Professional Documents

Culture Documents

CCM FMCSA Chassis Inspection Form

Uploaded by

ido4self100%(1)100% found this document useful (1 vote)

560 views1 pageChassis inspection fort

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentChassis inspection fort

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

560 views1 pageCCM FMCSA Chassis Inspection Form

Uploaded by

ido4selfChassis inspection fort

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

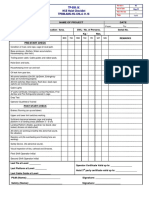

FMCSA Intermodal Chassis Inspection Form

Date: __/__/____ Location: ___________________ IEP: ______________________

Chassis # : ____________ VIN # : ______________________ OWNER: __________________

License Plate: __________ Expiration: __________________ State Registered: ___________

All inspection criteria derived from FMCSA CFR49 Part 396 and Appendix G subpart B

Component/System OK Defect Repair Description of Defect/Repair

BRAKE SYSTEM ABS Yes No

Service brakes – no absence of braking action

Inspect for Cracked, broken, missing, loose, deformed, brake parts

No Audible air leaks

Inspect brake drums for external cracking or missing pieces

Check and adjust travel on brake chamber -

L/F______ R/F______ L/R______ R/R______

Maximum travel = 2” Measured Travel

Measure brake lining thickness

L/F______ R/F______ L/R______ R/R______

Minimum Thickness = ¼” Measured Thickness

Inspect Brake hoses, tubing, air lines, couplings, fittings, gladhands and gladhand seals – NO

kinks, or blockages. NO worn; frayed loose hoses or lines. NO hoses in contact with moving parts

Drain Air tanks

Suspension

Inspect Ubolts; spring hangers; spring assemblies; leaves; torque radius or tracking components;

axles or any other axle positioning parts. NO cracked; broken loose or missing parts

Coupling Devices

Inspect Kingpin; upper coupler plate, slider, pintle hook; pintle hook latch; frame member

providing support/attachment to pintle hook; fasteners; No broken or cracked components. NO

cracked welds or parent metal. NO excessive wear or chipping of kingpin lip

Locking Devices

Inspect all twist locks, push pins, handles, and safety devices; NO cracked welds; NO ineffective

parts; NO excessively worn, bent; broken or missing parts.

Slider Assembly (if equipped)

Inspect for missing, broken, broken, damaged, binding, inoperative, worn, or cracked parts. NO

damage or bends to slider stops. NO elongated slider lock apertures in frame. NO cracked, or

improper welds to any components or parent metal.

Frame

Inspect main rails, bolsters, crossmembers, ICC Bumper, Light boxes, mudflap hangers. No

cracked welds or parent metal; NO broken, missing loose, sagging parts, no parts bent to affect

mating of container to chassis

Landing Gear

Inspect legs, sandshoes, mounting boxes, braces, cross shaft, and all mounting hardware; Check

operation of landing gear in both directions. NO cracked welds or parent metal. NO broken,

missing, or loose part or fasteners. All parts function properly

Electrical

Inspect seven way, wiring harness, lighting devices and reflectors. No broken, inoperative missing

or loose parts

Wheels & Rims

Inspect all wheels, rims spacers and fasteners. NO bent, broken, cracked, improperly seated,

sprung or mismatched parts. NO elongated bolt holes or stripped parts

Tires

Inspect all tires for, noticeable leaks, proper mating;, separations; cuts through one or more ply

of fabric; NO spot on tire with tread depth 2/32” or below when measured in major tread grove

Air all tires to 85PSI (+-5PSI)

Lubrication

Lube all fittings on landing gears, gear boxes, slack adjusters, brake cams, twist locks, pushpins,

slider mechanisms and sub-frames, add oil to wheel hubs (if equipped with oil bath bearings)

Documentation/Misc.

Check to ensure license plate is current, and that license plate, registration and chassis are

properly matched. Ensure that current registration and copy of most current FMCSA inspection is

in document holder. Update decal on inspection plate and any inspection markings on unit.

Ensure unit number is clearly marked and are correct. Ensure that mudflaps. are intact and

secured to chassis.

