Professional Documents

Culture Documents

Ijmet 10 01 044

Uploaded by

IAEME PUBLICATIONOriginal Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Ijmet 10 01 044

Uploaded by

IAEME PUBLICATIONCopyright:

International Journal of Mechanical Engineering and Technology (IJMET)

Volume 10, Issue 1, January 2019, pp. 424–433, Article ID: IJMET_10_01_044

Available online at http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=1

ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication Scopus Indexed

THE THEORETICAL RATIONALE FOR

TRACTION EFFORT EXPERIENCED WORKING

PART OF THE CULTIVATOR FERTILIZER

Arman Rustembayev

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Astana, Kazakhstan

Dzadiger Eskhozhin

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Astana, Kazakhstan

Sayakhat Nukeshev

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Astana, Kazakhstan

Zyada Zhaksylykova

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Astana, Kazakhstan

Kayrat Eskhozhin

S.Seifullin Kazakh Agrotechnical University, Zhenis 62, 010011, Astana, Kazakhstan

ABSTRACT

Traction effort required to move the working part of an experienced cultivator-

fertilizer in the soil depends on many factors. These include friction coefficients of the

soil, weight and humidity. In this article we arebconduct a theoretical research, the

purpose of which is to establish a relationship between the physicomechanical

properties, parameters of the under development working part and the technological

parameters of its work.

Keywords: Traction, Tillage, Plowshares, Depth of Processing, Forward Speed.

Cite this Article: Arman Rustembayev, Dzadiger Eskhozhin, Sayakhat Nukeshev,

Zyada Zhaksylykova and Kayrat Eskhozhin, The Theoretical Rationale For Traction

Effort Experienced Working Part of The Cultivator Fertilizer, International Journal of

Mechanical Engineering and Technology, 10(1), 2019, pp. 424–433.

http://www.iaeme.com/ijmet/issues.asp?JType=IJMET&VType=10&IType=1

http://www.iaeme.com/IJMET/index.asp 424 editor@iaeme.com

The Theoretical Rationale For Traction Effort Experienced Working Part of The Cultivator Fertilizer

1. INTRODUCTION

Traction effort which is necessary to move the working part of an experienced cultivator-

fertilizer in the soil depends on many factors. It is possible to refer physicomechanical

characteristics of the soil sphere to them, constructive characteristic of working part and

technical characteristics on working processing of the soil [1].

Physical and mechanical characteristics of the soil can be determined directly on the field.

Coefficients of friction of the soil about measures or soils about the soil, volume weight and

humidity are concerned to them. These indicators for characteristic soils can be defined also

from references. Design data such as, width of taking of the working part, corners of solution

and installation are appointed by the designer and depend on characteristics of the developed

machine.

2. MATERIALS AND METHODS

Technological parameters include the working speed and depth of the working part [2,3].

They depend on the agrotechnical requirements and tillage and traction machine capabilities.

In this work, a theoretical study is carried out, the purpose of which is to establish a mutual

relationship between the physicomechanical properties, as instructive parameters of the

working part being developed and the technological parameters of its work. Having such a

connection, to operate them and to define their optimum a combination [4,5,6].

3. RESULTS AND DISCUSSION

Picture 1a shows the working part of the cultivator-fertilizer, which represents a bivalve flat-

cut paw. The working part moves with the speed V and affects the soil sphere with the

resultant power Q. The soil sweat resists the following power.

R1 is the frontal sub time of unreformed soil layer;

R2 is the impulse of the head that will receive the soil under the inertial effects of the working

part

R3 is the reaction of the soil pliers on the edge of AA1, BB1;

R4 is the reaction of the bottom of the furrow to the bottom of АА1, ВВ1 faces;

F3 - soil resistance on the upper face AA1, BB1.

F4 - soil resistance at the sole of АА1, ВВ1 faces.

http://www.iaeme.com/IJMET/index.asp 425 editor@iaeme.com

Arman Rustembayev, Dzadiger Eskhozhin, Sayakhat Nukeshev, Zyada Zhaksylykova and Kayrat

Eskhozhin

Picture 1. The interaction of an experienced working part of the cultivator-fertilizer with the soil

The soil particles move on the upper face along the line of the largest slope MN and, in

the absence or friction, the normal pressure of the soil on the paw is directed along the line

Nv. The presence or friction rejects it at an angle. The reaction of the soil is directed along R3

in the direction opposite to the possible displacement of the soil particle. A impulse or R2 also

deviates in this direction, only not from the normal, but from the free-fall line.

The impulsive forces R2 arise at the initial moment of action of the working part on the

soil, because at this time the inertia of which soil is broken, its particles get instantaneous

accelerations and a certain absolute speed which does not coincide with a line.

Obviously, this scheme will be directed along the line of the absolute velocity of the

particles, only in the opposite direction.

