Professional Documents

Culture Documents

Bridge Design JKR Specification PDF

Uploaded by

Mohd FaizalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bridge Design JKR Specification PDF

Uploaded by

Mohd FaizalCopyright:

Available Formats

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 1

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 2

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

concrete beams have been the first choice since

CONTENTS then, because they are economical and durable.

For longer spans, prestressed concrete box

CHAPTER 1 - INTRODUCTION girders have been used, the first of which was

constructed in 1974.

CHAPTER 2 - BRIDGES - AN OVERVIEW

Other types of structural forms are less com-

CHAPTER 3 - BRIDGE DESIGN mon. Most of the steel truss bridges can be

STANDARD AND CODE found in East Malaysia (Sabah and Sarawak).

OF PRACTICE Some trusses are mainly in the form of Bailey

bridges. However they are usually used as tem-

CHAPTER 4 - DESIGN PRINCIPLE AND porary crossings.

APPROACH

Bridge Type Number Percentage

CHAPTER 5 - BRIDGE LOADING -

Pipe Culvert 3330 50.1%

PART I Box Culvert 1348 20.3%

Precast Concrete Beam and

CHAPTER 6 - BRIDGE LOADING - Deck Slab Bridges 665 10.0%

Reinforced Concrete Beams

PART II Bridges 557 8.4%

Buckle Plate Bridges 233 3.5%

CHAPTER 7 - DESIGN OF Reinforced Concrete Slab

Bridges 219 3.3%

SUBSTRUCTURE Concrete Arch Bridges 159 2.4%

WORKED EXAMPLE Steel Beam Concrete Deck

Bridges 126 1.9%

Steel Trough 12 0.2%

Total 6649

CHAPTER 1 - INTRODUCTION

Modern road bridge construction is relatively Table 1.1 - Bridges on Federal Road in

Peninsular Malaysia.

new in Malaysia, having been started in the

Source: JKR - BMS

early twentieth century. Most of the bridges

were constructed using established materials

and technology at the time of construction.

Early bridges were made up of simple struc-

CHAPTER 2 - BRIDGES - AN

tures. The earliest bridges were constructed

using steel beams and curved steel plates. This OVERVIEW

form of construction, which was introduced in

the early 1920s, came to be known as buckle

plate bridges. This form was popular until the 2.1 Introduction

late 1950s.

All bridges can be considered as made up of

Earliest reinforced concrete bridges were con- various components. Many times a bridge that

structed in the early 1930s. Standard reinforced is considered to be a non-concrete bridge will

concrete beam bridges however only became have numerous components that are made up

common in the 1960s with the introduction of of reinforced or prestressed concrete. For

precast reinforced concrete beams. instance, a typical steel beam or girder bridge,

which would be classified on the standard

Prestressed concrete was first used in bridges in inventory and appraisal form as a steel bridge,

Malaysia in the early 1950s. For most short to would most likely have reinforced concrete

medium span bridges, standard prestressed abutments and piers as well as a reinforced

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 3

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 4

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 5

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

concrete deck. These components, although on requires that the bridge designer/inspector

a non-concrete bridge, would be evaluated as if include several modifying terms, such as if the

they were part of a reinforced or prestressed primary load-carrying member is concrete, the

concrete bridge. bridge is classified as a concrete bridge, if the

member is steel, the bridge is classified as a

steel bridge. This classification applies even

2.2 Classification of the Bridges though other components, such as the deck or

piers, are a different material. The type of span

The bridge designers and inspectors must be design also enters into the description of the

familiar with the various types of bridges and bridge. Each bridge is described in according to

its components that may be constructed of type of span designed such as simple spans,

concrete, steel and other materials. Bridges are cantilever - suspended spans, or continuous

constructed for various purposes to support spans.

roads and highways at strategic points along

their routes. Bridge structures are required to Description of type of bridges.

cross over rivers and valleys, or for grade

separation with other roads and railways. 1. The primary load-carrying member or

Bridge structures are also required to be built members.

over roads and bridges just for pedestrian

crossings. Bridges are generally classified and Example: T-beams, 1-beams, box girder, slab,

separately called by purpose as follows: arch, trusses, frame.

(1) Road or Highway Bridges 2. Material of primary load-carrying member

Any bridge on roads and highways. Example: Concrete, steel.

(ii) Railway Bridges. 3. Type of span designed.

Any bridge on railways. Example: Simple span, cantilever-suspended

spans, continuous spans.

(iii) Flyover or Overpass Bridges.

Bridges for grade-separation with other roads,

highways or railways at intersection. 2.4 Types of Concrete Bridges.

(iv) Viaducts.

Bridges to support elevated roads, highways, or 2.4.1 Slab Bridges

railways, which are built mainly at where

ground space is limited in urban area or A concrete slab bridge is nothing more than a

embankment is difficult for ground is soft. wide shallow beam in which the beam itself

acts as the deck. A concrete slab bridge is usu-

(v) Overhead Footbridges. ally continuous, although some simple span

Bridges for pedestrian crossing. slabs exist. Slabs can be made of either rein-

forced concrete or prestressed concrete.

Precast units are sometimes used to form a slab

2.3 Types of Bridges. bridge. Several types of precast concrete units

are used by various highway agencies in slab

A bridge is classified by the primary load-car- bridge construction. These precast units include

rying member or members. For example, for channel slab, solid slab, voided slab, and the

girder-deck systems, the bridge esigner/ pan slab. These special precast units may be

inspector classifies the bridge according to the constructed of either reinforced concrete or pre-

type of girder used (T-beams, I-beams, and so stressed concrete.

on). An accurate description of a bridge

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 6

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

2.4.2 Girder or Beam Bridges. individual openings or boxes of less than 20ft,

but grouped together, they meet the definition

A girder or beam bridge consists of a deck sup- of a bridge and must be regarded as bridge.

ported directly by longitudinal girders or Concrete box culvert is usually analysed as a

beams. Concrete girder or beam-type bridges continuous concrete frame and is frequently

may be either reinforced concrete or pre- used over small or intermittent waterways.

stressed concrete and usually precast. Most

concrete-beam-type bridges are also composite; 2.4.5 Truss

that is, the beam and deck have a load-carrying

connection between the beam and deck. This A rare type of bridge is the reinforced concrete

composite section allows the beam and deck to truss. A truss bridge is one of in which the main

act together to carry the load. The T-beam, M- supporting members are made up of a series of

beam, Y-beam, Inverted T-beam, U-beam and triangles the sides of which act in tension or

the Ibeam are the common beam or girder-type compression.

concrete bridges. The T-beam is generally a

cast-in-place monolithic deck-and-beam sys- 2.4.6 Frame.

tem. The T-beam is named such because of the

"tee" shape used in a typical analysis of the A rigid frame reinforced concrete bridge is one

section. in which the piers or abutments are casted

monolithically with the main supporting mem-

2.4.3 Box Girders ber, either girders or slab, so that the abutment

can assist in carrying the main supporting

Concrete box girders have become quite popu- member loads. These rigid frame bridges can

lar in recent years. As the name implies, the be single span or multispan as in a concrete

girders are constructed with a cross section that box culvert. The bridge presents a pleasing aes-

is rectangular or box-shaped such that the roof thetic shape primarily because of the relatively

and floor act as flanges and the walls act as long span with a shallow depth.

webs. The bridge may be a large box, or a mul-

titude of smaller boxes. These structures may 2.4.7 Arch.

be simple span or continuous and either

prestressed or reinforced concrete. The box A concrete arch is the natural extension from

units may be castin-place or precast, depending Roman stone arch. The true arch carries load

on the location or experience of the highway by direct compression.

agency involved.

