Professional Documents

Culture Documents

201901xx Ref - No. NJSKWSP2 ReplyCWASALetter 2083ConstructionSupervisionByEngineer

Uploaded by

Mahibul HasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

201901xx Ref - No. NJSKWSP2 ReplyCWASALetter 2083ConstructionSupervisionByEngineer

Uploaded by

Mahibul HasanCopyright:

Available Formats

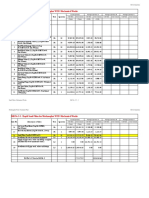

Detailed Estimate

City Governance Project

Local Government Engineering Department

Package Summary

Package Code : GCC B2 14 District : GAZIPUR

Part No Scheme Code/ Scheme Name Estimated Amount

(1) (33330-17-10009) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 4,413,586.00

- Provisional Sum

(2) (33330-17-10001) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 486,909.75

-Installation of Test Tubewell

(3) (33330-17-10012) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 12,294,204.46

Installation of PTW 400X200

(4) (33330-17-10003) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 6,266,766.59

- Electro-Mechanical Works

(5) (33330-17-10004) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 5,798,608.03

- Construction of Pump House

(6) (33330-17-10005) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 272,600.80

- Chlorination System

(7) (33330-17-10006) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 211,281.00

- Supply of Operation and Maintenance Tools

(8) (33330-17-10007) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 6,779,400.00

- Electric Service Connection

(9) (33330-17-10008) Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 respectively. 150,986,104.41

- Construction of Pipeline

Package Total : 187,509,461.04

Package Code : GCC B2 14 Page 1

Part : 1

Scheme Code : 33330-17-10009 Scheme Preparation Date :

Road Code : FY & Type of Rate : 2015-2016 (General)

Financial Year : 2016-2017 District : GAZIPUR

Name of the Scheme : Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 Upazila : GAZIPUR-S

respectively.

- Provisional Sum

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

1. PS item Provisional Sum for, compensation for shifting of water supply, LS 1.00 4413586 4413586.00

electrical, telephone, gas lines, re-test tubewell, and any items

of works beyond BOQ etc.(To be spent on approval of the

project Director as actual expenditure specially for utility

services)

Part : 1 TOTAL : 4,413,586.00

Part : 2

Scheme Code : 33330-17-10001 Scheme Preparation Date :

Road Code : FY & Type of Rate : 2015-2016 (General)

Financial Year : 2016-2017 District : GAZIPUR

Name of the Scheme : Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 Upazila : GAZIPUR-S

respectively.

-Installation of Test Tubewell

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

2. 27.1 PWD Mobilization for test boring or observation well: each set 1.000 3.00 3.000

2014 Transportation of materials,equipmenrs, tools and plants and

boring rig to work site. Construction of derric and dismantling 3.000 7034.00 21102.00

the same. Cleaning the site after completion of the work

accepted by the Engineer.

3. 10.02.01 Boring by using 100mm dia cutter and 38mm dia GI Pipe and m From 0.00m to 50 m=50m 50.000 50.000 3.00 150.000

other equipment capable of drilling up to a depth of 500m by

water jet system through all sorts of strata, protection of 150.000 123.98 18597.00

caving by supplying necessary casing pipe, collection of soil

samples at every 3m interval and at every change of strata

and preserve them for analysis, withdrawal of boring pipes &

casing pipes etc. all complete as per specification and direction

of the E-I-C.

From 0.0m to 50m = 50m

Package Code : GCC B2 14 Page 2

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

4. 10.02.02 Boring by using 100mm dia cutter and 38mm dia GI Pipe and m From 51.0 m to 100.0 m 50.000 50.000 3.00 150.000

other equipment capable of drilling up to a depth of 500m by =50m

water jet system through all sorts of strata, protection of

caving by supplying necessary casing pipe, collection of soil 150.000 136.38 20457.00

samples at every 3m interval and at every change of strata

and preserve them for analysis, withdrawal of boring pipes &

casing pipes etc. all complete as per specification and direction

of the E-I-C.

From 50m to 100m = 50m

5. 10.02.03 Boring by using 100mm dia cutter and 38mm dia GI Pipe and m From 100.0 m to 152m = 52.000 52.000 3.00 156.000

other equipment capable of drilling up to a depth of 500m by 52 m

water jet system through all sorts of strata, protection of

caving by supplying necessary casing pipe, collection of soil 156.000 150.01 23401.56

samples at every 3m interval and at every change of strata

and preserve them for analysis, withdrawal of boring pipes &

casing pipes etc. all complete as per specification and direction

of the E-I-C.

From 100m to 152m = 52m

6. 10.02.04 Boring by using 100mm dia cutter and 38mm dia GI Pipe and m From 152.0 m to 48.000 48.000 3.00 144.000

other equipment capable of drilling up to a depth of 500m by 200.0m=48m

water jet system through all sorts of strata, protection of

caving by supplying necessary casing pipe, collection of soil 144.000 164.89 23744.16

samples at every 3m interval and at every change of strata

and preserve them for analysis, withdrawal of boring pipes &

casing pipes etc. all complete as per specification and direction

of the E-I-C.

From 152m to 200m = 48m

7. 10.03.06 Supplying and lowering 38mm dia water grade PVC pipe each At bottom of sand trap 1.000 3.00 3.000

having wall thickness 2.5m to 3.0mm (‘D’ Class Aziz

pipe/equivalent), PVC sand trap of length 3.0m with cap, PVC 3.000 60.01 180.03

strainer of desired slot installing at the middle of the most

suitable water bearing strata. 38mm dia GI pipe of best quality

of length 1.52m with MS welded flat bar on each side to

prevent from rotation up to the desired depth, fitting fixing the

hand pump No. 6 etc. including the cost of solvent cement,

socket adapter, filling medium sand up to 18.0m above

strainer and the remaining portion with available soil from

boring etc. all complete as per standard specification and

direction of the E-I-C

Best quality 38mm dia PVC cap

Package Code : GCC B2 14 Page 3

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

8. 10.03.03 Supplying and lowering 38mm dia water grade PVC pipe m 38mm dia water grade 150.000 150.000 3.00 450.000

having wall thickness 2.5m to 3.0mm (‘D’ Class Aziz uPVC pipe and sand trap

pipe/equivalent), PVC sand trap of length 3.0m with cap, PVC

strainer of desired slot installing at the middle of the most 450.000 117.11 52699.50

suitable water bearing strata. 38mm dia GI pipe of best quality

of length 1.52m with MS welded flat bar on each side to

prevent from rotation up to the desired depth, fitting fixing the

hand pump No. 6 etc. including the cost of solvent cement,

socket adapter, filling medium sand up to 18.0m above

strainer and the remaining portion with available soil from

boring etc. all complete as per standard specification and

direction of the E-I-C

38mm dia water graded PVC pipe having thickness 2.5-

3.00mm (‘D’ class Aziz brand/equivalent) pipe sand trap

9. 10.03.04 Supplying and lowering 38mm dia water grade PVC pipe m 38mm dia strainer made 6.000 3.00 18.000

having wall thickness 2.5m to 3.0mm (‘D’ Class Aziz with water grade uPVC

pipe/equivalent), PVC sand trap of length 3.0m with cap, PVC pipe

strainer of desired slot installing at the middle of the most

suitable water bearing strata. 38mm dia GI pipe of best quality 18.000 116.14 2090.52

of length 1.52m with MS welded flat bar on each side to

prevent from rotation up to the desired depth, fitting fixing the

hand pump No. 6 etc. including the cost of solvent cement,

socket adapter, filling medium sand up to 18.0m above

strainer and the remaining portion with available soil from

boring etc. all complete as per standard specification and

direction of the E-I-C

38mm dia water graded PVC strainer having thickness 2.5 –

3.0mm (‘D’ class Aziz brand/equivalent) of recommended slot

size

10. PHE/CRDP- TW Material Supply and installation: Supply and lowering each Just below foot valve 1.000 3.00 3.000

Gazipu following well fixtures upto desired depth, placing of strainer at

the middle of most suitable water bearing aquifer including the 3.000 113.00 339.00

cost of solvent cement, filling bore hole with medium sand

(FM: 1.5) upto 18.0 m above the top of strainer and remaining

portion with available withdrawn soil from boring etc all

complete as per standard practice, drawing and direction of

EIC (depth of test tubewell and strainer location will be

decided by the Engineer of Implementing Agency in

consultation with the MDS Consultant based on borehole

lithology).

Best quality

75mmX 38mm dia uPVC reducer.

11. 10.22.02 Supplying tube well fixtures at working site, etc. all complete m 75mm dia water grade 45.000 45.000 3.00 135.000

as per standard practice, specifications and direction of the E-I- pipe for upper casing

C.

