Grade of Steel= Fe415

and total deformations generated5are compared with each other Details of the dimension of the structural elements

whichever will be more effective to be used in the field of used:

construction. Main beam, B1= 300*500mm

Secondary beam, B2= 300*400mm

Keywords—Finite Element Analysis, ANSYS, FRP

Plinth beam, B3= 300*400mm

I. INTRODUCTION Column, C1= 300*500mm

In a framed structure, the load transfer mechanism takes Column, C2= 400*400mm

place in the manner of loads from the slabs gets distributed to Column, C3= 400*500mm

the beams, then the loads from beams get distributed to the Slab thickness= 125mm

columns and then the loads from columns to the footings which Storey height= 3.5m (First floor)

eventually transfers the loads to the ground surface. The = 3.2m (Other floors)

junction of beam and column behaves as a crucial part during

the action of seismic forces and it tends to fail if the detailing is The beam-column joint to be analyzed is the connection

not proper. The failure of a beam-column joint will result in the between B29 and C2. The beam is in the first floor.

collapse of the structure. The joint of beam-column in a Loads:

structure can be said as the weakest part of a structure. These At all floors masonry load due to main beam= 11.96 kN/m

joints are the important zones for transfer of forces and At all floors masonry load due to Secondary beam=12.42kN/m

moments effectively between the subsequent connecting

At ground floor masonry load due to main beam= 13.34 kN/m

elements of beam and columns. The performance of a framed

At ground floor masonry load due to Secondary beam= 13.8

structure mostly depends upon the integrity of the joints for

which the beam-column joints joint is a crucial part. The kN/m

behaviour of the beam-column joint of a framed structure is Shell loads applied as:

being studied in this project. Upon the application of Fiber At the roof Live load= 1.5kN/m²

Reinforced Polymer (FRP) laminate in the beam-column joint, At the other floors Live load= 3kN/m² [18]

the behaviour is also studied. It is studied by doing Finite Taking the moments and axial forces from ETABS,

Element Analysis in ANSYS 14.5. The stresses and calculating the reinforcements manually the following results

deformations are obtained as results from the analysis. The are obtained:

building is being designed using Etabs 2016. Reinforcement for Beam:

Main bar diameter= 16mm

Number of bars=2

Anchor bar diameter= 10mm

IJERTV7IS050232 www.ijert.org 417

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 05, May-2018

Number of bars= 2

Provide 2 legged 8mm diameter stirrups with spacing of

260mm c/c.

Reinforcement for Column:

Number of bars= 5

Diameter of Bars= 20mm

Fig. 3: Application of FRP in the beam-column joint

In the fig. 2 it can be seen that the FRP has been applied to

the beam column joint in the area where the stress

concentration is more which is considered as 400mm in below

and top from the face of the column vertically and 1000mm in

below and top horizontally. The length of the application of

FRP is same throughout all other FRP.

Fig.1: Combined Bending Moment diagram of the beam B29 and column C2

at first floor and second floor

B. Analysis in ANSYS

In this study, 5 different models are created in ANYS. They

are: Beam-Column joint with reinforcement. Beam-Column

joint with reinforcement and Carbon FRP. Beam-Column joint

with reinforcement and Glass FRP (S2 Glass). Beam-Column

joint with reinforcement and Basalt FRP. Beam-Column joint

with reinforcement and Aramid FRP (Kevlar 49).

For the modelling part the length of the column considered

is= 3.35m. (half of the centre to centre distance between the

column heights has been assumed). And the length of the beam

is= 3.7m

Fig.4: Meshed model of the Beam-Column joint

Fine mesh property is being used and the size of the mesh is

selected as default.

Fixed support conditions are applied at the free ends of the

beam and column.

The load applied on the beam is applied as pressure load.

The pressure loads applied are as follows:

Pressure acting as slab load= 0.0321Mpa

Pressure acting as wall load= 0.046 Mpa

The same wall load and slab load is applied through all the

Fig. 2: Beam-Column joint with reinforcement modelled in ANSYS

5types of analysis performed: without FRP, with CFRP, with

The modelling of the 4 different types of FRP is also done GFRP, with BFRP and with AFRP.

in the same way with a thickness of 9.9mm of FRP applied in

all the types. It is considered that the FRP has an uniform

thickness of 1.1mm and 9 layers have been applied.

