Professional Documents

Culture Documents

Reu2015 Winston Chu

Uploaded by

aptridio0 ratings0% found this document useful (0 votes)

29 views1 pagebuku pelajaran

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbuku pelajaran

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views1 pageReu2015 Winston Chu

Uploaded by

aptridiobuku pelajaran

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Arduino Control System for a Temperature Bath

Winston Chu1, Theo Siegrist, Jeff Whalen

1Florida State University

One particularly interesting observation that we made in

ABSTRACT collecting thermal equilibrium data was that the curves

consistently had small deviations from the expected curve.

The goal of this work is to develop a process control system for Further investigation into this issue revealed drastic

a temperature bath that will ultimately control the reaction rate of temperature fluctuations in the ambient temperature. Ambient

a solution crystallizer. More specifically we wish to determine the temperatures on the third floor of the Maglab were found to

efficacy of an Arduino-based control system for controlling fluctuated by as much as 4 ⁰C.

temperatures to within 0.1 ⁰C of a target temperature. The target

temperatures for the crystallization reaction are in the range of

20 to 90 ⁰C. In addition to the implementation of hardware, this

requires the development of a quantitative model to describe the

thermodynamics of the system and the implementation of a PID QUANTITATIVE MODELS

control algorithm into the Arduino. By acquiring thermal

equilibrium data using the Arduino in data acquisition mode, we The quantitative model created predicts the temperature

were able to develop a quantitative model of the thermodynamics response of the system given a specific power input. The model

of the system. We tested a number of process control algorithms was created starting with an energy balance that combines the

that approached our target precision. heat losses into a single overall heat transfer coefficient that

represents a heat loss proportional to the temperature

INTRODUCTION difference between the ambient temperature and the system

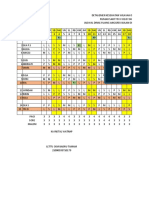

temperature. Integration of the differential equation gives the *Boxes highlight 24-hour periods *Time 0 is at 1pm on a Friday

final expression for the temperature as a function of time.

The Arduino UNO is a microcontroller board that facilitates the These results indicate the need for a large mass of water to

intelligent and precise control of a nearly limitless range of buffer the temperature fluctuations of the ambient air.

A number of control algorithms were tested. The most basic

applications via a large number of sensors and control elements.

control algorithm is the Overshoot. The Overshoot algorithm

We want to test its efficacy in controlling temperature because it

simply turns ON when the sensor reads below the target

offers a very economical and simple platform to implement The initial control algorithm trials indicate that the tested PID

temperature and turns OFF when the sensor reads above the

specialized and precise control of the system. tuning parameters do not out-perform the Overshoot algorithm.

target. The expected drawback to using the Overshoot algorithm

The temperature bath being controlled is intended to be used in The Overshoot algorithm was able to control the temperature to

is an oscillatory response rather than a stable lock on the target

a solution crystallizer. The specific crystallization reaction is the within 0.1 ⁰C of the target however the response was oscillatory

temperature. With the Overshoot algorithm as a baseline, a more

formation of KDP crystals (KDP = KH2PO4). The growth process rather than stable.

sophisticated PID algorithm was also tested. The PID algorithm

for these crystals is controlled by the supersaturation of an

contains three components that sum to the Manipulated Variable

aqueous solution, with an extreme sensitivity to temperature,

(MV). The three components are proportional, integral, and

requiring an accuracy of at least 0.1 ⁰C.

derivative components. Each of these responses can be

adjusted by corresponding tuning parameters (Kp, Ki , Kd).

SYSTEM DESCRIPTION

RESULTS

The system consists of a 3.5 liter glass vessel filled with DI

water. The system is constantly stirred by a magnetic stir-bar to

The quantitative model shows a strong match to the 𝑑 𝑡

maintain a homogeneous temperature profile. The system is

experimental data. All the variables with the exception of the 𝑀𝑀 𝑡 = 𝐾𝑝 𝑒 𝑡 + 𝐾𝑖 � 𝑒 𝜏 𝑑𝑑 + 𝐾𝑑 𝑒(𝑡)

heated by two 75 watt immersion heaters that draw power from a 0 𝑑𝑑

overall heat loss transfer coefficient (U) and the power input (P)

variac. This allows us to alter the maximum power output of the

were defined. These values were determined from the measured

heaters. The system is controlled by an Arduino UNO that

data to be 13.1 J/m2 K and 109.3 W respectively.

switches a solid state relay between the heaters and the variac.

