Professional Documents

Culture Documents

WPS Welding Procedure Specification

Uploaded by

Bhanu Pratap Choudhury0 ratings0% found this document useful (0 votes)

97 views1 pageSample WPS

Original Title

WPS Sample

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSample WPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

97 views1 pageWPS Welding Procedure Specification

Uploaded by

Bhanu Pratap ChoudhurySample WPS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

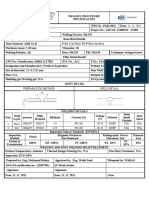

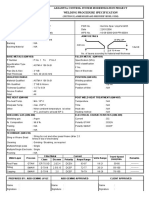

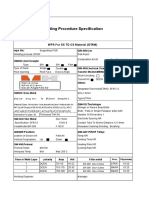

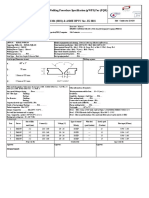

Welding Procedure Specification (WPS)

Welding Procedure Specification: WPS01 WPQR No.: PQR01

Manufacturer: Welding Manufacturer

Parent Material Designation:

Material Thickness (mm): 25 ≤ t ≤ 52

A, B, D, AH32/36, DH32/36, EH32/36

Outside Diameter (mm): N/A Method of Preparation and Cleaning: N/A

Filler Metal Designation and brand name: SA3YM, DSII81-K2 (SeAH, ESAB)

Welding Technique: Multipass, Single

Welding Process/Equipment: FCAW / Xsystem

Electrode

Joint Type and Weld Type: Butt weld joint Welding Position: PA, PC, PF

Weld Preparation Details

Joint Design Welding Sequences

Size of Type of Heat

Welding Voltage Speed Welding

Run Filler current/ Current (A) Input

Process (V) (cm/min) Position

Metal Polarity (KJ/cm)

Root 200-250 25-27 20-23 13-20

PA

Other 220-240 22.5-26 18-22 13.5-21

FCAW Root 1.4 mm DCEP 160-210 20-25 13-15 12.8-24

PC

Other 220-230 21-25 20-22 12.6-17.2

Root 170-180 20-22 8-10 20.4-30

PF

Other 200-220 20-23 13-15 16-23

Any Special Backing or Drying: Ceramic backing

Designation Gas /Flux: Gas Flow Rate:

- Shielding: CO2 - Shielding: 20-25L/min

- Backing: N/A - Backing: N/A

Preheat Temperature Min. : t ≤ 38mm: 12°C / 38 < t ≤ 52 mm: 66°C

Interpass Temperature: Max.250°C

Post-weld Heat Treatment and/or Ageing: N/A

Other Information*: Back side gouging and welding may be applied if back bead appearance is not

acceptable.

Checked by: M.Y

Prepared by: M.Z Approved by: MM

*If required

You might also like

- Welding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmDocument1 pageWelding Procedure Qualification Record: String or Weave Bead, Multipass, Single Electrode, Electrical Stick-Out:15-25mmBhanu Pratap ChoudhuryNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- PQR - Camsa-02Document1 pagePQR - Camsa-02Jean Carlo Gutarra SocualayaNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- WQT SmawDocument1 pageWQT Smawoperation btutNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationVISAKHAPATNAM MALAYALEES WELFARE ASSOCIATIONNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- WPS MCC 001 PDFDocument1 pageWPS MCC 001 PDFNuwan RanaweeraNo ratings yet

- Pessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/ADocument1 pagePessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/AMahmoud HaggagNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Preliminary Welding Procedure Specification No.: MCC/WF/pWPS/002Document1 pagePreliminary Welding Procedure Specification No.: MCC/WF/pWPS/002Nuwan RanaweeraNo ratings yet

- Pessing Libya INC: SA 312 TP 316 TO SA 312 TPDocument1 pagePessing Libya INC: SA 312 TP 316 TO SA 312 TPMahmoud HaggagNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- WPS 141-111 P460QH To SameDocument1 pageWPS 141-111 P460QH To SameakisdassasNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Welding Procedure Specification (AutoRecovered)Document2 pagesWelding Procedure Specification (AutoRecovered)virnmontalesNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Onex-Wps-100 - Single V - 27-Smaw-Vertical UpDocument1 pageOnex-Wps-100 - Single V - 27-Smaw-Vertical Upteopan PanNo ratings yet

- WPS 141-121 P460QH To SameDocument2 pagesWPS 141-121 P460QH To SameakisdassasNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNo ratings yet

- PRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWDocument8 pagesPRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWmegantara maromNo ratings yet

- Pessing Libya INC: Sfa. No: A5.9Document1 pagePessing Libya INC: Sfa. No: A5.9Mahmoud HaggagNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CMahmoud HaggagNo ratings yet

- Sample WPS for Carbon Steel GTAW+SMAW WeldingDocument2 pagesSample WPS for Carbon Steel GTAW+SMAW WeldingAmanSharmaNo ratings yet

