Professional Documents

Culture Documents

United States: Patent Office

Uploaded by

mehul109410 ratings0% found this document useful (0 votes)

16 views3 pagesus

Original Title

543a165

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentus

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views3 pagesUnited States: Patent Office

Uploaded by

mehul10941us

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Patented Aug.

13, 1940 2,211,625

UNITED STATES PATENT OFFICE

2,25,625

PROCESS FOR THE PRE PARATION OF

AKY GYCOATES

Donald J. Loder, Wilmington, Del, assignor to

E. I. du Pont de Nemours & Company, Wii

mington, Del, a corporation of Delaware

No Drawing. Application September 14, 1938,

Serial No. 229,875

Claims. (C. 260-484)

This invention relates to a process for the benzyl and the like. Polyhydric alcohols and

preparation of esters of glycolic acid and is more their ethers may likewise be substituted for ROH,

especially related to the preparation of esters of e. g., ethylene glycol, as well as its monoalkyl

glycolic acid by the interaction of formaldehyde ethers, e. g., monomethyl and monoethyl ethers

and an alcohol with carbon monoxide. of ethylene glycol et al. This reaction may be 6

Glycolic acid, otherwise known as hydroxy carried out by passing the mixture of the alde

acetic acid or ethanolic acid and having the hyde, alcohol and catalyst, in the presence or ab

formula CH2OHCOOH, has been usually pre sence of Water, into a converter and applying the

pared heretofore by treating monochloracetic necessary pressure by forcing carbon monoxide

10 acid with caustic potash, the esters being made, into the reactants, the reaction being effected at 10

if desired, by simple esterification of the acid a suitable temperature.

with the appropriate alcohol. In an attempt to The formaldehyde may be subjected to the re

develop a more economical process for the prep action in any convenient way or in any con

aration of the acid, various other methods have venient form. Thus, formaldehyde may be dis

5 been proposed as, for example, by the oxidation of solved in water to give an aqueous solution there- l8

ethylene glycol to glycolic aldehyde followed by of containing up to approximately 62% formalde

the subsequent oxidation of glycolic aldehyde to hyde (for instance, technical “formalin'), or

glycolic acid and by the preparation of formalde Solutions of polymeric formaldehyde, e.g., para

hyde cyanhydrin followed by hydration. Due in formaldehyde or trioxymethylene, may be used.

20 large measure to the high cost of the basic ma Such solutions may be employed for reaction with 20

terials required for the manufacture of this acid carbon monoxide, after, if desired, dissolving

by these and other known processes, the acid therein a suitable quantity of catalyst.

and its esters made therefrom have been ex I have found that, in the absence of added cat

pensive, and consequently have been limited in alysts the reaction is initiated slowly but, being

25 many of the important uses for which they are mildly autocatalytic, will proceed progressively 25

adapted. more rapidly after it has started, since glycolic

An object of the present invention is to pro acid, which is present, and acidic by-products of

vide an improved process for the preparation of the reaction, such as formic acid, accelerate the

glycolic acid esters. Another object of the in reaction. Initiation of the reaction is more rapid

30 vention is to provide an economical process for if a compound of an acidic nature, for example, 30

the preparation of glycolic acid esters from inex an organic acid, such as glycolic acid or formic

pensive raw materials. Yet another and more acid, or an inorganic acid, such as hydrochloric,

specific object of the invention is to provide a Sulfuric or phosphoric acid is present, although

process wherein formaldehyde and an aliphatic the reaction will start without the addition of any

monohydric alcohol are interacted with carbon Substance in the nature of the catalyst. 35

monoxide in the presence or absence of water Added catalysts are not, therefore, required to

and an acidic type catalyst to obtain an alkyl either institute or maintain the reaction, but I

glycolate. A further object is to provide a cata have found that they may be used with advan

lyst for this process. Other objects and advan tage to insure more rapid attainment of equilib