The power output of the heaters can also be controlled at the

Arduino level by control of the heater ON state for a variable

amount of time.

FUTURE & ACKNOWLEDGEMENTS

Future work on this will include more refinements of the PID

𝑷 −𝒕𝒕𝒕� 𝑷 algorithm. Once the PID algorithm has been optimized for the

𝑻 = 𝑻𝒐 − 𝑻𝒂𝒂𝒂 − 𝒆 𝝆𝝆𝝆𝝆 + + 𝑻𝒂𝒂𝒂

𝑼𝑼 𝑼𝑼 system, a crystal growth chamber will be added and the

temperature of the growth chamber controlled.

I would like to thank Dr.Siegrist for guiding me through this

learning process and allowing me to utilize the workspace. This

research was funded through DMR1157490

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- PID ControllerDocument4 pagesPID Controlleralokranjan1811412No ratings yet

- Pid WriteupDocument7 pagesPid Writeupapi-272488699No ratings yet

- XRRIA002EN-A Hotandcold03022011 FinalDocument3 pagesXRRIA002EN-A Hotandcold03022011 FinalDan MihailNo ratings yet

- FinalllllllDocument47 pagesFinalllllllSoresa JemalNo ratings yet

- Biochemical Engineering B.SC, University of DebrecenDocument6 pagesBiochemical Engineering B.SC, University of DebrecenArifuzzamanNo ratings yet

- A Definite Area or Space Where Some Thermodynamic Process Takes Place Is Known AsDocument13 pagesA Definite Area or Space Where Some Thermodynamic Process Takes Place Is Known Asrsankarganesh MECH-HICETNo ratings yet

- Design of Internal Model Controller For A Heat Exchanger SystemDocument5 pagesDesign of Internal Model Controller For A Heat Exchanger SystemAnonymous mIRrZKXNo ratings yet

- Process Systems Analysis and Control D Coughanowr 3rd Ed 2Document6 pagesProcess Systems Analysis and Control D Coughanowr 3rd Ed 2bismilishfaqNo ratings yet

- Seminar Report PPT (Zahid Mushtaq) (1) - 1Document19 pagesSeminar Report PPT (Zahid Mushtaq) (1) - 1Fun 360No ratings yet

- Design of Fuzzy Logic Controller For A Cross Flow Shell and Tube Heat-ExchangerDocument3 pagesDesign of Fuzzy Logic Controller For A Cross Flow Shell and Tube Heat-ExchangerSmilyAkankshaNo ratings yet

- Hawco Controller TheoryDocument8 pagesHawco Controller TheoryEduardo Ocampo HernandezNo ratings yet

- Effect of Thermostat Time Constant On Temperature Control and Energy ConsumptionDocument6 pagesEffect of Thermostat Time Constant On Temperature Control and Energy ConsumptionRagi Geetha RajendranNo ratings yet

- B.Tech. Project Progress Report: Progres Presentation For Final ProjectDocument20 pagesB.Tech. Project Progress Report: Progres Presentation For Final ProjectSolomon MebrahtuNo ratings yet

- Zhiqiang Gao and Thomas A. Trautzsch James G. DawsonDocument9 pagesZhiqiang Gao and Thomas A. Trautzsch James G. Dawsonmhernadnez134No ratings yet

- Innovation Lab: PresentationDocument24 pagesInnovation Lab: PresentationSushmitaNo ratings yet

- PID Control of Heat Exchanger SystemDocument7 pagesPID Control of Heat Exchanger SystemHaris IhsannurNo ratings yet

- Temperature Control System... Himanshu RamdeoDocument25 pagesTemperature Control System... Himanshu RamdeoSurya BandhuNo ratings yet

- Arduino Based Temperature and Humidity CDocument6 pagesArduino Based Temperature and Humidity CMauro MarafonNo ratings yet