Comments

This unit has been accurately and completely inspected on the date shown and any defective items repaired or replaced as required in 49CFR 396

Date of Inspection Company Performing Repairs

Inspector’s Name (Print) Inspector’s Signature

You might also like

- PpeDocument1 pagePpeBryan Rey Del Fierro100% (1)

- Daily Equipment Maintenance Checklist: Items Evaluators CommentDocument1 pageDaily Equipment Maintenance Checklist: Items Evaluators CommentCarwill TesdaNo ratings yet

- Daily Vehicle Checklist Ver1Document1 pageDaily Vehicle Checklist Ver1ScribdTranslationsNo ratings yet

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorAndara Asifa YudianaNo ratings yet

- D4 - Vehicle Inspection ReportDocument1 pageD4 - Vehicle Inspection ReportPolycarp Danson SigaiNo ratings yet

- Vehicle Checklist & Fault Reporting FormDocument2 pagesVehicle Checklist & Fault Reporting FormNikka RelampagosNo ratings yet

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDocument1 pageForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNo ratings yet

- Daily Factory Cleaning Sheet ChecklistDocument5 pagesDaily Factory Cleaning Sheet ChecklistSaroj KatwalNo ratings yet

- Laboratory Workshop Safety Inspection Checklist TemplateDocument8 pagesLaboratory Workshop Safety Inspection Checklist TemplateALILEM RHU CLINICAL LABORATOYNo ratings yet

- Supplier Accreditation RequirementsDocument2 pagesSupplier Accreditation RequirementsRamilArtatesNo ratings yet

- Movable Tower Light-Monthly Inspection Checklist: Acceptable Not Acceptable N/ADocument1 pageMovable Tower Light-Monthly Inspection Checklist: Acceptable Not Acceptable N/Amunna yadav100% (1)

- Forklift Daily Checklist ElectricDocument2 pagesForklift Daily Checklist Electricmikel derrickNo ratings yet

- 00-Material Submission FormDocument4 pages00-Material Submission FormHafiz AbdullahNo ratings yet

- Checklist For Equipment Inspection Air CompressorDocument1 pageChecklist For Equipment Inspection Air CompressorStephenNo ratings yet

- Hoist Checklist ReviewDocument1 pageHoist Checklist ReviewNavdeep Singh GrewalNo ratings yet

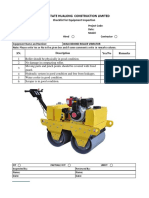

- Vibratory Compactor Maintenance Checklist: Carwill Construction IncDocument2 pagesVibratory Compactor Maintenance Checklist: Carwill Construction IncCarwill Tesda100% (1)

- GAS CUTTING/WELDING INSPECTIONDocument1 pageGAS CUTTING/WELDING INSPECTIONAdhy DarmawanNo ratings yet

- Check ListDocument88 pagesCheck ListRaafat SaadNo ratings yet

- DCP002FO5 - Strimmer Daily Check SheetDocument1 pageDCP002FO5 - Strimmer Daily Check SheetSTEVEN DELAHUNTYNo ratings yet

- M/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker ChecklistDocument2 pagesM/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker Checklistprojit basu100% (1)

- Vehicle Spot Check FormDocument1 pageVehicle Spot Check FormJHUPEL ABARIAL100% (1)

- Daily Backhoe Inspection ChecklistDocument1 pageDaily Backhoe Inspection ChecklistChaudhary Wasim Murtaza100% (1)

- Daily Checklist For DGDocument2 pagesDaily Checklist For DG7Days Facility ManagementNo ratings yet

- Equipment Damage Loss ReportDocument1 pageEquipment Damage Loss ReportlovelyNo ratings yet

- Safety Harness Monthly Checklist-Register JAN23Document1 pageSafety Harness Monthly Checklist-Register JAN23Iqbal HossainNo ratings yet

- Backhoe Safety Inspection ChecklistDocument1 pageBackhoe Safety Inspection ChecklistImran Alam100% (1)

- Job Hazard Analysis DemolishDocument4 pagesJob Hazard Analysis Demolishyajid bustomiNo ratings yet

- Inspection Sheet For Roller and ConveyorDocument2 pagesInspection Sheet For Roller and ConveyorPaintsil BrightNo ratings yet

- Warehouse Rack Inspection ChecklistDocument1 pageWarehouse Rack Inspection ChecklistWaqasNo ratings yet

- Tower Crane Inspection ChecklistDocument1 pageTower Crane Inspection Checklistshakti123456789No ratings yet

- Weekly excavator checklist template for construction projectsDocument4 pagesWeekly excavator checklist template for construction projectssamiran RouthNo ratings yet

- Vehicle Checklist TemplateDocument1 pageVehicle Checklist Templatebloggerkumel100% (1)

