Professional Documents

Culture Documents

Chemical Composition and Grades of Ductile Cast Iron

Uploaded by

parthCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chemical Composition and Grades of Ductile Cast Iron

Uploaded by

parthCopyright:

Available Formats

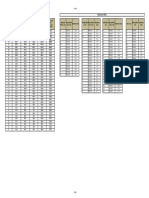

Chemical composition of Ductile Cast Iron

USA Germany ISO C% Si % Mn % P % S % Mg % Cu % Sn %

60-40- 3.50- 2.80- 0.2-0.5 0.03- 0.02- 0.020-

GGG40 400-18

18 3.78 2.85 0.06 0.035 0.060

65-45- GGG40 450-10 3.30- 2.40- 0.2-0.5 0.03- 0.02- 0.020-

12 3.80 2.90 0.06 0.040 0.060

70-50- GGG50 500-7 3.20- 2.30- 0.4-0.6 0.03- 0.02- 0.030- <0.4

05 3.60 2.90 0.06 0.040 0.055

80-60- GGG60 600-3 3.00- 2.40- 0.3-0.5 0.03- 0.02- 0.035- 0.30-

03 3.50 2.80 0.06 0.040 0.050 0.40

100-70- GGG70 700-2 3.65- 1.70- 0.3-0.5 <0.06 <0.03 0.035- 0.30- 0.03-0.06

03 3.90 1.90 0.050 0.40

120-90- GGG80 800-2 - - - - - - - -

02

Equivalent grades of Ductile Iron (SG Iron/ Nodular Graphite Iron Casting)

Standar Equivalent Grades of Ductile Iron (SG Iron, Nodular Graphite

Country

d Iron)

400-15

ISO ISO 1083 450-10 500-7 600-3 700-2 800-2 900-2

400-18

QT400- QT450- QT500- QT600- QT700- QT800- QT900-

China GB 1348

18 10 7 3 2 2 2

80-55-

ASTM 60-42-10 70-50- 06 100-70- 120-90-

USA 60-40-18 —

A536 65-45-12 05 80-60- 03 02

03

Germany DIN

GGG40 — GGG50 GGG60 GGG70 GGG80 —

Austria 1693

EN-GJS-

EN- EN- EN- EN- EN-

400-15 EN-GJS-

European EN 1563 GJS- GJS- GJS- GJS- GJS-

EN-GJS- 450-10

500-7 600-3 700-2 800-2 900-2

400-18

JIS

Japan FCD400 FCD450 FCD500 FCD600 FCD700 FCD800 —

G5502

UNI GS370- GS400-

Italy GS500-7 GS600-2 GS700-2 GS800-2 —

4544 17 12

NF A32- FGS370- FGS400- FGS500 FGS600 FGS700 FGS800

France —

201 17 12 -7 -2 -2 -2

UK BS 2789 400/17 420/12 500/7 600/7 700/2 800/2 900/2

SG370/1 SG400/1

India IS 1865 SG500/7 SG600/3 SG700/2 SG800/2 —

7 2

FGE38- FGE42- FGE50- FGE60- FGE70- FGE80-

Spain UNF —

17 12 7 2 2 2

NBN FNG38- FNG42- FNG50- FNG60- FNG70- FNG80-

Belgium —

830-02 17 12 7 2 2 2

300-17

Australia AS 1831 — 500-7 600-3 700-2 800-2 —

400-12

Sweden SS 14 07 0717-02 — 0727-02 0732-03 0737-01 0864-03 —

SJK-

NS11

Norway 400.3 — SJK-500 SJK-600 SJK-700 SJK-800 —

301

SJK-400

Ductile Iron Grade Chart

ASTM A536 1993 (USA)

Grade Tensile Yield Strength Elongation

Strength σ≥/Mpa δ≥(%)

σ≥/Mpa

ANSI/ASTM UNS

60-40-18 F32800 414 276 18

65-45-12 F33100 448 310 12

80-55-06 F33800 552 379 6.0

100-70-03 F34800 689 483 3.0

120-90-02 F36200 827 621 2.0

Special Purpose

60-42-10 415 290 10

70-50-05 485 345 5.0

80-60-03 555 415 3.0

GB/T 1348 1998 (CHINA)

