Professional Documents

Culture Documents

Composite Materials Exam Questions

Uploaded by

hsemarg0 ratings0% found this document useful (0 votes)

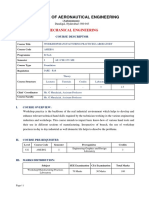

74 views1 pageThis document appears to be an exam for a course on composite materials and mechanics. It contains 14 questions divided into 3 parts (A, B, C) worth a total of 100 marks. The questions cover a range of topics related to composites including classification of composites based on constituents and structure, types of bonding and interfaces, fabrication processes like pultrusion and slurry infiltration, properties of fibers and matrices, failure criteria, and calculations related to fiber volume fraction.

Original Description:

hi

Original Title

Secondary Metallurgy

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document appears to be an exam for a course on composite materials and mechanics. It contains 14 questions divided into 3 parts (A, B, C) worth a total of 100 marks. The questions cover a range of topics related to composites including classification of composites based on constituents and structure, types of bonding and interfaces, fabrication processes like pultrusion and slurry infiltration, properties of fibers and matrices, failure criteria, and calculations related to fiber volume fraction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views1 pageComposite Materials Exam Questions

Uploaded by

hsemargThis document appears to be an exam for a course on composite materials and mechanics. It contains 14 questions divided into 3 parts (A, B, C) worth a total of 100 marks. The questions cover a range of topics related to composites including classification of composites based on constituents and structure, types of bonding and interfaces, fabrication processes like pultrusion and slurry infiltration, properties of fibers and matrices, failure criteria, and calculations related to fiber volume fraction.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

F F5856 Pages: 1

Reg No.:_______________ Name:__________________________

APJ ABDUL KALAM TECHNOLOGICAL UNIVERSITY

FIFTH SEMESTER B.TECH DEGREE EXAMINATION, APRIL 2018

Course Code: ME363

Course Name:COMPOSITE MATERIALS AND MECHANICS

Max. Marks: 100 Duration: 3 Hours

PART A

Answer any three full questions, each carries 10 marks Marks

1 a) Classify composites based on their constituents and structure. (7)

b) List out the various applications of composites. (3)

2 a) Describe the types of bonding in interfaces of composites. (7)

b) Define wettability. (3)

3 a) Explain the boron fiber fabrication procedure with a neat diagram. (7)

b) List out the types of fibers used in composites. (3)

4 a) Discuss the various types of carbon fibers with their properties and applications. (7)

b) Define whiskers. (3)

PART B

Answer any three full questions, each carries 10 marks

5 a) Explain the following: (7)

i) Spray layup methodii)Vacuum bagging method

b) Give a comparison between thermosetting and thermoplastic polymers. (3)

6 a) Write a short note on filament winding process with a neat sketch. (7)

b) List out the advantages of epoxy resin. (3)

7 a) Describe squeeze casting method. (7)

b) Write the advantages of using metals as matrices in composites. (3)

8 a) Write a short note on spray co-deposition process with a neat sketch. (7)

b) Write the advantages and disadvantages of MMCs compared to PMCs. (3)

PART C

Answer any four full questions, each carries 10 marks

9 a) Explain pultrusion process with a neat diagram. (7)

b) Classify ceramics based on their applications. (3)

10 a) Write a short note on slurry infiltration process with a neat sketch. (7)

b) Write down the properties of ceramic materials. (3)

11 a) Explain any two conventional techniques applied for the fabrication of CMCs. (7)

b) Write the major issues to be considered in the liquid infiltration process. (3)

12 a) Explain water jet cutting process with a neat diagram. (7)

b) State “Maximum stress failure theory” applied in composites. (3)

13 a) Find the weight fraction and volume fraction of fibers in the glass/epoxy (7)

composites. The following data is obtained from the burnout test.

Weight of empty crucible = 46.5401 gm

Weight of crucible and composite piece = 49.1201 gm

Weight of crucible and glass fiber = 48.3420 gm

Density of glass fiber = 2600 kg/m3

Density of glass/epoxy composite = 1300 kg/m3

b) Give a short note on mechanics of load transfer from matrix to fiber. (3)

14 State and explain Tsai-Hill and Tsai-Wu failure criteria. (10)

****

You might also like

- Ecs Omsm (Operation, Maintenance & Safety Manual) : Electro-Cleen™ SystemDocument233 pagesEcs Omsm (Operation, Maintenance & Safety Manual) : Electro-Cleen™ SystemElena Gaevska100% (1)

- Research Proposal On Antimicrobial and Antioxidant Properties of Kiwi FruitDocument25 pagesResearch Proposal On Antimicrobial and Antioxidant Properties of Kiwi FruitCatherine100% (1)