- Simulation of Intelligent Controller For Temperature of Heat Exchanger System Using MatlabDocument14 pagesSimulation of Intelligent Controller For Temperature of Heat Exchanger System Using MatlabAnonymous Gke2wm7No ratings yet

- PID Control of Heat Exchanger System: Yuvraj Bhushan Khare Yaduvir SinghDocument6 pagesPID Control of Heat Exchanger System: Yuvraj Bhushan Khare Yaduvir SinghJudy Ann BoseNo ratings yet

- AN20 PID Control LoopsDocument11 pagesAN20 PID Control Loopsmazaher karamiNo ratings yet

- Thermodynamics: Engr. Renel M. AlucijaDocument48 pagesThermodynamics: Engr. Renel M. AlucijaRenel AluciljaNo ratings yet

- Thermal Application Note Using The Heater Pid Method SegmentDocument4 pagesThermal Application Note Using The Heater Pid Method SegmentpeterNo ratings yet

- Modelling and Temperature Control of Heat Exchanger ProcessDocument7 pagesModelling and Temperature Control of Heat Exchanger ProcessDeriSuryadiNo ratings yet

- Temperature Prediction For Reheating Furnace by Gated Recurrent Unit ApproachDocument8 pagesTemperature Prediction For Reheating Furnace by Gated Recurrent Unit ApproachRodrigo LimaNo ratings yet

- 10 11648 J Acis 20140201 11 PDFDocument5 pages10 11648 J Acis 20140201 11 PDFEric DiazNo ratings yet

- Project Report: Temperature Measurement Using Personal Computer (PC)Document14 pagesProject Report: Temperature Measurement Using Personal Computer (PC)Poulomi MukherjeeNo ratings yet

- Project Report: Temperature Measurement Using Personal Computer (PC)Document14 pagesProject Report: Temperature Measurement Using Personal Computer (PC)Poulomi MukherjeeNo ratings yet

- Hvac BMS: HVAC Systems Eng. Ahmed MoustafaDocument126 pagesHvac BMS: HVAC Systems Eng. Ahmed MoustafaBahaa bunniNo ratings yet

- Temp Control Che LabDocument10 pagesTemp Control Che LabStephanie SomongcadNo ratings yet

- Automation of The Temperature Elevation Test in Transformers With Insulating OilDocument7 pagesAutomation of The Temperature Elevation Test in Transformers With Insulating Oilapi-19660864No ratings yet

- A New Method For The Calculation of The Hot-Spot Temperature in Power Transformers With ONAN CoolingDocument9 pagesA New Method For The Calculation of The Hot-Spot Temperature in Power Transformers With ONAN CoolingfmgonzalesNo ratings yet

- Control System LabDocument24 pagesControl System LabRahul Kumar KanoujiaNo ratings yet

- KG12403 CHP7Document17 pagesKG12403 CHP7Hannan adhwaNo ratings yet

- Temperature Control Using Fuzzy Logic: P. Singhala, D. N. Shah, B. PatelDocument10 pagesTemperature Control Using Fuzzy Logic: P. Singhala, D. N. Shah, B. PatelJayaNo ratings yet

- PID Control of Heat Exchanger SystemDocument6 pagesPID Control of Heat Exchanger SystemTuấn Anh Nguyễn100% (1)

- CollectionDocument122 pagesCollectionankur_1984No ratings yet

- Heat Exchanger2Document5 pagesHeat Exchanger2Motaz Ahmad AmeenNo ratings yet

- M.Givelberg, SH - Gurevich, R&D Israel IsraelDocument4 pagesM.Givelberg, SH - Gurevich, R&D Israel IsraelEdna LópezNo ratings yet

- Lab 2Document3 pagesLab 2Vu LeNo ratings yet

- Fuzzy Logic Controller For Superheated SDocument4 pagesFuzzy Logic Controller For Superheated Smahendra ANo ratings yet

- Instrument Ation, Control and Management of Batch Reactors Using Distributed ControlsDocument4 pagesInstrument Ation, Control and Management of Batch Reactors Using Distributed ControlsVytha MarmoetNo ratings yet