Grade Tensile strength Yield strength Elongation Hardness

σb≥/MPa σ0.2≥/MPa δ5≥(%) HBS

QT400-18 400 250 18 130~180

QT400-18-LT *

QT400-15 400 250 15 130~180

QT450-10 450 310 10 160~210

QT500-7 500 320 7 170~230

QT600-3 600 370 3 190~270

QT700-2 700 420 2 225~305

QT800-2 800 480 2 245~335

QT900-2 900 600 2 280~360

DIN 1693 1997 (GERMANY)

Grade Material No Tensile strength Yield strength Elongation

W-Nr. σb≥/Mpa σ0.2≥/Mpa δ≥(%)

GGG-40 0.7040 400 250 15

GGG-50 0.7050 500 320 7

GGG-60 0.7060 600 380 3

GGG-70 0.7070 700 400 2

GGG-80 0.7080 800 500 2

EN 1563 1997 (EUROPEAN STANDARD)

Grade Tensile Yield Strength Elongation

Strength σ≥/Mpa δ≥(%)

σ≥/Mpa

Symbol Number

EN GJS 350-22 EN JS1010 350 220 22

EN GJS 350-22-LT* EN JS1015 350 220 22

EN GJS 400-18 EN JS1020 400 250 18

EN GJS 400-18-LT* EN JS1025 400 240 18

EN GJS 400-15 EN JS1030 400 250 15

EN GJS 450-10 EN JS1040 450 310 10

EN GJS 500-7 EN JS1050 500 320 7

EN GJS 600-3 EN JS1060 600 370 3

EN GJS 700-2 EN JS1070 700 420 2

EN GJS 800-2 EN JS1080 800 480 2

EN GJS 900-2 EN JS1090 900 600 2

ISO 1083 1987 (INTERNATIONAL)

Grade Tensile Yield strength Elongation Hardness

strength

σ0.2≥/Mpa δ≥(%) HBS

σb≥/Mpa

900-2 900 600 2 280~360

800-2 800 480 2 245-335

700-2 700 420 2 225~305

600-3 600 370 3 190~270

500-7 500 320 7 170~230

450-10 450 320 10 160~210

400-15 400 250 15 130~180

400-18 400 250 18 130~180

400-18 AL*

350-22 350 220 22 ≤150

You might also like

- S275JRDocument1 pageS275JRShahzad QamarNo ratings yet

- SG Iron CompositionDocument5 pagesSG Iron CompositionamirgukharNo ratings yet

- Grade ST1 Ductile IronDocument2 pagesGrade ST1 Ductile Ironvinod100% (1)

- Carbon Steel EquivalentsDocument5 pagesCarbon Steel EquivalentssamatamNo ratings yet

- Chemical Composition of Some SteelsDocument3 pagesChemical Composition of Some Steelspratik bhoiteNo ratings yet

- Sae 1008Document3 pagesSae 1008lokesh38No ratings yet

- Bs970 SpecificationDocument2 pagesBs970 SpecificationGuru Samy100% (1)

- Hot-rolled steel sheet specificationDocument3 pagesHot-rolled steel sheet specificationlucecita1902No ratings yet

- S.G.Iron GuidelinesDocument28 pagesS.G.Iron GuidelinesTarun Chakraborty100% (3)

- Catalogue of SteelDocument4 pagesCatalogue of SteelIswar Rauf Aboo 'AqilahNo ratings yet

- Astm A131 PDFDocument8 pagesAstm A131 PDFMohamed Salem100% (2)

- Mapa MetalograficoDocument1 pageMapa MetalograficoBreno DellaNo ratings yet

- DIN 1681 Chemical CompositionDocument12 pagesDIN 1681 Chemical CompositionAshish Kesharwani100% (1)

- Astm A 297 PDFDocument5 pagesAstm A 297 PDFMuhammad Harits100% (1)

- AnyCasting Software Intro SAND PrintDocument45 pagesAnyCasting Software Intro SAND PrintChuah Chun KitNo ratings yet