- 2005-05 - WPS & PQR C5Document6 pages2005-05 - WPS & PQR C5misthahNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSDocument6 pagesWELDING PROCEDURE SPECIFICATION FOR TIE-IN WORKSAshishNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4Document1 pagePessing Libya INC: As Per P No.3,4 To As Per P No.3,4Mahmoud HaggagNo ratings yet

- P WPSDocument3 pagesP WPSAnilkumar G NairNo ratings yet

- AnilDocument7 pagesAnilanil kumarNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Asirusa WPS-P-002 1FDocument5 pagesAsirusa WPS-P-002 1FWalter RuedaNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- Nisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)Document3 pagesNisoc: Preliminary Welding Procedure Specification (PWPS) For (PQR)pejman.imaniNo ratings yet

- WPS for SS to CS WeldingDocument1 pageWPS for SS to CS WeldingLipika GayenNo ratings yet

- WPS Welding Procedure SpecificationDocument1 pageWPS Welding Procedure SpecificationburakNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Pessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/ADocument1 pagePessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/AMahmoud HaggagNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- ASTM-D4541-22Document7 pagesASTM-D4541-22Bhanu Pratap ChoudhuryNo ratings yet

- NF7WQFT2AN7C8X218109_ETicketDocument2 pagesNF7WQFT2AN7C8X218109_ETicketBhanu Pratap ChoudhuryNo ratings yet

- 07.01.05 Fabrication Galvanizing R1Document11 pages07.01.05 Fabrication Galvanizing R1Bhanu Pratap ChoudhuryNo ratings yet

- ADANII QAP 316L Npdf-SignedDocument3 pagesADANII QAP 316L Npdf-SignedBhanu Pratap ChoudhuryNo ratings yet

- Manufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsDocument4 pagesManufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsBhanu Pratap ChoudhuryNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Bhanu Pratap ChoudhuryNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Bhanu Pratap ChoudhuryNo ratings yet

- Hot-Dip Zinc Coatings On Structural Steel and Other Allied Products - SpecificationDocument9 pagesHot-Dip Zinc Coatings On Structural Steel and Other Allied Products - SpecificationBhanu Pratap ChoudhuryNo ratings yet

- QW 217 - Clad Plata Joining PDFDocument1 pageQW 217 - Clad Plata Joining PDFBhanu Pratap ChoudhuryNo ratings yet

- Format InvoiceDocument1 pageFormat InvoiceBhanu Pratap ChoudhuryNo ratings yet

- Subject: Handling of Public Grievances Received in Cpgrams On Covid-19 in States/Uts GovernmentsDocument1 pageSubject: Handling of Public Grievances Received in Cpgrams On Covid-19 in States/Uts GovernmentsBhanu Pratap ChoudhuryNo ratings yet

- (First Revision) : Indian StandardDocument8 pages(First Revision) : Indian StandardBhanu Pratap ChoudhuryNo ratings yet

- QW 217 - Clad Plata Joining PDFDocument1 pageQW 217 - Clad Plata Joining PDFBhanu Pratap ChoudhuryNo ratings yet

- FGD Sheet Lining LiteratureDocument8 pagesFGD Sheet Lining LiteratureBhanu Pratap ChoudhuryNo ratings yet

- Reaffirmed 2006Document23 pagesReaffirmed 2006Bhanu Pratap ChoudhuryNo ratings yet

- Separator - Performance CertificatesDocument1 pageSeparator - Performance CertificatesBhanu Pratap ChoudhuryNo ratings yet

- Corrosion-Resistant Alloy 686 Used in Demanding ApplicationsDocument10 pagesCorrosion-Resistant Alloy 686 Used in Demanding ApplicationsBhanu Pratap ChoudhuryNo ratings yet

- Special Alloys and Overmatched Welding Products SolveDocument14 pagesSpecial Alloys and Overmatched Welding Products SolveBhanu Pratap ChoudhuryNo ratings yet

- Separator QAPDocument1 pageSeparator QAPBhanu Pratap ChoudhuryNo ratings yet

- Roll-Bonded Clad Plates: Our Cost-Efficient Answer To CorrosionDocument40 pagesRoll-Bonded Clad Plates: Our Cost-Efficient Answer To CorrosionRoyster CabralNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Separator - Company ProfileDocument1 pageSeparator - Company ProfileBhanu Pratap ChoudhuryNo ratings yet

- TUV India Online Training Program With Fees and Registration LinksDocument3 pagesTUV India Online Training Program With Fees and Registration LinksBhanu Pratap ChoudhuryNo ratings yet

- Separator PODocument1 pageSeparator POBhanu Pratap ChoudhuryNo ratings yet

- CTC To Tata - 100320Document1 pageCTC To Tata - 100320Bhanu Pratap ChoudhuryNo ratings yet

- CTC To Tata - 100320Document1 pageCTC To Tata - 100320Bhanu Pratap ChoudhuryNo ratings yet

- Separator - Type Test ReportDocument1 pageSeparator - Type Test ReportBhanu Pratap ChoudhuryNo ratings yet

- Yahoo Mail - Booking Confirmation On IRCTC, Train - 12802, 23-Aug-2019, SL, TATA - CTCDocument1 pageYahoo Mail - Booking Confirmation On IRCTC, Train - 12802, 23-Aug-2019, SL, TATA - CTCBhanu Pratap ChoudhuryNo ratings yet