75mm dia water grade PVC blank pipe/sand trap having wall 135.000 316.17 42682.95

thickness 3.5mm to 4.1mm (‘C’ class Aziz/ equivalent Brand)

Package Code : GCC B2 14 Page 4

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

12. 02/DSM/CG TW Material Supply and installation: Supply and lowering each Modified deep set 1.000 3.00 3.000

P following well fixtures upto desired depth, placing of strainer at

the middle of most suitable water bearing aquifer including the 3.000 29117.00 87351.00

cost of solvent cement, filling bore hole with medium sand

(FM: 1.5) upto 18.0 m above the top of strainer and remaining

portion with available withdrawn soil from boring etc all

complete as per standard practice, drawing and direction of

EIC (depth of test tubewell and strainer location will be

decided by the Engineer of Implementing Agency in

consultation with the DSM Consultant). Modified Deep Set

(force mode) pump with #6 head complete set (as developed

by MAWTS) including pump head, stand pipe assembly, top

rod assembly , pump rod (9mm dia SS rod 32.92m long in 9

pieces), cyliner assembly (75mm dia made of uPVC with SS

linning 1m long), piston assembly, foot valve, reducing socket

(75mmx38mm) etc as per design, drawing and specification

with pump setting depth not less than 30m (MAWTS or

approved equivalent brand)

13. 05/DPHE/C TW Development : Complete development of well for atleast LS 3.00 1500 4500.00

RDP 24 hrs pumping.untill sand, turbidity free satisfactory yield is

reached etc all complete as per direction of EIC.

14. 27.6 PWD TW Disinfections: Disinfection of well by 3 kg bleaching power LS 3.00 380 1140.00

2014 ( 33% strength) including supply of sufficient quantity, making

chlorinated water having 150 mg/l available free chlorine and

applying to the tube well. After 24 hrs of retention, chlorinated

well water is to be pumped out untill chlorine free clear water

is reached etc all complete as per specification and direction of

EIC.

15. BUET pkg Seive Analysis of soil sample and design of Production TW: LS 3.00 39929 119787.00

Seive analysis of selected soil samples at various

depth(collected during drilling), ploting of grain size

distribution curve of each sample, leading to ascertain the best

suitable sustained aquifer, preparation of borehole log and

other data table, complete design of Production TW including

shrouding materials. This includes collection of soil sample,

packing in poly bag (each sample 500 gm) and transportation

to the soil testing laboratory of BUET, cost of analysis,

collection of report and submission to EIC, etc. all complete as

per specification and direction of Engineer-in charge. [The

work shall be done under the direct supervision of EIC]

Package Code : GCC B2 14 Page 5

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

16. 07/DPHE/C "Water qulityTest: Test for water quality parameters form each Water quality 12.000 3.00 36.000

RDP water testing laboratory at DPHE/BUET or any other

recognized laboratory. This includes collection of water sample 36.000 1500.00 54000.00

from the test tube-well in sample collection bottles previously

collected from the laboratory, filling in air-tight glass bottles

having no air space inside after taking advice from the

concerned laboratory regarding collection of sample,

preservation and transportation to the laboratory, cost of test,

collection of test report and submission to the EIC, etc

complete as specification and direction of Engineer in Charge.

(The work shall be done under the direct supervision of EIC).

[Parameters: Electro conductivity, PH, Total Alkanity(HCO3),

Hardness (CaCO3), TDS, Chloride, Arsenic, Iron, Lead,

Manganese (Mn), Total coliform or as decided by the EIC]. "

17. 10.76 Construction of platform of size 1.4mx1.0m as per drawing each Test Tubewell Platform 1.000 3.00 3.000

with 75mm thick Cement Concrete (1:2:4) over a layer of brick

flat soling and providing 125mmx75mm brick band all around 3.000 4946.01 14838.03

in/c finished with 12mm thick cement plaster (1:4) with neat

cement finishing, providing outlet drain up to 1m long, etc. all

complete as per direction of the E-I-C.

Part : 2 TOTAL : 486,909.75

Part : 3

Scheme Code : 33330-17-10012 Scheme Preparation Date : 27-Apr-2017

Road Code : FY & Type of Rate : 2015-2016 (General)

Financial Year : 2016-2017 District : GAZIPUR

Name of the Scheme : Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 Upazila : GAZIPUR-S

respectively.

Installation of PTW 400X200

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

18. PWD/27.49. Boring: Execution of 800 mm dia boring through all sorts of m 0-50 50.000 50.000 3.00 150.000

1 strata by reverse circulation or any other approved method

(Method other than reverse circulation is to be applied only for 150.000 1137.00 170550.00

wells deeper than 152 meter). For boring 800 mm dia vertical

hole up to designed depth and collection of soil samples at

every 3 meter interval and at every change of formation

including sinking and withdrawing necessary casing pipe and

all necessary arrangements complete as per specification and

accepted by the Engineer. (Measurement will be allowed form

G.L. to bottom of the blind pipe and the rate is required for

caving and siltation)

From 0.0 m to 50 m = 50 m

Package Code : GCC B2 14 Page 6

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

19. PWD/27.49. Boring: Execution of 800 mm dia boring through all sorts of m 50-100m 50.000 50.000 3.00 150.000

2 strata by reverse circulation or any other approved method

(Method other than reverse circulation is to be applied only for 150.000 1308.00 196200.00

wells deeper than 152 meter). For boring 800 mm dia vertical

hole up to designed depth and collection of soil samples at

every 3 meter interval and at every change of formation

including sinking and withdrawing necessary casing pipe and

all necessary arrangements complete as per specification and

accepted by the Engineer. (Measurement will be allowed form

G.L. to bottom of the blind pipe and the rate is required for

caving and siltation)

From 50 m to 100 m = 50 m

20. PWD/27.49. Boring: Execution of 800 mm dia boring through all sorts of m 100-152m 52.000 52.000 3.00 156.000

3 strata by reverse circulation or any other approved method

(Method other than reverse circulation is to be applied only for 156.000 1504.00 234624.00

wells deeper than 152 meter). For boring 800 mm dia vertical

hole up to designed depth and collection of soil samples at

every 3 meter interval and at every change of formation

including sinking and withdrawing necessary casing pipe and

all necessary arrangements complete as per specification and

accepted by the Engineer. (Measurement will be allowed form

G.L. to bottom of the blind pipe and the rate is required for

caving and siltation)

From 100 m to 152 m = 52 m

21. PWD/27.49. Boring: Execution of 800 mm dia boring through all sorts of m 152-200m 48.000 48.000 3.00 144.000

4 strata by reverse circulation or any other approved method

(Method other than reverse circulation is to be applied only for 144.000 1730.00 249120.00

wells deeper than 152 meter). For boring 800 mm dia vertical

hole up to designed depth and collection of soil samples at

every 3 meter interval and at every change of formation

including sinking and withdrawing necessary casing pipe and

all necessary arrangements complete as per specification and

accepted by the Engineer. (Measurement will be allowed form

G.L. to bottom of the blind pipe and the rate is required for

caving and siltation)

From 152 m to 200 m = 48 m

22. PWD/27.50. Supplying the following tube-well fixtures and pipes each MS Cap 1.000 3.00 3.000

1 conforming to standard BS-1387 & BDS-1031, having chemical

composition (in%) Carbon 0.17-0.25, Manganese 0.95-1.20, 3.000 1581.00 4743.00

Sulphur 0.060 max, Phosphorous 0.060 max, Tensile

properties: miminum Yield Strength 188 MPa, minimumTensile

Strength 313 MPa and marking for a) Manufacturer b) Material

c) Wall thickness d) Nominal outside dia e) Intended use etc.

on the body of the pipe at working site as per standard

practice and accepted by the Engineer.

200 mm dia M.S. cap 6mm thick for blind pipe/ sand strap

Package Code : GCC B2 14 Page 7

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

23. PWD/27.50. 200 mm dia 6 mm thick tube well pipe and blank G.I. pipe of m Blind pipe 77.000 77.000 3.00 231.000

2 wt. 33.45 kg per meter can withstand minimum 700 psi

hydraulic pressure 231.000 7005.00 1618155.00

24. PWD/27.50. 200 mm dia stainless steel strainer of continuous slot having m SS Filter 42.000 42.000 3.00 126.000

3.1 38.36 kg per meter.