IJERTV7IS050232 www.ijert.org 418

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 05, May-2018

III. RESULTS

A. Equivalent stress:

The results obtained from the equivalent stress can be

summarized as:

• The equivalent stress for concrete without FRP is

1.2047 MPa

• The equivalent stress for concrete with CFRP is

0.61384 MPa

• The equivalent stress for concrete with GFRP is

0.61263 MPa

• The equivalent stress for concrete with BFRP is

0.6124 MPa

• The equivalent stress for concrete with AFRP is

0.60545 Mpa

Fig 5: Slab load is applied in the form of Ramped Pressure on the beam

Fig. 6: Wall load is applied in the form of Ramped Pressure on the beam Fig 7: Equivalent stress in concrete without FRP

SOLID 65 element is used for concrete structural

rectangular or block. It is assigned to define the property of

concrete. LINK 180 is used to define the property of

reinforcement. SOLID 64 element is used to define the FRP

layer on concrete.

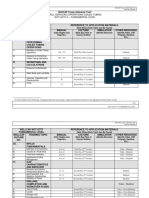

Properties of different types of FRP used:

NAME YOUNG’S MODULUS POISSON’S RATIO

CARBON [15,3] 76.35GPa 0.26

GLASS (S2 GLASS) 86.9 GPa 0.22

[8]

BASALT [16] 89 GPa 0.2

ARAMID (KEVLAR 151.7 GPa 0.35

49)[17]

Fig 8: Equivalent stress in concrete with CFRP

IJERTV7IS050232 www.ijert.org 419

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 05, May-2018

B. Total Deformation:

The results obtained after analyzing for total deformation

are as follows:

• The total deformation on concrete without FRP is

0.11372 mm

• The total deformation on concrete with CFRP is

0.44181 mm

• The total deformation on concrete with GFRP is

0.38282 mm

• The total deformation on concrete with BFRP is

0.37043 mm

• The total deformation on concrete with AFRP is

0.22815 mm

Fig. 9: Equivalent stress in concrete with GFRP

Fig. 12: Total deformation in the beam-column joint with reinforcement

Fig. 10: Equivalent stress in concrete with BFRP

Fig. 13: Total deformation in the beam-column joint with CFRP

Fig. 11: Equivalent stress in concrete with AFRP

IJERTV7IS050232 www.ijert.org 420

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 05, May-2018

IV. CONCLUSIONS

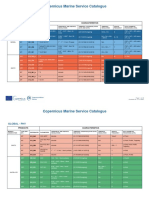

A comparison between the results obtained are shown

below:

50

45.716 46.29

44.426

45

40.596

40

EQUIVALENT STRESS, MPa

35

30

25

20

15

10

5

Fig. 14: Total deformation in the beam-column joint with GFRP 1.2047 0.61384 0.61263 0.6124 0.60545

0

0

Without FRP CFRP GFRP BFRP AFRP

MATERIAL TYPES

ON FRP WHOLE SPECIMEN

Fig 17: Comparison of equivalent stress obtained for different material

types

0.5

0.44181

0.45

0.4 0.38282 0.37043

0.35

DISPLACEMENT, mm

0.3

0.25 0.22815

0.2

0.15 0.11372

0.1

Fig. 15: Total deformation in the beam-column joint with BFRP

0.05 0.029554 0.026578 0.025944 0.019307

0

0

Without CFRP GFRP BFRP AFRP

FRP

MATERIAL TYPES

ON FRP WHOLE SPECIMEN

Fig 18: Comparison of total deformation obtained for different material types

From the results, it can be concluded that upon using the

different types of FRPs the equivalent stresses in the concrete

got reduced. The reduction is basically due to the fact that the

FRP is acting like an external reinforcement to the beam-

column joint and the stresses generated is taken by the FRPs.

Different types of FRPs have different modulus of elasticity

and different Poisson’s ratio. Therefore, the variation is

observed. The maximum equivalent stress is generated at the

junction of the FRP and the beam of the beam-column joint

because of the fact that the load applied on the beam is

Fig. 16: Total deformation in the beam-column joint with counteracted by the FRP and at the end point of the FRP the

AFRP stresses are concentrated.