Segmental box girders are frequently used for The concrete arch bridge is generally of three

long span bridges. These units are very large types: -

box girder segments usually constructed by a

cantilever method. The concrete segmental box - the open or spandrel arch

girders are also used in cable-stayed bridges. - the filled arch

- the through tied arch

2.4.4 Concrete Box Culverts

The spandrel arch consists of the deck system

A concrete box culvert consists of a box-like supported by columns or bents, which rest on

concrete frame, generally normal to the road- the arch proper.

way, which has a waterway or roadway passing

through the culvert underneath the roadway. The filled arch has fill material contained by

The National Bridge Inspection Standards walls resting on the arch.

(NBIS) USA defines a culvert as a bridge if the

distance from backwall to backwall equals or The third and older type, which resembles a

exceeds 20ft. Concrete box girder may have truss, is the through ties arch. The main sup-

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 7

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

porting member is the arch which hangers sup-

porting a floor system and deck. Several precast T-beam shapes are used by var-

ious highway agencies. This include the bulb

In all cases, the arch proper can be though of as tee, the double tee, the quad tee, the rib tee, and

a long curved column. decked bulb tee.

2.5 Superstructure (i) M-beam

The pretensioned prestressed M-beam was

2.5.1 Concrete Decks. developed in the late 1960s as a beam which

could conveniently be used to form a voided

The deck is the load-carrying part of the super- slab deck. It was modelled on the inverted T-

structure that has direct contact with the wheel beam but was made a wider metre width mod-

loads on a typical highway bridge. The most ule.

common construction material for decks is

reinforced concrete. These decks are usually In the 1960s the I-beam deck was used with the

cast in place. Some concrete decks are precast, in-situ diaphragms in the span, the moulds in

prestressed units if the designer wanted to take fact providing holes for transverse steel at

advantage of the compressive strength of the 3.050m centres. The properties and normal

concrete or minimise cracking of the deck. The construction of inverted T-beam, I and box sec-

precast units are becoming popular as replace- tion bridges, at that time.

ment decks where maintaining of traffic during

replacement is a concern. In the late 1960s the better structural efficiency

of a voided slab, rather than that of an I-beam

Concrete decks on girder bridges normally and slab, layout was appreciated, as was the

have the primary reinforcement in the trans- capacity of a voided slab to do without the

verse direction or perpendicular to the girder. need for inspan diaphragms. A joint Ministry of

Transport, Cement & Concrete Association and

industry based development programme in U.K

resulted in the derivation of the M-beam shape

2.5.2 Beams/Girders

A girder or beam bridge consists of a deck sup-

ported directly by longitudinal girders or

beams. Concrete girder or beam-type bridges

may be either reinforced concrete or pre-

stressed concrete and usually precast. Most

concrete-beam-type bridges are also compos-

ite,; that is, the beam and deck have a load-car-

rying connection between the beam and deck.

This composite section allows the beam and

deck to act together to carry the load. The T-

beam, M-beam, Y-beam, Inverted T-beam, U-

beam and the Ibeam are the common beam or

girder-type concrete bridges. The T-beam is

generally a cast-in-place monolithic deck-and-

beam system. The T-beam is named such

because of the "tee" shape used in a typical

analysis of the section.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 8

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

which was publicised in 1971. the construction. This is by far the most appli-

cation., With the new requirement for inspec-

Parameter study carried out in U.K pointed tion in mind and a further desire for economy,

some weakness of M-beams as follows. some designers placed M-beams with gaps of

up to 500mm and more between them. This

(i)M-beams were placed closely during con- had the penalty of the need for a deeper beam

struction. The current need for inspection of and possibly a deeper slab but does not have

bridge structures, spaces between bottom the advantage that all the superstructure may be

flanges of beams are needed for access and inspected.

inspection.

(ii) The lower flange of the beam should be

deeper than in a M-beam to allow for the

increased prestress used in recent designs and

also to allow higher covers for links without

impinging on manufacturing tolerances and

without requiring links to be bent through non-

standard radii.

(iii) The lower flange should have a more

steeply sloping top surface than on Mbeams to

keep it clean of debris and to allow it to be cast

without air bubbles and water gain under the

shutter forming the upper surface of the bottom

flange.

(iv) The beam should be ideally not have a dis-

crete top flange in order to eliminate the need After a series of reserches had been carried out,

for such a top flange to be provided with a set Y-beam was introduced in January 1991. The

of small portion links, as increasingly the case main points and advantages of M-beam are as

with M-beams. follows:

(v) The beam should have a top flange that Used on beams and deck slab of 14 to 32

would allow it to have an end cross diaphragm metres long

which is not the full depth of the deck. This

configuration is common in standard U-beam Better durability than existing bridge beams

bridges and allows access for jacking for bear- due to optimum shape for spaced beam and

ing maintenance and replacement. slab construction

All of deck, including between beams, readi-

(ii) Y-beam ly inspectable o Cost less than M-beams

M-beam decks were originally envisaged as Absence of discrete top flange allows easier

having a solid bottom flange with infill con- diaphragm and continuity detailing

crete and top flange cast on lost formwork. An

end diaphragm was used in all cases. This Decks may be shallower than M-beam decks

method of construction was found to be expen-

sive and, with the penalty of going to an extra

beam depth, it was possible to eliminate the

lower flange completely, greatly simplifying

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 9

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

(iii) T-beam

(v) I-beam

T-beams were introduced in the early 1990s.

The concept of a T-section arose to replace I- The most common concrete I-beam shape is

beams. Their shapes are nearly the same except the AASHTO shape used by most state high-

that T-beams are having wider and thin top way agencies. These 1-beams are normally pre-

flanges. The main purpose of this top flange is cast and prestressed. Several highway agencies

to form the permanent formwork for deck slab have developed variations of the AASHTO

construction. Because of this, the construction shapes to accommodate their particular needs.

time could be shortened and they had better Older prestressed girder bridges are generally

aesthetic appearance as compared to Ibeams. simple spans, where as many of the newer

Due to this advantage features, they became bridges are simple span for dead load and con-

popular and increasingly replaced I-beams. tinuous for live load. These bridges utilise cast-

Now T-beams are become the first choice in-place continuous decks constructed on pre-

beams for bridges having span ranging from 25 cast prestressed girders.

meter to 45 meter.

(vi) JKR Standard Beams

The Bridge Rehabilitation and Maintenance

Study in 1992 highlighted the various problems

of the bridges in this country. Some of the

problems came from lack of uniformity in both

(iv) U-beam design and construction. This study also recom-

mended the standardisation of bridge design, to

The development of U-beams was started in improve the design, construction and mainte-

1971 where the cross-section of a deck incor- nance of bridges in the country.

porating U-section beams. The main advantage

of U-beams is, in conjunction with an insitu In the study, the pre-cast pre-stressed structural

deck slab the necessary torsional stiffness is members were developed after taking into

provided for the distribution of live loads. account the technical and production capability

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 10

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

of the local manufacturers. Simple sectional

beam shape with straight edges were adopted

in the study to ensure high quality finished

products. In selecting the pre-cast beam, the

study team has also tried to reduce initial

investment cost of new bedding by the manu-

facturers.

Following are the summary of the slab and pre-

cast prestressed beams recommended by the

study to be adopted by JKR.

2.6 Other Elements

2.6.1 Expansion Joint Introduction

The expansion joint is an integral part of any

bridge structure and as such must be consid-

ered at an early stage in design. If the expan-

sion joint is carefully designed and detailed,

properly installed by specialist operators and

given reasonable maintenance in service, it

should be trouble free for many years.