126.000 16973.00 2138598.00

25. PWD/27.50. 200 mm x 400 mm dia 6 mm thick M.S. reducer. each Reducer 1.000 3.00 3.000

4

3.000 13118.00 39354.00

26. PWD/27.50. 400 mm dia 6 mm thick M.S. housing pipe (Welded) m Housing 81.000 81.000 3.00 243.000

5

243.000 13409.00 3258387.00

27. PWD/27.50. Centralizer made with 12 mm dia M.S. rod of approved design each Centralizer 20.000 3.00 60.000

7

60.000 364.00 21840.00

28. PWD/27.50. 450 mm dia M.S. cap of 6 mm thick for housing pipe covering. each MS Cap 1.000 3.00 3.000

8

3.000 1977.00 5931.00

29. PWD/27.53 Pumping test of the well by designed turbine/submersible hour Pumping Test 12.000 3.00 36.000

pump with supply of testing equipments for pressure/ velocity/

discharge etc. and all materials for 12 hours including yield 36.000 1044.00 37584.00

drawn and recovery test etc. complete as per specification and

accepted by the Engineer.

30. CTEIP/PTW Temporary Housing Pipe: Installation of temporary M.S. pipe m Temp Housing 20.000 20.000 3.00 60.000

/4.7 (inner dia 800 mm and thickness 3mm) to protect the bore

hole from cave in up to required depth including supply of 60.000 3500.00 210000.00

material, withdrawn of the installed pipe after work. All

complete as per direction of the Engr.-in -charge.

31. 09/DPHE/C Verticality Test: Carry out test for verticality and straightness LS 3.00 20000 60000.00

RDP of the upper well casing (housing pipe) with proper equipment

and arrangement. (Measurement to be taken at 3 m interval.

Deviation should not be more than 0.5m per meter at any

point from vertical axis in the housing length) all complete as

per specificaation and direction of EIC.

Package Code : GCC B2 14 Page 8

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

32. 10.67 Preparation and making gravel pack around the tube well cum Gravel Pack upto 15m 60.000 0.470 28.200 3.00 84.600

fixtures and bore hole with supply of designed graded pea above filter

gravel (passing through 10 mesh and retained on 40 mesh)

including screening, washing etc. all complete as per standard Gravel Pack at bottom 10.000 0.500 5.000 3.00 15.000

specifications and direction of the E-I-C. (The rate is inclusive

of the cost of extra amount required the caving and extra 99.600 4848.38 482898.65

depth below the tube well fixtures. Shrouding should not be

more than 15m above the strainer and measurement should

be allowed from bottom of the tube well fixture to top of the

gravel pack).

33. 10/DPHE/C Development of Well: Complete development of well by air-lift LS 3.00 20000 60000.00

RDP/1 pumping and alternate surging by using an air-compressor of

suitable capacity (the compressor shall be equipped with

means of controlling the volume of air using a 25mm diameter

hose pipe assembly will be lowered up to half of the total well

depth. Air will be injected at maximum 6 kg/cm2 to cause an

upward movement of air and water sufficient to bring out mud

particles and sediments) untill sand, turbidity free satisfactory

yield is reached for 1st calgon treatment followed by over

pumping for the 2nd and 3rd calgon treatment including

supply and adding of chemicals for treatment prior to each

stage of developement. Over pumping, surging and

backwashing using turbine pump of capacity at least 1.5 times

the design discharge(preferably diesel engine driven turbine

pump of variable speed should be used) should be done for

removing mud cakes from borehole wall etc all complete as

per specification and direction of EIC (developement should be

started within 24 hrs after completion of shrouding).

1st Stage (50 kg calgon + 25 kg bleaching powder)

34. 10/DPHE/C Development of Well: Complete development of well by air-lift LS 3.00 20000 60000.00

RDP/2 pumping and alternate surging by using an air-compressor of

suitable capacity (the compressor shall be equipped with

means of controlling the volume of air using a 25mm diameter

hose pipe assembly will be lowered up to half of the total well

depth. Air will be injected at maximum 6 kg/cm2 to cause an

upward movement of air and water sufficient to bring out mud

particles and sediments) untill sand, turbidity free satisfactory

yield is reached for 1st calgon treatment followed by over

pumping for the 2nd and 3rd calgon treatment including

supply and adding of chemicals for treatment prior to each

stage of developement. Over pumping, surging and

backwashing using turbine pump of capacity at least 1.5 times

the design discharge(preferably diesel engine driven turbine

pump of variable speed should be used) should be done for

removing mud cakes from borehole wall etc all complete as

per specification and direction of EIC (developement should be

started within 24 hrs after completion of shrouding).

2nd Stage (25 kg calgon + 10 kg bleaching powder)

Package Code : GCC B2 14 Page 9

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

35. 10/DPHE/C Development of Well: Complete development of well by air-lift LS 3.00 15000 45000.00

RDP/3 pumping and alternate surging by using an air-compressor of

suitable capacity (the compressor shall be equipped with

means of controlling the volume of air using a 25mm diameter

hose pipe assembly will be lowered up to half of the total well

depth. Air will be injected at maximum 6 kg/cm2 to cause an

upward movement of air and water sufficient to bring out mud

particles and sediments) untill sand, turbidity free satisfactory

yield is reached for 1st calgon treatment followed by over

pumping for the 2nd and 3rd calgon treatment including

supply and adding of chemicals for treatment prior to each

stage of developement. Over pumping, surging and

backwashing using turbine pump of capacity at least 1.5 times

the design discharge(preferably diesel engine driven turbine

pump of variable speed should be used) should be done for

removing mud cakes from borehole wall etc all complete as

per specification and direction of EIC (developement should be

started within 24 hrs after completion of shrouding).

3rd stage (25 kg calgon + 10 kg bleaching powder)

36. 12/DPHE/C Step Draw down Test: Conduct step draw down test (four LS 3.00 30000 90000.00

RDP steps) after each calgon treatment for 10hrs using turbine

pump at variable discharge( 50%, 75%, 100% and 150% of

design discharge) followed by recover test etc. all complete as

per specificaation, drawing and direction of EIC.

37. 13/DPHE/C Sealing over gravel pack: Sealing of annular space around the m Clay sealing 5.000 5.000 3.00 15.000

RDP well casing 3 m thick on the top of gravel pack and 5 m of

impervious clay layer (if exist) by dropping clay ball made of 15.000 1666.00 24990.00

50% puddle clay and 50% bentonite from top as per

specification, drawing, design and direction of EIC (sealing of

impervious clay layer will not be done if it does not exist).

38. 10.71 Filling the bore hole around the tube well from top of the m Borehole filling 144.000 144.000 3.00 432.000

shrouding up to the bottom of sanitary seal by withdrawal of

selected soil or local clay, etc. all complete as per standard 432.000 45.70 19742.40

specifications and direction of the E-I-C.

39. 10.62 Making a sanitary seal up to a minimum depth of 6m from G.L. cum Sanitary Seal 6.000 0.377 2.262 3.00 6.786

or as specified including the supply of approved quality of

cement, sand and brick aggregate, (10mm down graded) in 6.786 10645.08 72237.51

proportion 1:1.5:3 as per standard specification, etc. all

complete as per direction of the E-I-C.

40. 27.54 PWD Disinfections of well: Disinfection of well including including LS 3.00 2211 6633.00

supply of sufficient quantity of bleaching powder ( 33%

strength), chlorinated water having 150 ppm available free

chlorine complete as per standard specification and accepted

by the Engineer.

41. 16/DPHE/C Water qulityTest: Test for water quality parameters form each Water Quality 11.000 3.00 33.000

RDP laboratory at DPHE/BUET or any other recognized laboratory

including supply of smple collection bottles, collection of water 33.000 1500.00 49500.00

sample, transportation, cost of test, etc. and submission of test

report to the EIC.(Test parameters: Ellectro conductivity, PH,

Iron, Manganese, Arsenic, Hardness, Alkalinity, Boron, and

Barium, Total Coliform or as decided by the EIC)

Package Code : GCC B2 14 Page 10

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

42. CRDP/LGED RL Pillar: Taking RL and GPS reading at Pump base and LS 3.00 5000 15000.00

marking on a RCC pillar including construction and fixing at a

suitable place as per drawing, design and direction of E-I-C.

43. SO Providing and maintaining semi pucca site office (Appendix 5) LS 3.00 150000 450000.00

4.01.05.02 with necessary furniture, sanitary & electrical/ power facilities,

water supply arrangement, office and survey equipment for

the use of the Engineer and his staff, all complete including

remova of structures and restoration of the site on completion

of the work. The contractor shall submit the detailed plan and

drawing of the site office for the approval of the Engineer. The

site office should be provided with sufficient natural light, heat

protecting ceiling, dam proofing etc. as per direction of the

EIC. All materials, equipments and plant, furniture, fittings

recovered from dismantling the office and removing access

road will be the property of the contractor upon completion of

the work. The contractor will responsible for maintaining the

facilities of the site office in good condition throughout the

contract period and payment of this item shall be made only

with the final bill

Area of the field office : 50 sqm

44. SB 6.01.18 Supplying Sign Board at site of 1.5mx1.0m size in plain CI LS 3.00 5000 15000.00

sheet; painting, writing, erecting & fixing with bamboo

including all complete as per direction of Engineer-in-Charge.