- Monthly Smoke Detector Inspection ChecklistDocument1 pageMonthly Smoke Detector Inspection Checklistjonathan cambaNo ratings yet

- Towed Scraper Checklist V0810.1 PDFDocument1 pageTowed Scraper Checklist V0810.1 PDFcherifNo ratings yet

- Jumping Compactor Inspection ChecklistDocument1 pageJumping Compactor Inspection Checklistarunjith rNo ratings yet

- Air Compressor Inspection Checklist Global EHS 029Document1 pageAir Compressor Inspection Checklist Global EHS 029Safety Mohini100% (1)

- Vehicle Inspection SheetDocument1 pageVehicle Inspection Sheetcad curNo ratings yet

- Vehicle Inspection Checklist TemplateDocument3 pagesVehicle Inspection Checklist TemplateMaged HumaidNo ratings yet

- Truck Crane Inspection FormDocument3 pagesTruck Crane Inspection FormAdhy Darmawan100% (1)

- F - OPN - 05 R1 Assessment Form - Earthmoving EquipmentDocument1 pageF - OPN - 05 R1 Assessment Form - Earthmoving EquipmentJanaoo. comNo ratings yet

- Excavator Monthly Check ListDocument2 pagesExcavator Monthly Check ListJoy BDNo ratings yet

- Water System Test ReportDocument2 pagesWater System Test ReportNorman MuñizNo ratings yet

- Fire Safety Audit ChecklistDocument4 pagesFire Safety Audit Checklistsiswoyoazqih83No ratings yet

- 1.1 Principal Contractor Accreditation Application Letter Annexure 1 PDFDocument4 pages1.1 Principal Contractor Accreditation Application Letter Annexure 1 PDFbubele pamlaNo ratings yet

- JAPL-F-HE-004-Weekly Water Tanker Inspection LogDocument1 pageJAPL-F-HE-004-Weekly Water Tanker Inspection LogAli Hassan100% (1)

- Monthly vehicle inspection checklistDocument1 pageMonthly vehicle inspection checklistRísês Ãfröz0% (1)

- Warehouse Cleaning Checklist Daily TasksDocument6 pagesWarehouse Cleaning Checklist Daily TasksDanaNo ratings yet

- JAPL-F-HE-007-Concrete Pump ChecklistDocument1 pageJAPL-F-HE-007-Concrete Pump ChecklistFarrukh IjazNo ratings yet

- Vehicle Inspection ChecklistDocument1 pageVehicle Inspection ChecklistZaki Azizi100% (1)

- Pramac Portable Generator E5000Document15 pagesPramac Portable Generator E5000Filipe HortaNo ratings yet

- Crane Inspection Checklist: General InformationDocument7 pagesCrane Inspection Checklist: General InformationArunachu ArunachuNo ratings yet

- Dumper Truck Daily ChecklistDocument1 pageDumper Truck Daily ChecklistAbdus SamadNo ratings yet

- Welding MachineDocument1 pageWelding MachineProjects DepartmentNo ratings yet

- Truck Inspection Checklist 2021Document1 pageTruck Inspection Checklist 2021muhammad anasNo ratings yet

- Part Submission WarrantDocument4 pagesPart Submission WarrantSam AnuNo ratings yet

- Hazardous Material Weekly InspectionDocument1 pageHazardous Material Weekly InspectionYexiong YIALENGNo ratings yet

- Preventive Maintenance Checklist inDocument4 pagesPreventive Maintenance Checklist inALFIANNo ratings yet

- Pre-Use Welding ChecklistDocument2 pagesPre-Use Welding ChecklistNuno LopesNo ratings yet

- 3.3.9 Air Compressor Maintenance LogDocument1 page3.3.9 Air Compressor Maintenance Logkhrayzie bhoneNo ratings yet

- ForkliftDocument2 pagesForkliftAmanda MackNo ratings yet

- FCN Volume 37 Number 12 BrojabrilDocument3 pagesFCN Volume 37 Number 12 Brojabrilido4selfNo ratings yet

- The COINTELPRO PapersDocument490 pagesThe COINTELPRO PapersJesse Peterson100% (3)

- Cointelpro PapersDocument1 pageCointelpro Papersido4selfNo ratings yet

- EasterDocument32 pagesEasterido4selfNo ratings yet

- Noah Flood IIDocument174 pagesNoah Flood IIOmar ShahidNo ratings yet

- Water 80 Tri Fold Fill AbleDocument2 pagesWater 80 Tri Fold Fill Ableido4selfNo ratings yet