Sufficiently high probability we can assume that the particles will detach from the surface

of the working part with the same speed with which it will be implemented into it. In reality,

of course, they will not be equal, because at the expense of gas voids in the soil, and its

compression and collapse, the speed of the soil will lag behind the speed of the working part.

At the same time, this difference in comparison with absolute values may be insignificant.

However, the context under consideration is not so much important their value as their

directions.

As shown in picture 1b, in the absence or friction, the relative velocity of the soil particles

will be directed along the MN line. The friction forces arising from between the soil particle

and the metal of the working part over time t shifts the particle to point N1. In this case, the

relative velocity of the particle will be:

𝑉отл

𝑣от2 СЛ𝜑 . (1)

The angle of elevation of the blade of the working parts blade is insignificant. Therefore,

they can be equated: Vot2 = V

http://www.iaeme.com/IJMET/index.asp 426 editor@iaeme.com

The Theoretical Rationale For Traction Effort Experienced Working Part of The Cultivator Fertilizer

From mechanics it is known, according to the rule of the velocity triangle, the relative

speed must be closed by the absolute speed. In this case, you can use the sine theorem:

𝑠𝑖𝑛𝑀

𝑉𝑎 = 𝑉от2 𝑠𝑖𝑛𝑀 . (2)

0

The angle MO is determined from the relationship:

М0 = 𝜋 − (𝑁1 + 𝑀)

From the equality Vot2 = V, it follows that in the triangle MN0N1 <N1 = <MO

Therefore:

𝜋−𝛼

𝑀𝑜 = . (3)

2

Substituting (1) and (3) in (2) we get:

𝑠𝑖𝑛𝛼

𝑉𝑎 = 𝑉 𝛼

𝑐𝑜𝑠 2

1 − 𝑐𝑜𝑠𝛼

𝑉𝑎 = 2𝑉√ . (4)

2

From the expression (3) it follows that the absolute velocity of the soil particles Va is

directed at an angle (𝜋 − 𝛼)⁄2 to the direction of speed of the working part and in the

direction coinciding with the directional movement. From this we can conclude that the

impulsive forces that receive soil particles from the impact of the working part are also

directed along the line Vа. Only sent in the opposite direction.

The resistance of the soil environment to the working part of the cultivator-fertilizer can

be expressed to make up the equilibrium equation of all forces in the horizontal and vertical

direction.

𝜋 𝜋−𝛼 𝜋 𝜋 𝜋

𝑄𝑐𝑜𝑠 [ − (𝛼 + 𝜑)] = 𝑅2 𝑐𝑜𝑠 𝑐𝑜𝑠 ( − 𝛾) + 𝑅3 𝑐𝑜𝑠 [ − (𝛼 + 𝜑)] + 𝑅4 𝑠𝑖𝑛𝜑 + 𝑐𝑜𝑠 ( − 𝛾)

2 2 2 2 2

𝜋 𝜋−𝛼 𝜋 𝜋

𝑄𝑠𝑖𝑛 [ − (𝛼 + 𝜑)] 𝑅2 𝑠𝑖𝑛 𝑠𝑖𝑛 ( − 𝛾) + 𝑅3 𝑠𝑖𝑛 [ − (𝛼 + 𝜑)] − 𝑅4 𝑐𝑜𝑠𝜑

2 2 2 2

𝛼

𝑄𝑠𝑖𝑛(𝛼 + 𝜑) = 𝑅2 𝑠𝑖𝑛 ∙ 𝑠𝑖𝑛𝛾 + 𝑅3 𝑠𝑖𝑛(𝛼 + 𝜑) + 𝑅4 𝑠𝑖𝑛𝜑 + 𝑅1 𝑠𝑖𝑛𝛾

2

𝛼

𝑄𝑐𝑜𝑠(𝛼 + 𝜑) = 𝑅2 𝑐𝑜𝑠 ∙ 𝑐𝑜𝑠𝛾 + 𝑅3 𝑐𝑜𝑠(𝛼 + 𝜑) − 𝑅4 𝑐𝑜𝑠𝜑 (5)

2

In equations (5), the frontal support of the still unreformed formation in front of the

working bodies can be expressed by the transverse area of the still unreformed formation

through the working part:

𝑅1 = в ∙ ℎ ∙ 𝜎сж (6)

where: в - the width of the capture of one solution of the working part;

һ - tillage depth;

𝜎сж- ultimate soil resistance to compression.

http://www.iaeme.com/IJMET/index.asp 427 editor@iaeme.com

Arman Rustembayev, Dzadiger Eskhozhin, Sayakhat Nukeshev, Zyada Zhaksylykova and Kayrat

Eskhozhin

In equality (c) the width of the capture of one solution of the paw depends on the length of

the plowshare L:

𝑅1 = 𝐿 ∙ 𝑠𝑖𝑛𝛾 ∙ ℎ ∙ 𝜎сж (7)

The reaction of the bottom of the furrow on the lower sole of the working part is equal to:

𝑅4 = ℎ ∙ в𝜏 ∙ 𝜎сж (8)

where: - the width of the lower image of the plowshare in contact with the soil.