- EN 10025 S275 Steel (S275JR, S275J0 & S275J2)Document3 pagesEN 10025 S275 Steel (S275JR, S275J0 & S275J2)MohamedNo ratings yet

- SAE J434 1986 Automotive Ductile Iron Castings Nodular Iron CastingsDocument10 pagesSAE J434 1986 Automotive Ductile Iron Castings Nodular Iron Castingsvinicius_bacellarNo ratings yet

- The Relevance of YS/UTS RatioDocument21 pagesThe Relevance of YS/UTS RatiocarrespmNo ratings yet

- ASTM A572 Steel - Grade 50Document1 pageASTM A572 Steel - Grade 50FWICIP100% (1)

- Chemical DetailsDocument3 pagesChemical Detailsemmas18No ratings yet

- 8062 Tolerance CalculationDocument3 pages8062 Tolerance CalculationUmesh SakhareliyaNo ratings yet

- Grey Iron Castings Specification: Indian StandardDocument12 pagesGrey Iron Castings Specification: Indian StandardS Karthi100% (3)

- Recommended Target Analysis For Ductile IronDocument2 pagesRecommended Target Analysis For Ductile Ironarnaldorcr8646100% (2)

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Alloy Process Data Sheet - 105-85Document3 pagesAlloy Process Data Sheet - 105-85Ugur KayaNo ratings yet

- ASTM E 1268 2001 (Reapproved 2016) Ferrite Banding StandardDocument29 pagesASTM E 1268 2001 (Reapproved 2016) Ferrite Banding StandardRajoo Prajapati75% (4)

- Bluefracturemnm 2018Document8 pagesBluefracturemnm 2018Gomathi RNo ratings yet

- A367-11 Standard Test Methods of Chill Testing of Cast Iron PDFDocument4 pagesA367-11 Standard Test Methods of Chill Testing of Cast Iron PDFCarlos Guillermo Somoza Alvarenga100% (1)

- Astm A 297Document3 pagesAstm A 297friasdelacruz50% (2)

- Grey Cast Iron CompareDocument4 pagesGrey Cast Iron CompareagustingrtNo ratings yet

- ZG35 CR 24 Ni 7 Si NDocument2 pagesZG35 CR 24 Ni 7 Si NP.K.V Choudhary0% (1)

- Mechanical and Chemical Properties of Various Steel GradesDocument1 pageMechanical and Chemical Properties of Various Steel GradesPraveen Dodamani100% (7)

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)spiderblackNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4niladriprasadrNo ratings yet

- 26-ELKEM Poster-Graphite Structures in Cast IronsDocument1 page26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENNo ratings yet

- Reduction Ratio Chart in Steel Rolling MillDocument1 pageReduction Ratio Chart in Steel Rolling MillSoumyo Broto DasNo ratings yet

- Cast Iron StandardsDocument2 pagesCast Iron StandardsBao Duy NguyenNo ratings yet

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDocument2 pagesCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_9177100% (9)

- ASTM A633 GR E Data Sheet 2012 04 01Document2 pagesASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- ISO 8062-3-2007 Casting Tolerance ChartDocument1 pageISO 8062-3-2007 Casting Tolerance ChartJoe Scopelite100% (1)

- MATERIAL GRADE COMPARISON TABLE For Web PDFDocument9 pagesMATERIAL GRADE COMPARISON TABLE For Web PDFsucihaNo ratings yet

- EN1A - Mild SteelDocument2 pagesEN1A - Mild SteelSuyash TambeNo ratings yet

- Hot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017Document8 pagesHot Rolled Carbon Steel Sheet, Plate and Strip According To IS 1079:2017raghavendragouda patilNo ratings yet

- 16.0 Grade Wise Chemical CompositionDocument29 pages16.0 Grade Wise Chemical CompositionrohitNo ratings yet

- Ductile Iron Casting Specfications and Details All StandardsDocument15 pagesDuctile Iron Casting Specfications and Details All StandardsN.Palaniappan100% (1)

- Cast Iron Astm A247Document3 pagesCast Iron Astm A247CK100% (1)

