Professional Documents

Culture Documents

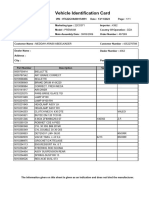

M J251 Spec

Uploaded by

jiaozhongxingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M J251 Spec

Uploaded by

jiaozhongxingCopyright:

Available Formats

FLETCHER

Model J-251-LS Single Boom Jumbo Drill Carrier

Specifications

Single boom jumbo is designed specifically for All operator controls for drilling and tramming are

limestone mines and efficient drilling of headings as either pilot operated of 24vdc solenoid controlled,

large as 50 ft. wide and 35 ft. high in one set up. minimizing the noise and heat generated in the cab.

All controls are conveniently located for comfortable

Self contained, diesel hydraulic jumbo drill, provides operation from the standard “captains” style seat.

the flexibility required to handle face, bench and roof

bolt drilling requirements. J-251-LS carries all fuel All hydraulic, infinitely variable, rock responsive drill

and pelletizing water necessary to operate a full 10 hydraulic system allows the machine to be matched

hour shift without service. to your drilling requirements. All drill system valves

are leak free replaceable cartridges in manifolds and

Four ram type stabilizers (two each front and rear) lift are in readily accessible cabinets.

the complete machine 1 ft. off ground. Optional

stabilizers lift machine 3.5 ft. Front stabilizers extend Flushing air is provided by an onboard hydraulic driven

out to a 14 ft. wide stance for the improved stability screw air compressor with high pressure output for

required for full width hole locations. better hole cleaning and more efficient drilling. A

horizontal 200 gallon water tank carries the water

Tram drive is provided by an engine driven closed loop required for pelletizing.

hydrostatic system driving through a two-speed drop

box and drive shafts to both axles. A single joystick Engine compartment covers are hinged and are easily

controls tram speed, direction and steering. opened for improved maintenance access. An

optional enclosed engine compartment with hinged

Optional exclusive “articulated” operator cab tilts and doors reduces noise levels.

swings providing unparalleled comfort and visibility for

hard to see rib and roof holes. Cab includes a Engine radiator and hydraulic/air compressor coolers

standard air conditioner/heater with filtered pressurizer are remote mounted at the back of the machine and

and designed to achieve an 80 dba noise level. swing open for complete access for cleaning.

Complete machine design and component location to

maximize serviceability.

Model J-251-LS

General Specifications

Engine Cummins QSB5.9 Water Tank 200 gallons

Height 9’11” Hydraulic Tank 45 gallons

Overall Width 8’6” Filters - Suction magnetic & 100 mesh

Length - Chassis 21’3” Filters - Return 3 micron

Length - Overall 43’ Filters - Pressure 3 micron

Weight (complete) 50,000 lbs. Air Filters Donaldson

Wheel Base 136” Precleaners Turbinair

Articulation 80 degrees Compressor 150cfm @ 150psi

Axle Oscillation 10 degrees Electrics 24vdc

Gradeability 40 percent Tires 14.00x20 SXMH, 20 ply

Maximum Speed 5 mph Operator Cab 80 dba, heater/air conditioner

Fuel Tank 80 gallons with filtered pressurizer

Fletcher Options

PERB175 Boom Wireless angle indicator for feed tilt

Boom Soft Ride Wireless angle indicator for feed swing and feed tilt

Single lever boom control system Hole depth system

Ansul fire suppression Greasing system

Articulated operators cab High output marine drill lights

Operator cab for low height Filled tires

High lift stabilizers to lift machine 3.5 ft Exhaust purifier

Dual output air compressor 210 Exhaust particulate filter

cfm@125psi/150 cfm@150 psi Caterpillar, Deere or Deutz diesel engine

Engine compartment side doors Electric powered drill hydraulic system with or without cable reel.