The values from (7) and (8) are substituted into equation (5):

𝛼

𝑄𝑠𝑖𝑛(𝛼 + 𝜑) − 𝑅2 𝑠𝑖𝑛 ∙ 𝑠𝑖𝑛𝛾 − 𝑅3 𝑠𝑖𝑛(𝛼 + 𝜑) = 𝐿 ∙ в𝜏 𝜎сж ∙ 𝑠𝑖𝑛𝜑 + 𝐿 ∙ ℎ𝑠𝑖𝑛𝛾𝜎сж

2

𝛼

𝑄𝑐𝑜𝑠(𝛼 + 𝜑) − 𝑅2 𝑐𝑜𝑠 2 ∙ 𝑐𝑜𝑠𝛾 − 𝑅3 𝑐𝑜𝑠(𝛼 + 𝜑) = −𝐿 ∙ в𝜏 ∙ 𝜎сж (9)

Let's transform in (9):

𝛼 𝛼

𝑄𝑠𝑖𝑛(𝛼 + 𝜑) − 𝑅2 𝑠𝑖𝑛 2 ∙ 𝑠𝑖𝑛𝛾 − 𝑅3 𝑠𝑖𝑛(𝛼 + 𝜑) 𝑄𝑐𝑜𝑠(𝛼 + 𝜑) − 𝑅2 𝑐𝑜𝑠 2 ∙ 𝑐𝑜𝑠𝛾 − 𝑅3 𝑐𝑜𝑠(𝛼 + 𝜑)

= ;

в𝜏 𝑠𝑖𝑛𝜑 + ℎ𝑠𝑖𝑛2 𝛾 −в𝜏

𝛼

−𝑄в𝜏 𝑠𝑖𝑛(𝛼 + 𝜑) + 𝑅2 в𝜏 𝑠𝑖𝑛 ∙ 𝑠𝑖𝑛𝛾 + 𝑅3 в𝜏 𝑠𝑖𝑛(𝛼 + 𝜑) =

2

𝛼

𝑄в𝜏 ∙ 𝑠𝑖𝑛𝛾 ∙ 𝑐𝑜𝑠(𝛼 + 𝜑) − 𝑅2 в𝜏 𝑠𝑖𝑛𝜑 ∙ 𝑐𝑜𝑠 ∙ 𝑐𝑜𝑠𝛾 − 𝑅3 в𝜏 ∙ 𝑠𝑖𝑛𝜑 ∙ 𝑐𝑜𝑠(𝛼 + 𝜑) +

2

𝛼

+𝑄ℎ ∙ 𝑠𝑖𝑛2 𝛾 ∙ 𝑐𝑜𝑠(𝛼 + 𝜑) − 𝑅2 ℎ𝑠𝑖𝑛2 𝛾 ∙ 𝑐𝑜𝑠 ∙ 𝑐𝑜𝑠𝛾 − 𝑅3 ℎ𝑠𝑖𝑛2 𝛾 ∙ 𝑐𝑜𝑠(𝛼 + 𝜑);

2

Group all terms in Q, R2, R3:

𝑄[−в𝜏 𝑠𝑖𝑛(𝛼 + 𝜑) − в𝜏 𝜑 ∙ 𝑐𝑜𝑠(𝛼 + 𝜑) − ℎ ∙ 𝑠𝑖𝑛2 𝛾𝑐𝑜𝑠(𝛼 + 𝜑)] = 𝑅2

Accept the following notation:

𝐴 = (в𝜏 𝑠𝑖𝑛𝜑𝑐𝑜𝑠(𝛼 + 𝜑) + ℎ𝑠𝑖𝑛2 𝛾)

𝐴 = (в𝜏 𝑠𝑖𝑛𝜑 + ℎ𝑠𝑖𝑛2 𝛾);

𝐶 = в𝜏 𝑠𝑖𝑛(𝛼 + 𝜑) (10)

In this case, the previous equation takes the form:

𝑄(𝐶 + 𝐴) = 𝑅2

𝑅2

𝑄 = С+𝐴 (11)

The traction force R1, for its precise definition, will project the latter twice, at the

beginning to the direction MN, and secondly to the direction of the translational speed of the

working organ V:

Р = 𝑄𝑠𝑖𝑛(𝛼 + 𝜑) ∙ 𝑠𝑖𝑛𝛾 (12)

To solve equation (12), it is necessary to substitute the value of Q in it. However, two

forces remain unknown in (11) - R2 and R3.

The impulse R2, according to classical mechanics, is determined by the mass of the soil,

which receives it and by the acceleration with which the soil element is excited [7].

http://www.iaeme.com/IJMET/index.asp 428 editor@iaeme.com

The Theoretical Rationale For Traction Effort Experienced Working Part of The Cultivator Fertilizer

𝑅2 = 𝑘 ∙ 𝑚, (13)

where: 𝑘 – acceleration of the excited soil element

𝑚 – the mass of the excited soil element..