- Ola - Tata Station To Adityapur - 110320Document3 pagesOla - Tata Station To Adityapur - 110320Bhanu Pratap ChoudhuryNo ratings yet

- Yahoo Mail - Booking Confirmation On IRCTC, Train - 18477, 11-Mar-2020, 3A, CTC - TATA PDFDocument1 pageYahoo Mail - Booking Confirmation On IRCTC, Train - 18477, 11-Mar-2020, 3A, CTC - TATA PDFBhanu Pratap ChoudhuryNo ratings yet

- MasterSeal 7000 CR Proof - of - Performance PDFDocument25 pagesMasterSeal 7000 CR Proof - of - Performance PDFbeck.26No ratings yet

- Organic Chem Packet - SLDocument10 pagesOrganic Chem Packet - SLMary GinetaNo ratings yet

- Exercise No: AIM Appartus: Chemicals: EquipmentDocument2 pagesExercise No: AIM Appartus: Chemicals: EquipmentjayantNo ratings yet

- Inconel 100 PDFDocument66 pagesInconel 100 PDF孙俊磊No ratings yet

- 56 Accesories enDocument2 pages56 Accesories enSyed AsadullahNo ratings yet

- Cems A 6 Part I AppxDocument15 pagesCems A 6 Part I AppxEngenharia APedroNo ratings yet

- European Steel and Alloy Grades: X1Crnimon25-22-2 (1.4466)Document3 pagesEuropean Steel and Alloy Grades: X1Crnimon25-22-2 (1.4466)farshid KarpasandNo ratings yet

- Royale Play InfinitexDocument2 pagesRoyale Play InfinitexchitraNo ratings yet

- WS2032D3Document4 pagesWS2032D3Luis David Méndez MirandaNo ratings yet

- Drug Delivery Lab - Effervescent Powder FormulationDocument3 pagesDrug Delivery Lab - Effervescent Powder FormulationAntonio CharismaNo ratings yet

- Golden Topsteel Year End Inventory ReportDocument64 pagesGolden Topsteel Year End Inventory ReportMichelle MontalboNo ratings yet

- Aerospace Standards UpdatesDocument5 pagesAerospace Standards UpdatesfiemsabyasachiNo ratings yet

- Amt 4201 Aircraft Structures Ii Compilation of Final Term DiscussionsDocument95 pagesAmt 4201 Aircraft Structures Ii Compilation of Final Term DiscussionsangeloNo ratings yet

- Flyer Non-Return-Valves Edition07 20-04-2018 ENDocument12 pagesFlyer Non-Return-Valves Edition07 20-04-2018 ENЊегош ТешановићNo ratings yet

- Sepuran® N Module 4": in NM /H at 7 Barg 25°CDocument2 pagesSepuran® N Module 4": in NM /H at 7 Barg 25°CsanjaigNo ratings yet

- Comparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Document12 pagesComparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Jawad K. OleiwiNo ratings yet

- Shibori Examples 1yzh7laDocument2 pagesShibori Examples 1yzh7laFathi Mustafa100% (1)

- Predicting Products WorksheetDocument2 pagesPredicting Products Worksheetkibbs921No ratings yet

- Refinery Balance PresentationDocument16 pagesRefinery Balance PresentationSiddharth sHARMANo ratings yet

- Crouse Hinds LCC Cable Tray Clamps Catalog PageDocument1 pageCrouse Hinds LCC Cable Tray Clamps Catalog Pageadibella77No ratings yet

- Foam Concentrate For Producing Mechanical Foam For Fire Fighting - SpecificationDocument26 pagesFoam Concentrate For Producing Mechanical Foam For Fire Fighting - SpecificationInyamul HasanNo ratings yet

- Lithium RecoveryDocument16 pagesLithium RecoverynikitaambeNo ratings yet

- Compelete CEP ReportDocument16 pagesCompelete CEP ReportAhmer EjazNo ratings yet

- Industrial Hose Chemical Resistance GuideDocument32 pagesIndustrial Hose Chemical Resistance Guidemat gaiatoNo ratings yet

- Material Demand uPVC (Stock List)Document1 pageMaterial Demand uPVC (Stock List)Umer HanifNo ratings yet

- Kemper™ Oilfield Hammer UnionsDocument2 pagesKemper™ Oilfield Hammer UnionsFabian MontoyaNo ratings yet

- Cladding Details PDFDocument144 pagesCladding Details PDFzaki_th00880% (5)

- MSDS-RIPSTAR 156-Part 1Document6 pagesMSDS-RIPSTAR 156-Part 1Ankita Baban GavadeNo ratings yet

- Part One Existing Magnesia Cement Technologies: Acknowledgments 0 Introduction - Characterization of MgoDocument3 pagesPart One Existing Magnesia Cement Technologies: Acknowledgments 0 Introduction - Characterization of MgoRamón RamalhoNo ratings yet

- Chemistry How To Make StuffDocument185 pagesChemistry How To Make StuffvasiliyNo ratings yet