Professional Documents

Culture Documents

Certificate Details

Uploaded by

Mukesh ShahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificate Details

Uploaded by

Mukesh ShahCopyright:

Available Formats

Certificate No.

:B201211014-004

CONTRACT NO.: HBH201211202

-

Page 2 of 2

Tensile strength at 20 C ,a M p a

Where

E,= Yield point at temperature t (0.2% proof stress)

**S, = Average stress to produce an elongation of 1% (creep) in 100,000 hours at various

working metal temperatures.

**S,=Averageandlowest stress to produce rupture in 100,000hours at the various working

metal temperatures.

L.

Temperature range in the table may extend uptothe limit of applicability ofthematerial.

The value of S,and S, need be furnished only in respect of Pipes/Tubes intended to be

used for working metal temperature above 454" C (850° F).

Certified that the particulars entered herein are correct.

The particulars of fabricated component are show in drawing No.__.

The part has been designed and constructed to comply with the Indian Boiler Regulations

for a working pressure of --- and temperature --- and

satisfactorily withstood a water test of ---

on the --- day of

representative whose signature is appended

Maker's Representative

\-

ManagerIQC 8114@

We have satisfied ourselves constructed in accordd~k

with chapter VIII. The tests conducted on the samples taken from the finished pi

been witnessed by us and the particulars entered herein are correct.

Place: LINYI China Name and Signature of

Date :Dec. 3 1,20 12 Inspecting Authority:

vm-py I

NOTE (I).- This form is intended for the use of both pipe manufacturers and pipe fabricators. Only such of the columns or

paragraphs that are applicable, or information that can be obtained and furnished from other certificates, need be

filled or entered in this form.

NOTE (2).- In the case of fabrications made from steel pipes obtained from elsewhere, particulars in regard to the "material"

and "pipes" shall be take! from similar forms of certificates obtained in respect of pipes and noted in the

appropriate columns or paragraphs.

In the case of pipes made from steel, made and tested by well known Steel Makers

in India or other countries, particulars regarding the 'material' as certified by them

(in any form) shall be noted in the appropriate columns or paragraphs in this certificate.

SHANDONG HUABAO STEEL PIPE CO.,LTD

ZAOGOUTOU INDUSTRY DISTRICT,LINYI , SHANDONG , '

INSPECTION CERTIFICATE POST CODE:276038

TEL: 0539-2915327 FAX: 0539-2915327

Rkt:www. huabaosteel. corn HTTP://www. huabaosteel.corn

6

$4 8i 2

39 6 VU %E B7kE%% b7NH.Hif(d %@ I% 9b%&K @%

EDDY DETECTION ULTRASONIC BENDIN FLATTE EXPAN COATING HYDROSTATIC HYDROSTATIC DRIFT THREADINGif- 4#

plain SUM 8 1066 14.967

DETECTION G NING SION TEST TIME TEST CHECK end

DIMENSI

acceptable - accept - - acceptable - - - - accepta accept

ti->'

able ble able 8 1066 14.967

@Tl%ZA

f s8Declaration: $ P

~ Z ~ B $ S E R F~~~., ~ . b i . i $##?g!$~~n~~~

AND SPECIFICATION AND SATISFIED THE REQUIREMENT.

a,z

WE

The certificate is based on the original,copy is invalid

~ .CERTIFY THAT THE MATERIAL HERE IN R E ~ ~ R I B EHAS

HERE

--

r" -

APPROVER

D BEEN MANUFACTURED TESTED IN ACCORDANCE WITH AZVE STANDARD

You might also like

- Vacuum Box Test Report of Tank T-8112 Bottom PlatesDocument8 pagesVacuum Box Test Report of Tank T-8112 Bottom PlatesShalom LivingstonNo ratings yet