40 tages of the invention will hereinafter appear. rium conditions. The deleterious effect of certain 40

The above and other objects of the invention Side reactions may be lessened appreciably by ac

are realized by dissolving formaldehyde, or one celerating the glycolic acid ester synthesis reac

of its polymers, in an anhydrous alcohol or an tion. This is accomplished by adding such wide

alcohol in the presence of water and, preferably ly different compounds as formic acid, phosphoric

45 using a catalyst having acidic characteristics, acid, Sodium acid phosphate, glycolic acid itself 45

subjecting the resulting solution to heat and and hydrochloric acid. Many actual trials have

pressure and an atmosphere of carbon monoxide demonstrated that organic and inorganic cata

whereupon an ester of glycolic acid is obtained lysts which have or give a free hydrogen ion are

in accordance with the equation: suitable altho, of course, some are more effective

50 than others. 50

HCHO--CO--ROH->CH2OHCOOR, Acidic catalysts generally, which are especially

R, designating an alkyl group Such as methyl, active in promoting the synthesis of aliphatic

ethyl, normal and isopropyl, normal and iso acids in accord with the known process of pre

butyl, amyl, hexyl and the higher alkyl groups paring these acids by the interaction of aliphatic

55 such, for example, as cyclohexyl, octyl, nonyl, alcohols with carbon monoxide and more particu- 55

2 2,211,625

larly those of this class which give a pH value in The reaction proceeds at ordinary pressures

aqueous solution of less than 7 may, if desired, although it is advantageous to use pressures in

be employed for catalyzing the reaction of this excess of atmospheric, Say from 5 to 1500 atmos

invention. A number of the catalysts which are pheres or more. The reaction, which is exo

Suitable, all of which catalysts are of an acidic thernic, may be effected over a wide range of

nature, include, for example, the inorganic acids temperatures although the optimum temperature

and especially hydrochloric acid; inorganic acidic varies with specific conditions depending upon

Salts, such, for example, as potassium acid Sul the relative concentrations of catalysts, water,

fate, sodium acid phosphate, boron fluoride; and formaldehyde and carbon monoxide. Generally,

0 generally the acidic catalysts designated in the the reaction can be carried out at temperatures O

patents to G. B. Carpenter, A. T. Larson and J. C. ranging from 50° C. to 350° C., although tem

Woodhouse, Nos. 1924,766, 2,037,654 and peratures ranging between 125 and 225° C. have

2,053,233, respectively. Organic acids and or been found preferable. Mild cooling means should

ganic acid salts may likewise be employed, such, generally be provided to maintain the temper

5 for example, as formic, acetic, glycolic acids and ature within the selected range. By subject s

their salts and acid esters. ing the reactants to temperatures and pressures

These catalysts may be used in amounts rang within the designated ranges the normally liquid

ing from 0.02 to 1.0 mol thereof per mol of form reactants are maintained in the liquid phase and

aldehyde, although the range between 0.02 to 0.15 apparently the carbon monoxide is forced into

20 is preferred. Proportions higher than 1.0 mol the liquid and reacts therein with the form 20

per mol of formaldehyde, however, may be used aldehyde and water present. While the inven

in many instances, such, for example, as in proc tion is not limited to any theory or explanation

esses in which boron trifluoride or hydrochloric of the operation of the process the foregoing ap

acid are employed as a catalyst. While With Sull pears Satisfactorily to explain its mechanism and

25 furic acid as the catalyst, the ratio of from 0.02 accordingly in certain of the claims the process

to 0.15 mol thereof per mol of formaldehyde is is designated as being conducted in the liquid

preferred. Such catalysts may be employed in phase for the reaction appears to take place pri

amounts up to and even greater than molal pro marily, if not entirely, in that phase.

portions With the formaldehyde, but usually, in The reaction product consists essentially of a