Before the excitation is obtained, the initial velocity of the soil elements is zero, V0 = 0.

After the excitation of the soil element is obtained, the velocity Va is acquired. They pass the

width of the upper edge of the MN ploughshare in time:

𝑡 = в𝑖 ⁄𝑉от2 ,

where: в𝑖 – width the upper edge of the plowshare;

𝑉от2 –the relative velocity of the soil element will be equal:

𝑉𝑎 ∙𝑉от2 𝑉2 1−𝑐𝑜𝑠𝛼

𝑢= =2 ∙√ . (14)

в𝑙 в𝑙 2

For the considered time t, a soil layer with a mass passes through the upper edge of the

plowshare edge:

𝑚 = 𝐿 ∙ в𝑖 ∙ ℎ ∙ 𝜌, (15)

where: һ – tillage depth;

𝜌 – soil weight.

Substituting (14) and (15) in (13) we get:

1−𝑐𝑜𝑠𝛼

𝑅2 = 2𝐿ℎ𝜌𝑉 2 √ 2

. (16)

Oblique backwater formation, located on the upper face of the plowshare is characterized

by its size:

𝑅3 = 𝐿в𝑙 ∙ ℎ ∙ 𝜌 ∙ 𝑞 ∙ 𝑐𝑜𝑠(𝛼 + 𝜑), (17)

where: q – acceleration of gravity.

Taking into account (16) and (17) from (11) we get:

1−𝑐𝑜𝑠𝛼2

2𝑉 2 √ 𝛼 𝛼

2

𝑄 = 𝐿ℎ𝜌 [ 𝐴+𝐶

(в𝜏 𝑠𝑖𝑛 2 𝑠𝑖𝑛𝛾 + 𝐵𝑐𝑜𝑠 2 𝑐𝑜𝑠𝛾) + 𝐿в𝑖 ℎ ∙ 𝜌 ∙ 𝑞 ∙ 𝑐𝑜𝑠(𝛼 + 𝜑)] (18)

In this case, equation (12) takes the form:

𝑃 = 𝐿ℎ𝜌 ∙ 𝑠𝑖𝑛(𝛼 + 𝜑)𝑠𝑖𝑛𝛾 (20)

http://www.iaeme.com/IJMET/index.asp 429 editor@iaeme.com

Arman Rustembayev, Dzadiger Eskhozhin, Sayakhat Nukeshev, Zyada Zhaksylykova and Kayrat

Eskhozhin

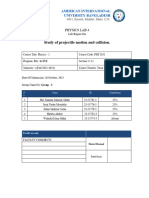

Table 1 The dependence of the traction effort of the tillage working part on the length of the

plowshare, the depth of treatment and the translational speed

№ Ploughshare Traction Processing Traction Speed Traction

length L(н) Р(Кт) depth һ (m) Р(Кт) V(M/c) Р(Кт)

1 0,1 3,22 0,06 7,39 1,8 9,72

2 0,12 9,86 0,08 9,86 2,0 10,88

3 0,14 11,5 0,1 12,33 2,2 12,33

4 0,16 13,15 0,12 14,79 2,4 13,58

5 0,18 14,79 0,14 17,26 2,6 15,1

Traction

Picture 2 Dependences of traction effort of an experienced soil-cultivating working part on the length

of the plowshare, the depth of treatment and the translational speed

We will check the theoretical result by calculating the pulling force of the working part

using equation (20). The numerical values of the are taken from the literature [8,9].

Һ = 0.1m - tillage depth;

L = 0.15 m - the length of the share;

α = 25 ° - cutting angle, plowshare angle;

V = 8 km / h = 2.22 m / s - the translational speed of the working part;

γ = 45° is the angle of the half-solution of the working part;

в𝑖 = 0,1м –width of the upper edge of the plowshare;

в𝜏 = 0,01м – the width of the lower edge of the plowshare in contact with soil;

кг

𝜌 = 103 см3 – Bulk weight of the soil.

http://www.iaeme.com/IJMET/index.asp 430 editor@iaeme.com

The Theoretical Rationale For Traction Effort Experienced Working Part of The Cultivator Fertilizer

At the beginning, we calculate the values of the constant values A, B, C:

𝐴 = (0,01 ∙ 𝑠𝑖𝑛30°𝑐𝑜𝑠55° + 0,1𝑠𝑖𝑛2 45°) = 0,0775;

𝐵 = (0,01𝑠𝑖𝑛30° + 0,1𝑠𝑖𝑛45°) = 0,099;

𝐶 = 0,01𝑠𝑖𝑛55° = 0,082.