- DGC20i 50109 MAADocument2 pagesDGC20i 50109 MAAabdulla kasimNo ratings yet

- HooksDocument4 pagesHooksomar sadiqNo ratings yet

- Certificado GrilletesDocument1 pageCertificado GrilletesviniloperuoficialNo ratings yet

- Material Submittal for King Salman Air Base FacilitiesDocument1 pageMaterial Submittal for King Salman Air Base FacilitiesKscf KhereijiNo ratings yet

- Calibration HammerDocument2 pagesCalibration Hammerraju_420034520No ratings yet

- 12V DC Pin Hole TesterDocument1 page12V DC Pin Hole TesterjamilNo ratings yet

- Attach # 2. Routine Test Reports (Internal) - ReviewedDocument3 pagesAttach # 2. Routine Test Reports (Internal) - ReviewedAvinash PatilNo ratings yet

- SAIC-P-3719 Rev 0Document2 pagesSAIC-P-3719 Rev 0mkalidas2006No ratings yet

- PTW S13 310523Document2 pagesPTW S13 310523letslearnbd01No ratings yet

- Certificate of Examination and Test of Lifting Gears, Lifting Appliances & Lifting EquipmentsDocument1 pageCertificate of Examination and Test of Lifting Gears, Lifting Appliances & Lifting EquipmentsAkhilNo ratings yet

- Drainage NEW Approval CopiesDocument45 pagesDrainage NEW Approval CopiesIram StoresNo ratings yet

- Instruction Leaflets For Component - R0Document214 pagesInstruction Leaflets For Component - R0رامي طالب القروانيNo ratings yet

- TUV 400 Ton Crane PDFDocument1 pageTUV 400 Ton Crane PDFSyed Muzammil AliNo ratings yet

- Pin BrazingDocument10 pagesPin BrazingNguyen Ninh BinhNo ratings yet

- GALA TEST CERTIFICATE Size 4Document1 pageGALA TEST CERTIFICATE Size 4dow cMNo ratings yet

- Y Strainer CatalogDocument21 pagesY Strainer CatalogIrfan FahmiNo ratings yet

- Inspection & Test Plan: Dangote Oil Refinery CompanyDocument7 pagesInspection & Test Plan: Dangote Oil Refinery CompanyGowtham VenkatNo ratings yet

- Cmit 737 Ii 20 Sert Qua 30.18 190002Document2 pagesCmit 737 Ii 20 Sert Qua 30.18 190002SERT-QA/QC- BUZNo ratings yet

- SPEC TECHNICAL SPECIFICATION FOR 36KV LV BUSHINGDocument10 pagesSPEC TECHNICAL SPECIFICATION FOR 36KV LV BUSHINGabhishekgupta9990No ratings yet

- 242694634-Itp-for-Tank-Fabrication-Installation-Work1-rev02Document22 pages242694634-Itp-for-Tank-Fabrication-Installation-Work1-rev02au9t5teyrNo ratings yet

- B I1ding Be Haphil IarkDocument7 pagesB I1ding Be Haphil IarkTanya Marie ArgameNo ratings yet

- T T - Tubacex Ubos Inox Dables S A: Mill Test C T IcateDocument3 pagesT T - Tubacex Ubos Inox Dables S A: Mill Test C T IcatePRANAY OMTECHNo ratings yet

- CT - PT MQPDocument12 pagesCT - PT MQPGnanavel GNo ratings yet

- Air Compressor and ReceiverDocument17 pagesAir Compressor and ReceiverRafeeq Ur RahmanNo ratings yet

- DFFDocument25 pagesDFFcsolanki6586No ratings yet

- OPTIMIZED SPECIFICATION FOR HONG YU ENCODER MODEL HEC12L3-40E3N-25K7-24P6-0025Document9 pagesOPTIMIZED SPECIFICATION FOR HONG YU ENCODER MODEL HEC12L3-40E3N-25K7-24P6-0025Ananatha KarthikNo ratings yet

- Approved - 400kV LADocument22 pagesApproved - 400kV LAGuru MishraNo ratings yet