It is important to appreciate that the expansion

joint is in the most vulnerable position on any

bridge, situated at surface level where it is sub-

jected to the unabsorbed impact and vibration

of the traffic and exposed not only to dust, silt,

grit and water but also to the effects of ultra-

violet rays, ozone attack and chemicals such as

salt solutions, cement alkalis and petroleum

derivatives.

Expansion Joints Requirements

In view of the aggressive situations above, the

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 11

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

following requirements must be met in select-

ing an expansion joint. It must 2.6.2 Parapet

(i)accommodate all movements of structure

and withstand all loadings; Introduction

(ii) not impart stress to the structure unless the The main objectives of the forms of parapet are

structure has been designed accordingly;

(i)To provide specified levels of containment to

(iii) have good riding characteristics; limit penetration by errant vehicles.

(iv) not present a skid hazard; (ii) To protect highway users and others in the

vicinity by redirecting errant vehicles with min-

(v) not present a danger to traffic such as imum deceleration forces on to a path as close

cyclists, animals, etc; as possible to the line of the parapet and to

reduce the risk to the vehicle of overtopping

(vi) be silent and vibration free in operation; the parapet and of overturning.

(vii)give reliable operation throughout the

expected temperature range; General Design

(viii) be sealed against water and foreign matter (i)Level of Containment

or make provision for their disposal;

Normal level of containment

(ix) resist corrosion and withstand attack from

grit, chemicals, etc; Vehicle : Saloon car

Mass : 1500 kg

(x) facilitate easy inspection, maintenance and Height of centre of gravity : 600mm

repair. Angle of impact : 20°

Speed : 113 km/h (70m/h)

Today there is a large variety of proprietary

expansion joints on the market and the problem High level of containment

facing the bridge engineer is now so often that

of selecting the most suitable joint to give good Vehicle : 4 axle rigid tanker

performance and a trouble free life for at least or equivalent

as long as that of the surfacing. Mass : 30,000 kg

Height of centre of gravity : 1800mm

Types of Expansion Joints Angle of impact : 20°

Speed :64 km/h (40 m/h)

Expansion joints are classified by the

magnitude of movements of the structure in (ii) Vehicle Impact Loading

longitudinal mode.

The parapet shall be designed to resist loading

(i)Joint for small movements (Below 10mm) appropriate to the designated level of

containment usinp- the equivalent static

(ii) Joints for medium movements nominal loadings from Table 2.1.

(10 - 25mm)

(iii) Joints for large movements (Over 25mm)

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 12

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Parapet Containment Panel Nominal Bending Panel Nominal Panel Joint

Level Moment Shear Nominal Shear

Transfer

Nominal -

* without shear transfer

provision between 50 kN over lm 80L kN/panel

panels

High -

• with shear transfer

(180 + 40L) kN/panel (90 + 50H) L 110 kN

provision between

panels

• without shear transfer

(210 + 40L) kN/panel (110 + 50H) L

provision between

panels

Table 2.1 - Equivalent static nominal loads for insitu and precast concrete parapets

applicable to panel lengths (L) 1.5m to 3.5m

The load and movement capacities of the bear-

(iii) Parapet Height ing for any particular structure should be com-

patible with the assumptions made in the over-

The minimum height of concrete parapets shall all design of that structure.

be measured from the datum to the top of the

front face and it shall be for a particular Where practicable and whenever the expected

application as noted in Table 2.2. design life of the bearing is significantly less

than of the structure, provision should be made

Parapet Height Application

1.00 m • for vehicle and vehicle pedestrian parapets for the removal and replacement of the whole

• for bridges carrying motorways over railways, or

1.25 m

situations where pedestrians are excluded _ or parts of the bearings. Facilities for correcting

• for all other bridges over railways

1.50.m • for high containment applications the effects of any differential settlement and tilt

• for protection of animals

should be provided unless the structure has

Table 2.2 - Height of Parapets

been designed to accommodate such effects.

Adequate space should be provided around

If additional height is required only for the bearings to facilitate their inspection and main-

protection of animals, this may be provided by tenance. Consideration should be given in the

the addition of a metal rail mounted on posts design of the structure to the means of access

anchored into the top of the to the bearings.

concrete parapet. The rail, posts and Bearings should be detailed to exclude crevices

anchorages shall be designed to resist a and the like, which allow moisture and dirt to

horizontal ultimate loadings of 1.4 kN/m be trapped.

applied to the rail.

Where restraints are required to restrict the

translational movement of a structure, either

totally, partially or in a selected direction, they

2.6.3 Bearings may be provided as part of or separate from the

bearings and normally take the form of dowels,

keys or side restraints. In each case the

Introduction restraints should allow freedom of movement

in the desired direction(s).

The function of bearings is to provide a con-

nection to control the interaction of loading and

movements between parts of a structure, usual-

ly between superstructure and substructure.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 13

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

2.7 Substructures

2.8 Foundation - Piles

2.7.1 Abutment

2.8.1 Introduction

Abutments are the part of the substructure that

form the terminal ends of the bridge and sup- Piles are relatively long and slender members

port the end spans. Typical types of abutments used to transmit foundation loads through soil

are full heights, stub or semistub. The abutment strata of low bearing capacity to deeper soil or

is normally composed of footing (pile cap), a rock strata having a high bearing capacity.

breast wall (ballast wall), a bridge seat, wing They are also used in normal ground condition

walls, curtain walls and sometimes approach to resist heavy uplift forces or in a poor soil

slab seats on cobel. The most common con- conditions to resist horizontal loads. Piles are

struction material for abutments is reinforced convenient method of foundation construction

concrete. Some special cases call for precast for works over water such as jetties and bridge

units or prestressed units, but the great majority piers.

are cast-in-place reinforced concrete. Because

abutments are supports for end spans of The load transfer may be by friction, end bear-

bridges, they must also retain the soil on the ing or combination of both. If the bearing stra-

approaches. tum for foundation piles is a hard and relatively

impenetrable material such as rock or a very

dense sand and gravel, the piles derive most of

2.7.2 Piers their carrying capacity from the resistance of

the stratum at the toe of the piles. In these con-

Concrete piers are the substructure element ditions they are called end bearing or point

between the abutments and are usually made bearing piles (Figure 2.8). On the other hand, if

up of capping beams, footings, columns and the piles do not reach an impenetrable stratum

caps. The footings may be spread, pile or but are driven for some distance into a penetra-

drilled shafts. Each of these components of a ble soil, their carrying capacity is derived partly

pier is frequently constructed of reinforced con- from end bearing and partly from the skin fric-

crete with precast or prestressed units used tion between the embedded surface of the pile

occasionally. and the surrounding soil. Piles which obtain the

greater part of their carrying capacity by skin

Another common name for a small pier con- friction or adhesion are called friction piles

sisting of a cap or two or more columns or (Figure 2.9).

piles is a bent.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 14

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

2.8.2 Common Type of Piles Used in steel H-pile is about 300 to 1800kN depending

Malaysia on size.

(1)Precast Reinforced Concrete Piles (4)Cylindrical Steel Piles (Driven cast-

in-situ Displacement Pile).

Used to be the common used pile in bridge

project before the introduction of prestressed Driven cast-in-place piles are installed by

spun piles. The pile is designed as compression drilling to the desired penetration a steel tube

members and longitudinal steel is provided to with its end closed. A reinforcing cage is next

withstand bending and tensile stress during placed in the tube which is then filled with

handling and driving. The common sizes of concrete. The tube is then withdrawn while

reinforced square concrete piles used varies placing the concrete. This system of pilling is

from 250mm to 400mm square section. The usually patented basing on using different types

usual design load for this type are in the range of shoes of driving technique or casing

of 300 to 600 kN. withdrawal procedure. The system used in this

country is patented Franki pile. The design load

(2)Prestressed Spun Piles per pile is in the range of 650 to 1500 kN.