30 order to facilitate the Separation of the glycolic Solution containing ester, glycolic acid, a small 30

acid ester or its derivatives from the reaction amount of formic acid, unconverted formalde

product, it is preferable to employ proportions of hyde, the catalyst, if such be used, and water.

the catalyst Within the range Specified. It Will The glycolic acid and ester may be separated

be found that With increased catalyst amount the from this crude mixture by distillation, prefer

reaction will proceed at a lower temperature ably after the addition of an alcohol correspond 35

and/or preSSure While with decreased catalyst ing to that used in the Synthesis, the distillation

amount a SOineWhat higher temperature and/or being preferably carried out at from 80 to 100

preSSure is required to effect the reaction at an mm. preSSure.

equal late. The following examples will illustrate methods

40 For the preparation of glycolic acid esters it is of practicing the invention although it will be un 40

preferable to have a quantity of Water present derstood that the invention is not limited to the

equal to at least 0.5 mol of water per mol of the details therein given. The percentage yields given

formaldehyde present. While concentrations of are calculated on the formaldehyde used.

Water higher than 1.0 mol per mol of formalde Eacample I.-There was placed in a high pres

45 hyde may be present the higher concentrations, Sure silver-lined autoclave a mixture containing

say, 15 to 20 mols per mol of formaldehyde, are 1 mol of formaldehyde, 1 mol of methanol, 6 mols

not used advisedly for they tend to lower the con of water and 0.05 mols of sulfuric acid. A car

centration of the product with resultant greater bon monoxide atmosphere was superimposed

difficulty in Subsequent concentration thereof. above the liquid and its pressure increased to

50 The preparation of glycolic acid esters is car 800-900 atmospheres. The autoclave and con

ried out by having present an alcohol together tents were heated to a temperature between 210

with the formaldehyde and, if desired, Water. and 220 C. for approximately 60 minutes with

As has been indicated, various aliphatic mono continuous agitation. The pressure was released

hydric alcohols may be used in lieu of or to and the contents of the autoclave analyzed to in

gether with Water and Such alcohols as methanol, dicate an approximate 40% yield of methyl glyco

55 late.

ethanol, propanol, butanol, ethylene glycol and

the higher alcohols may be used to produce di Eacample II.-An autoclave charge containing

rectly the corresponding esters of glycolic acid. 1 mol of formaldehyde, 6 mols of methanol, 6 mols

Generally, I prefer to employ per mol of form of water and 0.05 mol of sulfuric acid was proc

60 aldehyde present at least 0.5 and preferably from essed in a manner similar to that given in Ex

0.5 to 6 mols of alcohol; Water, (in ester reac ample I at a temperature between 259 and 263°

tions), being preferably present in the ratio of C. and at 900 atmospheres pressure for approxi

from 0.5 mol to 6 mols thereof per mol of the mately 35 minutes. Analysis of the product in

formaldehyde. dicated the presence of approximately 50%

65 The carbon monoxide required for the Synthesis methyl glycolate. (5

may conveniently be derived from various com Eacample III.-An autoclave was charged with

mercial Sources, as, for example, from Water gas, approximately 5 mols of glycolic acid, 3 mols of

producer gas, etc., by liqtefaction or other meth methanol, 3 mols of formaldehyde and 1.25 mols

ods and should for best results be relatively pure. of water and 0.09 mol of sulfuric acid. This mix

70 The carbon monoxide should preferably be pres ture was Subjected to a temperature between 70

134 and 140 C. and a carbon monoxide pressure

ent in sufficient excess to insure an adequate Sup

ply thereof for absorption by the formaldehyde of 700 atmospheres for 53 minutes. The analysis

in order to inhibit any appreciable decomposi of the product indicated approximately 30%

tion of the formaldehyde to carbon monoxide methyl glycolate.

5 and hydrogen or other products. Eacample IV.- The process of Example III was 7s.