IJERTV7IS050232 www.ijert.org 421

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 7 Issue 05, May-2018

While observing at the total deformation, it can be [8] Sathish Kumar T P, Naveen J. and S Satheeshkumar on

concluded that the total deformation is lower when there is no “Glass fiber-reinforced polymer composites – A review” in

use of FRP due to the fact that when FRP is used in the Journal of Reinforced Plastics and Composites, 2014

structure, the total load applied on the structure is taken up by [9] Mehmet Mustafa Önal on “Strengthening Reinforced

the FRP used which results in maximum deformation in the Concrete Beams with CFRP and GFRP” in Advances in

FRP used specimen. Therefore, FRP helps to take up the load Materials Science and Engineering, 2014

applied on concrete and reinforcement and it counteracts it. So, [10] Asst. Prof. Anumol Raju & Asst. Prof. Liji Anna Mathew

at the junction of beam-column joint it can be observed that the on “Retrofiiting of RC Beams using FRP” in International

Journal of Engineering Research & Technology, Volume 2,

maximum deformation is occurring at the junction of the FRP

Issue 1, 2013

and the beam of the beam-column joint. [11] T.Manikandan. G.Balaji Ponraj, in “Strengthening Of RC

Beam Using GFRP Wraps” on International Journal of

V. ACKNOWLEDGMENT Engineering Trends and Technology (IJETT) -

This paper is based on the work carried out by me (Arindom Volume4,Issue5- May 2013

Bora), as part of my PG course, under the guidance of [12] Robert Ravi.S & Prince Arulraj.G on “Experimental

Tejaswini M.L. (Assistant Professor, MVJ College of Investigation on Behavior of Reinforced Concrete Beam

Column Joints Retrofitted with GFRPAFRP Hybrid

Engineering) and Kiran S.M. (Assistant Professor, MVJ

Wrapping” in International Journal of Civil and Structural

College of Polytechnic). The fruitful interactions held with my Engineering, Volume 1, No 2, 2010

guides during my project are duly acknowledged. [13] Hannibal Ólafsson & Eyþór Þórhallsson on “Basalt fiber

bar” in Basalt fiber Seminar, Reykjavik University, 2009

REFERENCES [14] V.M. karbhari, J.W. Chin, D. Hunston, B. Benmokrane, T.

[1] Zhishen Wu, Xin Wang and Gang Wu on “Basalt FRP Juska, R. Morgan, J. J. Lesko, U. Sorathia and D. Reynaud

Composite as Reinforcements in Infrastructure” in 17th on “Durability Gap Analysis for Fiber-Reinforced Polymer

Annual International Conference on Composites/Nano Composites in Civil Infrastructure” in Journal of

Engineering (ICCE-17). 21-24. Composites for Construction, 2003

[2] Nagumalli Kedar Nath & T. M. Jeyashree on “Analytical [15] Richard D. Iacobucci, Shamim A. Sheikh and Oguzhan

study on reinforced concrete beam column joint wrapped

Bayrak on “Retrofit of Square Concrete Columns with

with CFRP” in International Journal of Advanced Carbon Fiber-Reinforced Polymer for Seismic Resistance”

Structures and Geotechnical Engineering, Vol. 05, No. 02, in ACI Structural Journal, V. 100, No. 6, November-

2016 December 2003.

[3] Jijin V & Preetha Prabhakaran on “Effect of GFRP

[16] Ali Nawaz Mengal, Saravanan Karuppanan and Azmi

Jacketing & CFRP Jacketing on RC Columns of Different Abdul Wahab on “Structural Analysis of Basalt Fiber

Cross-Sectional Shapes” in IOSR Journal of Mechanical Reinforced Plastic Wind Turbine Blade” in MATEC Web

and Civil Engineering, 2016 of Conferences 13, 2014

[4] Anusree Lal on “Analysis of Exterior Beam Column Joint [17] K.K. Herbert Yeung and K.P. Rao, on “Mechanical

Using ANSYS” in International Journal of Science and Properties of Kevlar-49 Fibre Reinforced Thermoplastic

Research Volume 5 Issue 7, July 2016 Composites” in Polymers & Polymer Composites, Vol. 20,