- Grey Cast Iron GG25 - EN GJL 150 - PropertiesDocument2 pagesGrey Cast Iron GG25 - EN GJL 150 - PropertiesBalasundaramSrinivasaRajkumar100% (1)

- 06 Spec. STD Raw MaterialDocument10 pages06 Spec. STD Raw MaterialVikas KashyapNo ratings yet

- Steel Rivets and Bars For Rivets, Pressure VesselsDocument4 pagesSteel Rivets and Bars For Rivets, Pressure VesselsxaviereduardoNo ratings yet

- Astm A245 2020Document5 pagesAstm A245 2020CK CkkouNo ratings yet

- Cerium in Ductile IronDocument2 pagesCerium in Ductile Ironvivek1312100% (2)

- EN24 Steel PropertiesDocument1 pageEN24 Steel Propertieskanha15102003100% (1)

- 26-ELKEM - Poster-Graphite Structures in Cast IronsDocument1 page26-ELKEM - Poster-Graphite Structures in Cast IronsSalvador Rocha100% (2)

- SG Iron Casting Grades and StandardsDocument4 pagesSG Iron Casting Grades and Standardsvkhavate100% (1)

- Gjs GGG AstmDocument17 pagesGjs GGG AstmmakmuntohirNo ratings yet

- SG Iron Castings GuideDocument4 pagesSG Iron Castings Guidebbaskaran100% (1)

- Equivalent Grades of Cast IronsDocument2 pagesEquivalent Grades of Cast IronsVinh Do ThanhNo ratings yet

- Material For Roll CastingDocument5 pagesMaterial For Roll CastingPankaj PandeyNo ratings yet

- EN-GJS-500-7 Equivalent Grades, Properties, and CompositionDocument5 pagesEN-GJS-500-7 Equivalent Grades, Properties, and CompositionPankaj PandeyNo ratings yet

- Gray and Ductile Iron Grade Comparison TableDocument2 pagesGray and Ductile Iron Grade Comparison Tableariefihsan100% (1)

- Application of The Ring-On-ring Test For Abrasive Wear Modeling (IMPORTANT)Document10 pagesApplication of The Ring-On-ring Test For Abrasive Wear Modeling (IMPORTANT)parthNo ratings yet

- Identification of Low Cycle Dynamic Loads Acting On Heavy Machinery Identification of Low Cycle Dynamic Loads Acting On Heavy MachineryDocument6 pagesIdentification of Low Cycle Dynamic Loads Acting On Heavy Machinery Identification of Low Cycle Dynamic Loads Acting On Heavy MachineryparthNo ratings yet

- Metals TheoryDocument1 pageMetals TheoryparthNo ratings yet

- READ Ductile Iron Heat Treatment PDFDocument58 pagesREAD Ductile Iron Heat Treatment PDFparthNo ratings yet

- Magnetic Flux ConcentratorsDocument1 pageMagnetic Flux ConcentratorsparthNo ratings yet

- Metals TheoryDocument1 pageMetals TheoryparthNo ratings yet

- Metals TheoryDocument1 pageMetals TheoryparthNo ratings yet

- Reference Book Volume 2Document1 pageReference Book Volume 2parthNo ratings yet

- Reference Book Volume 3Document1 pageReference Book Volume 3parthNo ratings yet

- Reference Book Volume 1Document1 pageReference Book Volume 1parthNo ratings yet

- Imp BookDocument1 pageImp BookparthNo ratings yet

- Class-XII Chemistry syllabus changesDocument3 pagesClass-XII Chemistry syllabus changesShivanshu JainNo ratings yet

- Rock Failure under Confined Brazilian TestDocument9 pagesRock Failure under Confined Brazilian TestMichel SartoNo ratings yet

- Hazard AnalysisDocument39 pagesHazard AnalysisvishnuNo ratings yet

- RADIATION SAFETY FUNDAMENTALSDocument69 pagesRADIATION SAFETY FUNDAMENTALSJay Lawson100% (1)

- Coordinated Sciences IGSCE 0654 - s12 - QP - 63 PDFDocument20 pagesCoordinated Sciences IGSCE 0654 - s12 - QP - 63 PDFjanovaNo ratings yet