2,211,625 3

repeated utilizing substantially the same molec 5. The process of claim conducted at a tem

ular ratio of reactants, the temperature, how perature between 50 and 350° C.

ever, being maintained at 160° C., the pressure of 6. A process for the preparation of a glycolic

Carbon monoxide at 700 atmospheres and the re acid ester which comprises reacting a formalde

5 action time shortened to approximately 10 min hyde, water and an aliphatic monohydric alcohol 5

utes. Approximately a 25% yield of methyl with carbon monoxide at a temperature between

glycolate was indicated. 125 and 225° C. and under a pressure of at least 5

Eacample V.-An autoclave was charged with atmospheres, at least 0.5 mol of alcohol being

approximately 1 mol of formaldehyde, 1.5 mols present per mol of formaldehyde.

O of ethylene glycol, 6 mols of water and 0.1 mol of 7. The process of claim 6 conducted with sul 0.

Sulfuric acid. This mixture was subjected to a furic acid as the catalyst.

temperature between 203 and 208 C. and a car 8. The process which comprises reacting form

bon monoxide pressure of 800-900 atmospheres aldehyde, Water and an aliphatic monohydric

for 60 minutes. An appreciable yield of glycol alcohol with carbon monoxide and thereby pro

5 glycolate was obtained. ducing an alkyl glycolate.

While the examples have referred particularly 9. A process for the preparation of a glycolic

to carrying out the process in a more or less dis acid ester which comprises intinnately contacting

continuous manner the process of the invention carbon monoxide With an aqueous solution con

may likewise be effected in a continuous manner taining formaldehyde, an aliphatic monohydric

20 by passing the aldehyde, alcohol, water and alcohol, Water and an acidic type catalyst, there 20

catalyst through a reaction zone either co-current being present per mol of formaldehyde at least

or counter-current to the flow of carbon non 0.5 mol of water and from 0.02 to 1 mol of catalyst.

oxide, the rates of flow being adjusted to yield the 10. A process for the preparation of a glycolic

desired degree of reaction. The carbon monoxide acid ester which comprises intimately contacting

should be maintained, as in the processes de carbon monoxide with an aqueous solution con 25

Scribed in the examples, at a suitable pressure taining formaldehyde, an aliphatic monohydric

and the temperature of the continuous reaction alcohol, water and an acidic type catalyst, there

Should be held within the prescribed range by being present per mol of formaldehyde from 0.5

suitable heating means. to 6 mols of alcohol and from 0.5 to 6 mols of

30 In order to insure adequate intimate contact be Water. 30

tWeen the reactants, thorough stirring is an es 11. A process of making methyl glycolate which

Sential to high yields when conducting the process comprises reacting formaldehyde, Water and

in an autoclave and no manner what the type of methanol with carbon monoxide.

reaction VeSSel used intimate contact is of con 12. A process of making ethyl glycolate which

35 siderable importance if optimum results are de comprises reacting formaldehyde, water and etha 35

sired. nol With carbon monoxide.

Because of the corrosive nature of the catalyst 13. A process of making butyl glycolate which

and reactants it is advisable to carry out the proc comprises reacting formaldehyde, Water and a

eSS of the present invention in glass, silica, porce butyl alcohol With carbon monoxide.

40 lain-lined or glass-lined vessels, or the inner 14. A process of making methyl glycolate which 40

surfaces of the reaction vessel which contact with comprises reacting formaldehyde, Water and

the reactants should be constructed of such cor methanol. With carbon monoxide at a temperature

rosion-resistant metals as silver, chromium, stain between 125 and 225 C., a pressure of at least 5

less steel, and the like. atmospheres with from 0.02 to 0.15 mol of sulfuric

45 When formaldehyde is referred to in the ap acid per mol of formaldehyde as the catalyst. 45

pended claims it will be understood that para 15. A process for the preparation of methyl

formaldehyde, formalin, or trioxymethylene or glycolate which comprises reacting approximately

other polymeric or monomeric form of formalde 1 mol of formaldehyde, 6 mols of rhethanol and 6

hyde as well as formaldehyde are also included. mols of water with 0.05 mol of Sulfuric acid as