[5] Shabana T S, Dr. K.A Abubaker, Renny Varghees on No. 5, 2012

“Finite Element Analysis of Beam Column Joint with [18] IS 875(Part 1)- 1987, “Code of Practice for Design Loads

GFRP under Dynamic Loading” in International Journal of (Other Than Earthquake) for Buildings and Structures”

Engineering Trends and Technology (IJETT), Volume 28

Number 8, 2015

[6] Fareed Elgabbas, Ehab A. Ahmed and Brahim Benmokrane

on “Physical and mechanical characteristics of new basalt-

FRP bars for reinforcing concrete structures” in

Construction and Building Materials, 95, 2015

[7] Kaliluthin.A.K. & Kothandaraman.S on “Experimental

investigation on behavior of reinforced concrete beam-

column Joint” In International Journal of Civil and

Structural Engineering, Volume 4, No 3, 2014

IJERTV7IS050232 www.ijert.org 422

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

You might also like

- Ijert Ijert: Strengthening of RC Beams by Wrapping FRP On Steel BarsDocument6 pagesIjert Ijert: Strengthening of RC Beams by Wrapping FRP On Steel BarsAkhilesh B.MNo ratings yet

- Finite Element Simulation of Low Concrete Strength Beam Beam-Column Joint Strengthened With CFRPDocument10 pagesFinite Element Simulation of Low Concrete Strength Beam Beam-Column Joint Strengthened With CFRPlalitha kandikaNo ratings yet

- Experimental and Analytical Study On Strengthening of Deformed Cold Formed Steel Lipped Channel Section IJERTCONV5IS13172Document6 pagesExperimental and Analytical Study On Strengthening of Deformed Cold Formed Steel Lipped Channel Section IJERTCONV5IS13172sathishNo ratings yet

- Finite Element Analysis of Cohesion Between Reinforced Concrete Beam and Polymer Lamella Reinforced by Carbon FibersDocument8 pagesFinite Element Analysis of Cohesion Between Reinforced Concrete Beam and Polymer Lamella Reinforced by Carbon FiberscdestudosNo ratings yet

- Case Studies in Construction Materials: Ra Fid Saeed AteaDocument8 pagesCase Studies in Construction Materials: Ra Fid Saeed Ateaviewer208No ratings yet

- Bi 2011Document5 pagesBi 2011Zana QaderNo ratings yet

- Numerical Analytics For Plastic HingeDocument7 pagesNumerical Analytics For Plastic HingeBala SubramanianNo ratings yet

- Finite Element Modeling of Reinforced Concrete Beams Strengthened With FRP Laminates: A ReviewDocument8 pagesFinite Element Modeling of Reinforced Concrete Beams Strengthened With FRP Laminates: A ReviewAfia.S.HameedNo ratings yet

- Journalnx UnreinforcedDocument4 pagesJournalnx UnreinforcedJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Comparative Study of Flexural Strength of R.C. Beam Using Basalt Fiber Polymer As ReinforcementDocument4 pagesComparative Study of Flexural Strength of R.C. Beam Using Basalt Fiber Polymer As ReinforcementShreeHarunKrishnanNo ratings yet

- FileserveDocument9 pagesFileserveThiri AungNo ratings yet

- An Experimental Study On Behaviors of Beam-Column Joint Wrapped With Aramid FiberDocument5 pagesAn Experimental Study On Behaviors of Beam-Column Joint Wrapped With Aramid FiberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Irjet V3i523Document4 pagesIrjet V3i523anon_294850851No ratings yet

- R 1631014112018Document8 pagesR 1631014112018bhanu jammuNo ratings yet

- Behavior of Non Metallic Reinforcement (FRP) in Beam: International Journal For Trends in Engineering & TechnologyDocument5 pagesBehavior of Non Metallic Reinforcement (FRP) in Beam: International Journal For Trends in Engineering & TechnologyTigon Vo NgocNo ratings yet

- Diff Shear RFT - BharathinatharDocument2 pagesDiff Shear RFT - BharathinatharBlessyNo ratings yet

- Construction and Building Materials: Taha A. El-Sayed, Abeer M. ErfanDocument10 pagesConstruction and Building Materials: Taha A. El-Sayed, Abeer M. ErfanAbdulkhaliq AbdulyimahNo ratings yet