LumSum

45. 5.2 Providing pure drinking water/sanitary facilities, First Aid box, LS 3.00 20000 60000.00

Safety sign boards, Safety measures, chainage marking pegs,

female labour toilet and rest shed etc. complete as per

specification and direction of the EIC.

46. 4.01.08 As-Built Drawings: Providing 3 full sets of as-built drawings of per scheme As built 1.000 1.00 1.000

the completed works subject to Engineer's approval in

AutoCAD software in standard drawing paper. The As-Built 1.000 16365.08 16365.08

Drawing shall clearly show the lines and dimensions of the

permanent construction actually made based on the changes

to the original design from time to time as ordered by the

Engineer or proposed by the Contractor and approved by the

Engineer. One set of as-built drawings shall be considered for

final measurement and payment. The soft copy of the as-built

drawings must be submitted to the Design Unit, LGED for

future reference. If the contractor does not supply the as-

built drawings by the date stated in the Particular Conditions of

Contract (PCC), or they do not receive the Engineer's approval,

the Engineer shall withhold the amount stated in the PCC from

the payment due to the contractor.

Package Code : GCC B2 14 Page 11

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

47. PWD/27.49. Boring: Execution of 800 mm dia boring through all sorts of m 200-210 10.000 10.000 3.00 30.000

5 strata by reverse circulation or any other approved method

(Method other than reverse circulation is to be applied only for 30.000 1989.00 59670.00

wells deeper than 152 meter). For boring 800 mm dia vertical

hole up to designed depth and collection of soil samples at

every 3 meter interval and at every change of formation

including sinking and withdrawing necessary casing pipe and

all necessary arrangements complete as per specification and

accepted by the Engineer. (Measurement will be allowed form

G.L. to bottom of the blind pipe and the rate is required for

caving and siltation)

From 200 m to 250 m = 50 m

48. PTW/DSM/I Complete installation of 150mm dia deep tube-well fixtures m Installation 201.000 201.000 3.00 603.000

ns such as expanded top pipes, reducer, tube well pipes, strainer,

blind pipe, pipe cap etc. fitting and fixing with best quality PVC 603.000 3370.94 2032676.82

solution, iron screws and PVC tape and placing in position with

proper size bamboo split centralizer @3m c/c in strainer

portion in/c. blank pipe etc. all complete as per standard

practice, specifications and direction of the E-I-C.

49. PL/CT/05.3 Supply and laying of MS Presure Pipe: Supplying, m 200 MS pipe 35.000 3.00 105.000

Laying,Fitting, Fixing and Jointing the following pipes including

specials ( API-5L,Grade B, ERW pipe) with welded 105.000 4661.00 489405.00

flange(12.5mm thick)/Socket,including welding, cutting,

shaping, 3mm thick rubber gaskets, painting with two coats of

high class enamel paint over a coat of anticorrosive paint, nuts

and bolts for each flanged joints etc. All complete as per

direction of E/C. M.S pipes (seamless) minimum pipe length

should be 6m.

200 mm dia of thickness 6.0 mm

Part : 3 TOTAL : 12,294,204.46

Package Code : GCC B2 14 Page 12

Part : 4

Scheme Code : 33330-17-10003 Scheme Preparation Date :

Road Code : FY & Type of Rate : 2015-2016 (General)

Financial Year : 2016-2017 District : GAZIPUR

Name of the Scheme : Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 Upazila : GAZIPUR-S

respectively.

- Electro-Mechanical Works

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

50. 8.45/8.46 "Supply of submersible pump motor set: Supply of submersible set Submersible pump (Inside 1.000 3.00 3.000

PWD pump motor set: Supplying the following capacity multistage housing)

energy efficient sub-mersible water pump motor set of

GRUNDFOS/WILO/KSB/PEDROLLO and made in USA / JAPAN 3.000 835303.00 2505909.00

/ EU/iNDIA Countries comprising of 2900 RPM, 3-phase sub-

mersible re-windable type motor suitable for operation at 400

± 5% volt, 50 Hz AC supply with 18.29 meter (60'-0") column

pipe (AP1-5L, grade B) with flange, gasket, non-return valve,

pressure guage, 40 meter (131'-0") long required marine cable

in a single length etc. complete in all respect manufactured

inbuilt with the pump bowl etc all complete as per specification

and direction of EIC.[All things are to be manufactured

according to DIN/NEMA/IEC/VDE/JIS and ISO level (ISO

9906.:2012 grade 3B or equivalent) and as per technical

specification] Motor Rating: Power: 30 kW to 38 kW as per

pump design based on pump test report; Temperature: ≤

300C ; Type of enclosure: IP 68; Insulation: Class F; Shaft

seal: Water and wear resistant; Alignment: Vertical; Starter:

Star-Delta. Cable Size: Not < 3X16 mm2, 2x3m length, PVC

sheathed copper wire, water registant insulated cable as

requirement of motor rating with tolerance of voltage

fluctuation(± 10%). Pump Capacity: Discharge: 70 m3/hr at

90m Head or 90 m3/hr at 95m Head (discharge and head of

pump will be as per pump design based on pump test report of

PTW); Service fluid: Water; Stages: As required; Rotation: Anti

clock; Bearing: Water cooled and sand channel; Material of

pump casing: Stainless steel AISI-304; Impeller: Stainless steel

AISI-304; Accessories: Inlet strainer, Priming screw, Stop ring

to prevent upward thrust. [ Pump capacity will be decided by

the Engineer in charge in consultation with the DSM Consultant

as per pump design based on pump test report of the relevent

PTW].

Package Code : GCC B2 14 Page 13

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

51. 17.a PWD Star-Delta Motor control Panel: Supply, installation, testing and each Control panel in PH 1.000 3.00 3.000

commissioning of metal clad surface mounting type 3 - phase

400 ± 5% volt 50 Hz automatic star-delta motor control panel 3.000 65323.50 195970.50

for submersible Pump Motor set manufactured in accordance

with DIN/NEMA/IEC/VDE/JIS/BS and latest ISO Standard

incorporating circuit breaker of required capacity, Ammeter,

and Voltmeter with selector switch with proper circuit ratio and

burden, adequate rated MCCB Rated insulating voltage: 660

V, rated operating voltage: 415 V, short circuit: 50kA for 1 sec

rms. Metering Electronics: Energy, Volt, Amphere. Safety: all

controled wired circuits through PVC conduit and components

to have Transparent Shroud and all live parts should have

acrylic shroud. Protection: Overload, Termal, Over Voltage,

Dry run, Reverse Phase, etc. with indicating lamps for 3-phase

and on trip etc.all coplete for the following capacity as per

specification and direction of EIC.

30/38 KW

52. 1CRDP/LGE Pump motor Test : Conducting test for submersible pump set Test from BUET 1.000 1.00 1.000

D motor including stand by set for head, discharge and efficiency

from BUET including carrying and testing charge etc all 1.000 27889.00 27889.00

complete as per direction of EIC. (combined pump-motor

efficiency must not be less than 60

%).

[ only on

satisfactory pump test report, contractor will allowed to use

the same in work]

53. 03/CRDP/L Automatic Power Factor Improvement Plant: Supply, each In Pump House 1.000 3.00 3.000

GED installation, testing and commissioning of automatic Power

Factor improvement plant 30~40 KVAR in five steps, sheet 3.000 179000.00 537000.00

steel fabricated, floor mounting, tropicalized designed, indoor

type low tension swtchgear for 3-phase, 4 wire, 50 Hz, 415

Volt AC system including TP and Bus bar of suitable size,

capacitor tolerance: -5% to +10%, linear load tolerance:

115%, manufactured and tested as per

NEMZ/EPCOS/SCHNEIDER/GE, Protection: MCCB; Over heat,

cooling arrangement, etc. for the following capacity as per

specification and direction of EIC. Etc all complete as per

specification and direction of EIC.

54. 9.4 PWD Column Pipe: Supplying and fitting fixing column pipe made of each Submersible motorto top 15.000 3.00 45.000

seamless steel pipe (ERW, API-5L, grade- B), each 3m long level

with 12mm thick MS flange at both end to be connected with

submersible pump motor (column pipe to be supplied without 45.000 16574.00 745830.00

paint for inspection and after acceptance, to be painted with 2

coats sysnthetic enamel paint over a prime coat of anti

corrosive paint) including supply of gasket, nut-bolts etc all

complete as per sample approved by EIC.