- Material Safety Data Sheet (PKE)Document8 pagesMaterial Safety Data Sheet (PKE)ffeedsupplierNo ratings yet

- 0157 - TI - MG - REBOX HLL - SYS - Customer - Reference - A4 - RZ - VIEW - tcm17-526907Document2 pages0157 - TI - MG - REBOX HLL - SYS - Customer - Reference - A4 - RZ - VIEW - tcm17-526907Văn Tuấn NguyễnNo ratings yet

- CH 7 ObjDocument4 pagesCH 7 ObjchongpeisiNo ratings yet

- A Fixed-Bed Reactor Modeling Study On The Methanation of CO: Chemical Engineering Research and DesignDocument11 pagesA Fixed-Bed Reactor Modeling Study On The Methanation of CO: Chemical Engineering Research and DesignJames LivingstonNo ratings yet

- Essay 2Document3 pagesEssay 2Norhaida NdNo ratings yet

- Chapter 2 - Analysis of Steam Power Plant CycleDocument57 pagesChapter 2 - Analysis of Steam Power Plant Cycledmc constructionNo ratings yet

- Book of AbstractsDocument56 pagesBook of AbstractsCojocaru Bogdan EugenNo ratings yet

- Erba Total Protein PDFDocument2 pagesErba Total Protein PDFAniket dubey100% (1)

- Water Salinity To Gradient ConversionDocument2 pagesWater Salinity To Gradient ConversionStanley OkaforNo ratings yet

- Chapter Three Amino Acids and Peptides: Mary K. Campbell Shawn O. FarrellDocument29 pagesChapter Three Amino Acids and Peptides: Mary K. Campbell Shawn O. FarrellSheila GarciaNo ratings yet

- Inorganic Chemistry: Concept Based NotesDocument63 pagesInorganic Chemistry: Concept Based NotesijdnsNo ratings yet

- Global Warming DebateDocument2 pagesGlobal Warming DebateAry WulanNo ratings yet

- Active AbsorptionDocument2 pagesActive AbsorptionANo ratings yet

- SpeedCEM BrochureDocument4 pagesSpeedCEM BrochureIvoclar VivadentNo ratings yet

- Catalyticreformingprocess 17Document29 pagesCatalyticreformingprocess 17Sahil GuptaNo ratings yet

- Determine Xenon's Ionization PotentialDocument3 pagesDetermine Xenon's Ionization PotentialAbhi Rami50% (2)

- CH 8201 PCE AU Question Bank AnswersDocument11 pagesCH 8201 PCE AU Question Bank Answersarulrakk100% (2)

- Air PollutionDocument19 pagesAir PollutionMika Hakimie100% (1)

- TDS CHEMCLEAR EnglishDocument3 pagesTDS CHEMCLEAR EnglishthirdNo ratings yet

- Question: Describe The Personal Responsibility To Reduce The Indoor Air ContaminantsDocument4 pagesQuestion: Describe The Personal Responsibility To Reduce The Indoor Air Contaminants17025 Md. Seam Hasan ArifNo ratings yet

- Electric Breakdown in Gases GuideDocument80 pagesElectric Breakdown in Gases GuideHafsa Ijaz50% (2)

- Dielectric Constants Chart: How To Use This GuideDocument10 pagesDielectric Constants Chart: How To Use This GuideDewet VirmondNo ratings yet

- Udel PSU Design Guide - EN v5.0 - 0 - 0 PDFDocument84 pagesUdel PSU Design Guide - EN v5.0 - 0 - 0 PDFReza Pencinta AL HadadNo ratings yet

- The Tensile-Yield Behavior ., of Ship'"S Ee.L: W: S. Owen, B, L Averbach and "Morris Coh&hDocument45 pagesThe Tensile-Yield Behavior ., of Ship'"S Ee.L: W: S. Owen, B, L Averbach and "Morris Coh&hKaung Myat HeinNo ratings yet

- Pyrocrete 241Document2 pagesPyrocrete 241Carboline2013No ratings yet