Driven and cast-in-situ piles have the principal

This is the most commonly used type pile in advantage of being readily adjustable in length

bridge project in Malaysia currently. to suit the desired depth of penetration. The

Prestressed spun piles are produced by process design load per steel pipe pile is in the region

of spinning. The concrete used in producing the of 200 to 3000 kN.

piles are high concrete strength, e.g. Grade 56,

60 or more. Their principal advantage over (5)Bored Piles

ordinary reinforced concrete piles is the higher

strength to weight ratio, enabling long slender Bored cast-in-place piles are installed by first

units to be lifted and driven. The second main removing the soil by a drilling process, and

advantage is the effect of prestressing in clos- then constructing the pile by placing concrete

ing up cracks during handling and driving. This in the drilled hole. The simplest form of

effect, combined with the high quality concrete construction consists of drilling an unlined hole

necessary for economic employment of and filling it with concrete. In water-bearing

prestressing, gives the prestressed concrete pile soils and soft clay, casing is needed to support

increased durability. Sizes varies from 250mm the sides of the borehole. The casing is

diameter to 800mm diameter. withdrawn after placing concrete. In stiff to

hard clays and weak rock, an enlarged base can

(3)Steel H-Piles be formed to increase the end bearing

resistance. Design load for bored cast-in-situ

Steel piles have the advantage of being robust, pile varies from 400 to 6500 kN.

light to handle and capable of being driven

hard to deep penetration to reach a bearing (6) Micropiles

stratum. They can carry high compressive loads

when they are seated in a hard stratum. They Micropiles are classified as small diameter (less

can be designed as small displacement piles, than 200mm) bored cast-in-situ piles. The

which is advantageous in situations when special feature of micropile is its strength,

ground heave and lateral displacement must be resulting from placing of steel and its seating in

avoided. They can be readily cut down and a hole of sufficient diameter which may be

extended where the level of the bearing stratum bored in whatever direction is best suited to the

varies. H-section piles are the common steel requirements of the projects. The equipments

piles used in this country. The design load for used in the installation of micropiles are much

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 15

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

smaller than those used in bored piles and so it

is very convenient to move and install these (3) Minimum span length

equipments. In areas where the ground consist

of hard weathered rock they require special (i) Span length has a direct relation to the

diamond-tipped drills and for large diameter possibility of clogging the bridge opening

boreholes the process of drilling will be quite with floating logs or debris.

difficult. Moreover only few contractors can (ii) Pier location close to bank

supply these drills. Whereas for micropiles the (iii) Impediment ratio of pier width to water

drilling process can be easily done due to the way

small diameter. The micropiles are good

foundation in fractured rocks where the

cracks/fractures can be grouted at the same (4) Abutment Design

time of grouting the micropiles. For existing

structures where the foundation is found to fail, (i) Retaining Wall-type (or Inverted T-type)

these micropiles can be used because they do Abutment

not require large equipments or space to work (ii) Embedding depth of pie cap .

on and so the other parts of the structure will Footing shall be embedded into riverbed.

not effected. The working loads of micropiles Where the scouring risk is high, it shall be

as specified by the soils lab are between 400 deepened below the anticipated scour

kN to 800 kN but some contractors claim that depth.

they can reach up to 1500 kN for 250mm (iii) Parallel to flow

diameter. Abutments shall be laid in parallel to flow

of water.

2.9 Authorities Requirements (5) Pier Design

(i) Oval or round shape for pier column

2.9.1 Waterway Crossing (Jabatan (ii) Embedding depth of pile cap

Pengairan dan Saliran) Footing shall be embedded into riverbed

deeper than the anticipated scour depth.

General Requirement

(6) Bank Protection

(1) Location and Direction of Crossing Bank protection is required to protect the slope

of bank from the erosion which may be caused

(i) Cross river at its straight reach by the turbulence water flow induced by the

(ii) Cross river in perpendicular to its flow construction of piers.

(i)Covering Area

(2) Waterway Width and Freeboard (ii) Embedding Depth

(iii) Foot Protection

(i) Lay abutments outside waterway The toe of bank protection shall be

(ii) Minimum freeboard on highest water level protected against scouring with gabion

(HWL) packs or stones.

The freeboard between HWL and the soffit

of bridge shall not be less than 1.0 meter.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 16

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Figure 2.10 shows a diagram issued by Jabatan

Pengaliran dan Saliran Negeri Selangor in the (i)About Existing Road

pamphlet - Prosedur Memproses Pembinaan

Jambatn / Paip Menyeberangi Sungai. Class and grade

Cross sectional profile

Right of way

Hydrological Calculation - DID Clearance limit

Hydrological Procedures Longitudinal profile

Few methods have been established by the (ii) About Future Plan

Jabatan Pengaliran and Saliran, Malaysia ,

to.determine hydrological requirements Designated, or not designated to roads of

namely; city planning

Sidewalk plan, or not

1. Rational Method (HP No.5) Overlay and widening plan, or not

2. Unit Hydrograph Method (HP No. 11) Cycle track plan, or not

3. Regional Flood Frequency Method (HP

No.4) (iii) About Public Utilities

4. Urban Drainage Design Standards and

Procedures for Peninsular Malaysia (2)Consultation Items

The following items are to be consulted with

2.9.2 Roadway Crossing (State JKR, the competent authority of the crossing road:

Local Authorities, Bandaraya, etc.)

(i)Bridge length and span

(1)Information of Crossing Road (ii) Location of abutments and piers

(iii) Embedding depth of foundations

The following information of the crossing road (iv) Under bridge clearance

is required for bridge planning (v) Diversion road

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 17

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

(vi) Construction method (includes protection

of existing road and traffic) Class and grade

Rail gauge and cross sectional profile o

(3)Vertical Clearance Limit Right of way

Clearance limit

A clearance height of 5.3m above the existing Electrified or not

road surface under the soffit of the planned

bridge beam is recommended. ii. About future plan

(4)Location of Abutments and Piers Electrification plan, or not

Double tracking plan, or not

(i) General Elevating plan, or not

Abutments and piers are prohibited inside a (2) Consultation Items

roadway. It is favourable for the traffic of the

crossing road to have sufficient lateral margins The following items are to be consulted with

between roadway and abutment, and not to the competent authority of crossing railway:

have a pier on median strip.

(i) Bridge structural type

However, the following cases are technically (ii) Bridge length and span

and economically very difficult to avoid a pier (iii) Embedding depth of foundation

on median strip: (iv) Location of abutments and piers

(v) Under bridge clearance

i. Crossing road is very wide having six lanes (vi) Construction method (includes relocation

or more. and protection of existing railway

ii. Bridge is skewed to crossing road with over facilities)

about 50 degrees even if it has only four lanes (vii)Consignment construction, or delegation of

or less. supervisors

iii. Crossing road is separated into up and (viii)Installation of guard fence

down lanes.

iv.Frontage road and/or waterway run in paral- (3) Clearance Limit

lel to crossing road. When a pier is designed on

median strip, it is required to consider collision The clearance limit of railway is different

load of vehicles for the design of pier. depending on the type and kind of railways.

The railway of Malaysia has been developed

(ii) Lateral Clearance based on the British gauge and is now in

progress of electrification. Figure 2.11 shows

(iii) Special Lateral Clearance for the clearance of Keretapi Tanah Melayu

Expressway Berhad both for the electrified and not

electrified.