150 mm dia

Package Code : GCC B2 14 Page 14

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

55. 10.6 PWD Marine Cable: Supplying and fixing additional marine cablePVC m From Submersible motor 120.000 120.000 3.00 360.000

sheathed copper wire, water resistant insulated cable as to control panel

requirement of the motor rating with tolerance of voltage

fluctuation (± 10%) for sub-mersible pump motor 360.000 1620.00 583200.00

manufactued according DIN/ISO standards (foreign made) and

as per sample approved by EIC (In access of 3.0 m supplied

with the pump motor).

3C-16 sq mm

56. 02/CRDP/L Timer Switch: Supply, installation, testing of 230 Volt, single each In pump room 1.000 3.00 3.000

GED phase, 50 Hz electronic timer switch with multiple period

setting with programmable interval between operation and on- 3.000 20000.00 60000.00

off dealy for on-off application of water pump as per

specification and direction of EIC.

57. 8.01.1.3 Supplying, fitting and fixing main/sub-main switches with fuse each In pump house 1.000 3.00 3.000

on live side and neutral line on concealed iron frame

(Bangladeshi made of prior approved quality) or equivalent as 3.000 5443.87 16331.61

per specification and direction of the E-I-C.

500 Volts ICTP

100 amps

58. 12.3/12.4 Installation & Testing: Instalation, testing and commissioning each 1.000 3.00 3.000

PWD of the following capacity deep well sub-mersible pump motor

set by lowering down and connecting pump bowl assembly 3.000 12673.50 38020.50

and column pipes with marine cable with the help of chain

pully after checking and testing the pump motor set including

filling distilted water supplying and fixing a long bend, 6.35

mm thick M.S sheet tube well cover required, heavy duty

holding clamp with nut-bolts and making all electrical and pipe

connection complete as required as per direction of EIC.

Motor 30/38 KW

59. 01/DWASA/ Complete installation of 2000mm dia deep tube-well fixtures m In delivery line 8.000 3.00 24.000

CRDP such as expanded top pipes, reducer, tube well pipes, strainer,

blind pipe, pipe cap etc. fitting and fixing with best quality PVC 24.000 2762.00 66288.00

solution, iron screws and PVC tape and placing in position with

proper size bamboo split centralizer @3m c/c in strainer

portion in/c. blank pipe etc. all complete as per standard

practice, specifications and direction of the E-I-C.

60. 04/CRDP/L 2) 150 mm dia. multi jet water flow meter conforming ISO each In delivery line 1.000 3.00 3.000

GED 4064 and EEC directives 73/33 or equivalent AWWA Standard (

made in Taiwan/Italy/UK/France/Germany or equivalent EU 3.000 45000.00 135000.00

brand) [Water flow meter will be tested from BUET as per

standard specification at contractor's cost and only on

satisfactory test report, contractor will be allowed to use the

same in work.

61. 02/DWASA/ 150 mm dia GI Bend 45 degree each In delivery line 2.000 3.00 6.000

CRDP

6.000 4701.00 28206.00

62. 03/DWASA/ 150 mm dia GI Bend 90 degree each Just over column pipe 1.000 3.00 3.000

CRDP

3.000 5092.00 15276.00

Package Code : GCC B2 14 Page 15

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

63. 04/DWASA/ 150 mm x 200 mm GI Enlarger with welded flange at both each Before interconnection 1.000 3.00 3.000

CRDP end.

3.000 7111.00 21333.00

64. 05/CRDP/L Dial type 0~ 12 bar Pressure Gauge including air vent cock, each At just after water meter 1.000 3.00 3.000

GED necessary pipe connection and all other accessories and

consumable. (country of origin: Japan/Germany/EU/Korea) 3.000 4970.00 14910.00

65. 05/DWASA/ 150 mm dia MS flange adapter with rubber ring, nut-bolts etc each 2.000 3.00 6.000

CRDP

6.000 1913.00 11478.00

66. 06/DWASA/ 150 mm dia MS Blind Flange/End Cap with rubber ring, nut- each At delivery line 1.000 1.00 1.000

CRDP bolts etc for capping the discharge measuring pipe.

1.000 1333.00 1333.00

67. 07/DWASA/ 16 mm dia nut-bolts (best quality, hot deep) each For different place 100.000 3.00 300.000

CRDP

300.000 30.00 9000.00

68. 08/DWASA/ 3 mm thick rubber gasket (150mm dia) each 40.000 3.00 120.000

CRDP

120.000 40.00 4800.00

69. 09/DWASA/ 150 x 150 x 150 mm dia MS Tee with welded fange at each each 1.000 3.00 3.000

CRDP end including rubber gasket and nut-bolts

3.000 8000.00 24000.00

70. 10/DWASA/ 150mm dia loose flange (16mm thick) including cutting GI/MS each 6.000 3.00 18.000

CRDP pump delivery pipe according to required size, welding loose

flange for fitting fixing S/V, Bulk Meter, NRV, etc 18.000 663.00 11934.00

71. 19/DPHE/C Well Head Sole Plate: Supply and fitting fixing 12mm thick set 1.000 3.00 3.000

RDP 500mm dia. MS well head head sole plate (pump supporting

plate) integral with 125/150mm dia, 300 mm long flange 3.000 5000.00 15000.00

ended MS short piece passing through the head plate with

welded connection including making a provision for measuring

the drawdown and passing of submersible pump cable etc.all

complete as per specification, drawing and direction of EIC.

72. 6.09.08.10 Supplying and Installation of different diameter Gate Valve each 150mm Sluice Valve 1.000 3.00 3.000

used in any pipe line system including different dia flange,

dresser 3.000 38806.71 116420.13

rubber washer, nut, bolts, gasket, welding, fitting, fixing etc.

all complete as per drawing , specification and direction of

the E-I-C.

150mm dia gate valve

Package Code : GCC B2 14 Page 16

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

73. 21/DPHE/C Supply & fitting Non-return Valve in pump delivery line : each In delivery line just before 1.000 3.00 3.000

RDP Supplying and fitting fixing swing type Cast Iron Non-return sluice valve

Valves on thrust block with cast iron body , reflux valve cover

plate, flap, valve disk and flap lined with leather, cast iron 3.000 15000.00 45000.00

hanging arm, stainless steel louver shaft and bolt with cover

gasket etc. including all other standard accessories

(Manufacture according to DIN/ISO 9001-2000 standard)

including rubber gasket, nut-bolts (MPL or equivalent brand

approved by the EIC).

For 150mm dia Non-return valve

74. 5.02.01 Earthwork in excavation of foundation trenches, including cum For pipeline 15.000 0.450 1.300 8.775 6.00 52.650

layout, by excavating earth to the lines, grades and elevation interconnection

as shown in the drawing providing center lines, local bench

mark pillars, fixing bamboo spikes and marking layout with For sluice Valve 1.550 1.400 1.575 3.418 3.00 10.254

chalk powder filling baskets, carrying and disposing of all

excavated materials at a safe distance designated by the E-I-C 62.904 125.53 7896.34

in all types of soils except rocky, gravelly, slushy or organic

soil, leveling, ramming, dressing and preparing the base, etc.

all complete for an initial excavation depth of 2m and an initial

lead not exceeding 20m, including arranging all necessary

tools and equipment at work site, etc. complete as per

direction of the E-I-C.

75. 5.02.06 Earth filling inside plinth in 150mm layers with earth available cum Above sand cousioning 15.000 0.450 0.550 3.713 6.00 22.278

within 90m of the building site, watering, leveling and

consolidating each layer up to finished level, etc. all complete 22.278 322.09 7175.52

as per direction of the E-I-C.. Dry density after compaction

shall not be less than 90% of MDD (STD).

76. 5.02.03 Sand filling in foundation trenches and inside plinth with sand cum Around interconnection 15.000 0.450 0.400 2.700 3.00 8.100

(minimum FM 0.80) in 150mm layers in/c leveling, watering pipe

and consolidating each layer up to finished level etc. all

complete as per direction of the E-I-C. Dry density after 8.100 753.17 6100.68

compaction shall not be less than 95% of MDD (STD).

