Professional Documents

Culture Documents

(Woodworking Plans) American Woodworker Lock Rabbet Drawer Joinery PDF

Uploaded by

Martin Granados Sanguino0 ratings0% found this document useful (0 votes)

2 views4 pagesOriginal Title

[Woodworking Plans] American woodworker Lock Rabbet Drawer Joinery.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views4 pages(Woodworking Plans) American Woodworker Lock Rabbet Drawer Joinery PDF

Uploaded by

Martin Granados SanguinoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

By Randy Johnson

For fast, easy, accurate joinery in everything from

kitchen-cabinet drawers to jewelry boxes, the lock

rabbet isthe way to go. Lock rabbets are self-aligning

and sufficiently strong for light- and medium-duty

drawers,

As with most woodworking techniques, there is more

than one way to makea lock rabbet. We experimented

with several methods using the tablesaw and router

table and setled on thisas our favorite. It usesa router

t called a drawer lock bit (see Sources, page 63)

And for the wood, we chose 1/2-in. Baltic birch ply-

‘wood. Its multiple layers and lack of internal

voids make it strong and stable.

Router Bit Setup

Setting up the drawer lock bitis not difficult

Start by aligning this bit with the fence, as

shown in Photo 1. Next, adjust the height of

the bit to approximately 3/8 in. (Photo 2).Run

a couple of test boards (Photo 3) and check the

fit (Photo 4). The first test boards you make are

unlikely to give you a perfec fit so adjust the bits

height until the fitis just right.

Use a drawer lock router bit on

drawer sides from 1/2- to I-in, thick,

60 American Woodworker ruanian a2

Here’s a router-made

drawer joint that’s quick,

simple and self-aligning.

Adjust the router fence until the lower cutting edge just

‘touches the straightedge, which i tight against the fence.

Be sure your machine is unplugged curing this adjustment!

‘Adjust the height of the router bit to approximately 3/8 in.

above the table. This is not the final setting but a scarting point.

Bo sure your machine is unplugged during this adjustment

‘Test the setup by routing a couple of serap boards.

‘Check the fit, The tost joints should fic together ensily, but

without any gaps. Remember: Lower to loosen and heighten to

tighten Lip thickness will be between 1/16 in. and 1/8 in. when

using 1/2-in. material

61

eu

Make both cuts for a lock rabbet joint with one router bic.

“To clarify the process, we've cclored the sides yellow and the

front and back blue.

Rout the panels for the drawer sides. Keep even pressure

‘on the panel so it stays against che fence and in constant,

‘contact with the table, Use a all fence for good support.

Pata

MATERIAL

Reset the fence for fronts and backs using a scrap piece of

ddrawer-box material, Move the fence back so the upper cutting

‘edge aligns with the outer edge of the material

‘Be sure your machine Is unplugged during this adjuserent

62 American Woodworker reanuiaz2

Lock Rabbet Drawer Joinery

Making the Drawer Sides

‘To determine the length of your drawer sides, subtract two

times the thickness of the ip on your tet board (Photo 4)

from your final drawer box length. For example, if youre

making a 12-in.-long drawer box and the lip on the test

board is 1/16 in, the material for the drawer sides should

be 11-7/8-in. long. Heres the math:

L/16"x2= 1/8"

12"=1/8" = 11-718"

Prepare your plywood by cutting it into panels that

equal the length you calculated with the formula above

and are two to three drawer-sides wide (Photo 9). Add

1 in, to the width to allow for saw kerfs and edge waste

“The edge waste will accommodate the chip-out that usu-

ally occurs when the router bt exits the cut. To rout the

joint for drawer sides, hold the pane! vertically against the

fence (Photo 6).

Making the Drawer Box Fronts and Backs

Reset your router-table fence before you rout the fronts

and backs. Seta serap piece of your drawer-box material

‘on top ofthe bit and move the fence back until the cutting,

depth matches the thickness of the material (Photo 7).

Run a test cut with a scrap of drawer-box material and

check the fit with the drawer side panels you cut earlier,

It should look like the joint in Photo 5. Ifthe lip doesn't

flush up with the side panel, readjust the router-table

fence and run another test cut until the lip is flush with

the side.

‘The drawer fronts and backs should be as long as the

final width of the drawer box because they span the fall

width (Photo 5). These front and back panels are routed

flat on the table (Photo 8).