2.9.3 Railway Crossing (KTMB) However, in recent years new commuter

railway system is going to be constructed in

(1) General Requirements urban area. To cross with such new system,

clearance limit should be confined by

Information of Crossing Railway Similar to individual consultation.

road crossing, the following information of the

crossing is required beforehand:

i. About existing railway:

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 18

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

2.10 JKR Current Practice 2.10.2 Discouraging The Usage of

Close Spaced Beams

2.10.1 Introduction During bridge inspection, bridge engineers are

facing problem in inspecting deck slab of the

Based on The Annual Mandatory Bridge closed space beams. Based on this difficulty,

Inspection (AMBI) for 1995. Irrespective of the the department had come up with a policy to

type of observed defects, one of the agents to discourage and finally eliminating the usage of

the initiation and propagation of defects was closely spaced beams.

the presence of water. In view of the observed

defects, some new design procedures were 2.10.3 Continuous Deck Slab For

adopted whether the design would be carried Multiple-Span Bridges

out in-house or by to the consultants. Some of

these procedures were: After having recognised the problems

associated with expansion joints, adoption of

(1) To discourage the usage of closed space continuous deck slab for multi-span bridges

beams. was introduced. The expansion joints are

probably only limited at the abutments.

(2), Providing continuous deck slab for multi- Adopting continuous concept and integral

span bridges. bridges whenever is possible in bridge

superstructure construction may result in the

(3) To maintain the existing practice of reduction in maintenance liability associated

providing approach slabs at the abutments. with moving parts such as expansion joints and

bearings. Last but not least, the public users

(4) Providing retaining wall type abutments now have a better riding quality associated with

for bridges across rivers instead of bank seat a lesser number of expansion joints and

types. The invert level of the pile cap must be environmental noise disturbance reduced.

at least 1 m below the existing bed level. Figure 2.12 shows one of the typical details of

a continuous deck slab adopted over a pier.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 19

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 20

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

2.10.4 Retaining Wall Type Abutments 2.10.5 Approach Slab

The majority of the existing bridges were In Malaysia, due to her climatic and

designed and constructed more than twenty geographical condition, it is a traditional

years ago. The hydrological requirement practice to provide approach slabs at both ends

required during the design stage was based on of a bridge. Initially, the approach slab was

the existing hydrological parameters such as located just below the wearing course. Due to

hydraulic gradient and type of vegetation. For the settlement at a few locations and the

the last twenty years, rapid development has difficulties to maintain, the location of the

taken place where jungles had been cleared and approach slab was placed about l.Om below

replaced with rubber and oil palm plantations. the wearing course surface.

Hills had been flattened, valleys had been filled

for the construction of roads, highways, and CHAPTER 3 - BRIDGE DESIGN

residential and industrial areas in the name of STANDARD AND CODE OF

developments. As these developments have PRACTICE

been taken place, hydrological parameters

changed resulted in new set of water volume 3.1 Code of Practices in Bridge

and flood levels. There were few occasions

Design - Malaysia

where the earthfill behind abutments were

washed due to the limited flow area of the

In 1972, Limit State Design was first appeared

water. To overcome this problem in the future,

in British Codes of Practice in the Building

only retaining wall type of abutment will be

Code - CP 110. Since then it has been used in

adopted for bridges spanning over the rivers.

the water retaining structures codes (BS 5337)

For the future deepening of the river, Drainage

in 1976, the masonry code (BS 5628) in 1978

and Irrigation Department of Malaysia requires

and finally the bridge code (BS 5400) in 1978.

that all the soffit of the pile cap must be at least

one metre below the existing bed level of the

The introduction of limit state design of

river.

concrete bridges constitutes a radical change in

the design philosophy because the existing

design documents are written, principally, in

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 21

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

terms of a working load and permissible stress

design philosophy. Thus, the use f BS 5400 The contents of the individual parts are

may change design procedures, though it is summarised below:

unlikely to change significantly the final sizes

adopted for concrete bridges. Part 1: The philosophy of limit state design is

presented and the method of analysis which

3.2 BS 5400 may be adopted are stated

The Codes consist of the ten parts as listed in Part 2: Details are given of the loads to be

Table 3.1. It should be noted that BS 5400 is considered for all types of bridges, the partial

both a Code of Practice and a Specification. safety factors to be applied to each load and the

However, not all aspects of the design and con- load combinations to be adopted.

struction of bridges are covered; exceptions

worthy of mention are the design of parapets Part 3: Design rules for steel bridges are given.

and such constructional aspects as expansion

joints and water proofing. Part 4: Design rules for reinforced, prestressed

and composite (Precast plus insitu) concrete

BS 5400 CODE

bridges are given in terms of material

properties, design criteria and methods of

PART 1 GENERAL STATEMENT

compliance.

PART 2 SPECIFICATION FOR LOADS Part 5: Design rules for steel-concrete

PART 3 CODE OF PRACTICE FOR DESIGN OF

composite bridges are given.

STEEL BRIDGES

Part 6: The Specification of materials and

PART 4 CODE OF PRACTICE FOR DESIGN OF

CONCRETE BRIDGES workmanship in connection with structural

steelwork is given.

PART 5 CODE OF PRACTICE FOR DESIGN OF

COMPOSITE BRIDGES

Part 7: The Specification of materials and

PART 6 SPECIFICATION FOR MATERIALS AND workmanship in connection with concrete,

WORKMANSHIP, STEEL

reinforcement and prestressing tendons is

PART 7 SPECIFICATION FOR MATERIALS AND given.

WORKMANSHIP, CONCRETE,

REINFORCEMENT AND PRESTRESSING

TENDONS Part 8: Recommendations are given for the

application of Part 7.

PART 8 RECOMMENDATIONS FOR MATERIALS

AND WORKMANSHIP, CONCRETE,

REINFORCEMENT AND PRESTRESSING Part 9: The design, testing and specification of

TENDONS bridge bearings are covered.

PART 9 BRIDGE BEARINGS.

Part 10: Loading for fatigue calculations and

SECTION CODE OF PRACTICE FOR DESIGN OF methods of assessing fatigue life are given.

9.1 BRIDGE BEARINGS

SECTION SPECIFICATION FOR MATERIALS, MAN- 3.3 Departmental Standard BD

9.2 UFACTURE AND INSTALLATION OF

BRIDGE BEARINGS 37/88 - Loads for Highway Bridges

PART 10 CODE OF PRACTICE FOR FATIGUE

3.3.1 Introduction

BSI committee CSB 59/1 has reviewed BS

Table 3.1 -BS 5400 5400: Part 2 1978 (including BSI Amendment

No. l (AMD 4209) dated March 1983) and has

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 22

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

agreed a series of major amendments including

the revision of the HA loading curve. It has 3.4 Foundation

been agreed that as an interim measure,

pending a long term review of BS 5400 as a Foundation shall follow British Standard

whole and bearing in mind the current work on Institution BS 8004: Foundation

Eurocodes, the present series of amendments to

Part 2 shall be issued by the Department of 3.5 Expansion Joints in Deck

Transport, U.K rather than BSI. Because of the Slabs

large volume of technical and editorial

amendments involved it has also been decided

Expansion Joints in Bridge Decks shall follow

that a full composite version of BS 5400: Part 2

Department of Transport Highways and Traffic

including all the agreed revisions should be

Departmental Standard BD 33/88- Expansion

produced, and this forms and appendix to the

Joints For Use in Highway Bridge Decks.

Departmental Standard.