- Heat Resistant Cable Certification ScheduleDocument1 pageHeat Resistant Cable Certification ScheduleKalim HaralNo ratings yet

- Valve Test ReportDocument3 pagesValve Test ReportHery MukhlisNo ratings yet

- A325M - M24x70Document3 pagesA325M - M24x70nam nguyengiangNo ratings yet

- AD2000 W0 EngDocument1 pageAD2000 W0 Engottcomputerec100% (1)

- 4.06 EC 10M QUAD BOP Man PDFDocument23 pages4.06 EC 10M QUAD BOP Man PDFAlexander tulcanNo ratings yet

- Tech Manual: Tech-4.06 10K Ec Quad BopDocument23 pagesTech Manual: Tech-4.06 10K Ec Quad BopAlexander tulcan100% (1)

- Inspection Release Note: ChevronDocument3 pagesInspection Release Note: ChevronHassan M. OsmanNo ratings yet

- General Plumbing Notes and Specification GuideDocument1 pageGeneral Plumbing Notes and Specification GuideAntonio EstradaNo ratings yet

- Name Sign Date DSGN NK/CRR 10-12-2020 CHKD: Sensitivity: LNT Construction Internal UseDocument14 pagesName Sign Date DSGN NK/CRR 10-12-2020 CHKD: Sensitivity: LNT Construction Internal UserengaramanujanNo ratings yet

- Upvc Catch Basin Submittal - CosmoplastDocument30 pagesUpvc Catch Basin Submittal - CosmoplastAburvaraj0% (1)

- PO - 302404 - TSD - Electric Equipt. Power CableDocument3 pagesPO - 302404 - TSD - Electric Equipt. Power CableClint Bryan VirayNo ratings yet

- General Plumbing Notes and Specification SheetDocument1 pageGeneral Plumbing Notes and Specification SheetAntonio EstradaNo ratings yet

- 2b5e8230ff4b4b58b88637bc8d611ec5_20230819092652203Document74 pages2b5e8230ff4b4b58b88637bc8d611ec5_20230819092652203HARMOHAN DASNo ratings yet

- In Process - HT55 PinDocument1 pageIn Process - HT55 PinGulfeng SafetyNo ratings yet

- 00060Document2 pages00060dieselmotorsbogotasasNo ratings yet

- Design Qualification 12022023151550Document14 pagesDesign Qualification 12022023151550remarkhb.maintenanceNo ratings yet

- Instrument Materials Inspection GuideDocument10 pagesInstrument Materials Inspection GuidehapinefeNo ratings yet

- 1250Document1 page1250Deepak BhatiNo ratings yet

- Wi - Hardness TestingDocument8 pagesWi - Hardness Testingvipulsharma655No ratings yet

- 3 - Hdpe - Itp Pipe WeldingDocument2 pages3 - Hdpe - Itp Pipe Weldingasif712100% (6)

- Paint Durability Tester Certificate Earns SEO-Optimized TitleDocument1 pagePaint Durability Tester Certificate Earns SEO-Optimized TitleHanbo ENC Vina Công ty TNHHNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Flyback Transformer Specification: Code: First Issue DateDocument21 pagesFlyback Transformer Specification: Code: First Issue Datefrancisco navarroNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Engineering instruction for first officer side EFB installationDocument9 pagesEngineering instruction for first officer side EFB installationEdwar ZulmiNo ratings yet

- Sawant Rupesh C.: B. Tech. (PRODUCTION) (D-050729) Under Guidance ofDocument33 pagesSawant Rupesh C.: B. Tech. (PRODUCTION) (D-050729) Under Guidance ofDIPAK VINAYAK SHIRBHATENo ratings yet

- MOS Duct Sealing & Bentonite CalculationDocument12 pagesMOS Duct Sealing & Bentonite CalculationSenthilnathan NagarajanNo ratings yet