Substitute the values of the components of the equation (20)

𝑃 = 0,15 ∙ 0,1 ∙ 103 ∙ 0,81

2 ∙ 4,43 ∙ 0,3

∙ 0,7 [ (0,01 ∙ 0,216 ∙ 0,7 + 0,099 ∙ 0,97 ∙ 0,7) + 0,1 ∙ 9,81 ∙ 0,57]

1,41 ∙ 0,16

= 12,33кг

4. CONCLUSION

• The calculation showed that the traction force of the working part with the adopted

technological and design parameters is equal to P = 12.33 kg, which fully corresponds

to a certain result.

• According to the structure and nature of equation (20), it can also be noted that the

traction force of the working part is directly proportional to the length of the

plowshare, the depth of processing and the angles of cutting and solution of the paw,

as well as the square of the translational speed.

• The calculated values of the traction effort are presented in Table 1 and illustrated in

Picture 1. At the next stage of the study, the results obtained should be checked in

laboratory experiments, by pulling an experienced working part in the soil channel and

by dynamometer traction.

http://www.iaeme.com/IJMET/index.asp 431 editor@iaeme.com

Arman Rustembayev, Dzadiger Eskhozhin, Sayakhat Nukeshev, Zyada Zhaksylykova and Kayrat

Eskhozhin

REFERNCES

[1] Gribanovsky A.P., Bidlingmayer A.P. Complex of antierosion machines (theory,

design). - Almaty: Kaynar, 1990 - P.180-183.

[2] Eskhozhin Z.D. Modern problems of mechanization of tillage in the agriculture

zone of Kazakhstan and ways to solve them. Astana - 2004.-192 p.

[3] Virk S.S., Mullenix D.K., Sharda A. et al Casestudy: distribution uniformity of

ablended fertilizer applied using avariable – ratespinner-discspreader // Applied

Engineering in Agriculture. – 2013.-Vol.29 (5).-P.1-10.

[4] S.Nukeshev, N.N. Romanyuk On the effectiveness of soilless tillage, deep

chopping with the introduction of the main dose of fertilizer // Modern problems

of the development of new technology, technology, organization of technical

service in the agricultural sector. Mat-s International. science.-practical.conf.,

Dedicated. The 60th anniversary of the Belarusian State Agrarian Technical

University and the memory of the first rector of the BIMSH (BGATU), Doctor of

Technical Sciences, Prof.V.P. Suslova (June 4-6, 2014). In 2h. Part 2 / under the

general ed. I.N. Shilo, N.A. Labusheva. - Minsk: BGATU, 2014. - P.16-24.

[5] NukeshevS., Eskhozhin K., EskhozhinD., Syzdykov D. Justification of design and

parameters of seeding unit for fertilizers / Journal of the Brazilian Society of

Mechanical Sciences and Engineering T.39, вып.4. – С.11.39-1149. (IF-1.235);

[6] Nukeshev S., Yeskhozhin K., Kusainov R. Substantiation of the constructive and

technological scheme of the machine for intra soil differentiated three application

of mineral fertilizers/ Agricultural machinery 2016: materials of IV scientific

congress. 22-25 june. – Varna, 2016 – P.3-6.

[7] Drong V.I., Markeev A.P. Theoretical Mechanics - M.2005.MGTU-740 p.

http://www.iaeme.com/IJMET/index.asp 432 editor@iaeme.com

The Theoretical Rationale For Traction Effort Experienced Working Part of The Cultivator Fertilizer

[8] Kovalev N.G. and others. Mechanical and technological properties of agricultural

materials - K .: IK Rodnik, Agrarian science, 1998-208p.

[9] Mechanical and technological power of materials. S.S. Yatsuna. - К .: Mega.2003

– 448p.

http://www.iaeme.com/IJMET/index.asp 433 editor@iaeme.com

You might also like

- Modeling of The Motion Clay Mass in The Screw Channel of The Screw PressDocument5 pagesModeling of The Motion Clay Mass in The Screw Channel of The Screw PressHossein NajafiNo ratings yet

- J P DwivediDocument15 pagesJ P DwivediManoj UpadhyayNo ratings yet

- Mapping 091Document14 pagesMapping 091Ade M KramadibrataNo ratings yet

- Stress Distribution in Soil Under Action of Paraplow Ripper: ArticleDocument6 pagesStress Distribution in Soil Under Action of Paraplow Ripper: ArticleLiv CBNo ratings yet

- Large Deflection Static Analysis of Stiffened Plates Through Energy MethodDocument6 pagesLarge Deflection Static Analysis of Stiffened Plates Through Energy MethodSamik MitraNo ratings yet

- Aritonang 2023 IOP Conf. Ser. Earth Environ. Sci. 1244 012012Document12 pagesAritonang 2023 IOP Conf. Ser. Earth Environ. Sci. 1244 012012Tobok AritonangNo ratings yet

- Excavation Force CalculationDocument7 pagesExcavation Force CalculationJose FisherNo ratings yet

- JESR201904V25S01A0002Document7 pagesJESR201904V25S01A0002alin.butunoi865No ratings yet