From a consideration of the above specification the catalyst with carbon monoxide at a tempera 50

it will be appreciated that many details therein ture between approximately 259 and 263 C. and

given may be changed without departing from the at a pressure of 900 atmospheres.

scope of the invention or sacrificing any of the 16. A process for the preparation of an alkyl

55 advantages that may be derived therefrom. glycolate which comprises reacting formaldehyde,

I claim: Water, and an aliphatic monohydric alcohol with 55

1. A process for the preparation of a glycolic Carbon monoxide at a temperature between 125

acid ester Which comprises reacting formalde and 225 C. and under a pressure of from 5 to 1500

hyde and an aliphatic monohydric alcohol with atmospheres.

17. A process for the preparation of a glycolic

60 carbon monoxide.

2. Process of claim 1 carried out in the presence acid ester which comprises interacting formalde

hyde, carbon monoxide and an aliphatic mono

60

of a hydrogen ion concentration on the acid side hydric alcohol in accord with the equation

of pH 7.

3. The process of claim 1 conducted in the HCHO--ROH--CO->CH2OHCOOR.

presence of an acidic catalyst adapted for carry in which R, designates an alkyl group, the re 6.

ing out the interaction of alcohols with carbon action being conducted in the presence of a

monoxide to give aliphatic organic acids. catalyst, at a temperature between 125 and 225 C.

4. The proceSS of claim 1 conducted at a pres and under a pressure in excess of 5 atmospheres.

sure between 5 and 1500 atmospheres. DONATD. J. LODER

You might also like

- US3093691Document2 pagesUS3093691Ayu GirlsNo ratings yet

- United States Patent 0: '3, l50, l74 ICCDocument2 pagesUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNo ratings yet

- United States Patent Office: Patented June 29, 1948Document3 pagesUnited States Patent Office: Patented June 29, 1948jhartmann8No ratings yet

- US1918622Document3 pagesUS1918622Yurelii ChiguiilsNo ratings yet

- Balestrero 1986Document4 pagesBalestrero 1986shenn0No ratings yet

- Us 5883295Document8 pagesUs 5883295Manuel Gonzalez GalvezNo ratings yet

- Es Patent Office IDocument7 pagesEs Patent Office IShandy ArmandoNo ratings yet

- PetroleumDocument13 pagesPetroleumPrashantNo ratings yet

- Pentaeritritol 2Document6 pagesPentaeritritol 2Ibnul BaasithNo ratings yet

- United States Patent (10) Patent N0.: US 6,743,952 B2Document8 pagesUnited States Patent (10) Patent N0.: US 6,743,952 B2Rizka AndhikaNo ratings yet

- Us 2265548Document6 pagesUs 2265548paulina holguinNo ratings yet

- United States Patent (19) : MansfieldDocument7 pagesUnited States Patent (19) : MansfieldLeandro Alberto Villanueva MancillaNo ratings yet

- Alcohols2halides hcl-zncl2Document5 pagesAlcohols2halides hcl-zncl2mancivalNo ratings yet

- Us 4377495Document5 pagesUs 4377495DWNLD USRMLNo ratings yet

- A Convenient Preparation of Volatile Acid ChloridesDocument4 pagesA Convenient Preparation of Volatile Acid ChloridesScott SwartzNo ratings yet

- United States Patent Office: Patented Mar. 21, 1950Document2 pagesUnited States Patent Office: Patented Mar. 21, 1950alexNo ratings yet

- KOH From K2SO4 and NaOHDocument3 pagesKOH From K2SO4 and NaOHamirNo ratings yet

- United States Patent Office: Patented Sept. 5, 1950Document2 pagesUnited States Patent Office: Patented Sept. 5, 1950ari factoryNo ratings yet