- Ijert Ijert: Economical Span in Composite BridgesDocument4 pagesIjert Ijert: Economical Span in Composite BridgesCIVIL ENGINEERINGNo ratings yet

- NR 410110 Prestressed ConcreteDocument8 pagesNR 410110 Prestressed ConcreteSrinivasa Rao G100% (2)

- Đề tài - Analysis of Multistory Building with shear wall by using ansysDocument5 pagesĐề tài - Analysis of Multistory Building with shear wall by using ansysQuốc Quyền ĐặngNo ratings yet

- Shear and Flexural Strengthening in RC Beams Using FRP: D.Preetam Prem RajDocument9 pagesShear and Flexural Strengthening in RC Beams Using FRP: D.Preetam Prem RajAkhilesh B.MNo ratings yet

- Experimental Study On The Ferrocement PanelsDocument8 pagesExperimental Study On The Ferrocement PanelsIJRASETPublicationsNo ratings yet

- Optimum Proportions For The Design of Suspension Bridge: Tanvir Manzur and Alamgir HabibDocument14 pagesOptimum Proportions For The Design of Suspension Bridge: Tanvir Manzur and Alamgir HabibKUNDAN.KDNo ratings yet

- Investigation On Buckling Behaviour of RC Rectangular Long Column Confined With Aluminium MeshDocument10 pagesInvestigation On Buckling Behaviour of RC Rectangular Long Column Confined With Aluminium MeshIJRASETPublicationsNo ratings yet

- Parametric Study On Reinforced Concrete Beam Using ANSYSDocument8 pagesParametric Study On Reinforced Concrete Beam Using ANSYSLuhur BudiNo ratings yet

- FRP Paper PDFDocument6 pagesFRP Paper PDFRikson TandelilinNo ratings yet

- Seismic Evaluation of High Rise Building With and Without Base IsolationDocument4 pagesSeismic Evaluation of High Rise Building With and Without Base IsolationÖzgür DoğanNo ratings yet

- Retrofitting of Reinforced Concrete Beams in Shear Using External Prestressing TechniqueDocument12 pagesRetrofitting of Reinforced Concrete Beams in Shear Using External Prestressing TechniqueAli OmarNo ratings yet

- Structural Properties of NSC and HSC Beams Bonded by GFRP WrapsDocument9 pagesStructural Properties of NSC and HSC Beams Bonded by GFRP WrapsEnggHabibUlAlamNo ratings yet

- Sham Rao 2021Document11 pagesSham Rao 2021nabin nitNo ratings yet

- Using FRP-bars in Concrete Beams: A General Review: June 2009Document7 pagesUsing FRP-bars in Concrete Beams: A General Review: June 2009Kawan EngNo ratings yet

- Numerical Study On Retrofitting of BeamDocument7 pagesNumerical Study On Retrofitting of BeamJohn Robert Dizon GabrielNo ratings yet

- Analysis and Design of Ferrocement Panels An Experimental StudyDocument8 pagesAnalysis and Design of Ferrocement Panels An Experimental StudyNick CordetaNo ratings yet

- 4th ACDT Paper 5Document6 pages4th ACDT Paper 5Rocketer OatrocketerNo ratings yet

- Behaviour of FRP Reinforced Concrete Beam-Column Joints Under Cyclic Loading PDFDocument8 pagesBehaviour of FRP Reinforced Concrete Beam-Column Joints Under Cyclic Loading PDFAhmed NafieNo ratings yet

- Effect of Ribs and Stringer Spacings On The Weight of Composite StructuresDocument7 pagesEffect of Ribs and Stringer Spacings On The Weight of Composite StructuresVesa RäisänenNo ratings yet

- IET BICET 2014 El-Gamal Et Al-FinalDocument6 pagesIET BICET 2014 El-Gamal Et Al-FinalmfhfhfNo ratings yet

- CFRP Strengthening of Steel Beams With Web Openings: October 2017Document13 pagesCFRP Strengthening of Steel Beams With Web Openings: October 2017Muhammad MalikNo ratings yet

- Ak26230233 PDFDocument4 pagesAk26230233 PDFRahil QureshiNo ratings yet

- Strength Behavior of Bamboo Reinforced CDocument9 pagesStrength Behavior of Bamboo Reinforced CBRYLLE KYLLE OIDEMNo ratings yet

