Professional Documents

Culture Documents

Project JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552

Uploaded by

Darshan PanchalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project JG Summit Stage1 Expansion Title: Screening Procedure As Per ASME Section VIII, Div 2. PE3-E6552

Uploaded by

Darshan PanchalCopyright:

Available Formats

PROJECT JG SUMMIT STAGE1 EXPANSION

Rev 0A

TITLE Screening Procedure as per ASME Section VIII,Div 2.

TagNo PE3-E6552

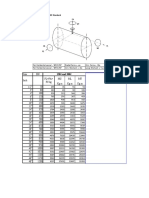

…. 1 Equipment Description PE3-E6552

…. 2 Design Code ASME Sec VIII.Div.1

…. 3 Basic Design data

…. 4 Shell / Head SA-516 70 UTS (MPa) 482.7 552 Method A is applicable

…. 5 Nozzle neck pipe SA-106B UTS (MPa) 413.7 552 Method A is applicable

…. 6 Nozzle flange / Blind flange SA-105/SA 266 Gr.2 UTS (MPa) 482.7 552 Method A is applicable

…. 7 Internal Design Pressure 0.241 MPa

…. 8 External Design Pressure 0.8 MPa

…. 9 Design Temperature 100 Degree

…. 10 Operating Pressure 0.107 MPa

…. 11

…. 12 Vessel to be designed for 55000 cycles from 0 to 0.2 Mpa(g),Based on1100 cycles per year.

…. 13 Pressure Cycle

Note:-

…. 14 Pmax (Mpa) 0.2 Pmin(Mpa) 0 Arrival of cyle 1100 Year

As per MDS

…. 15 Temperature Cycle

…. 16 Tmax (◦C) NA Tmin (◦C) NA Arrival of cyle NA days

…. 17

…. 18 Load history:- 1) Vessel designed Life span 20 Years

…. 19 2) No of Pressure cyclesin life span of 20 Years 55000 No of cycles

…. 20 3)No of Temperature cycles in life span of 20 years NA No of cycles

…. 21

…. 22 N∆FP Expected Number of Full -range pressure cycle including Startup & Shutdown 55000 Cycles

…. 23

…. 24 Type of Construction Integral Construction Pmax- Pmin Result

Criteria check

…. 25 Integral Construction No of times(Pmax-Pmin)>0.20*Design Pressure 0.2 0.0482 Applicable

N∆PO

…. 26 Expected Number of Pressure variation cycle including Startup & Shutdown 55000 Cycles

…. 27

…. 28 N∆TE No of Change metal temperature difference Not applicable

…. 29

…. 30 N∆Tα No of Temperature cycle Not applicable

…. 31

…. 32 Fatique Screening Criteria For Method A…………………….Table 5.9

…. 33 Integral Construction Total Limit of

Cases Equal To Result

…. 34 N∆FP + N∆PO + N∆TE + N∆Tα Cycles Cycles

…. 35 Operating 55000 55000 0 0 110000 110000 1000 Fatique Analysis is required

You might also like

- WRC-107 Lifting Trunnions - Vert. LiftDocument5 pagesWRC-107 Lifting Trunnions - Vert. LiftManoj MulikNo ratings yet

- Blind Flange Design CalculationsDocument4 pagesBlind Flange Design CalculationsamaNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- WRC-107 lifting lug calculations procedureDocument5 pagesWRC-107 lifting lug calculations procedureManoj MulikNo ratings yet

- E4.5.1 6 PTB 4 2015 PDFDocument50 pagesE4.5.1 6 PTB 4 2015 PDFKingston RivingtonNo ratings yet

- Trunnion 6 TonDocument3 pagesTrunnion 6 TonEngr Khurram Jaan RamayNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- Flat Ends With A Relief GrooveDocument11 pagesFlat Ends With A Relief GrooveEng-CalculationsNo ratings yet

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- Design of base plate for columnDocument6 pagesDesign of base plate for columnsoumyaNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Tor. Dish EndDocument4 pagesTor. Dish EndSiva ShankarNo ratings yet

- Seismic Load Calculation Using G-Values in PV EliteDocument3 pagesSeismic Load Calculation Using G-Values in PV EliteMas Arman TewoNo ratings yet

- 1830 - Fea Fatigue Analysis Report PDFDocument19 pages1830 - Fea Fatigue Analysis Report PDFGabbar SinghNo ratings yet

- External Pressure Calculation Results SummaryDocument8 pagesExternal Pressure Calculation Results SummaryAndika DearsonNo ratings yet

- Design of lifting lug on spreader beamDocument2 pagesDesign of lifting lug on spreader beamSabrang LorNo ratings yet

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocument17 pages181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542No ratings yet

- Determine Shell ThicknessDocument53 pagesDetermine Shell ThicknessRajul MuraliNo ratings yet

- Calculation Trunion (By Maniacs)Document5 pagesCalculation Trunion (By Maniacs)SyahkullahNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- HE Header E535Document91 pagesHE Header E535rizal mubarokNo ratings yet