3.6 Parapet

3.3.2 Additional Requirements

1. All road bridges shall be designed to carry Parapet shall be of New Jersey type concrete

HA loading. In addition, a minimum of 30 structure and in accordance to Department of

units of type HB loading shall be taken for all Transport (U.K) Technical Memorandum

road bridges except for accommodation bridges No.BE.5: The Design of Highway Parapets.

which shall be designed to HA loading only. The design of New Jersey concrete guardrail

The actual number of units shall be related to shall be in accordance to Arahan Teknik (Jalan)

the class of road as specified below: 1/85 (Pindaan 1/89) mannual on Guardrail of

Longitudinal - Traffic Barrier.

Class of road carried Number of units of type HB

by structures loading

3.7 Anti-Corrosion Protective

Motorways and Trunk 45

Roads (or principal System

road extensions of

trunk routes)

The steel materials used for the bridge struc-

Principal roads 337.5 tures shall follow BS 5400: Part 6. A compre-

hensive anti-corrosion protective system shall

Other public roads 33 0

be in accordance with BS 5493 or equivalent.

3.8 Ship Impact

2. For highway bridges where the superstruc-

ture carries more than seven traffic lanes (i.e. Appropriate ship collision forces shall be estab-

lanes marked on the running surface and nor- lished and follow AASHTO Guide

mally used by traffic), application of type HA Specification and Commentary for Vessel

and type HB loading shall be agreed with the Collision Design of Highway Bridges; 1991.

Authority (UK - Technical Approval Authority,

Malaysia - JKR). 3.9 Elastomeric Bridge Bearings

3. In determining the wind load and tempera- The elastomeric bridge bearing shall be

ture effects for foot / cycle track bridges, the designed in accordance to BS 5400: Part 9.1

return period may be reduced from 120 years - Code of Practice for Design of Bridge

to 50 years subject to the agreement of the Bearings. Elastomeric bearings shall be of

Authority (UK - Technical Approval Authority, natural rubber and in accordance with the

Malaysia - JKR). specification proposed by the Committee on

Natural Rubber in Construction, Rubber

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 23

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Research Institute, Malaysia. acceptable probability of it not being achieved.

Different acceptable probabilities are associated

3.10 Vehicle Collision Loads on with the different limit states. The partial safety

Highway Bridge Supports and factors and design criteria are chosen to give

Superstructure similar levels of safety and serviceability to

those obtained at present code. However,

Vehicle Collision Loads on Highway Bridge typical levels of risk in the design life of a

Supports and Superstructure shall be designed structure are taken to be 10-6 against collapse

in accordance with BD 60/94. and 10-2 against unserviceability occurring.

Thus the chance of collapse occurring is made

remote and much less than the chance of the

CHAPTER 4 - DESIGN PRINCIPLE serviceability limit state being reached.

Limit state design principles have been agreed

AND APPROACH

internationally and set out in International

Standard ISO 2394 which becomes a document

4.1 Introduction

forms the basis of the limit state design

philosophy of BS 5400.

Rules and procedures for the design of bridges

have been the subject of continuous amend-

4.3 Limits States

ment, improvement and development over the

years. A significant development took place in

A limit state is a condition, which a structure or

1967 when a meeting was held to discuss the

a part of a structure would become less than

revision of B.S 153, on which many bridge

completely fit for its intended uses. Two limit

design documents were based. It was suggested

states are considered in BS 5400;

that a unified code of practice should be written

in .terms of limit state design which would

i) Ultimate Limit State

cover steel, concrete and composite steel con-

ii) Serviceability Limit State

crete bridge of any span. A number of subcom-

mittees were formed to draft various sections of

4.3.1 Ultimate Limit State

such a code; the work of these sub-committees

has culminated in B.S 5400.

Ultimate limit state is corresponding to the

maximum load-carrying capacity of the

4.2 Limit State Design

structure or a section of the structure, and could

be attained by:

Limit state design is a design process which

aims to ensure that the structure being designed

(i)Loss of equilibrium when a part or the

will not become unfit for the use for which it is

whole of the structure is considered as rigid

required during its design life.

body.

(ii) A section of the structure or the whole of

The structure may reach a condition at which it

the structure reaching its ultimate strength in

becomes unfit for use for one of many reasons

terms of post-elastic or post-buckling

(e.g. collapse or excessive cracking) and each

behaviour.

of these conditions is referred to as a limit state.

(iii) Fatigue failure. However, it can be seen

In limit state design each limit state is exam-

that fatigue is considered not under ultimate

ined separately in order to check that it is not

loads but under a loading similar to that at the

attained. Assessment of whether a limit state is

serviceability limit state.

attained could be made on a deterministic or a

probabilistic basis. In BS 5400, a probabilistic

4.3.2 Serviceability Limit State

basis is adopted and, thus, each limit state is

examined in order to check whether there is an

This denotes a condition beyond which a loss

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 24

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

of utility or cause for public concern may be = yf3 [effect of yfL Qx ]

expected, and remedial action required. For

concrete bridges the serviceability limit state is, Where

essentially, concerned with crack control and [Partial Load Factor] is a factor that takes

stress limitations. In addition, the serviceability account

limit state is concerned with the vibrations of

footbridges. (i) inaccurate assessment of the effect of

loading

4.3.3 Design Life (ii) unforeseen stress distribution in the

structure

This is defined in BS 5400 as 120 years. (iii) variation in dimensional accuracy achieved

However, The Code emphasises that this does in construction Where linear relationships

not necessarily mean that a bridge designed in can be assumed between loading and load

accordance with it will no longer fit for its effects,

purpose after 120 years, nor that it will

continue to be serviceable for that length of S* = [effect of YS. Yn..QKI

time, without adequate and regular inspection

and maintenance. 4.4.4 Design Resistance (R*)

4.4 Loads R* = function (fk)/(YR,)

4.4.1 Nominal Load (Qx) or

Where adequate statistical distributions are R* = function (fk-)

available, nominal loads are those appropriate (Ym)

to a return period of 120 years. In the absence

of such statistical data, nominal load values that where

are considered to appropriate to a 120 year

return period are given. fk = characteristic (or nominal) strength

of material

4.4.2 Design Load (Q*)

Ym = reduction factor

Q* = Yfl QK = function (Ym i . Ym2 )

Where where

Ym1 is intended to cover the possible reductions

yfl = function (yfl . yf ) in the strength of the materials in the structure

as a whole as compared with the characteristic

And value deduced from the control test specimen.

yfl take account the possibility of unfavourable Ym2 is intended to cover possible weakness of

deviation of the loads from their nominal the structure arising from any cause other than

values the reduction in the strength of the materials

allowed for in Ym1, including manufacturing

yfz takes account acting together will all attain tolerances.

their nominal values simultaneously

4.5 Partial Safety Factors

4.4.3 Design Load Effects (S*)

The values of the partial safety factor Yn, to be

S* = yf-,[effect of Q*] applied at the ultimate and serviceability limit

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 25

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

states for the various load combinations are tude. In the case of dead load this entails apply-

given in Table 8.4. Followings are some of ing a yn. value of 1.0: it is emphasised that this

general points should be noted: value is applied to all parts of the dead load

effect. In the case of superimposed dead load

(i)Larger values are specified for the ultimate and live load, these loads should not be applied

than for the serviceability limit state. to those portions of the structure where their

presence would diminish the load effect under

(ii) The values are less for reasonably well consideration.

defined loads, such as dead load, than for more

variable loads, such as live or superimposed Influence lines are frequently used in bridge

dead load. Hence the greater uncertainty asso- design and, in view of the above, it can be seen

ciated with the latter loads is reflected in the that superimposed dead load and live load

values of the partial safety factors. should be applied to the adverse parts of an

influence line and not to relieving parts. It is

(iii) The value for a live load, such as HA load, not intended that parts of parts of influence

is less when the load is combined with other lines should be loaded.

loads, such as wind load in Load Combination

2 or temperature loading in Load Combination 4.6.2 Overturning of Structure

3, than when it acts alone, as in Load

Combination 1. This is because of the reduced The stability of a structure against overturning

probability that a number of loads acting is calculated at the ultimate limit state. The

together will all attain their nominal values criterion is that the least restoring moment due

simultaneously. This fact is allowed for by the to unfactored nominal loads should be greater

partial safety factor Yrz, which is a component than the greatest overturning moment due to

of Yo.. design loads.