- Exercise 1 and 2 - Revised2Document5 pagesExercise 1 and 2 - Revised2Vivekka Olivia JohnNo ratings yet

- Dubai UAE InformationDocument28 pagesDubai UAE InformationsefdeniNo ratings yet

- Secondary Metallurgy PDFDocument63 pagesSecondary Metallurgy PDFhsemargNo ratings yet

- Plastics as a Building Material GuideDocument24 pagesPlastics as a Building Material GuideVinod Nair100% (1)

- Metal Casting Processes Chapter ExplainedDocument88 pagesMetal Casting Processes Chapter ExplainedTham Wai Hung89% (9)

- Lake Lanao Policy StudyDocument30 pagesLake Lanao Policy StudyGodfrey MordenoNo ratings yet

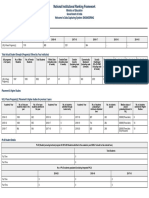

- National Index of Ranking Framework 2017Document36 pagesNational Index of Ranking Framework 2017patrodeskNo ratings yet

- National Index of Ranking Framework 2017Document36 pagesNational Index of Ranking Framework 2017patrodeskNo ratings yet

- Rr412109 Composite Materials and StructuresDocument8 pagesRr412109 Composite Materials and StructuresSrinivasa Rao GNo ratings yet

- Advanced Materials R16 Oct 2019Document4 pagesAdvanced Materials R16 Oct 2019AbdulaleemNo ratings yet

- F E192110 Pages:2: Answer Any Three Full Questions, Each Carries 10 MarksDocument2 pagesF E192110 Pages:2: Answer Any Three Full Questions, Each Carries 10 MarksAir SevakkNo ratings yet

- Answer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameDocument1 pageAnswer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameAir SevakkNo ratings yet

- Candidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksDocument1 pageCandidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksManish ShresthaNo ratings yet

- E D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDocument3 pagesE D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDrRoja A RNo ratings yet

- 2019 May ME210-H - Ktu QbankDocument2 pages2019 May ME210-H - Ktu QbankkannanNo ratings yet

- E C1165 Pages 2: Answer Any Three Questions, Each Carries 10 MarksDocument2 pagesE C1165 Pages 2: Answer Any Three Questions, Each Carries 10 MarksShine KunnathNo ratings yet

- Aircraft Materials and Processes Exam QuestionsDocument2 pagesAircraft Materials and Processes Exam QuestionsJohny GeorgeNo ratings yet

- E D1065 Pages: 2: Answer Any Three Full Questions, Each Carries 10 MarksDocument2 pagesE D1065 Pages: 2: Answer Any Three Full Questions, Each Carries 10 MarksJohny GeorgeNo ratings yet

- Rr310801 Mechanical Unit OperationsDocument7 pagesRr310801 Mechanical Unit OperationsSrinivasa Rao GNo ratings yet

- 07CE7315 Advanced Concrete TechnologyDocument2 pages07CE7315 Advanced Concrete TechnologytirursachinNo ratings yet

- Set No: 1 R10Document4 pagesSet No: 1 R10Varun pNo ratings yet

- Seventh Semester B.Tech Degree Supplementary Examination August 2021Document2 pagesSeventh Semester B.Tech Degree Supplementary Examination August 2021vivekNo ratings yet

- E C192062 Pages:2: Answer Any Three Questions, Each Carries 10 MarksDocument2 pagesE C192062 Pages:2: Answer Any Three Questions, Each Carries 10 MarksClive Jerison VNo ratings yet

- Answer Any Three Questions, Each Carries 10 Marks.: Reg No.: - NameDocument2 pagesAnswer Any Three Questions, Each Carries 10 Marks.: Reg No.: - NameRajulapati Sunil KumarNo ratings yet

- Rr211803 Ceramic Science and TechnologyDocument4 pagesRr211803 Ceramic Science and TechnologySRINIVASA RAO GANTANo ratings yet

- Apj Abdul Kalam Technological University: Fourth Semester B.Tech Examinations (S), September 2020Document2 pagesApj Abdul Kalam Technological University: Fourth Semester B.Tech Examinations (S), September 2020Johny GeorgeNo ratings yet

- Integrated Dual Degree (B.Tech.+M.Tech.) Examination Electronics & Communication EngineeringDocument2 pagesIntegrated Dual Degree (B.Tech.+M.Tech.) Examination Electronics & Communication Engineeringkohli kingNo ratings yet