- SADDLE SUPPORT DESIGNDocument6 pagesSADDLE SUPPORT DESIGNSISIR KR BARMAN0% (1)

- PDS Air CompressorDocument1 pagePDS Air Compressordhavalesh1No ratings yet

- PO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDDocument18 pagesPO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDUmair RazaNo ratings yet

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDocument1 pageNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191No ratings yet

- Calculation of Davit ArmDocument1 pageCalculation of Davit ArmpiziyuNo ratings yet

- PVElite RefDocument6 pagesPVElite RefakhilNo ratings yet

- Stillwell Pipe ArrangementDocument1 pageStillwell Pipe ArrangementVishalDhimanNo ratings yet

- Ellipsoidal Flange to Circular Conversion DimensionsDocument3 pagesEllipsoidal Flange to Circular Conversion Dimensionsnaveenkumar_madasettNo ratings yet

- Auto PipeDocument18 pagesAuto PipeAdi SutardiNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin5586No ratings yet

- 194 2427 194 T Tot H H : Input OutputDocument19 pages194 2427 194 T Tot H H : Input Outputxuankhoi doanvanNo ratings yet

- Cylindrical ShellsDocument3 pagesCylindrical ShellsEng-CalculationsNo ratings yet

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- How To Consider Sea Transportation LoadDocument7 pagesHow To Consider Sea Transportation LoadSharun SureshNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- Assignment CSTT 1Document21 pagesAssignment CSTT 1KHÁNH VÕ ĐĂNGNo ratings yet

- Mozzle Repad Design ToolDocument2 pagesMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNo ratings yet

- Shell Thickness CalculationsDocument2 pagesShell Thickness CalculationsskocogluNo ratings yet

- Design partition plate for refinery distillation columnDocument5 pagesDesign partition plate for refinery distillation columnpippo2378793No ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Shell Thickness Calculations for Pressure Vessel ComponentsDocument16 pagesShell Thickness Calculations for Pressure Vessel ComponentsClaudia BonocoreNo ratings yet

- Design 3Document2 pagesDesign 3JOY NATHNo ratings yet

- Output Data: Design CaseDocument3 pagesOutput Data: Design CaseAnonymous RytT6uvX1No ratings yet

- UG-37 F FactorDocument7 pagesUG-37 F FactorjamesNo ratings yet

- 120MW Generator Static & Dynamic Testing FormatDocument25 pages120MW Generator Static & Dynamic Testing FormatnadeshenNo ratings yet

- Dt002gb000-Ir 01Document33 pagesDt002gb000-Ir 01LorenzoNo ratings yet

- Memoria de Calculo Actual 1339460 - 0Document20 pagesMemoria de Calculo Actual 1339460 - 0JAVIER ANTONIO PEREZ ALVARADONo ratings yet

- Fatigue Analysis SeminarDocument42 pagesFatigue Analysis SeminarDavid JeongNo ratings yet

- SelectricDocument153 pagesSelectricLuissmrmix ER DjTraxNo ratings yet

- Screeing Method Fea FatigueDocument34 pagesScreeing Method Fea FatigueGokul Amarnath0% (1)

- E02 SC4692-601-02JS A.C. Short Circuit CalculationDocument18 pagesE02 SC4692-601-02JS A.C. Short Circuit CalculationAli BelabedNo ratings yet

- 31.PEAK Depressurization RATEDocument1 page31.PEAK Depressurization RATEDILIP MATALNo ratings yet

- Aermec NCD Data Sheet EngDocument2 pagesAermec NCD Data Sheet EngRene Jaqi Runa100% (1)

- Oscilloscope OS-9020G Service Manual: LG Precision Co., LTDDocument77 pagesOscilloscope OS-9020G Service Manual: LG Precision Co., LTDielc_cardosoNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) : 2 Mbit (256Kb X 8) UV EPROM and OTP EPROMDocument26 pagesObsolete Product(s) - Obsolete Product(s) : 2 Mbit (256Kb X 8) UV EPROM and OTP EPROMBermeo Perez MichaelNo ratings yet

- Flange Leakage 6Document2 pagesFlange Leakage 6hamid sobirinNo ratings yet

- AD9852Document42 pagesAD9852cbernal73No ratings yet

- Vanillin Crude B Column Mechanical DatasheetDocument3 pagesVanillin Crude B Column Mechanical DatasheetDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDocument4 pagesVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNo ratings yet

- Transportation - Bearing LoadDocument3 pagesTransportation - Bearing LoadDarshan PanchalNo ratings yet

- Pressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDocument3 pagesPressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDocument130 pagesVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDocument4 pagesVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDocument270 pagesVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDocument130 pagesVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNo ratings yet

- IBIC Nozzle Local LoadDocument1 pageIBIC Nozzle Local LoadDarshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalNo ratings yet

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDocument270 pagesVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- VDU Lift Stair Tower 302 - Material Summary - ListDocument4 pagesVDU Lift Stair Tower 302 - Material Summary - ListDarshan PanchalNo ratings yet