- Finite Element Analysis of RC Beams With Externally Bonded Sifcon and Simcon Laminates Using Ansys IJERTV8IS010115Document4 pagesFinite Element Analysis of RC Beams With Externally Bonded Sifcon and Simcon Laminates Using Ansys IJERTV8IS010115SAFNANo ratings yet

- Monti 2007Document11 pagesMonti 2007Tùng-65XD11 Nguyễn XuânNo ratings yet

- Assignment No. 1Document2 pagesAssignment No. 1brownie143loveNo ratings yet

- Effect of Steel Reinforcement Ratio On Flexural Enhancement in Cfrp-Strengthened Concrete Curved BeamsDocument13 pagesEffect of Steel Reinforcement Ratio On Flexural Enhancement in Cfrp-Strengthened Concrete Curved BeamsAbhishek PawarNo ratings yet

- Comparative Analysis of RCC and Steel Building Using STAAD ProDocument11 pagesComparative Analysis of RCC and Steel Building Using STAAD ProIJRASETPublicationsNo ratings yet

- ZF 0712251258Document8 pagesZF 0712251258Md. Mizanur RahamanNo ratings yet

- Regain in Strength of Reinforced Concrete Columns-Akash ChauhanDocument6 pagesRegain in Strength of Reinforced Concrete Columns-Akash ChauhanAkash ChauhanNo ratings yet

- Strengthening of Solid Brick Masonry Columns With Joints Collared by Steel WiresDocument9 pagesStrengthening of Solid Brick Masonry Columns With Joints Collared by Steel WiresAmrul KaishNo ratings yet

- Shear-Bond Capacity of Composite Slabs Made With Profiled SheetingDocument7 pagesShear-Bond Capacity of Composite Slabs Made With Profiled SheetingPrapa KaranNo ratings yet

- Archive of SID: Evaluation of Parameters Effective in FRP Shear Strengthening of RC Beams Using Fe MethodDocument9 pagesArchive of SID: Evaluation of Parameters Effective in FRP Shear Strengthening of RC Beams Using Fe MethodYara MounaNo ratings yet

- Design of Prestressed Concrete Structures 15cese2005-1 PDFDocument2 pagesDesign of Prestressed Concrete Structures 15cese2005-1 PDFvineela saiNo ratings yet

- Finite Element Analysis of Different Types of Composite ColumnDocument7 pagesFinite Element Analysis of Different Types of Composite Columnrameshbabu_1979No ratings yet

- Sway and No-Sway Behaviour of Pitched Roof Portal Frames Composed of Cold-Formed Steel SectionsDocument18 pagesSway and No-Sway Behaviour of Pitched Roof Portal Frames Composed of Cold-Formed Steel SectionsAhmed SalehNo ratings yet

- Analysis of Different Grades of Reinforced Concrete Beam After Exposure To Elevated Temperature Using AbaqusDocument10 pagesAnalysis of Different Grades of Reinforced Concrete Beam After Exposure To Elevated Temperature Using AbaqusIJRASETPublicationsNo ratings yet

- 2013 - G - Terrasi JMSR - 1 - 2 - 2013-20556Document14 pages2013 - G - Terrasi JMSR - 1 - 2 - 2013-20556Engr Muhammad AbidNo ratings yet

- An Experimental Investigation of Steel CDocument4 pagesAn Experimental Investigation of Steel CnomadiczapatoNo ratings yet

- Experimental Study On Strengthening of RC Slab Using GFRP Sheets IJERTCONV6IS06028Document3 pagesExperimental Study On Strengthening of RC Slab Using GFRP Sheets IJERTCONV6IS06028AminNo ratings yet

- Seismic Upgrade of Beam-Column Joints With FRP ReinforcementDocument17 pagesSeismic Upgrade of Beam-Column Joints With FRP Reinforcementodhie79No ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- BLL ExportDocument372 pagesBLL Exportpnmawade123No ratings yet

- CH 13 Nuclear Physics and RadioactivityDocument14 pagesCH 13 Nuclear Physics and RadioactivityAkash KoulNo ratings yet

- (Bungee Jumper) : Activity No. 7Document3 pages(Bungee Jumper) : Activity No. 7Princess Lheakyrie CasilaoNo ratings yet