- Acetaldehyde Methods 2520of 2520 ProductionDocument6 pagesAcetaldehyde Methods 2520of 2520 Productionapi-3714811100% (3)

- AlkylationDocument9 pagesAlkylationabhishek sharma100% (1)

- Us 3229777Document4 pagesUs 3229777Parth AggarwalNo ratings yet

- US2301231Document2 pagesUS2301231Abu Mejza'atNo ratings yet

- HCLDocument13 pagesHCLHussein AlkafajiNo ratings yet

- US3689216Document5 pagesUS3689216PABLO URIZ CEREZONo ratings yet

- US2789119Document3 pagesUS2789119Feride Elif ErtürkNo ratings yet

- N30 Xo Ho & Iv,: Filed April 20, 195lDocument6 pagesN30 Xo Ho & Iv,: Filed April 20, 195lGaby SaragihNo ratings yet

- N Butyraldehyde To 2 Ethyl 2 HexenalDocument6 pagesN Butyraldehyde To 2 Ethyl 2 HexenalAyie Nazri100% (1)

- Copie de US2899444-1Document4 pagesCopie de US2899444-1KHALED KHALEDNo ratings yet

- Catalytic Application of Al-MCM-41 in The Esterification of Acetic Acid With Various AlcoholsDocument9 pagesCatalytic Application of Al-MCM-41 in The Esterification of Acetic Acid With Various AlcoholsJenny CórdobaNo ratings yet

- United States Patent 1191: Tu (45) Sep. 7, 1982Document4 pagesUnited States Patent 1191: Tu (45) Sep. 7, 1982AdyNo ratings yet

- OxidationDocument25 pagesOxidationMir HamzaNo ratings yet

- United States Patent 0: Patented July 29, 1969Document5 pagesUnited States Patent 0: Patented July 29, 1969PeterWangNo ratings yet

- Comparison of Formic and Sulfuric Acids As A Glucose Decomposition CatalystDocument6 pagesComparison of Formic and Sulfuric Acids As A Glucose Decomposition Catalyst김병철No ratings yet

- United States Patent Office: Preparation of Affo Itrile by HydroDocument5 pagesUnited States Patent Office: Preparation of Affo Itrile by HydroAgnes Anggi SimanjuntakNo ratings yet

- Transition Element: The Use of Catalyst in IndustryDocument9 pagesTransition Element: The Use of Catalyst in Industrycuksam27No ratings yet

- United States: Patent OfficeDocument3 pagesUnited States: Patent Officegonzalo7cornejo7ramiNo ratings yet

- Asam SinamatDocument12 pagesAsam SinamatacaramelliaNo ratings yet

- Us 1045139Document1 pageUs 1045139mahmoud IbrahimNo ratings yet

- Peigao Duan, Xiujun Bai, Yuping Xu, Aiyun Zhang, Feng Wang, Lei Zhang, Juan MiaoDocument9 pagesPeigao Duan, Xiujun Bai, Yuping Xu, Aiyun Zhang, Feng Wang, Lei Zhang, Juan MiaoyemresimsekNo ratings yet

- US2373717Document2 pagesUS2373717Ruchita PoilkarNo ratings yet

- US4780224Document4 pagesUS4780224Mohamad Reza JahanbakhshNo ratings yet

- Sulfuric Acid TreatmentDocument9 pagesSulfuric Acid TreatmentShankar AcharNo ratings yet

- Dohoo????????: 2,838,575 June 10, 1958Document5 pagesDohoo????????: 2,838,575 June 10, 1958Dorotea TirtaNo ratings yet

- Us 5221800Document7 pagesUs 5221800Mochamad Abdul MalikNo ratings yet

- A Safe Method For Preparation of Uncontaminated Hydrazoic AcidDocument1 pageA Safe Method For Preparation of Uncontaminated Hydrazoic Acidgeovani2No ratings yet