- Civil Engineering MaterialsDocument1 pageCivil Engineering MaterialssushilNo ratings yet

- QP2016Document1 pageQP2016Kiran Kumar Nethrakere/EMD/UAENo ratings yet

- Zimbabwe HEXCO National Certificate Construction Materials ExamDocument3 pagesZimbabwe HEXCO National Certificate Construction Materials ExamShyleenNo ratings yet

- 2019 May ME306-C - Ktu QbankDocument2 pages2019 May ME306-C - Ktu QbankHaris P.A.No ratings yet

- ACFrOgBHxzCZaZfrA9rDOFKfKBCT0u3EzFliyhYxidlQFmxNs5m9MEH2zKbFqfsDSfpetyeQ-8KdbC8Ob6qZg3ddpdD wEALEBSskuDepkxP702G2hy-vNaiECq1X6 JAoAIlksCab143BNj4MitDocument2 pagesACFrOgBHxzCZaZfrA9rDOFKfKBCT0u3EzFliyhYxidlQFmxNs5m9MEH2zKbFqfsDSfpetyeQ-8KdbC8Ob6qZg3ddpdD wEALEBSskuDepkxP702G2hy-vNaiECq1X6 JAoAIlksCab143BNj4MitShine KunnathNo ratings yet

- E F1110 Pages: 2: Answer Any Three Full Questions, Each Carries 10 MarksDocument2 pagesE F1110 Pages: 2: Answer Any Three Full Questions, Each Carries 10 MarksMidhun SukumaranNo ratings yet

- Concrete Technology: B.E. (Civil Engineering) Third Semester (C.B.S.)Document15 pagesConcrete Technology: B.E. (Civil Engineering) Third Semester (C.B.S.)bharatiya technologyNo ratings yet

- 9abs103 Engineering ChemistryDocument4 pages9abs103 Engineering ChemistrysivabharathamurthyNo ratings yet

- MSEE02: RamaiahDocument2 pagesMSEE02: Ramaiahhari krishnaNo ratings yet

- AEE Regular PDFDocument2 pagesAEE Regular PDFAbdul NafihNo ratings yet

- Model Question Paper (CBCS) with effect from 2015-16Document2 pagesModel Question Paper (CBCS) with effect from 2015-16Shaikh MuzaffarNo ratings yet

- Rr321803 Foundry TechnologyDocument5 pagesRr321803 Foundry TechnologySrinivasa Rao GNo ratings yet

- ACFrOgAKq0cnCrVNaUnOG8x3Rz37Dx4lL51ywVQOIZyXrllm3CuF0qwwhbyLysO-L44ha HoLGUr4oWpcYEqTTae0BIBP3ly9XSFm6nzLk5bADYZnSJ 0W7WrMH jxDn34l3g0LyJJpL6Yh6typlDocument2 pagesACFrOgAKq0cnCrVNaUnOG8x3Rz37Dx4lL51ywVQOIZyXrllm3CuF0qwwhbyLysO-L44ha HoLGUr4oWpcYEqTTae0BIBP3ly9XSFm6nzLk5bADYZnSJ 0W7WrMH jxDn34l3g0LyJJpL6Yh6typlShine KunnathNo ratings yet

- May 2018Document2 pagesMay 2018Mohammed FurqanNo ratings yet

- 2017 Dec. ME369-A Tribology - Ktu QbankDocument2 pages2017 Dec. ME369-A Tribology - Ktu QbankAir SevakkNo ratings yet

- ECT362-QP May 2023Document3 pagesECT362-QP May 2023rijovskNo ratings yet

- Structural Analysis Techniques for Frames and BeamsDocument3 pagesStructural Analysis Techniques for Frames and BeamsirshadNo ratings yet

- Structural Analysis Techniques for Frames and BeamsDocument3 pagesStructural Analysis Techniques for Frames and BeamsirshadNo ratings yet

- Final Exam QuestionsDocument4 pagesFinal Exam QuestionsAndil MaulanaNo ratings yet

- rr322003 Foundry - WeldingDocument5 pagesrr322003 Foundry - WeldingSRINIVASA RAO GANTANo ratings yet

- 2023 June CET352-CDocument2 pages2023 June CET352-CManju MNo ratings yet

- WWW - Manaresults.Co - In: (Electronics and Communication Engineering)Document8 pagesWWW - Manaresults.Co - In: (Electronics and Communication Engineering)Adhvay KrishnaNo ratings yet

- PU Paper Manufacturing Science KME-403 - NewDocument2 pagesPU Paper Manufacturing Science KME-403 - Newdaso khagoNo ratings yet