- EXP 1 - Physics Finals PDFDocument10 pagesEXP 1 - Physics Finals PDFPearl ArcamoNo ratings yet

- Astm E1641 - 1 (En)Document6 pagesAstm E1641 - 1 (En)Sainath AmudaNo ratings yet

- Temperature ControlDocument7 pagesTemperature ControlDina099No ratings yet

- Dynamic Simulation of Double Pipe Heat Exchanger Using MATLAB SimulinkDocument8 pagesDynamic Simulation of Double Pipe Heat Exchanger Using MATLAB SimulinkacepwcxNo ratings yet

- Irjet V7i5176Document3 pagesIrjet V7i5176sagarvivek kothapalliNo ratings yet

- Shunt A 1971Document5 pagesShunt A 1971kishore dasmunshiNo ratings yet

- Control of Temperature, Humidity, Pressure, Flow Rate, Level or PH Process VariablesDocument8 pagesControl of Temperature, Humidity, Pressure, Flow Rate, Level or PH Process VariablessaravananNo ratings yet

- Temperature ControlDocument9 pagesTemperature ControlMauricio López NúñezNo ratings yet

- 6 Adiabaticcalorimetry PDFDocument14 pages6 Adiabaticcalorimetry PDFEvelyn TapiaNo ratings yet

- Lfa 457 Thermal TesterDocument12 pagesLfa 457 Thermal TesterlbnxxxxNo ratings yet

- Development of Temperature Process Control Method Using Smith PredictorDocument6 pagesDevelopment of Temperature Process Control Method Using Smith PredictorAndrei BujaNo ratings yet

- Bath Ratio and Temperature Control Enhancement in The PotroomDocument2 pagesBath Ratio and Temperature Control Enhancement in The PotroomMarc DupuisNo ratings yet

- Central Heating SystemsDocument8 pagesCentral Heating SystemsZoya SyediNo ratings yet

- KG12403 CHP7 (Part 2)Document17 pagesKG12403 CHP7 (Part 2)MOHAMAD IJAM SIREGAR BIN MULIA MoeNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- Advanced Engineering Thermodynamics: Thermodynamics and Fluid Mechanics SeriesFrom EverandAdvanced Engineering Thermodynamics: Thermodynamics and Fluid Mechanics SeriesRating: 4 out of 5 stars4/5 (9)

- Jadwal Desember 2022Document2 pagesJadwal Desember 2022aptridioNo ratings yet

- 2013 Arduino PID Lab 0Document7 pages2013 Arduino PID Lab 0Uma MageshwariNo ratings yet

- Scale-Up of The Reversible Addition-FragmentationDocument13 pagesScale-Up of The Reversible Addition-FragmentationaptridioNo ratings yet

- 1 s2.0 S0960148117307838 MainDocument11 pages1 s2.0 S0960148117307838 MainaptridioNo ratings yet

- Harga KambingDocument1 pageHarga KambingaptridioNo ratings yet

- NDT Review Helicopter Composite Material PDFDocument10 pagesNDT Review Helicopter Composite Material PDFChandrasekar MuthukumarNo ratings yet

- Unit - 5 Electric DipolesDocument9 pagesUnit - 5 Electric DipolesELMURNo ratings yet

- Finite Element Analysis of Soil Bearing Capacity Using PlaxisDocument5 pagesFinite Element Analysis of Soil Bearing Capacity Using PlaxisRehan HakroNo ratings yet

- Rexnord Bearings Catalog: Download The Most Up-To-Date VersionDocument530 pagesRexnord Bearings Catalog: Download The Most Up-To-Date VersionCelmira Borda AcuñaNo ratings yet

- Mechanical Test Laboratory Price ListDocument6 pagesMechanical Test Laboratory Price ListFrancisNo ratings yet

- Evaluation and Assessment of The Nfatigue in The Architectural Artwork On The Lighting Poles in The Anzac Drive BridgeDocument29 pagesEvaluation and Assessment of The Nfatigue in The Architectural Artwork On The Lighting Poles in The Anzac Drive BridgeFabrizio BisernaNo ratings yet