- United States: Patent OfficeDocument2 pagesUnited States: Patent OfficeShandy ArmandoNo ratings yet

- Vinyl Acetate Production: Chemical CharacterizationDocument3 pagesVinyl Acetate Production: Chemical CharacterizationHamzah A. LaftaNo ratings yet

- Us 3109732Document4 pagesUs 3109732Ahmed RabeaNo ratings yet

- Patent Office: 5 Claims. (CL 260-69)Document2 pagesPatent Office: 5 Claims. (CL 260-69)Teleson MarquesNo ratings yet

- Indigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnDocument4 pagesIndigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnCillian CreedonNo ratings yet

- US2758124 Continuous Hydrolisys of ArganohalogenosilanesDocument5 pagesUS2758124 Continuous Hydrolisys of ArganohalogenosilanesBruna PlentzNo ratings yet

- United States Patent O?ice: 15H: LLQ?ZDocument3 pagesUnited States Patent O?ice: 15H: LLQ?ZadamNo ratings yet

- Dietanolamina 1955Document6 pagesDietanolamina 1955Leek AgoessNo ratings yet

- A Guide To Kjeldahl Nitrogen Determination Methods and ApparatusDocument13 pagesA Guide To Kjeldahl Nitrogen Determination Methods and ApparatusNoranisza MahmudNo ratings yet

- Organic Chemistry Reaction ListDocument4 pagesOrganic Chemistry Reaction ListAliSulaimanMohammadNo ratings yet

- A Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidFrom EverandA Further Investigation of the Symmetrical Chloride of Paranitroorthosulphobenzoic AcidNo ratings yet

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Biochemistry Applied to Beer Brewing - General Chemistry of the Raw Materials of Malting and BrewingFrom EverandBiochemistry Applied to Beer Brewing - General Chemistry of the Raw Materials of Malting and BrewingRating: 4 out of 5 stars4/5 (1)

- Qu'Est-ce Qu'Un RisqueDocument6 pagesQu'Est-ce Qu'Un RisquejojoNo ratings yet

- Suzler Liquid Tray RatesDocument8 pagesSuzler Liquid Tray RatesSushant PaiNo ratings yet

- Piping - Design - Info (Version 2)Document245 pagesPiping - Design - Info (Version 2)mehul10941No ratings yet

- Design of Packed Towers For AbsorptionDocument21 pagesDesign of Packed Towers For Absorptionmehul10941No ratings yet

- Predicting Distillation Tray Efficiencies Based On Modified O'Connell Correlation Analysis (MOCA) TechniqueDocument12 pagesPredicting Distillation Tray Efficiencies Based On Modified O'Connell Correlation Analysis (MOCA) Techniquemehul10941No ratings yet

- Fractionation Tray Design HandbookDocument43 pagesFractionation Tray Design Handbookmehul1094150% (2)

- Fractionation Tray Design HandbookDocument43 pagesFractionation Tray Design Handbookmehul1094150% (2)

- Process Description and ASPEN Computer Modelling oDocument32 pagesProcess Description and ASPEN Computer Modelling omehul10941No ratings yet

- GPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionDocument44 pagesGPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For Revisionmehul10941100% (1)

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water Requirementmehul10941No ratings yet

- University of Cape Town Department of CHDocument6 pagesUniversity of Cape Town Department of CHmehul10941No ratings yet

- Packed Tower Internals PDFDocument32 pagesPacked Tower Internals PDFmehul10941No ratings yet

- Om 1064 PDFDocument128 pagesOm 1064 PDFMiguelNo ratings yet

- Daniel J. Jacob: Atmospheric Chemistry: From Air Pollution To Global Change and BackDocument21 pagesDaniel J. Jacob: Atmospheric Chemistry: From Air Pollution To Global Change and BackKaren AlcedoNo ratings yet

- CUET 2022 PYQ English (3 Sets)Document35 pagesCUET 2022 PYQ English (3 Sets)Sarvesh SreedharNo ratings yet