- Foundation Design Taking Into Account Non-Linear SDocument8 pagesFoundation Design Taking Into Account Non-Linear SKafui KluNo ratings yet

- Balance of Thread On The Surface of FabricDocument6 pagesBalance of Thread On The Surface of FabricResearch ParkNo ratings yet

- HSM OedometerDocument7 pagesHSM OedometerDjamel Eddine BOURINo ratings yet

- Ijaret: ©iaemeDocument9 pagesIjaret: ©iaemeIAEME PublicationNo ratings yet

- A Procedure For Determining The Optimal Cross-Section of Sub-Rectangular TunnelDocument5 pagesA Procedure For Determining The Optimal Cross-Section of Sub-Rectangular TunnelTai TienNo ratings yet

- Stability Analysis of VerticalDocument11 pagesStability Analysis of VerticalRamiro RicardoNo ratings yet

- Settlements of Rigid Ring-Footings On Two-Layered Soil: January 2020Document8 pagesSettlements of Rigid Ring-Footings On Two-Layered Soil: January 2020زوزو جيجيNo ratings yet

- Module 3 Hydrostatic Force On Surfaces PDFDocument14 pagesModule 3 Hydrostatic Force On Surfaces PDFAragones, Trisha Marie CNo ratings yet

- Composite Pipe Burst CalculationDocument12 pagesComposite Pipe Burst CalculationMuhammad Rafiq RavinNo ratings yet

- Laser Field Characteristics Investigation in The Chemisorption Process For The System Na/WDocument12 pagesLaser Field Characteristics Investigation in The Chemisorption Process For The System Na/WInternational Association of Scientific Innovations and Research (IASIR)No ratings yet

- Shishkin 2017 IOP Conf. Ser. Earth Environ. Sci. 87 022018Document6 pagesShishkin 2017 IOP Conf. Ser. Earth Environ. Sci. 87 022018Kallol MahalanabisNo ratings yet

- Analysis of The Double-Tunnels Interaction by Using Finite Element-CompressedDocument13 pagesAnalysis of The Double-Tunnels Interaction by Using Finite Element-CompressedprioNo ratings yet

- JETIR1903277Document10 pagesJETIR1903277Karwan JwamerNo ratings yet

- Ijaret: ©iaemeDocument16 pagesIjaret: ©iaemeIAEME PublicationNo ratings yet

- Adhesive Impact of Micromechanical Surface Contact: Biswajit BeraDocument6 pagesAdhesive Impact of Micromechanical Surface Contact: Biswajit BeraIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- 296 General Solution of Thick Plates On Winkler-Pasternak - EJEST-V4 (4) 1-14+Document14 pages296 General Solution of Thick Plates On Winkler-Pasternak - EJEST-V4 (4) 1-14+gmpintorNo ratings yet

- Anoyatis Et Al 2016Document44 pagesAnoyatis Et Al 2016Pablo AmestoyNo ratings yet

- ME2050 Exam Mock Exam 2 ScriptDocument9 pagesME2050 Exam Mock Exam 2 ScriptS.A. BeskalesNo ratings yet

- Vibration Cone Crusher For Disintegration of SolidDocument10 pagesVibration Cone Crusher For Disintegration of SolidLAURA LYNCOLN ARUCUTIPA LLAVENo ratings yet

- Hase Halfspace AnalysisDocument9 pagesHase Halfspace AnalysisИлья ХафизовNo ratings yet

- Motamed Et Al. (2015) - 6ICEGEDocument9 pagesMotamed Et Al. (2015) - 6ICEGEgiuseppe.colamarinoNo ratings yet

- Experiment No 3Document3 pagesExperiment No 3Hassan ZahidNo ratings yet

- The Surface Wave Attenuation As The Effect of VibrDocument9 pagesThe Surface Wave Attenuation As The Effect of VibrItalo CDKNo ratings yet

- Synchronous Reluctance MotorDocument10 pagesSynchronous Reluctance MotorJisha KuruvillaNo ratings yet

- JMRA - Volume 10 - Issue 2 - Pages 49-58Document10 pagesJMRA - Volume 10 - Issue 2 - Pages 49-58amira khaldiNo ratings yet

- Past Year FM LabDocument14 pagesPast Year FM LabOmar A-gNo ratings yet

- ISTAM - Stress Concentration Factor Convergence Study of A Thin PlateDocument7 pagesISTAM - Stress Concentration Factor Convergence Study of A Thin PlateKanak_KalitaNo ratings yet

- Analysis of Unbalanced Magnetic Pull in A Multi-Physic Model of Induction Machine With An Eccentric RotorDocument9 pagesAnalysis of Unbalanced Magnetic Pull in A Multi-Physic Model of Induction Machine With An Eccentric Rotor9096664279No ratings yet