J. H. Fletcher & Co. cannot anticipate every Specifically engineered for each customer’s needs.

mine hazard that may develop during use of

these products. A roof control plan must be

approved by MSHA before use of these prod- J. H. Fletcher & Co.

ucts begins. Proper use, maintenance and

continued use of (OEM) original equipment

402 High St. P.O. Box 2187

parts will be essential for maximum Huntington, WV 25702-2187

operating results.

jhf@jhfletcher.com

C 12/2003 J. H. Fletcher & Co. (rev 9/2009) 304-525-7811

You might also like

- Model J-352-LS: SpecificationsDocument2 pagesModel J-352-LS: SpecificationsjiaozhongxingNo ratings yet

- Cubex 6200 Spec Sheet PDFDocument4 pagesCubex 6200 Spec Sheet PDFtharciocidreira0% (1)

- Drill Aries CubexDocument4 pagesDrill Aries CubexAlexanderAvtushenkoNo ratings yet

- DT190CBROCDocument4 pagesDT190CBROCJhonny RodriguezNo ratings yet

- Atlas Copco Explorac 220RC - Reverse Circulation Drilling RigsDocument4 pagesAtlas Copco Explorac 220RC - Reverse Circulation Drilling Rigsவிமல் அந்தோணி100% (1)

- Laundry DesignDocument11 pagesLaundry DesignrajevskumarNo ratings yet

- DML-SP Series: Atlas Copco Blasthole DrillsDocument4 pagesDML-SP Series: Atlas Copco Blasthole DrillsAli ShRNo ratings yet

- IDM 70 Series: Atlas Copco Blasthole DrillsDocument4 pagesIDM 70 Series: Atlas Copco Blasthole DrillsSACHIDHANANDHAM A100% (1)

- 03 Oil Lub. Piston LER, LTR, Oil-Free Piston LFRDocument2 pages03 Oil Lub. Piston LER, LTR, Oil-Free Piston LFRSerban Aurel CosminNo ratings yet

- Sullair 900electricDocument2 pagesSullair 900electricchavezramirez.carlosdanielNo ratings yet

- PM 565 BDocument21 pagesPM 565 BFlorin Gabor100% (1)

- Ranger 500 1 PDFDocument4 pagesRanger 500 1 PDFWilman CFNo ratings yet

- Waterless Eagle Spec SheetDocument1 pageWaterless Eagle Spec SheetMariano PonsNo ratings yet

- Model J-152-DE: Application SpecificationsDocument2 pagesModel J-152-DE: Application SpecificationsjiaozhongxingNo ratings yet

- "Superior Quality Nce!": & PerformaDocument4 pages"Superior Quality Nce!": & PerformaAARON HESTERFORDNo ratings yet

- Rig Sa 04: Delfico-General Trading - LLCDocument31 pagesRig Sa 04: Delfico-General Trading - LLCAdhie Waelacxh100% (1)

- EDM 95K SeriesDocument2 pagesEDM 95K SerieskingsfordathleeNo ratings yet

- SCH5000C&CL F&B 2006Document23 pagesSCH5000C&CL F&B 2006Washington HuallpaNo ratings yet

- Aries: Underground DrillsDocument3 pagesAries: Underground DrillsEmanuel Nicolas Villarruel100% (1)

- Boltec 335hDocument4 pagesBoltec 335hErick AlarconNo ratings yet

- Boltec 435hDocument4 pagesBoltec 435hErick AlarconNo ratings yet

- LIEBHERR R934-Tier4Final-US-PI-2021-01Document16 pagesLIEBHERR R934-Tier4Final-US-PI-2021-01ganendra santantikaNo ratings yet

- Brochure Hm150 MailDocument8 pagesBrochure Hm150 MailDan Banul100% (1)

- Pit Viper 235 Series: Atlas Copco Blasthole DrillsDocument4 pagesPit Viper 235 Series: Atlas Copco Blasthole DrillsJulio Acevedo MartinezNo ratings yet

- Cane-Loader 1850 EnglishDocument2 pagesCane-Loader 1850 EnglishEmmanuelNo ratings yet

- R944CDocument12 pagesR944Cequipment9278No ratings yet

- 8w-Detc Maintenance ManualDocument87 pages8w-Detc Maintenance Manualarun100% (1)

- M J151 ADEspecDocument2 pagesM J151 ADEspecjiaozhongxingNo ratings yet

- Ecm5901 1Document8 pagesEcm5901 1Oscarito Vázquez100% (1)