- Iso 15686-2-2012Document32 pagesIso 15686-2-2012Jesus BarrazaNo ratings yet

- Science 6 - Q4 - W1Document8 pagesScience 6 - Q4 - W1Jennifer OledanNo ratings yet

- Mathematics: Quarter 3: Week 7 (Week 7-Week 9) Learning Activity SheetDocument8 pagesMathematics: Quarter 3: Week 7 (Week 7-Week 9) Learning Activity SheetFrances DatuinNo ratings yet

- Architectural Design of Future Sustainable Primary School in Iran Using Multi-Purpose AtriumDocument4 pagesArchitectural Design of Future Sustainable Primary School in Iran Using Multi-Purpose AtriumThắm PhạmNo ratings yet

- Examination PaperDocument11 pagesExamination PaperMuedi MukonazwotheNo ratings yet

- B1, Timber Beam Analysis & Design (AS1720)Document3 pagesB1, Timber Beam Analysis & Design (AS1720)Saiful IslamNo ratings yet

- Mixed Methods and Processes in Applied Linguistics ResearchDocument343 pagesMixed Methods and Processes in Applied Linguistics ResearchSCARLET PAULETTE ABARCA GARZONNo ratings yet

- Buckling TestDocument16 pagesBuckling TestfilibertoNo ratings yet

- Bayhydrol UV 26891 - en - 79962983 12942311 14257784Document3 pagesBayhydrol UV 26891 - en - 79962983 12942311 14257784zaryab khanNo ratings yet

- Design & Development of Helmholtz Coil For Hyperpolarized MRIDocument6 pagesDesign & Development of Helmholtz Coil For Hyperpolarized MRIJosué Daniel Meneses DíazNo ratings yet

- Concrete Failure Mechanisms (Final) - 1Document44 pagesConcrete Failure Mechanisms (Final) - 1Hemin ZZNo ratings yet

- Fundamental Level Curriculum (Coiled Tubing)Document6 pagesFundamental Level Curriculum (Coiled Tubing)missaouiNo ratings yet

- Tensor Intro PDFDocument2 pagesTensor Intro PDFMayank MittalNo ratings yet

- NSEJS IJSO Stage 1 2016 17-20-11 2016 Detailed AnalysisDocument7 pagesNSEJS IJSO Stage 1 2016 17-20-11 2016 Detailed AnalysisCharvi Kothari0% (1)

- A Short History of Nearly Everything SummaryDocument4 pagesA Short History of Nearly Everything SummarySAR1MNo ratings yet

- Complex Refractive IndexDocument8 pagesComplex Refractive Indexashutosh pandeyNo ratings yet

- Topic-1-Bending, Shearing and DeflectionDocument17 pagesTopic-1-Bending, Shearing and DeflectionAngelo VilleroNo ratings yet

- CE322 Assignment 3Document5 pagesCE322 Assignment 3PARAN, DIOSCURANo ratings yet

- Datasheet Diodo SB360Document2 pagesDatasheet Diodo SB360Gonzalo RojasNo ratings yet

- Worksheet 6CDocument2 pagesWorksheet 6CZhang JiangNo ratings yet

- Form 4 Student Subject AllocationDocument5 pagesForm 4 Student Subject Allocationapi-484150872No ratings yet

- Infinite Series and The Residue Theorem: Noah A. Hughes May 7, 2013Document12 pagesInfinite Series and The Residue Theorem: Noah A. Hughes May 7, 2013jerson campos100% (1)

- Catalogue CmemsDocument40 pagesCatalogue CmemsAgung PratamaNo ratings yet

- Cambridge International AS & A Level: Physics 9702/11Document20 pagesCambridge International AS & A Level: Physics 9702/11aliexpress0230170No ratings yet

- Syntho-Glass FX Datasheet (Rev 1. - 12.31.09)Document2 pagesSyntho-Glass FX Datasheet (Rev 1. - 12.31.09)Masood KhanNo ratings yet

- Coaching ProblemsDocument31 pagesCoaching Problemsanon_9647963360% (1)

- Mumax: A New High-Performance Micromagnetic Simulation ToolDocument9 pagesMumax: A New High-Performance Micromagnetic Simulation ToolArnab PattanayakNo ratings yet