- Calculation of Unbalanced Magnetic Pull in A Salient-Pole Synchronous GeneratorDocument8 pagesCalculation of Unbalanced Magnetic Pull in A Salient-Pole Synchronous GeneratorVikas KumarNo ratings yet

- Boundary Conditions of Mining SupportDocument3 pagesBoundary Conditions of Mining SupportLidijaNo ratings yet

- Analysis of The Moiré Pattern of Moving Periodic Structures Using Reciprocal Vector ApproachDocument10 pagesAnalysis of The Moiré Pattern of Moving Periodic Structures Using Reciprocal Vector Approachklounas2003No ratings yet

- 18ME54 Turbo Machines Module 02 Question No 4a & 4bDocument15 pages18ME54 Turbo Machines Module 02 Question No 4a & 4bThanmay JSNo ratings yet

- EM-20-020 - Full - Conf. Paper - IIT KGPDocument11 pagesEM-20-020 - Full - Conf. Paper - IIT KGPSatyajit SahuNo ratings yet

- Energy Efficiency of Bladed Wind TurbineDocument13 pagesEnergy Efficiency of Bladed Wind TurbineMuhammad Irfan AlatasNo ratings yet

- Physics Lab Report 3 Oct 26Document6 pagesPhysics Lab Report 3 Oct 26jarin2439No ratings yet

- Zhang2018 PDFDocument14 pagesZhang2018 PDFFrancisco Javier BaculimaNo ratings yet

- Simplified Numerical Method For Evaluation ofDocument12 pagesSimplified Numerical Method For Evaluation ofAhmad Mahmoud AhmadNo ratings yet

- Design of Geocell Reinforcement For Supporting Embankments On Soft GroundDocument15 pagesDesign of Geocell Reinforcement For Supporting Embankments On Soft Groundreshan champikaNo ratings yet

- Engineering Journal Estimation of Rolling-Contact Bearings Operational Properties by Electrical Probe MethodDocument7 pagesEngineering Journal Estimation of Rolling-Contact Bearings Operational Properties by Electrical Probe MethodEngineering JournalNo ratings yet

- A Multiscale Approach For Cohesive and Unsaturated Soils As A Constitutive Model Designed For FLAC3DDocument5 pagesA Multiscale Approach For Cohesive and Unsaturated Soils As A Constitutive Model Designed For FLAC3DMarcelo AguilarNo ratings yet

- 159e 16 (1) .PdfyeryerDocument6 pages159e 16 (1) .PdfyeryerankitsarvaiyaNo ratings yet

- Lateral Pressure Developed On Piles in Clay Slopes: Numerical StudyDocument8 pagesLateral Pressure Developed On Piles in Clay Slopes: Numerical StudyLucian AliciucNo ratings yet

- Tikhomirov 2020 IOP Conf. Ser. Mater. Sci. Eng. 996 012026Document9 pagesTikhomirov 2020 IOP Conf. Ser. Mater. Sci. Eng. 996 012026VictorNo ratings yet

- A Suggested Analytical Solution of Orthotropic Composite Plate Structure With Crack EffectDocument26 pagesA Suggested Analytical Solution of Orthotropic Composite Plate Structure With Crack Effectiaset123No ratings yet

- 13 55 PDFDocument9 pages13 55 PDFtrungceNo ratings yet

- Numerical Modeling of Direct Shear Tests On Sandy Clay: January 2012Document6 pagesNumerical Modeling of Direct Shear Tests On Sandy Clay: January 2012sasan bluelineNo ratings yet

- Modeling A Repair Machining of A Rotary Kiln TireDocument7 pagesModeling A Repair Machining of A Rotary Kiln TireAmran WiratmaNo ratings yet

- Slope Stability Analysis Using Sheet Pile ReinforcDocument8 pagesSlope Stability Analysis Using Sheet Pile ReinforcMohiuddin AhmedNo ratings yet

- Mechanics: Problems in Undergraduate PhysicsFrom EverandMechanics: Problems in Undergraduate PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Geometry of Surfaces: A Practical Guide for Mechanical EngineersFrom EverandGeometry of Surfaces: A Practical Guide for Mechanical EngineersNo ratings yet

- Ijmet 10 01 054Document7 pagesIjmet 10 01 054IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 047Document10 pagesIjmet 10 01 047IAEME PUBLICATION100% (1)

- Ijmet 10 01 062Document14 pagesIjmet 10 01 062IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 064Document10 pagesIjmet 10 01 064IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 050Document11 pagesIjmet 10 01 050IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 034Document9 pagesIjmet 10 01 034IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 039Document10 pagesIjmet 10 01 039IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 041Document4 pagesIjmet 10 01 041IAEME PUBLICATIONNo ratings yet

- Optimisation of 3D Printing Parameter For Improving Mechanical Strength of Abs Printed PartsDocument6 pagesOptimisation of 3D Printing Parameter For Improving Mechanical Strength of Abs Printed PartsIAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 031Document10 pagesIjmet 10 01 031IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 013Document9 pagesIjmet 10 01 013IAEME PUBLICATIONNo ratings yet