PANEL FOR FRONT

[AND BACK PIECES

Rout the front and back panels. Hold the panel firmly against

the table to prevent fe from iting, oF you!l spoil the joine.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Vivienda Social, Una Mirada Desde El Hábitat.Document41 pagesVivienda Social, Una Mirada Desde El Hábitat.carlos97% (39)

- El ABC de Las Instalaciones Eléctricas ResidencialesDocument121 pagesEl ABC de Las Instalaciones Eléctricas ResidencialesHugo GallegosNo ratings yet

- Rubimix9 V5 07-2014 24271Document60 pagesRubimix9 V5 07-2014 24271Martin Granados SanguinoNo ratings yet

- (Woodworking Plans) Woodsmith Magazine Oak BookcaseDocument8 pages(Woodworking Plans) Woodsmith Magazine Oak Bookcasejaime100% (1)

- Desodorantes y Antitranspirantes1Document7 pagesDesodorantes y Antitranspirantes1Martin Granados SanguinoNo ratings yet

- 511 Manual Del InstaladorDocument40 pages511 Manual Del InstaladorCesar Morales100% (1)

- Arte y Alienacion Herbert Read 1967 1 PDFDocument240 pagesArte y Alienacion Herbert Read 1967 1 PDFphotoimation100% (3)

- Rodilleras V4 12-2009 81000Document2 pagesRodilleras V4 12-2009 81000Martin Granados SanguinoNo ratings yet

- Curso Completo de HTML Jorge Ferrer Victor Garcia Rodrigo Garcia HTML Programacion ManualDocument447 pagesCurso Completo de HTML Jorge Ferrer Victor Garcia Rodrigo Garcia HTML Programacion ManualT-Punisher100% (2)

- Calidociclos y PoliedrosDocument67 pagesCalidociclos y PoliedrosMartin Granados SanguinoNo ratings yet

- Rubilim-25 V1 05-2008 60373Document16 pagesRubilim-25 V1 05-2008 60373Martin Granados SanguinoNo ratings yet

- Clase 6 Generadores de ObraDocument22 pagesClase 6 Generadores de ObraJulio Perez JimenezNo ratings yet

- Manual Consejos Seguridad Operaciones Maquinaria Pesada Caterpillar Explotacion Canteras AridosDocument5 pagesManual Consejos Seguridad Operaciones Maquinaria Pesada Caterpillar Explotacion Canteras AridosMiguel Ángel MatehualaNo ratings yet

- Aisc 2010Document2 pagesAisc 2010robox514No ratings yet

- Costos ParametricosDocument16 pagesCostos ParametricosJavier Vazquez67% (6)

- Almohadilla V1 04-2006 65943Document1 pageAlmohadilla V1 04-2006 65943Martin Granados SanguinoNo ratings yet

- Cálculo de Cantidad de Obra para Una ViviendaDocument64 pagesCálculo de Cantidad de Obra para Una ViviendaMercedes Villa93% (84)

- Tablas de Proporcion de ConcretoDocument6 pagesTablas de Proporcion de ConcretobaloyEduardo81% (64)

- COLOMBIA - Manual de Construccion, Evaluacion y Rehabilitacion Sismo Resistente de Viviendas de MamposteriaDocument82 pagesCOLOMBIA - Manual de Construccion, Evaluacion y Rehabilitacion Sismo Resistente de Viviendas de Mamposterialaura_p_16No ratings yet

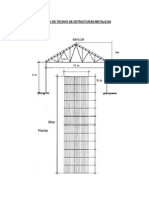

- Calculo de Techos de Estructuras MetalicasDocument19 pagesCalculo de Techos de Estructuras MetalicasWalter E. Pinillos86% (7)

- 2040 Manual EspDocument12 pages2040 Manual EspMartin Granados SanguinoNo ratings yet

- 3.08.0 Presupuestos Arq. PaniaguaDocument3 pages3.08.0 Presupuestos Arq. PaniaguaSandra CastañedaNo ratings yet

- 68catalogo RACKS 2013 Low PDFDocument47 pages68catalogo RACKS 2013 Low PDFMartin Granados SanguinoNo ratings yet

- Calculo de MaterialesDocument174 pagesCalculo de MaterialesErick EscobarNo ratings yet

- Manual de ColocaciónDocument16 pagesManual de ColocaciónManuales de InteresNo ratings yet

- Esmelux Instrucciones Montaje Banco TrabajoDocument4 pagesEsmelux Instrucciones Montaje Banco TrabajoMartin Granados SanguinoNo ratings yet

- Calidociclos y PoliedrosDocument67 pagesCalidociclos y PoliedrosMartin Granados SanguinoNo ratings yet

- Cálculo de MaterialesDocument9 pagesCálculo de Materialesanon-51224899% (74)

- COLOMBIA - Manual de Construccion, Evaluacion y Rehabilitacion Sismo Resistente de Viviendas de MamposteriaDocument82 pagesCOLOMBIA - Manual de Construccion, Evaluacion y Rehabilitacion Sismo Resistente de Viviendas de Mamposterialaura_p_16No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)