- Calculate Hertz Contact Stresses SafelyDocument5 pagesCalculate Hertz Contact Stresses SafelyDarshan PanchalNo ratings yet

- Fractal NetworksDocument7 pagesFractal NetworksAsociación laCuerdaNo ratings yet

- Design of RCC Structure: Department of Civil Engineering Diploma Section 3 YEAR - 5 Semester 2020 - 2021Document6 pagesDesign of RCC Structure: Department of Civil Engineering Diploma Section 3 YEAR - 5 Semester 2020 - 2021Tapabrata2013No ratings yet

- 23Document4 pages23Suka JoshuaNo ratings yet

- Earth Continental Drift Plate Tectonics Sea Floor Spreading-0Document59 pagesEarth Continental Drift Plate Tectonics Sea Floor Spreading-0roziel A.mabitasanNo ratings yet

- Flow Simulation in SW (Inlet-Outlet) - DASSAULT - SOLIDWORKS Simulation - FEA - Eng-TipsDocument3 pagesFlow Simulation in SW (Inlet-Outlet) - DASSAULT - SOLIDWORKS Simulation - FEA - Eng-TipsJA KNo ratings yet

- Lesson Plan4Document3 pagesLesson Plan4api-410721710No ratings yet

- Workout TrackerDocument3 pagesWorkout TrackerGuriNo ratings yet

- Stats Form 4Document35 pagesStats Form 4kirin19100% (2)

- The Standard EIA Resistor Color Code TableDocument1 pageThe Standard EIA Resistor Color Code TableGerritvdbergNo ratings yet

- Active Directory Interview Questions and AnswersDocument4 pagesActive Directory Interview Questions and AnswersUlaga NathanNo ratings yet

- Rational Numbers ListDocument4 pagesRational Numbers ListnishagoyalNo ratings yet

- Noise, Nonlinear Distortion and System ParametersDocument200 pagesNoise, Nonlinear Distortion and System ParametersKhang Nguyen0% (1)

- Bowens Reaction SeriesDocument9 pagesBowens Reaction SeriesManfinflaNo ratings yet

- Questionbank - DCN 8th Sem 1Document2 pagesQuestionbank - DCN 8th Sem 1tanuj125No ratings yet

- General Direction: Each Item Below Has Four Choices. Select The Best Answer and Write Only The Letter of YourDocument4 pagesGeneral Direction: Each Item Below Has Four Choices. Select The Best Answer and Write Only The Letter of Yourmary grace fuegoNo ratings yet

- MCQ Iapm Double Final 1Document48 pagesMCQ Iapm Double Final 1moamen BNo ratings yet

- Giovanni Boccaccio Boccaccio, Giovanni 1313-75, Italian Poet and Storyteller, Author of The DecameronDocument3 pagesGiovanni Boccaccio Boccaccio, Giovanni 1313-75, Italian Poet and Storyteller, Author of The Decameronmay ann dimaanoNo ratings yet

- Sequences WorksheetDocument8 pagesSequences WorksheetAsh LoopsNo ratings yet

- Rotrex Technical Datasheet C30 Range V4.0Document7 pagesRotrex Technical Datasheet C30 Range V4.0Blake Newman0% (1)

- Comilla University: Department of Computer Science & Engineering Presentation On: Data StructureDocument23 pagesComilla University: Department of Computer Science & Engineering Presentation On: Data StructureEaib Aminul IslamNo ratings yet

- User Guide For Auto-WEKA Version 2.2: Lars Kotthoff, Chris Thornton, Frank HutterDocument15 pagesUser Guide For Auto-WEKA Version 2.2: Lars Kotthoff, Chris Thornton, Frank HutterS M IbrahimNo ratings yet

- PGCRSM-01-BLOCK-03 Research Design ExperimentalDocument29 pagesPGCRSM-01-BLOCK-03 Research Design ExperimentalVijilan Parayil VijayanNo ratings yet

- IO2654 - F11 - 2013 - WDM Management PDFDocument23 pagesIO2654 - F11 - 2013 - WDM Management PDFKlaudio MarkoNo ratings yet

- Unit 4 Multiple Linear RegressionDocument3 pagesUnit 4 Multiple Linear RegressionManchilot TilahunNo ratings yet

- Single Slider Crank ChainDocument9 pagesSingle Slider Crank ChainSunny RajNo ratings yet

- A Multi Clustering Method Based On Evolutionary Multi - 2020 - Swarm and EvolutiDocument12 pagesA Multi Clustering Method Based On Evolutionary Multi - 2020 - Swarm and Evolutimohamed albasunyNo ratings yet

- Foundation Earth ElectrodesDocument1 pageFoundation Earth ElectrodesSandeep KumarNo ratings yet

- 145 - Cafco MANDOLITE CP2 - Cellular BeamsDocument0 pages145 - Cafco MANDOLITE CP2 - Cellular Beamswidayat81No ratings yet

- PaperDocument8 pagesPaper法林No ratings yet

- Apb Calculation (Natural Gas)Document8 pagesApb Calculation (Natural Gas)Nasrul HazimNo ratings yet