- Superior University: 5Mwp Solar Power Plant ProjectDocument3 pagesSuperior University: 5Mwp Solar Power Plant ProjectdaniyalNo ratings yet

- Eship 1Document18 pagesEship 1Yash SoniNo ratings yet

- WM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersDocument4 pagesWM3000U - WM3000 I: Measuring Bridges For Voltage Transformers and Current TransformersEdgar JimenezNo ratings yet

- RoboticsDocument2 pagesRoboticsCharice AlfaroNo ratings yet

- Leapfroggers, People Who Start A Company, Manage Its Growth Until They Get Bored, and Then SellDocument3 pagesLeapfroggers, People Who Start A Company, Manage Its Growth Until They Get Bored, and Then Sellayesha noorNo ratings yet

- Siyaram S AR 18-19 With Notice CompressedDocument128 pagesSiyaram S AR 18-19 With Notice Compressedkhushboo rajputNo ratings yet

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDDocument6 pagesMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaNo ratings yet

- Synopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaDocument5 pagesSynopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaAnu GraphicsNo ratings yet

- Lirik and Chord LaguDocument5 pagesLirik and Chord LaguRyan D'Stranger UchihaNo ratings yet

- S4H - 885 How To Approach Fit To Standard Analysis - S4HANA CloudDocument16 pagesS4H - 885 How To Approach Fit To Standard Analysis - S4HANA Cloudwai waiNo ratings yet

- Etp ListDocument33 pagesEtp ListMohamed MostafaNo ratings yet

- Whats The Average 100 M Time For An Olympics - Google SearchDocument1 pageWhats The Average 100 M Time For An Olympics - Google SearchMalaya KnightonNo ratings yet

- RS-RA-N01-AL User Manual of Photoelectric Total Solar Radiation TransmitterDocument11 pagesRS-RA-N01-AL User Manual of Photoelectric Total Solar Radiation TransmittermohamadNo ratings yet

- AssDocument9 pagesAssJane SalvanNo ratings yet

- AssemblyinstructionsDocument12 pagesAssemblyinstructionsPriscila AzevedoNo ratings yet

- FilesDocument12 pagesFilesRajesh TuticorinNo ratings yet

- GSM Multi-Mode Feature DescriptionDocument39 pagesGSM Multi-Mode Feature DescriptionDiyas KazhiyevNo ratings yet

- Manual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteDocument94 pagesManual de Instalare Centrala de Incendiu Adresabila 1-4 Bucle Teletek IRIS PRO 250bucla 96 Zone 10000 EvenimenteAlexandra DumitruNo ratings yet

- Amended ComplaintDocument38 pagesAmended ComplaintDeadspinNo ratings yet

- Verifyning GC MethodDocument3 pagesVerifyning GC MethodHristova HristovaNo ratings yet

- nrcs143 009445Document4 pagesnrcs143 009445mdsaleemullaNo ratings yet

- Harry Styles: The Rise of a Pop StarDocument9 pagesHarry Styles: The Rise of a Pop StarBilqis LaudyaNo ratings yet

- Corena s2 p150 - Msds - 01185865Document17 pagesCorena s2 p150 - Msds - 01185865Javier LerinNo ratings yet

- Instruction/Special Maintenance Instruction (IN/SMI)Document2 pagesInstruction/Special Maintenance Instruction (IN/SMI)ANURAJM44No ratings yet

- DAP FullTextIntroductionByStuartLichtman PDFDocument21 pagesDAP FullTextIntroductionByStuartLichtman PDFAlejandro CordobaNo ratings yet

- Difference Between Knowledge and SkillDocument2 pagesDifference Between Knowledge and SkilljmNo ratings yet

- December 2018: Russian Journal of Agricultural and Socio-Economic SciencesDocument339 pagesDecember 2018: Russian Journal of Agricultural and Socio-Economic Sciencesnahla saviraNo ratings yet

- Request Letter To EDC Used PE PipesDocument1 pageRequest Letter To EDC Used PE PipesBLGU Lake DanaoNo ratings yet

- Final Project Report: Uop, LLCDocument165 pagesFinal Project Report: Uop, LLCSiddharth KishanNo ratings yet

- Leyte Geothermal v. PNOCDocument3 pagesLeyte Geothermal v. PNOCAllen Windel BernabeNo ratings yet