- Plasma Orbital Expansion Electrons Water FrequencyDocument140 pagesPlasma Orbital Expansion Electrons Water FrequencyVincent J. Cataldi100% (1)

- Worksheet On Metal Forming ProcessesDocument38 pagesWorksheet On Metal Forming Processesberhane100% (1)

- BIW Thinwall Structures PDFDocument3 pagesBIW Thinwall Structures PDFsmani170No ratings yet

- S D S D: Measurement of Normal Incidence Sound Transmission of Acoustical Materials Based On The Transfer Matrix MethodDocument14 pagesS D S D: Measurement of Normal Incidence Sound Transmission of Acoustical Materials Based On The Transfer Matrix MethodMina Remon100% (2)

- Goodbye, Hazen Hello, Kozeny-CarmanDocument3 pagesGoodbye, Hazen Hello, Kozeny-CarmanOscarNo ratings yet

- Bauchau Benchmark 16Document20 pagesBauchau Benchmark 16Victor Hugo Garcia de CamposNo ratings yet

- Chapter5 Diffusion HandoutsDocument13 pagesChapter5 Diffusion Handouts777894292No ratings yet

- Contact Pressure-Overclosure Relationships in AbaqusDocument8 pagesContact Pressure-Overclosure Relationships in AbaqusOliver GiraldoNo ratings yet

- Work and Energy: Part A. Vocabulary ReviewDocument2 pagesWork and Energy: Part A. Vocabulary ReviewForeignnX PhayyNo ratings yet

- Sri Chaitanya IIT Academy., India.: Key Sheet PhysicsDocument10 pagesSri Chaitanya IIT Academy., India.: Key Sheet PhysicsCE-026 BharadwajaNo ratings yet

- TSWF - 900.2 - Earthing Calculation For 110kV OHTL - Rev2Document4 pagesTSWF - 900.2 - Earthing Calculation For 110kV OHTL - Rev2Shinekhuu99No ratings yet

- Daftar Buku Mechanical Engineering, ManufacturingDocument398 pagesDaftar Buku Mechanical Engineering, ManufacturingsatoNo ratings yet

- Uniheat - Transfer Thermal Unitst II Convective Heat Transfer Thermal UnitsDocument33 pagesUniheat - Transfer Thermal Unitst II Convective Heat Transfer Thermal Unitsaerosanth100% (1)

- Advanced Quantum Physics: Lecture HandoutDocument5 pagesAdvanced Quantum Physics: Lecture HandoutPhyo ThihaNo ratings yet

- 1st Puc Physics Chapter14-Oscillations Notes by U N SwamyDocument9 pages1st Puc Physics Chapter14-Oscillations Notes by U N Swamyashwinikumari b100% (1)

- Heavy-Duty Lubricant: FeaturesDocument2 pagesHeavy-Duty Lubricant: Featuresarjun vsNo ratings yet

- 1993 - Avshalom C. Elitzur, Lev Vaidman - Quantum Mechanical Interaction-Free Measurements BOMBADocument14 pages1993 - Avshalom C. Elitzur, Lev Vaidman - Quantum Mechanical Interaction-Free Measurements BOMBAGxilleNo ratings yet

- CH en 3453 - HW 02 - 2014Document2 pagesCH en 3453 - HW 02 - 2014Dennis LingNo ratings yet

- Qpedia Apr09 Basic Principles of Wind Tunnel Design9Document3 pagesQpedia Apr09 Basic Principles of Wind Tunnel Design9Ryan FadhliNo ratings yet

- Water Cooled Chiller - SOPDocument13 pagesWater Cooled Chiller - SOParunceedee100% (4)

- C-SCP360H38B R410aDocument8 pagesC-SCP360H38B R410aRaúl RodríguezNo ratings yet

- Philips StreetStarDocument3 pagesPhilips StreetStarintheblanketNo ratings yet

- Reddy K Veera - Reaction Mechanisms in Metal ComplexesDocument20 pagesReddy K Veera - Reaction Mechanisms in Metal Complexeseasy BooksNo ratings yet

- Newtons Laws and MotionDocument11 pagesNewtons Laws and Motionvictoria kairooNo ratings yet