77. 06/CRDP/L Inter connection with distribution/transmission line (with road each Interconnection 1.000 3.00 3.000

GED crossing)

3.000 3317.00 9951.00

78. 07/CRDP/L Inter connection with distribution/transmission line (without each Interconnection 1.000 2.00 2.000

GED road crossing)

2.000 1659.00 3318.00

79. 22/DPHE/C 200 mm nominal dia ( Minn thickness 6.4 mm) API-5L grade- m For interconnection with 15.000 15.000 3.00 45.000

RDP B ERW pipe including cutting of pipes as per requirement existing pipeline

45.000 4824.00 217080.00

80. 08/CRDP/L 200x200x200 mm dia MS Tee(thickness: 6.4mm) with welded each 1.000 4.00 4.000

GED flnge at each end including rubber gasket, nut bolts, etc. (MS

fittings will be painted with anti corrosive paint in 3 coats after 4.000 10000.00 40000.00

inspection and acceptance)

Package Code : GCC B2 14 Page 17

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

81. 11/DWASA/ 200 mm dia CI Flange Adopter(min. 12mm thick) with rubber each Beside sluice valve 4.000 3.00 12.000

CRDP ring, nut-bolts, etc.

12.000 2650.00 31800.00

82. 10/CRDP/L 200 mm dia loose flange (min. 12mm thick) including welding, each For interconnection 4.000 3.00 12.000

GED fitting fixing in position with necessary nut-bolts, rubber gasket.

12.000 2750.00 33000.00

83. 11/CRDP/L 250mm brick work in Brick Pillar ( 250x250x750mm piller on each 3.000 3.00 9.000

GED 500x500x300mm footing) for resting pump delivery pipe

including 12mm cement plaster with net cement finishing etc 9.000 920.00 8280.00

all complete as per drawing, direction of EIC.

84. 23/DPHE/C Supply & installation Sluice Valve for interconnection: each For interconnection 2.000 3.00 6.000

RDP Supplying and fitting fixing Sluice Valve with cast iron flat

body, inside stem screw, non-rising bronze spindle nuts, bush 6.000 12980.00 77880.00

& gland nuts (Manufacture according to DIN/ISO standard)

including rubber gasket, nut-bolts etc. all complete as per

specification, drawing and direction of EIC.

200mm nomonal dia SV

85. 5.03.01 Single layer brick flat soling with 1st class or picked bricks, sqm Soling for sluice valve 1.900 1.750 3.325 6.00 19.950

true to level, camber/super elevation and grade including (heavy)

carrying bricks, filling the interstices tightly with sand of

minimum FM 0.80, etc. all complete as per direction of the E-I- 19.950 374.91 7479.45

C.

86. 5.04.02 Brick work with 1st class bricks in cement mortar (1:4) in cum Side wall 6.300 0.250 1.525 2.402 12.00 28.824

foundation and plinth with Portland Composite cement (CEM

II/AM, 42.5N) and best quality sand (minimum FM1.2), filling 28.824 6688.24 192781.83

the interstices tightly with mortar, raking out joints, cleaning

and soaking bricks at least for 24 hours before use, washing of

sand, curing for requisite period, etc. all complete as per

direction of the E-I-C.

87. 5.12.01 Minimum 12mm thick cement plaster (1:4) with Portland sqm In floor 1.400 1.250 1.750 12.00 21.000

Composite cement (CEM II/AM, 42.5N) and best quality sand

(minimum FM1.2) to dado, plinth wall up to 150mm below Inside wall 5.300 1.525 8.083 12.00 96.996

ground level, water tank or any where directed with neat

cement finishing in/c washing of sand, racking out joint and At top of wall 6.300 0.250 1.575 12.00 18.900

picking up cement morter i/c finishing the edges and corners

and curing for the requisite period etc. all complete as per At out side 6.300 0.150 0.945 12.00 11.340

direction of the E-I-C.

Top slab top and bottom 1.900 1.750 3.325 24.00 79.800

side

228.036 242.78 55362.58

Package Code : GCC B2 14 Page 18

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

88. 5.05.02.01 RCC:1:2:4, 20MPa, Stone Chips (SC): Reinforced cement cum Over the foundation soling 1.900 1.750 0.100 0.333 12.00 3.996

concrete works with minimum cement content relates to mix

ratio (tentative 1:2:4) and maximum water cement ratio 0.40 Fort op slab 1.900 1.750 0.150 0.499 12.00 5.988

having minimum required average strength, f'cr = 26 Mpa and

satisfying a specified compressive strength f'c = 20 Mpa at 28 9.984 11261.70 112436.81

days on standard cylinders as per standard practice of Code

AASHTO/ ASTM and Portland Composite Cement conforming

to BDS EN 197-1 : 2003 CEM-II 42.5N best quality sand of

minimum FM 2.2, 20mm down well graded crushed stone

chips (Preferably stone chips from Madhyapara, Dinajpur) (LAA

value not exceeding 33) conforming to Aggregate Grading

Appendix-3 LGED Schedule of Rates and Water reducing

chemical admixture of complying type A under ASTM C 494,

in/c cost of breaking chips, screening through proper sieves,

cleaning and washing thoroughly, centering, shuttering in

position, with plain 16 BWG steel sheet fitted over 38mm thick

wooden plank panels suitably braced and Standard size

Bamboo Props making shuttering fully leak proof, placing of

reinforcement cage in position, mixing the aggregates with

standard mixer machine with hoper, fed by standard

measuring boxes, maintaining allowable slump of 75mm to

100mm casting in steel forms, compacting by Mechanical

vibrators and tapered rods and curing at least for 28 days

removing centering-shuttering after approved specified time

period, i/c cost of additional testing charges of materials and

cylinders required. Excluding the cost of reinforcement and its

fabrication, welding, coupling, placing, binding etc. additional

quantity of Plasticizer i.e. Water reducing chemical admixture

of complying type A under ASTM C 494 to reduce mixing water

required for normal workability and to maintain low water-

cement (W/C) ratio (Doses of admixture to be fixed by the mix

design as per instruction of Engineer) and Portland Composite

Cement to be added if required to attain the strength at the

contractor's own cost. etc. all complete as per direction and

approval of the Engineer.

In individual and continuous footing of column, raft and floor

slab at plinth level.

Package Code : GCC B2 14 Page 19

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

89. 5.06.01.02 Supplying and fabrication of M.S High strength Ribbed or kg Over soling 10mm dia 1.900 0.616 1.170 156.00 182.520

deformed bar reinforcement conforming to BDS ISO 6935-

2:2006 (or standard subsequently released from BSTI) of Over soling 10mm dia 1.750 0.616 1.078 180.00 194.040

required size and length for all types of RCC work in/c

straightening removing rusts, cleaning, cutting, hooking, For top slab 16mm dia 0.850 1.580 1.343 300.00 402.900

bending, binding or tieing with supply of 22 B.W.G. annealed

binding wire double fold, placing in position in/c lapping, or For top slab 12mm dia 0.600 0.890 0.534 288.00 153.792

welding wherever required as directed, anchoring to the

adjoining members wherever necessary, spacing and securing For top slab 10mm dia 1.750 0.616 1.078 360.00 388.080

them in position by proper size concrete cover blocks (1:1)

supports, metal chairs, spacers, splices or laps etc. complete 1321.332 82.54 109062.74

in/c cost of all materials, labour, local handling, cost includes

necessary equipment and machinery, loading and unloading,

transportation, all other necessary incidental charges including

all leads and lifts etc. to complete the work as per

specifications, design, drawings and direction of the E-I-C.

(Undersize reinforcement will not be accepted under any

circumstance. Measurement will be made based as length of

bar on standard weight i.e. 77KN/m3 (BNBC Table 6.2.1)

basis. Chairs, laps, Splice and separators will not be measures

for payment. The cost of these remains inclusive in the unit

rate).

RB 400/400W: Ribbed bar or Deformed bar Produced and

marked as BDS ISO 6935-2:2006 with minimum yield strength,

fy(ReH)=400 MPa, but the actual yield strength based on mill

tests dose not exceed fy by more than the 125 MPa and the

ratio of actual ultimate strength, fu(Re) to to actual tensile

yield strength (fy) shall be at least 1.25 and minimum total

elongation after fracture (A565) & minimum total elongation

and maximum force (Agt) is 16% and 2.5% respectively.

90. 5.03.05.01 Mass concrete work in foundation or floor with Portland cum Thrust block for TEE 0.400 0.400 0.400 0.064 6.00 0.384

Composite Cement (CEM II/AM, 42.5N), sand (minimum FM

1.20) and 20mm down well graded 1st class/picked brick Thrust block for bend 0.600 0.600 0.450 0.162 12.00 1.944

chips (LAA value not exceeding 38), including shuttering,

mixing by concrete mixer machine, casting, laying compacting Thrust block sluice valve 0.450 0.450 0.300 0.061 6.00 0.366

with mechanical vibrator machine and curing for the requisite

period breaking bricks into chips etc. all complete as per 2.694 7960.73 21446.21

direction of the E-I-C. Cylinder crushing strength of concrete

should not be less than 17Mpa at 28 days of curing (suggested

mix proportion 1:2:4). Additional quantity of cement to be

added if required to attain the strength at the contractors own

cost.