- Selina Concise Chemistry Solutions Class 8 Chapter 9 Carbon and Its CompoundsDocument18 pagesSelina Concise Chemistry Solutions Class 8 Chapter 9 Carbon and Its CompoundsSinjini BasuNo ratings yet

- Kfa PT Eng OipmDocument16 pagesKfa PT Eng OipmGabi MeschNo ratings yet

- Risk AssessmentDocument251 pagesRisk Assessmentmarjan 01No ratings yet

- Specifications: Carbon DioxideDocument2 pagesSpecifications: Carbon DioxideShofi100% (1)

- Fuel EnergizerDocument23 pagesFuel EnergizerShan K AntonyNo ratings yet

- Toxicology Module 4 PDFDocument34 pagesToxicology Module 4 PDFm_adiNo ratings yet

- f321 f322 f323 f324 f325 f326 June10 ReportDocument33 pagesf321 f322 f323 f324 f325 f326 June10 ReportLam YipNo ratings yet

- Case Study 11 Centralia Underground Mine FireDocument11 pagesCase Study 11 Centralia Underground Mine Firemigire kennedyNo ratings yet

- Butts A. Metallurgical Problems (027-032)Document6 pagesButts A. Metallurgical Problems (027-032)Miguel Lopez BarretoNo ratings yet

- 11 - Transition Metal ChemistryDocument310 pages11 - Transition Metal ChemistryKatarina WuriyaniNo ratings yet

- Malibu 23 LSV 2006 ManualDocument84 pagesMalibu 23 LSV 2006 ManualMike GilfillanNo ratings yet

- AirGEN Brochure EnglishDocument12 pagesAirGEN Brochure EnglishAlceu DluzniewskiNo ratings yet

- Pgmfi WorksDocument34 pagesPgmfi WorksAndriyan Gtg100% (2)

- ACKNOWLEGEMENT WaiverDocument178 pagesACKNOWLEGEMENT WaiverAllen PerladoNo ratings yet

- Environmental Science: Dr. Hemanta MedhiDocument16 pagesEnvironmental Science: Dr. Hemanta MedhiItmej NNo ratings yet

- Environmental Chemistry: Multiple Choice QuestionsDocument9 pagesEnvironmental Chemistry: Multiple Choice QuestionsSuryaNo ratings yet

- TM 10-7310-281-13&PDocument400 pagesTM 10-7310-281-13&P"Rufus"100% (1)

- OTBA Science 9thDocument28 pagesOTBA Science 9thitsmohanecomNo ratings yet

- Pollution RegulationDocument6 pagesPollution RegulationJaikishan KumaraswamyNo ratings yet

- MSHA 2012 Mine Rescue Contest RulesDocument138 pagesMSHA 2012 Mine Rescue Contest Rulesbigfist171No ratings yet

- Implementation of Monitoring System For Air Quality Using Raspberry PI: Experimental StudyDocument8 pagesImplementation of Monitoring System For Air Quality Using Raspberry PI: Experimental StudyMoroianu AdrianNo ratings yet

- Stairwell PresentationDocument32 pagesStairwell PresentationEdz EduardoNo ratings yet

- Isc US EN - PDF 2Document11 pagesIsc US EN - PDF 2Doncrot OyeNo ratings yet

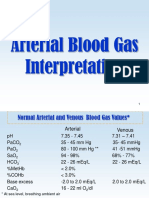

- Arterial Blood Gas InterpretationDocument69 pagesArterial Blood Gas InterpretationostuffeNo ratings yet

- Design of Emission Reduction For Diesel Automobile by UsingDocument65 pagesDesign of Emission Reduction For Diesel Automobile by UsingAMIR MOHAMMEDNo ratings yet

- Ethylene Glycol Production From Synthesis GasDocument1 pageEthylene Glycol Production From Synthesis GasBramJanssen76100% (3)