- D NSA192007 Pages:4: Answer All Questions, Each Carries 4 MarksDocument4 pagesD NSA192007 Pages:4: Answer All Questions, Each Carries 4 MarksAswith R ShenoyNo ratings yet

- F E1228 Pages: 2: Answer Any Three Full Questions, Each Carries 10 MarksDocument2 pagesF E1228 Pages: 2: Answer Any Three Full Questions, Each Carries 10 MarksAir SevakkNo ratings yet

- 2018 Dec. EC465-A - Ktu QbankDocument2 pages2018 Dec. EC465-A - Ktu Qbankkaveri srinivasanNo ratings yet

- Concrete Technology Exam QuestionsDocument1 pageConcrete Technology Exam QuestionsRahul GandhiNo ratings yet

- GTU BE-SEMESTER-VII Composite Technology Exam QuestionsDocument1 pageGTU BE-SEMESTER-VII Composite Technology Exam Questionsyicef37689No ratings yet

- Building Materials Exam Questions on Tiles, Timber Decay & Concrete TestsDocument43 pagesBuilding Materials Exam Questions on Tiles, Timber Decay & Concrete TestsKochuzNo ratings yet

- B0 31bt31bp15Document23 pagesB0 31bt31bp15Ashok KotthapalliNo ratings yet

- MSM Re-2Document1 pageMSM Re-2Vijay GajeraNo ratings yet

- ENGINEERING CHEMISTRY May 2017Document1 pageENGINEERING CHEMISTRY May 2017bvs957946No ratings yet

- Fifth Semester B.Tech Degree Regular and Supplementary Examination December 2020Document3 pagesFifth Semester B.Tech Degree Regular and Supplementary Examination December 2020Sreejith S NairNo ratings yet

- Answer Any Three Full Questions, Each Carries IO Marks.: Part ADocument4 pagesAnswer Any Three Full Questions, Each Carries IO Marks.: Part AMinnuNo ratings yet

- Question Paper Code:: PART A - (10 X 2 20 Marks) 1. State Gibbs Phase RuleDocument2 pagesQuestion Paper Code:: PART A - (10 X 2 20 Marks) 1. State Gibbs Phase RuleKanagasabai SabaNo ratings yet

- Met307 Machine Tools and Metrology, December 2021Document2 pagesMet307 Machine Tools and Metrology, December 2021Aravind SNo ratings yet

- Me306 ADocument2 pagesMe306 ASafeer MNo ratings yet

- rr321803 Foundry TechnologyDocument6 pagesrr321803 Foundry TechnologySRINIVASA RAO GANTANo ratings yet

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapFrom EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancherieNo ratings yet

- Biomimetic Principles and Design of Advanced Engineering MaterialsFrom EverandBiomimetic Principles and Design of Advanced Engineering MaterialsNo ratings yet

- Structure of m4Document2 pagesStructure of m4hsemargNo ratings yet

- Structure of 2Document2 pagesStructure of 2hsemargNo ratings yet

- Structure 1Document2 pagesStructure 1hsemargNo ratings yet

- ARCH NIRF FrameworkDocument63 pagesARCH NIRF FrameworkhsemargNo ratings yet

- Stress Solution at Crack Tip (Westergaard (1934) )Document7 pagesStress Solution at Crack Tip (Westergaard (1934) )theamantheNo ratings yet

- Engineering PDFDocument25 pagesEngineering PDFSouparna BanerjeeNo ratings yet

- Institute Name: RGUKT-RK Valley (IR-E-C-45102)Document7 pagesInstitute Name: RGUKT-RK Valley (IR-E-C-45102)hsemargNo ratings yet

- Plasticity Stress AnalysisDocument7 pagesPlasticity Stress AnalysisAvijit DeyNo ratings yet

- SolidsDocument86 pagesSolidsweNo ratings yet

- 01 DifferentialEquations Complete PDFDocument18 pages01 DifferentialEquations Complete PDFOğuzhan KocaNo ratings yet

- 10 5923 J Ep 20170705 03Document6 pages10 5923 J Ep 20170705 03hsemargNo ratings yet

- 2-Introduction To Structure and Bonding in MaterialsDocument9 pages2-Introduction To Structure and Bonding in MaterialsMohamed Em AliNo ratings yet

- 30 AirConditionarsDocument1 page30 AirConditionarshsemargNo ratings yet

- Chap8lect 2015Document70 pagesChap8lect 2015Tengku Arief Buana PerkasaNo ratings yet