- R914Compact Tier4Final US PI 2020 12Document16 pagesR914Compact Tier4Final US PI 2020 12izael jesusNo ratings yet

- Surface Miner 2200 SM: Technical SpecificationDocument9 pagesSurface Miner 2200 SM: Technical SpecificationNitesh JainNo ratings yet

- Shack Mounted Drill Rig VD3000Document5 pagesShack Mounted Drill Rig VD3000Alfredo PozosNo ratings yet

- Liebherr R992 GB TBDocument12 pagesLiebherr R992 GB TBAhmad Fajar Humaidi100% (1)

- Klaedningardreifari Malardreifari Spc12e 2020Document2 pagesKlaedningardreifari Malardreifari Spc12e 2020Dan PatchNo ratings yet

- PLAT ELECTRICA OLYMPIAN Gep44-9 - RentalDocument4 pagesPLAT ELECTRICA OLYMPIAN Gep44-9 - RentalYeison Jair Guaca TrujilloNo ratings yet

- WA470-5 KatalogDocument7 pagesWA470-5 KatalogPhilip Chandra100% (2)

- Brochure PV-271 Low Res (A4) - tcm835-3434016Document4 pagesBrochure PV-271 Low Res (A4) - tcm835-3434016rigoberto otiniano100% (1)

- Linha Ucd Decanter - GeaDocument20 pagesLinha Ucd Decanter - GeaGustavo100% (2)

- R9800Document12 pagesR9800tugu_tgNo ratings yet

- Super Duty, Independent Dual System Hydraulic Power Unit / Diesel PoweredDocument6 pagesSuper Duty, Independent Dual System Hydraulic Power Unit / Diesel PoweredTrần Quang ThắngNo ratings yet

- Truemax: 38m Truck Mounted Boom Pump Upper PartDocument7 pagesTruemax: 38m Truck Mounted Boom Pump Upper PartRizkiRamadhanNo ratings yet

- R 920 Compact: Product Information Crawler ExcavatorDocument16 pagesR 920 Compact: Product Information Crawler Excavatorpebi liveNo ratings yet

- H80-120FT BrochureDocument16 pagesH80-120FT BrochureDavid MarcanoNo ratings yet

- 001-232500-0 2.7 Filtration EquipmentDocument34 pages001-232500-0 2.7 Filtration Equipmentmolinach100% (1)

- Aard Scissorslift BolterDocument4 pagesAard Scissorslift BolterMoodNo ratings yet

- Kershaw 12-12BridgeCraneDocument3 pagesKershaw 12-12BridgeCranecamelia_pirjan5776No ratings yet

- Tech Spec CV 350Document6 pagesTech Spec CV 350Sugeng DarmintoNo ratings yet

- Pit Viper 235 High Resolution US Tcm1241-3515574Document4 pagesPit Viper 235 High Resolution US Tcm1241-3515574Mackarena Isabel Santander Alegre100% (1)

- pm565b PDFDocument8 pagespm565b PDFManuel Calderon Cortes100% (1)

- V Ec330b d10b Eae2 2214351644 2001 12Document12 pagesV Ec330b d10b Eae2 2214351644 2001 12yansenbarus0% (1)

- Gar 11-37Document2 pagesGar 11-37moisesNo ratings yet

- Especificaciones Boomer l2dDocument4 pagesEspecificaciones Boomer l2dJuan RodriguezNo ratings yet

- Daf Brochure xf105 PowerDocument6 pagesDaf Brochure xf105 PowerНедељко АнђелићNo ratings yet

- D75KS Data SheetDocument14 pagesD75KS Data SheetGrabiela Hidalgo MedinaNo ratings yet

- PC1250-8 PC1250SP-8Document20 pagesPC1250-8 PC1250SP-8Banu Agus Hartoyo100% (1)

- Finisher Ap1000bDocument12 pagesFinisher Ap1000bDaniel FarfanNo ratings yet

- L1850 PDFDocument6 pagesL1850 PDFbraviross_418157489No ratings yet

- Shack Mounted Drill Rig VD8000Document5 pagesShack Mounted Drill Rig VD8000Alfredo Pozos100% (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Model HDR: Standard EquipmentDocument2 pagesModel HDR: Standard EquipmentjiaozhongxingNo ratings yet