(iv) A value of unity is specified for certain 4.6.3 Foundations

loads (e.g. superimposed dead load) when this

would result in a more severe effect. The soil mechanics aspects of foundations

should be assessed in accordance with CP

(v) The values for dead and superimposed 2004, which is not written in terms of limit

dead load at the ultimate limit state can be dif- state design, Hence these aspects should be

ferent to the tabulated values. considered under nominal loads. However,

when carrying out the structural design of a

foundation, the reaction from soil should be

4.6 Application of Loads calculated for the appropriate design loads.

4.6.1 General 4.7 Material Properties

The general philosophy governing the applica- 4.7.1 Concrete

tion of the loads is that the worst effects of the

loads should be sought. In practice, this implies Characteristic Strengths

that the arrangement of the loads on the bridge

is dependent upon the load effect being consid- Material strengths are defined in terms of

ered, and the critical section being considered. characteristic strengths. The characteristic cube

In addition, the Code requires that, when the compressive strength (f,-") of concrete is

most severe effect on a structural element can referred to as its grade, e.g. grade 40 concrete

be diminished by the presence of a load on a has a characteristic strength of 40 N/mm2.

certain portion of the structure, then the load is Grades 20 to 50 may be used for normal

considered to act with its least possible magni- weight reinforced concrete and 30 to 60 for

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 26

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

prestressed concrete.

4.8 Design Criteria

4.7.2 Reinforcement

The design criteria are given in Part 4 : BS

Characteristic Strengths 5400 under the heading:

The quoted characteristic strengths of rein- Ultimate limit state

forcement (fy) are 250 N/mm2 for mild steel; Serviceability limit state

410 N/mm2 for hot rolled high yield steel; 460 Other considerations

N/mm2 for cold worked high yield steel,

except for diameters in excess of 16mm when Other considerations includes those criteria

it is 425 N/mm2 ; and 485 N/mm2 for hard which are not specified in BS 5400 but which

drawn steel wire. are, nonetheless, important in design terms

4.7.3 Prestressing Steel Table 4.2 shows the list of the criteria from

which it can be seen that there are a great

Characteristic Strengths number of criteria to be satisfied and, if

calculation has to be carried out for each, the

Tables are given for the characteristic strengths design procedure may be extremely lengthy.

of wire, strand, compacted strand and bars of

Limit State Design Criteria

various nominal sizes. Each tabulated value is

given as a force which is the product of the

Ultimate Limit State Rupture

characteristic strength (fp,,) and the area (Aps) Buckling

of the tendon. Overturning

Vibration

4.7.4 Material Partial Safety Factors - Serviceability Limit State Steel Stress Limitations

ym Values Concrete Stress Limitations

Cracking of Prestressed

Concrete

Design strengths are defined as characteristic Cracking of Reinforced

strengths divided by the appropriate partial Concrete

safety factors (ym). The ym values appropriate

Other Considerations Deflections

to the various limit states are summarised in Fatigue

Table 4.1. Durability

Limit State Concrete Steel

Table 4.2 - Design Criteria

Serviceability Limit State

Analysis of Structure 1.0 1.0

Reinforced Concrete Cracking 1.0 1.0

Prestressed Concrete Cracking 1.3 1.0

4.8.1 Ultimate Limit State

Stress Limitation 1.3 1.0

Vibration 1.0 1.0 The criterion for rupture of one or more

Ultimate Limit State sections, buckling or overturning is simply that

Analysis of 'Structure 1.0 1.0 these events should not occur.

Section Design 1.5 1.15

Deflection 1.0 1.0 A vibration criterion, which would be

concerned with vibrations to cause collapse of

Fatigue 1.3 1.0

a bridge, is not given, but, instead, compliance

with the serviceability limit state vibration

Table 4.1 - ym Values criterion is deemed to satisfy the ultimate limit

state requirements.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 27

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

4.8.2 Serviceability Limit State hypothetical tensile stresses exist at the

maximum size of cracks.

(i) Steel Stress Limitations

(a) Serviceability limit state

It is generally only necessary to check cracks Loading Allowable Stress

widths in bridges under HA loading for load

Bending 0.33fcu (0.4f fcu at

combination 1. This means that there is an Direct compression supports)

indirect check on reinforcement stresses under 0.25 fi

primary HA loading but not under other loads. (b) Transfer

Stress Distribution Allowable Stress

(ii)Concrete Stress Limitations

Triangular 0.5fi

Concrete stress limitations include compressive Uniform 0.4fi

stresses in reinforced and prestressed concrete,

and compressive, tensile and interface shear Table 4.2 - Limiting Concrete Compressive

stresses in composite construction. Stresses in Prestressed Concrete

In order to prevent micro-cracking, spalling (iv) Cracking of Reinforced Concrete

and unacceptable amounts of creep occurring The design surface crack widths were assigned

under serviceability condition, compressive from considerations of appearance and

stresses are limited to 0.5 f"' for compressive durability. They are summarised in Table 4.3.

stresses in reinforced concrete.

The limiting compressive stresses in pre- 4.8.3 yf3 Values

stressed concrete for the serviceability limit

state and at transfer are given in Table 4.3. The nominal loads and the values of the partial

safety factors yf., by which these loads are

multiplied to give design loads. Then, the

(iii) Cracking of Prestressed effects of the latter have to be multiplied by a

Concrete partial safety factor yf3 in order to obtained

design load effects. The values of yt3 are

The criteria for the control of cracking in pre- dependent upon the material of the bridge.

stressed concrete are presented in terms of

limiting flexural tensile stresses for three The value of yr3 should be taken as 1.0 for

classes of prestressed concrete. serviceability limit state.

Class 1: No tensile stresses are permitted For ultimate limit state, the value of yf3 should

except for 1 N/mm2 under prestress plus dead be taken as 1.10, except that where plastic

loads, and at transfer. methods are used for the analysis of the

structure, yea should be taken as 1.15.

Class 2: The tensile stresses should not

exceed the design flexural tensile strength of

the concrete, which is 0.454fcu for

pretensioned member and 0.36Jfcu for post

tensioned members.

Class 2: For Class 3 members in which

cracking is allowed, it may be assumed that the

concrete section is uncracked and that

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 28

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

4.8.3 yf3 Values

The nominal loads and the values of the partial

safety factors yf., by which these loads are

multiplied to give design loads. Then, the

effects of the latter have to be multiplied by a

partial safety factor yf3 in order to obtained

design load effects. The values of yt3 are

dependent upon the material of the bridge.

The value of yr3 should be taken as 1.0 for

serviceability limit state.