Mass concrete in foundation (1:2:4) with Portland Composite

Cement (CEM II/AM, 42.5N), sand (minimum FM 1.20) and

20mm down well graded 1st class/picked brick chips.

Package Code : GCC B2 14 Page 20

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

91. 8.07.1.01 Earthing the electrical installation with 38mm dia GI pipe set Electrical Earthing for 1.000 3.00 3.000

(earth electrode) having 6mm dia holes across the dia at 1.0m each site

interval securedly bonded with 2 SWG HDBC earth lead with

washer, nuts, bolts etc. sunk upto under-mentioned depth and 3.000 16862.23 50586.69

protection of earth lead by 12mm dia GI pipe upto plinth level

run at a depth of 6.6m below G.L upto main board to be

earthed in/c necessary connecting copper sockets, bolts, nuts,

in/c additional vertical run of 12mm dia GI pipe upto G.L. from

6.6m depth with blind socket for water pouring facility etc. all

complete for maintaining earth resistance within 1 ohm.

Depth of main electrode at 12.0m and length of the electrode

11.0 m

92. CTEIP/EM/0 Air Rlease Valve (Itali/France/Taiwan/China): Supplying, fitting each 1.000 3.00 3.000

1 and fixing 25mm dia automatic air release valve with GI/MS

pipe by gas welding, nipple and 19mm gate valve, 40mm 3.000 15000.00 45000.00

padlock also be supplied along with other necessary fittings as

per instruction of Engineer-in-Charge.(At bridge crossing) etc.

all complete.

Part : 4 TOTAL : 6,266,766.59

Part : 5

Scheme Code : 33330-17-10004 Scheme Preparation Date :

Road Code : FY & Type of Rate : 2015-2016 (General)

Financial Year : 2016-2017 District : GAZIPUR

Name of the Scheme : Installation of 3 nos. production tube-wells, pump house, necessary electrical work with 10.0 km. distribution pipeline at zone-2, 4 and 5 Upazila : GAZIPUR-S

respectively.

- Construction of Pump House

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

93. 5.01.01 Providing Layout and carry over Bench Mark (BM) at site from sqm Konabari PH 10.120 10.000 101.200 1.00 101.200

nearby BM pillar, demarcating property lines, existing ground

level (EGL), formation ground level (FGL), highest flood level Board Bazar PH 14.159 8.066 114.206 1.00 114.206

(HFL), plinth level (PL). Setting and marking all pillars,

markers, pegs etc. showing and maintaining reduced levels Chowrasta PH 34.254 22.000 753.588 1.00 753.588

(RLs) including locating, establishing, protecting all public

utilities within the premise of work and finally all to be 968.994 6.71 6501.95

presented in black and white etc. all complete as per direction

of the E-I-C.

Package Code : GCC B2 14 Page 21

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

94. 5.02.01 Earthwork in excavation of foundation trenches, including cum Foundation footing CF 1.150 1.150 1.650 2.182 18.00 39.276

layout, by excavating earth to the lines, grades and elevation

as shown in the drawing providing center lines, local bench 39.276 125.53 4930.32

mark pillars, fixing bamboo spikes and marking layout with

chalk powder filling baskets, carrying and disposing of all

excavated materials at a safe distance designated by the E-I-C

in all types of soils except rocky, gravelly, slushy or organic

soil, leveling, ramming, dressing and preparing the base, etc.

all complete for an initial excavation depth of 2m and an initial

lead not exceeding 20m, including arranging all necessary

tools and equipment at work site, etc. complete as per

direction of the E-I-C.

95. 5.02.04 Sand filling in foundation trenches and inside plinth with sand cum In foundationr 1.150 1.150 0.075 0.099 18.00 1.782

(minimum FM 1.20) in 150mm layers in/c leveling, watering

and consolidating each layer up to finished level, etc. all Inside floor 6.500 4.500 0.600 17.550 3.00 52.650

complete as per direction of the E-I-C. (to be used only if

required by the design). Dry density after compaction shall not 54.432 967.03 52637.38

be less than 95% of MDD (STD).

96. 5.02.06 Earth filling inside plinth in 150mm layers with earth available cum Konabari PH 10.120 10.000 6.000 607.200 1.00 607.200

within 90m of the building site, watering, leveling and

consolidating each layer up to finished level, etc. all complete Board Bazar PH 14.159 8.066 2.500 285.516 1.00 285.516

as per direction of the E-I-C.. Dry density after compaction

shall not be less than 90% of MDD (STD). Chowrasta PH 34.254 22.000 1.500 1130.382 1.00 1130.382

2023.098 322.09 651619.63

97. 5.03.01 Single layer brick flat soling with 1st class or picked bricks, sqm Below foundation 1.000 1.000 1.000 18.00 18.000

true to level, camber/super elevation and grade including

carrying bricks, filling the interstices tightly with sand of In floor 6.500 4.500 29.250 3.00 87.750

minimum FM 0.80, etc. all complete as per direction of the E-I-

C. Verandah 3.250 0.900 2.925 3.00 8.775

Below Step 2.250 0.750 1.688 3.00 5.064

Below fins 0.400 0.250 0.100 18.00 1.800

121.389 374.91 45509.95

98. 5.03.05.02 Mass concrete work in foundation or floor with Portland cum In floor 6.500 4.500 0.075 2.194 3.00 6.582

Composite Cement (CEM II/AM, 42.5N), sand (minimum FM

1.20) and 20mm down well graded 1st class/picked brick Below Verendah 3.250 0.900 0.075 0.219 3.00 0.657

chips (LAA value not exceeding 38), including shuttering,

mixing by concrete mixer machine, casting, laying compacting Below step 2.250 0.750 0.075 0.127 3.00 0.381

with mechanical vibrator machine and curing for the requisite

period breaking bricks into chips etc. all complete as per 7.620 8116.39 61846.89

direction of the E-I-C. Cylinder crushing strength of concrete

should not be less than 17Mpa at 28 days of curing (suggested

mix proportion 1:2:4). Additional quantity of cement to be

added if required to attain the strength at the contractors own

cost.

Mass concrete in floor (1:2:4) with Portland Composite Cement

(CEM II/AM, 42.5N), sand (minimum FM 1.20) and 20mm

down well graded 1st class/picked brick chips.

Package Code : GCC B2 14 Page 22

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

99. 5.03.08 38mm thick Damp Proof Course (DPC) with cement concrete sqm Outer longwall 6.500 0.125 0.813 3.00 2.439

(1:1.5:3) in Portland Composite Cement (CEM II/AM, 42.5N),

sand (minimum FM 1.80) and 10mm down well graded 1st Outer short wall 4.500 0.125 0.563 3.00 1.689

class/picked brick chips (LAA value not exceeding 38), in/c

casting by concrete mixture machine, compacting, curing for Inner wall 9.375 0.125 1.172 3.00 3.516

requisite period, coal tar/bitumen painting, etc. all complete as

per direction of the E-I-C. Door D1 1.200 0.125 0.150 3.00 (-) 0.450

Door D2 0.900 0.125 0.113 3.00 (-) 0.339

6.855 418.15 2866.42

100 5.03.10 Providing single layer polythene sheet (0.18mm thick) sqm In floor 6.650 4.650 30.923 3.00 92.769

weighing one kilogram per 6.5 square meter in floor or any

where in ground floor underneath the cement concrete, etc. In Foundation 1.150 1.150 1.323 18.00 23.814

all complete as per specifications and direction of the E-I-C.

116.583 18.98 2212.75

101 5.04.01 Brick work with 1st class bricks in cement mortar (1:6) in cum 250mm brick work in 3.500 0.500 0.075 0.131 3.00 0.393

foundation and plinth with Portland Composite cement (CEM foundation verendah

II/AM, 42.5N) and best quality sand (minimum FM1.2), filling

the interstices tightly with mortar, raking out joints, cleaning At verendah 2nd footing 3.500 0.375 0.075 0.098 3.00 0.294

and soaking bricks at least for 24 hours before use, washing of

sand, curing for requisite period, etc. all complete as per At verendah 3rd footing 3.500 0.250 0.600 0.525 3.00 1.575

direction of the E-I-C.