- Model J-152-DE: Application SpecificationsDocument2 pagesModel J-152-DE: Application SpecificationsjiaozhongxingNo ratings yet

- Technical Specifications: Type HC95 LMDocument1 pageTechnical Specifications: Type HC95 LMjiaozhongxingNo ratings yet

- En Fdj01 Jumbo Drills BrochureDocument5 pagesEn Fdj01 Jumbo Drills BrochurejiaozhongxingNo ratings yet

- Model 3000: Standard Equipment FeaturesDocument2 pagesModel 3000: Standard Equipment FeaturesjiaozhongxingNo ratings yet

- Troidon 44 XP (English) - Rev. 160915Document4 pagesTroidon 44 XP (English) - Rev. 160915jiaozhongxingNo ratings yet

- M J151 ADEspecDocument2 pagesM J151 ADEspecjiaozhongxingNo ratings yet

- J. H. Fletcher & Co.: B251 Bench DrillDocument1 pageJ. H. Fletcher & Co.: B251 Bench DrilljiaozhongxingNo ratings yet

- R20T PDFDocument2 pagesR20T PDFjiaozhongxing100% (1)

- FRD Has A Lot of Missions On The World For The Next GenerationDocument6 pagesFRD Has A Lot of Missions On The World For The Next GenerationjiaozhongxingNo ratings yet

- M 3411 REsalesDocument1 pageM 3411 REsalesjiaozhongxingNo ratings yet

- Di550 t4 Specification Sheet EnglishDocument4 pagesDi550 t4 Specification Sheet EnglishjiaozhongxingNo ratings yet

- Di550 t3 Specification Sheet EnglishDocument4 pagesDi550 t3 Specification Sheet EnglishjiaozhongxingNo ratings yet

- J. H. Fletcher & Co.: Cj151E Face DrillDocument2 pagesJ. H. Fletcher & Co.: Cj151E Face DrilljiaozhongxingNo ratings yet

- Di650i t3 Specification Sheet EnglishDocument3 pagesDi650i t3 Specification Sheet EnglishjiaozhongxingNo ratings yet

- Pcr200 200dth BroDocument9 pagesPcr200 200dth BrojiaozhongxingNo ratings yet

- Di450 t3 Specification Sheet EnglishDocument4 pagesDi450 t3 Specification Sheet EnglishjiaozhongxingNo ratings yet

- Down The Hole Drill Rigs (D700) CatalogDocument4 pagesDown The Hole Drill Rigs (D700) CatalogjiaozhongxingNo ratings yet

- Specsheet D700 DTH Drill Rigs (Eng) Vol01Document2 pagesSpecsheet D700 DTH Drill Rigs (Eng) Vol01jiaozhongxingNo ratings yet

- Prof Essi Onal I SM, Advanced Qui L I Ty, Real Sati SF Acti OnDocument1 pageProf Essi Onal I SM, Advanced Qui L I Ty, Real Sati SF Acti OnjiaozhongxingNo ratings yet

- Capital Markets Day 2017 Mining and Rock Excavation TechniqueDocument23 pagesCapital Markets Day 2017 Mining and Rock Excavation TechniquejiaozhongxingNo ratings yet

- Boltec LC DHDocument4 pagesBoltec LC DHjiaozhongxingNo ratings yet

- Axera D06Document2 pagesAxera D06Cristián Fernando Cristóbal RoblesNo ratings yet

- Boltec MC SimulatorDocument12 pagesBoltec MC SimulatorjiaozhongxingNo ratings yet

- 6-9655-C (DD320-26C)Document4 pages6-9655-C (DD320-26C)jiaozhongxingNo ratings yet

- Brochure Tamrock Axera D05Document4 pagesBrochure Tamrock Axera D05Esteban Fernando Meza IbacetaNo ratings yet

- 7-6015-G (DL420-7C) PDFDocument4 pages7-6015-G (DL420-7C) PDFjiaozhongxing100% (1)