For ultimate limit state, the value of yf3 should

be taken as 1.10, except that where plastic

methods are used for the analysis of the struc-

ture, yea should be taken as 1.15.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 29

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

LIMIT STATE REQUIREMENTS

SLS OTHER

ULS CONSIDERATIONS

DEFLECTIONS

CRACKING VIBRATION FATIGUE

RUPTURE

STRESS

OR

LIMITATIONS DURABILITY

INSTABILITY

REINFORCED

CONCRETE

IN IN

BUCKLING

CONCRETE STEEL

PRESTRESSED

CONCRETE

OVERTURNING

VIBRATION

CLASS 1 CLASS 2 CLASS 3

Figure 4.1 - Design : Limit State Requirements

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 30

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 31

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 32

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

4.9 Reaction Forces paths

4.9.1 Free-Fixed Single Span Bridge

Figure 4.4 shows the paths of reacting forces of a Fixed-Free Single Span Bridge.

The vertical forces from the superstructure will be shared between the abutments. These loads and

vertical loads from the abutments will be transferred to the pile caps and finally-will be supported

by the pile foundation.

The horizontal forces from the superstructure will be transferred to the abutment at the fixed

joint. Depending on the direction of the horizontal forces, they may be resisted by the passive

reactions at the abutment or the abutment wall will solely resist them.

In normal practice, it is assumed that the stiff foundation where the piles are assumed to be pin

jointed to the pile cap. At the toe of the abutment wall, the vertical and horizontal forces will be

represented by the vertical forces acting at the centroid of the piles and a couple.

The piles will resist the vertical forces and the couple. Normally, in the designing the pile founda-

tion, the horizontal foundation will be resisted by the horizontal components of the raked piles

while the vertical forces will be resisted by the vertical piles and the vertical components of the

raked piles.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 33

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Figure 4.5 shows the paths of reacting forces of a Free-Fixed-Free Two Spans Bridge. The verti-

cal forces from the superstructure will be shared between the pier and abutments. These loads

and vertical loads from the abutments will be transferred to the pile caps and finally will be sup-

ported by the pile foundation.

The horizontal forces from the superstructure will be transferred to the pier at the fixed joint.

At the toe of the pier, the vertical and horizontal forces will be represented by the vertical forces

acting at the centroid of the piles and a couple. The piles will resist the vertical forces and the

couple.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 34

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Figure 4.6 shows the paths of reacting forces of a three spans bridge. The vertical forces from the

superstructure will be shared between the piers and abutments.

The horizontal forces from the superstructure will be transferred to one of the piers, which is fixed

to the superstructure.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 35

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Figure 4.7 shows the paths of reacting forces of a four span bridge. The vertical forces from the

superstructure will be shared between the piers and abutments.

The horizontal forces from the superstructure will be transferred to the middle pier where is fixed

to the superstructure.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 36

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

4.10 Step By Step in Design Due to the complex design requirements of

each component of the bridge mentioned

Logically, steps in designing bridge above, it is very difficult and troublesome to

components should follow the paths of reacting carry the design procedure as per path of

reacting forces. The author suggested the steps

forces. Therefore, superstructure should be the to be followed in are as shown in Figure 4.8. It

first component to be determined and designed. can be seen that initially the design has to be

Then follows by the design of abutment or pier started by determining the dimension and

pile caps and lastly the pile foundation. But this designing of the superstructure. It follows by

not really true in designing a bridge. In the design of pile foundation, pile caps, pier

designing each component of a bridge, each and/or abutment and finally designing of other

one of them has its own unique requirements. bridge components.

Pier may be designed either as a column or as a

reinforced concrete wall. On top of that column By referring to Figure 4.9, the process of

design may be designed either as a short or design can be divided into three independent

slender column. For either column or a design processes, i.e. Design of Superstructure,

reinforced concrete wall, the member should be Design of Pile Cap and Sub Structure and lastly

designed to satisfy the Ultimate Limit State Design of Other Bridge Components.

requirements and follows by the checking for

Serviceability Limit State conditions. Similarly,

abutment wall may be designed as cantilever

beam or as a reinforced concrete wall

depending on the configuration. For both cases,

the member should be designed to satisfy the

Ultimate Limit State requirements and follows

by the checking for Serviceability Limit State

limitations.

Slightly different from designing column and

abutment wall, in designing pile cap, it requires

to fulfil the flexural bending requirement and

checking to satisfy the flexural and punching

shears. Both flexural bending and shear designs

are to the Ultimate Limit State requirements.

Flexural bending and punching shears may be

determined by reactions of piles. Therefore,

pile number and arrangement and the reaction

at each pile at the Ultimate Limit State must be

determined and known before pile cap can be

designed.

In designing the pile foundation, the loads to be

considered are only nominal loads, i.e. without

any Factor of Safety. The factor of safety

adopted in designing pile foundation is 2.0. In

this case, validation of factor of safety will be

carried during construction where the test load

will be carried out. The test load will be twice

the design load of the pile.

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 37

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

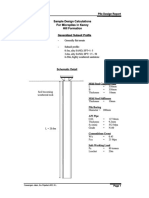

Determine dimension

of Superstructure

Design Superstructure

Determine dimension

of Substructure

Determine All Loads

1) Live Loads

2) Dead Loads

3) Superimposed

Dead Loads

Nominal Load

Design Pile Foundation

Design Load

(1) Type of Pile

( Multiplied

(2) Number of Piles

by Factor

(Vertical + Rake)

of Safety)

(3) Pile Arrangement

Design Substructure

(1) Pile Cap + Pier

(2) Pile Cap + Abutment

Design Other Bridge Components

(1) Bearing

(2) Dowels

(3) Continuity Connection

Figure 4.8 - Sequence of Design

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 38

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

Cawangan Jalan, Ibu Pejabat JKR, K.L Page 39

FOR INTERNAL USE ONLY Bridge Design For JKR Specification

CHAPTER 5

in the consideration of loading effects which

BRIDGE LOADING - PART I are positive, the positive areas of the influence

line are referred to as adverse areas and their

effects as adverse effects and the negative areas

5.1 Definitions

of the influence line are referred to as relieving

areas and their effects as reliving effects.

Loads. External forces applied to the structure Conversely, in the consideration of loading

and imposed deformations such as those effects which are negative, the negative areas

caused by restraint of movement due to of the influence line are referred to as adverse

changes in temperature. areas and their effects as adverse effects and

the positive areas of the influence line are

Axle loads referred to as relieving areas and their effects as

Bending moments relieving effects.

Shear forces

Total effects. The algebraic sum of the adverse

Load effects. The stress resultants in the and relieving effects.

structure arising from to response to loads.

Dispersal. The spread of load through surfac-

Compressive stresses ing, fill, etc.

Flexural stresses

Shear stresses Distribution. The sharing of load between

directly loaded members and other members

Dead Load. The weight of the materials and not directly load as a consequence of the

parts of the structure that are structural stiffness of intervening connection members, as

elements, but excluding superimposed eg diaphragms between beams, or the effects of

materials such as road surfacing, rail track distribution of a wheel load across the width of

ballast, parapets, mains, ducts, miscellaneous a plate or slab.

furniture, etc.

Superimposed dead load. The weight of all

5.2 Classification of Bridge

materials forming loads on the structure that

Loads

are not structural elements.

BD 37/88 divides the nominal loads into two

Live loads. Loads due to vehicle or pedestrian

groups, largely

traffic.

- Permanent Loads.

Primary live loads. Vertical live loads, consid-

- Transient Loads

ered as static loads, due directly to the mass of

traffic.

Secondary live loads. Live loads due to 5.3 Permanent Loads.

changes in speed or direction of the vehicle

traffic, eg. Lurching, nosing, centrifugal, longi- Permanents loads consist of dead loads,

tudinal, skidding and collision loads. superimposed dead loads, loads due to filling

materials, differential settlement and load