- MOS Duct Sealing & Bentonite Calculation PDFDocument12 pagesMOS Duct Sealing & Bentonite Calculation PDFSenthilnathan NagarajanNo ratings yet

- Mc1495datasheet 3609985603Document16 pagesMc1495datasheet 3609985603pepenitoNo ratings yet

- Itp For Tank Fabrication Installation Work1 Rev02 PDFDocument22 pagesItp For Tank Fabrication Installation Work1 Rev02 PDFMichelNo ratings yet

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesFrom EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNo ratings yet

- Flange DrawingDocument1 pageFlange DrawingMukesh ShahNo ratings yet

- Flange Drawing 1Document1 pageFlange Drawing 1Mukesh ShahNo ratings yet

- Credit Note FormatDocument1 pageCredit Note FormatMukesh ShahNo ratings yet

- Is 1239 Part Ii - 2011Document3 pagesIs 1239 Part Ii - 2011Mukesh ShahNo ratings yet

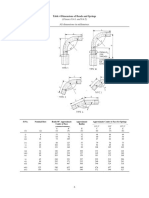

- Carbon steel butt weld pipe fittings and specificationsDocument1 pageCarbon steel butt weld pipe fittings and specificationsMukesh ShahNo ratings yet

- Is 1239 Part Ii - 2011Document3 pagesIs 1239 Part Ii - 2011Mukesh ShahNo ratings yet

- Credit Note: Credit Note No Date Name of The ClientDocument1 pageCredit Note: Credit Note No Date Name of The ClientMukesh ShahNo ratings yet

- Alliance Pipes and FittingsDocument24 pagesAlliance Pipes and FittingsMukesh ShahNo ratings yet

- Debit Note Format PDFDocument1 pageDebit Note Format PDFMukesh ShahNo ratings yet

- Welding EndDocument1 pageWelding EndMukesh ShahNo ratings yet

- Is 1239 Part Ii - 2011Document3 pagesIs 1239 Part Ii - 2011Mukesh ShahNo ratings yet

- Is 1239 Part Ii - 2011Document3 pagesIs 1239 Part Ii - 2011Mukesh ShahNo ratings yet

- Flange DrawingDocument1 pageFlange DrawingMukesh ShahNo ratings yet

- Is 1239 Part Ii - 2011Document3 pagesIs 1239 Part Ii - 2011Mukesh ShahNo ratings yet

- AnnexureD PDFDocument1 pageAnnexureD PDFMukesh ShahNo ratings yet

- Annex UredDocument23 pagesAnnex UredMukesh ShahNo ratings yet

- Csadd18 2016Document5 pagesCsadd18 2016Heavy MetalNo ratings yet

- HSN Product Code For GST PDFDocument855 pagesHSN Product Code For GST PDFkashyap_ajNo ratings yet

- Alliance Catlouge 1-5Document5 pagesAlliance Catlouge 1-5Mukesh ShahNo ratings yet

- MS Fittings BOQ - First LOTDocument3 pagesMS Fittings BOQ - First LOTMukesh ShahNo ratings yet

- Bends Dimension ReportDocument2 pagesBends Dimension ReportMukesh ShahNo ratings yet

- IranOilShow2014-ParticipantDocument29 pagesIranOilShow2014-Participantsanghvi_mukeshNo ratings yet

- FORM6Document9 pagesFORM6syampnaiduNo ratings yet

- Pre Galvanised TubesDocument7 pagesPre Galvanised TubesMukesh ShahNo ratings yet

- Nickel Alloys and Stainless Steel SpecsDocument2 pagesNickel Alloys and Stainless Steel SpecsMukesh ShahNo ratings yet

- Election Enrollment FORM7Document5 pagesElection Enrollment FORM7Raman PatilNo ratings yet

- PREN Calculator Rev Feb 2011Document2 pagesPREN Calculator Rev Feb 2011swapnilNo ratings yet