Above GL, outer projection 0.400 0.250 3.450 0.345 18.00 6.210

Step 2.250 0.500 0.450 0.506 3.00 1.518

9.990 6322.25 63159.28

102 5.04.10.01 125mm brick work with 1st class bricks in cement mortar (1:4) sqm Wall in long direction 6.750 3.450 23.288 6.00 139.728

with Portland Composite cement (CEM II/AM, 42.5N) and best

quality sand (minimum FM1.2) and making bond with Wall in long direction 3.500 3.450 12.075 6.00 72.450

connected walls with uniform width and depth joints, true to wash room

vertical and horizontal lines in/c necessary scaffolding, raking

out joints, cleaning and soaking the bricks at least for 24 hours Wall in short direction 4.750 3.450 16.388 9.00 147.492

before use, washing of sand, curing for requisite period, etc.

all complete as per direction of the E-I-C. Wall in short direction 1.875 3.450 6.469 3.00 19.407

Ground Floor wash room

379.077 950.45 360293.73

Package Code : GCC B2 14 Page 23

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

103 5.05.03.01 RCC:1:1.5:3, 20MPa, Brick Chips (BC): Reinforced cement cum Grade Beam in long 6.800 0.300 0.300 0.612 6.00 3.672

concrete works with minimum cement content relates to mix direction

ratio (tentative 1:1.5:3) and maximum water cement ratio

0.40 having minimum required average strength, f'cr = 26 Mpa Grade Beam in short 5.600 0.300 0.300 0.504 9.00 4.536

and satisfying a specified compressive strength f'c = 20 Mpa at direction

28 days on standard cylinders as per standard practice of

Code AASHTO/ ASTM and Portland Composite Cement Coumn Footing 1.000 1.000 0.200 0.200 18.00 3.600

conforming to BDS EN 197-1 : 2003 CEM-II 42.5N, sand of

minimum FM 2.20, 20mm down well graded picked brick chips In frustum part (1+0.1225)/2 0.10 0.056 18.00 1.008

(LAA value not exceeding 38) conforming to ASTM C 33 and

Aggregate Grading Appendix-3 LGED Schedule of Rates and Padestal Column up to GL 1.200 0.350 0.350 0.147 18.00 2.646

Water reducing chemical admixture of complying type A under

ASTM C 494, in/c breaking chips and screening through Column GL to Beam 3.450 0.300 0.300 0.311 18.00 5.598

proper sieves, centering, shuttering in position, making bottom

shuttering fully leak proof & shuttering with plain 16 BWG steel

21.060 10064.20 211952.05

sheet fitted over 38mm thick wooden plank panels and

Standard size Bamboo Props suitably braced, placing of

reinforcement in position, mixing the aggregates with standard

mixer machine with hoper, fed by standard measuring boxes,

maintaining allowable slump of 75mm to 100mm, pouring,

casting, compacting by mechanical vibrator machine's and

tampered rod and curing at least for 28 days, removing

centering-shuttering after approved specified time period, i/c

cost of additional testing charges of materials and cylinders

required. Excluding the cost of reinforcement and its

fabrication, welding, coupling, placing, binding etc. additional

quantity of Plasticizer i.e. Water reducing chemical admixture

of complying type A under ASTM C 494 to reduce mixing water

required for normal workability and to maintain low water-

cement (W/C) ratio (Doses of admixture to be fixed by the mix

design as per instruction of the Engineer) and Portland

Composite Cement to be added if required to attain the

strength at the contractor's own cost. etc. all complete as per

direction and approval of the Engineer.

In individual and continuous footing of column, raft and floor

slab at plinth level.

Package Code : GCC B2 14 Page 24

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

104 5.05.04.03. RCC: Mix Design 20MPa, Stone Chips (SC):, Batching Plant cum Roof Beam RB1 4.250 0.370 0.250 0.393 6.00 2.358

2 (BP): Reinforced cement concrete work with minimum cement

content and maximum water cement ratio as specified by Roof Beam RB2 6.750 0.250 0.250 0.422 6.00 2.532

specified Laboratory through mix design having minimum

required average compressive strength, f'cr = 26 Mpa and Roof Beam RB3 4.250 0.375 0.300 0.478 3.00 1.434

satisfying a specified compressive strength, f'c = 20 Mpa at 28

days on standard cylinder as per standard practice of Code Lintel 33.120 0.125 0.150 0.621 3.00 1.863

AASHTO/ ASTM and Ordinary Portland Cement conforming to

BDS EN 197-1 : 2003 CEM-I 52.5N / ASTM C150 Type-1, high Roof Slab 7.550 5.500 0.125 5.191 3.00 15.573

range water reducing chemical admixture of complying type

F/G under ASTM C494 which is required to produce concrete Sunshade for W1 2.000 0.300 0.100 0.060 15.00 0.900

of consistency by 12% or greater (flowing concrete) and for

higher strength and intend to retard setting time of concrete. Sunshade for W2 3.250 0.300 0.100 0.098 4.00 0.392

(Doses of admixture to be fixed by the mix design from

approved laboratory instruction by the Engineer) for smart Parapet 26.200 0.075 0.300 0.590 3.00 1.770

dynamic concrete (i.e. Low fines self compacting concrete),

sand of minimum FM 2.20 and 20mm down well graded 26.822 15858.28 425350.79

crushed stone chips broken from boulders (Preferably stone

chips from Madhyapara, Dinajpur) (LAA value not exceeding

33) conforming to ASTM C33 and Aggregate Grading Appendix-

3 LGED Schedule of Rates in/c cost of breaking chips,

screening through proper sieves, cleaning and washing

thoroughly, centering, shuttering in position, making shuttering

fully leak proof & shuttering with plain 16 BWG steel sheet

fitted over 38mm thick wooden plank panels and Standard size

Bamboo Props suitably braced, placing of reinforcement in

position, mixing in mechanized a batching and mixing plant

and pumping using line pump or boom placer, maintaining

allowable slump of 75mm to 100mm casting in steel forms,

compacting by Mechanical vibrators and tapered rods and

curing at least for 28 days removing centering-shuttering after

approved specified time period i/c cost of additional testing

charges of materials and cylinders required etc all complete as

per direction of the Engineer in charge (Excluding the cost of

reinforcements and its fabrication welding, coupling, placing,

binding etc. Additional quantity of cement to be added if

required to attain the strength at the contractor's own cost)

etc. all complete as per direction and approval of the Engineer

The Mix Design shall have to be approved by the Central

Quality Control Laboratory (CQCL), LGED or approved

laboratory instruction by the Engineer before execution of the

work.

In pedestal, column, capital lift wall and wall :

Add for each additional floor upto 5th floor

Package Code : GCC B2 14 Page 25

SL Item Code Description of Work Unit Location / Length Width Height / Area / No of Total Qty Unit Amount

No Component Depth Volume Item of Works Rate

1 2 3 4 5 6 7 8 9 10 11 12 13

105 5.06.01.01 Supplying and fabrication of M.S High strength Ribbed or kg Column footing 12mm dia 1.150 0.890 1.024 216.00 221.184

deformed bar reinforcement conforming to BDS ISO 6935-

2:2006 (or standard subsequently released from BSTI) of For Column 20mm dia 4.000 2.470 9.880 72.00 711.360

required size and length for all types of RCC work in/c

straightening removing rusts, cleaning, cutting, hooking, For Column tie 0.900 0.616 0.554 375.00 207.750

bending, binding or tieing with supply of 22 B.W.G. annealed

binding wire double fold, placing in position in/c lapping, or for Grade beam 20mm dia 31.000 2.470 76.570 18.00 1378.260

welding wherever required as directed, anchoring to the

adjoining members wherever necessary, spacing and securing For grade beam 10mm 1.100 0.616 0.678 480.00 325.440

them in position by proper size concrete cover blocks (1:1) dia stirrup

supports, metal chairs, spacers, splices or laps etc. complete

in/c cost of all materials, labour, local handling, cost includes For RB1 20mm dia 4.250 2.470 10.498 30.00 314.940

necessary equipment and machinery, loading and unloading,

transportation, all other necessary incidental charges including For RB1 10mm dia stirrup 1.300 0.616 0.801 132.00 105.732

all leads and lifts etc. to complete the work as per

specifications, design, drawings and direction of the E-I-C. For RB2 16mm dia 6.750 1.579 10.658 30.00 319.740

(Undersize reinforcement will not be accepted under any

circumstance. Measurement will be made based as length of For RB2 10mm dia stirrup 0.800 0.616 0.493 204.00 100.572

bar on standard weight i.e. 77KN/m3 (BNBC Table 6.2.1)

basis. Chairs, laps, Splice and separators will not be measures For RB3 20mm dia 4.250 2.466 10.481 21.00 220.101