- Gauri Singjh EvDocument6 pagesGauri Singjh EvcarefelNo ratings yet

- J22CC38976 58980 4745898000Document11 pagesJ22CC38976 58980 4745898000mebarki aberraoufNo ratings yet

- 2806a-E18tag2 Electropak Pn1871Document2 pages2806a-E18tag2 Electropak Pn1871Charles CallahanNo ratings yet

- B626 Ray ZRDocument56 pagesB626 Ray ZRsitaramsahandsonsNo ratings yet

- Metal Smith MiniplaneDocument4 pagesMetal Smith Miniplanetdfsks50% (2)

- New Ceramic Products: Visit Us Online atDocument5 pagesNew Ceramic Products: Visit Us Online atmiab1No ratings yet

- Bell Cane Loader 125 ADocument2 pagesBell Cane Loader 125 AAlexi Pratama0% (1)

- Cat 725Document2 pagesCat 725Milorad Zelenovic100% (2)

- 2021 - Beta RSC24, C45PRODocument12 pages2021 - Beta RSC24, C45PROTan Xin YiNo ratings yet

- Engine Control Mitsubishi v6 3.0Document5 pagesEngine Control Mitsubishi v6 3.0Juanck Todelar100% (1)

- 新项目胶带粘贴位置Document10 pages新项目胶带粘贴位置王川No ratings yet

- I.C. Engines: Content - 4 Unit 6Document30 pagesI.C. Engines: Content - 4 Unit 6experiment z24No ratings yet

- Alphard GGH20# SesDocument24 pagesAlphard GGH20# SesMyo Myint HtweNo ratings yet

- ListDocument2 pagesListRahul KumarNo ratings yet

- WTVET Assessment Notice - MVR Level 2 Petersfield - Cluster 2Document1 pageWTVET Assessment Notice - MVR Level 2 Petersfield - Cluster 2TevernNo ratings yet

- A Study On Customer Buying Behaviour and Brand Preference Towards Automobiles-3Document36 pagesA Study On Customer Buying Behaviour and Brand Preference Towards Automobiles-3ADIDEV TsNo ratings yet

- MAN TGA ZF Transmission 16S151/16S181 (RL)Document4 pagesMAN TGA ZF Transmission 16S151/16S181 (RL)Mircea Gilca100% (2)

- Royal Enfield Spare Price ListDocument2 pagesRoyal Enfield Spare Price Listhemanth321No ratings yet

- Twingo Accessories 2003/4 (English)Document12 pagesTwingo Accessories 2003/4 (English)Matt SephtonNo ratings yet

- 737nxg Dark and Cold TutorialDocument30 pages737nxg Dark and Cold TutorialLucas FurlanNo ratings yet

- 25T Franna Charts SpecificationsDocument17 pages25T Franna Charts SpecificationsAdam NewellNo ratings yet

- Nameplate: 1. For GearmotorsDocument1 pageNameplate: 1. For Gearmotorsheru purwantoNo ratings yet

- BUS 620 Class ActivityDocument5 pagesBUS 620 Class ActivityRashìd RanaNo ratings yet

- Stadler Kiss BerlinerDocument2 pagesStadler Kiss BerlinerRodrigo SampaioNo ratings yet

- 6D110 SeriesDocument301 pages6D110 SeriesEduardo Sanchez67% (3)

- Technical Service Bulletin Bulletin NBR: 522-2732 Date: Maj 2010 Market: All Sinking Brake Pedal in Stationary Car at Idling SpeedDocument2 pagesTechnical Service Bulletin Bulletin NBR: 522-2732 Date: Maj 2010 Market: All Sinking Brake Pedal in Stationary Car at Idling SpeedBruse WayneNo ratings yet

- Corksport Install Instr For Axleback Muffler CX5!6!102-10-WEBDocument9 pagesCorksport Install Instr For Axleback Muffler CX5!6!102-10-WEBhutz5000No ratings yet

- Propulsion 1Document64 pagesPropulsion 1jtradio13100% (1)

- Spitfire Mk2aDocument3 pagesSpitfire Mk2avscribNo ratings yet

- th200 4r TDocument6 pagesth200 4r TRainbow WalkerNo ratings yet