- Types of LogoDocument3 pagesTypes of Logomark anthony ordonioNo ratings yet

- PGP TutorialDocument21 pagesPGP TutorialSabri AllaniNo ratings yet

- Sheqxel Bbs Participation Dashboard TemplateDocument39 pagesSheqxel Bbs Participation Dashboard TemplateMuhammad Adytio DarmawanNo ratings yet

- Ireland in Pre Celtic TimesDocument398 pagesIreland in Pre Celtic TimesGrant MacDonald100% (5)

- My16-Td My16-AtDocument6 pagesMy16-Td My16-AtRodrigo ChavesNo ratings yet

- Tugas B InggrisDocument6 pagesTugas B Inggrisiqbal baleNo ratings yet

- BMXNRPDocument60 pagesBMXNRPSivaprasad KcNo ratings yet

- EQ - Module - Cantilever MethodDocument17 pagesEQ - Module - Cantilever MethodAndrea MalateNo ratings yet

- HP 5973 Quick ReferenceDocument28 pagesHP 5973 Quick ReferenceDavid ruizNo ratings yet

- Body Scan AnalysisDocument9 pagesBody Scan AnalysisAmaury CosmeNo ratings yet

- Quality CircleDocument33 pagesQuality CircleSudeesh SudevanNo ratings yet

- Application Programming InterfaceDocument12 pagesApplication Programming InterfacesorinproiecteNo ratings yet

- Fundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDocument35 pagesFundamental Managerial Accounting Concepts 9th Edition Edmonds Solutions ManualDrMichelleHutchinsonegniq100% (15)

- Voltaire's Candide and the Role of Free WillDocument3 pagesVoltaire's Candide and the Role of Free WillAngy ShoogzNo ratings yet

- City of Brescia - Map - WWW - Bresciatourism.itDocument1 pageCity of Brescia - Map - WWW - Bresciatourism.itBrescia TourismNo ratings yet

- The Emperor Jones: What's Inside in ContextDocument27 pagesThe Emperor Jones: What's Inside in ContextHarshvardhan RaiNo ratings yet

- Febrile SeizureDocument3 pagesFebrile SeizureClyxille GiradoNo ratings yet

- Little Book of Effective WritingDocument44 pagesLittle Book of Effective Writingshalashvili100% (1)

- Learning Online: Veletsianos, GeorgeDocument11 pagesLearning Online: Veletsianos, GeorgePsico XavierNo ratings yet

- Osora Nzeribe ResumeDocument5 pagesOsora Nzeribe ResumeHARSHANo ratings yet

- Levels of Attainment.Document6 pagesLevels of Attainment.rajeshbarasaraNo ratings yet

- Hotel Design Planning and DevelopmentDocument30 pagesHotel Design Planning and DevelopmentTio Yogatma Yudha14% (7)

- Bitcoin MambaDocument17 pagesBitcoin MambaJean MilenixNo ratings yet

- Long Run Average Cost (LRAC) : Economies of ScaleDocument3 pagesLong Run Average Cost (LRAC) : Economies of ScaleA PNo ratings yet

- Kastanakis 2014Document8 pagesKastanakis 2014Andreea Georgiana MocanuNo ratings yet

- The Slave Trade and The British Empire An Audit of Commemoration in WalesDocument133 pagesThe Slave Trade and The British Empire An Audit of Commemoration in WaleslegoarkeologNo ratings yet

- E PortfolioDocument76 pagesE PortfolioMAGALLON ANDREWNo ratings yet

- Tutorial 3Document2 pagesTutorial 3prasoon jhaNo ratings yet

- Youth, Time and Social Movements ExploredDocument10 pagesYouth, Time and Social Movements Exploredviva_bourdieu100% (1)

- 7 Tactical Advantages of Explainer VideosDocument23 pages7 Tactical Advantages of Explainer Videos4ktazekahveNo ratings yet