- Order Management System With Enterprise Service Bus in Telecommunication IndustryDocument7 pagesOrder Management System With Enterprise Service Bus in Telecommunication IndustryIAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 018Document7 pagesIjmet 10 01 018IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 009Document8 pagesIjmet 10 01 009IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 005Document10 pagesIjmet 10 01 005IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 008Document15 pagesIjmet 10 01 008IAEME PUBLICATIONNo ratings yet

- Ijmet 10 01 001Document7 pagesIjmet 10 01 001IAEME PUBLICATIONNo ratings yet

- Power System StabilityDocument23 pagesPower System StabilityJasmeet Dua100% (1)

- MotorAnalysis v2.2 Manual EngDocument105 pagesMotorAnalysis v2.2 Manual EngTd KishoreNo ratings yet

- TMC Catalogue 2019Document26 pagesTMC Catalogue 2019Muh. Yousuf KhanNo ratings yet

- Electric Unicycle (EUC)Document15 pagesElectric Unicycle (EUC)HimanshuNo ratings yet

- Mathematical Model of Flexible Alternating Current Link Based On Phase-Shifting Transformer With Circular Rotation of The Phase AngleDocument6 pagesMathematical Model of Flexible Alternating Current Link Based On Phase-Shifting Transformer With Circular Rotation of The Phase AngleCosmic GateNo ratings yet

- Three Phase Motor Starter DesignDocument9 pagesThree Phase Motor Starter Designnimaboat4589No ratings yet

- Rectifier Filter Spreadsheet Instructions PDFDocument7 pagesRectifier Filter Spreadsheet Instructions PDFUnderc OnstructionNo ratings yet

- New Gate Driver Baser Ir2110Document4 pagesNew Gate Driver Baser Ir2110Ayoub RajawiNo ratings yet

- Non-Isolated Buck APFC LED Driver Description FeaturesDocument9 pagesNon-Isolated Buck APFC LED Driver Description FeaturesRisoSilvaNo ratings yet

- Steam Blowing BASICSDocument14 pagesSteam Blowing BASICSadarsh_gangradeNo ratings yet

- Seminar Report On WitricityDocument27 pagesSeminar Report On WitricityNITIKA KULVINo ratings yet

- CompleteMaxwell3D V11Document675 pagesCompleteMaxwell3D V11shantanu142No ratings yet

- High Voltage Experimenters HandbookDocument219 pagesHigh Voltage Experimenters HandbookreconxNo ratings yet

- Light Dependent Resistor-Physics Investigatory Project.Document16 pagesLight Dependent Resistor-Physics Investigatory Project.Saicharan NaiduNo ratings yet

- Cambridge International AS & A Level: Physics 9702/COMP March 2021Document13 pagesCambridge International AS & A Level: Physics 9702/COMP March 2021Osama Mehmood TariqNo ratings yet

- T-Chapter-1-2 Electric and ElectrostaticsDocument34 pagesT-Chapter-1-2 Electric and ElectrostaticsIRSATH ROSHANNo ratings yet

- Module 1 - IntroductionDocument7 pagesModule 1 - IntroductionraiNo ratings yet

- Schrack Power PCB Relay U/UB (V23148) : General Purpose Relays PCB RelaysDocument3 pagesSchrack Power PCB Relay U/UB (V23148) : General Purpose Relays PCB Relaysremus popescuNo ratings yet

- Moments & Centre of Mass QPDocument14 pagesMoments & Centre of Mass QPs.beshimova2026No ratings yet

- Friction - Engineering Mechanics Questions and AnswersDocument7 pagesFriction - Engineering Mechanics Questions and AnswersAmit Kumar Sharma100% (1)

- CH 27Document9 pagesCH 27siddharthsrathor04No ratings yet

- 600 PSRDocument2 pages600 PSRJohn GarnetNo ratings yet

- EM&MIDocument20 pagesEM&MIManjunath RaoNo ratings yet

- Rotary DryerDocument22 pagesRotary DryerRiza Dikromo100% (4)

- CIRCUITS 1 - Module 1Document29 pagesCIRCUITS 1 - Module 1Jose EspinoNo ratings yet

- CH-1 - DC Generator Q.bank PDFDocument2 pagesCH-1 - DC Generator Q.bank PDFjaythakar8887No ratings yet

- Basic Electric Engineering Unit 2 Notes RGPVDocument13 pagesBasic Electric Engineering Unit 2 Notes RGPVMufaddal HamidNo ratings yet

- 1985-ACI-ASCE Committee 352-Recommendations For Design of Beam-Column Joints in Monolithic Reinforced Concrete StructuresDocument18 pages1985-ACI-ASCE Committee 352-Recommendations For Design of Beam-Column Joints in Monolithic Reinforced Concrete StructuresRomanbabu OinamNo ratings yet