- Slip CastingDocument10 pagesSlip CastinghsemargNo ratings yet

- Ubc 2009 Spring Kubiak AngelaDocument128 pagesUbc 2009 Spring Kubiak AngelahsemargNo ratings yet

- Electronics Service Point Provides Quote for Speaker and Amplifier SystemDocument1 pageElectronics Service Point Provides Quote for Speaker and Amplifier SystemhsemargNo ratings yet

- Central Library Tender FinalDocument28 pagesCentral Library Tender FinalhsemargNo ratings yet

- Slip CastingDocument13 pagesSlip CastingRishi DasguptaNo ratings yet

- Lec 8Document35 pagesLec 8hsemargNo ratings yet

- Foundation Engg SyllabusDocument2 pagesFoundation Engg SyllabushsemargNo ratings yet

- Investment Cast Cobalt AlloysDocument10 pagesInvestment Cast Cobalt AlloyshsemargNo ratings yet

- Mse314 315 316Document390 pagesMse314 315 316hsemargNo ratings yet

- © 1890 Nature Publishing GroupDocument4 pages© 1890 Nature Publishing GrouphsemargNo ratings yet

- The Design of Tomato Paste Plant - Problem StatementDocument3 pagesThe Design of Tomato Paste Plant - Problem StatementvictorNo ratings yet

- BCH102 Unit - III: Physiology Topic: BloodDocument18 pagesBCH102 Unit - III: Physiology Topic: Blooddivya vajpayeeNo ratings yet

- Cinnamon Streusel Muffin Recipe (Coffee Cake) - DDocument3 pagesCinnamon Streusel Muffin Recipe (Coffee Cake) - DBryce MitchellNo ratings yet

- BX 560GDocument20 pagesBX 560Gmacanipharoldf6220No ratings yet

- BBB BCP-15W Cycling ComputerDocument2 pagesBBB BCP-15W Cycling ComputerDannyNo ratings yet

- Jss Academy Unit 1 BDocument13 pagesJss Academy Unit 1 BbomtozorNo ratings yet

- Effect of Accidental EccentricityDocument7 pagesEffect of Accidental EccentricityNani TirumalasettiNo ratings yet

- Automated Home Rainwater Harvesting Earns MoneyDocument4 pagesAutomated Home Rainwater Harvesting Earns MoneysaravananNo ratings yet

- EHV SERIES 2-WAY HIGH PRESSURE CARBON STEEL BALL VALVEDocument2 pagesEHV SERIES 2-WAY HIGH PRESSURE CARBON STEEL BALL VALVESHANENo ratings yet

- Kisii University course explores environmental biotech, bioprocessingDocument4 pagesKisii University course explores environmental biotech, bioprocessingRyan ReighnsNo ratings yet

- Chevrolet 2005 Uplander Electrical Wiring DiagramDocument62 pagesChevrolet 2005 Uplander Electrical Wiring Diagramromain.richertNo ratings yet

- ALL-Q (Coenzyme Q10) Plus - PDSDocument3 pagesALL-Q (Coenzyme Q10) Plus - PDSMarlon2370No ratings yet

- Precious Metals AlfaDocument83 pagesPrecious Metals AlfaPraveenNo ratings yet

- Avl Tree Definition: Avl Trees Are Balanced Anavltreeisa Such That For Every Internal Node V of T, TheDocument3 pagesAvl Tree Definition: Avl Trees Are Balanced Anavltreeisa Such That For Every Internal Node V of T, TheSumanta DattaNo ratings yet

- G9_Q4_W2_MODDocument4 pagesG9_Q4_W2_MODKkkkkNo ratings yet

- Workshop Practices Lab Course DescriptorDocument8 pagesWorkshop Practices Lab Course DescriptorWossenu MekonnenNo ratings yet

- Tactile Internet MSC V2Document28 pagesTactile Internet MSC V2hendNo ratings yet

- Geometry Dba Study Guide 07.07Document3 pagesGeometry Dba Study Guide 07.07Tyler CosgroveNo ratings yet

- How The World Was Created (Panayan)Document25 pagesHow The World Was Created (Panayan)Mary Kris De AsisNo ratings yet

- 4 Tutorial Present Worth AnalysisDocument4 pages4 Tutorial Present Worth AnalysisMuhamad SyazwanNo ratings yet

- Engineering Declaration Unit # 2 JindalDocument16 pagesEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- BIOpolitics PDFDocument3 pagesBIOpolitics PDFalpar7377No ratings yet

- Vikas KumarDocument4 pagesVikas Kumarsanju sharmaNo ratings yet

- Animal Talk Spring 09Document32 pagesAnimal Talk Spring 09chuckc23No ratings yet