Professional Documents

Culture Documents

L&T Construction Risk Assessment for Retaining Wall Project

Uploaded by

Rohit SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L&T Construction Risk Assessment for Retaining Wall Project

Uploaded by

Rohit SinghCopyright:

Available Formats

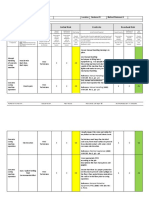

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

Cluster : Chennai

Name of the project: Establishment of 400/220kv GIS SS at Mylasandra Date: 21-01-2019

Legal Additional Control

Routine/ Consequences /

Activity Hazard Require Evaluation of Existing Control Measures After existing control

Non- Risk ments Hazard measure

Routine /

Emergen Risk

Sl cy Risk

Proba Seve Leve Proba Sever Responsibilit

No Situation Level

(R/NR/E) bility rity l bility ity

M

L=J x

A B C E F G H= F I J K

D K

xG

01 Excavatio 1. For finding out

n underground utilities to

be used method of "trial

pit" or earth penetrating

radar (If exists)

1. Physical identification of excavation pits are

2. Trial pit shall be

ensuring with client/concern authority.

Electrical shock/ excavated manually to

Underground 2. Prior to start of the job ensuring excavation

Electrocution/ identify the UG utilities Project

utilities/ demarcation, location of all hydrant pipe line,

NR Fire Yes 4 5 20 4 3 12 3. If underground Manager/ Site

Installations earthing rod & electric cable etc. From client.

electrical cables are Incharge

3. Adequate PPE’s like reflective jacket, safety

present, the power

shoes / gumboot, helmet etc. are provided to

supply shall be de-

workmen.

energized.

4. All tools shall be well

insulated to prevent

electrical shock.

Swing area of R/E LTA Yes 3 4 12 1. Earth moving equipment /Excavator’s inspection 3 3 9 1. Swing area of Site Engineer/

Excavator / Major injury has been done by plant dept. before engaging to excavator to be Supervisor

Hitting of bucket work. barricaded with

to workers 2. Only Fit earth moving equipment are using for signboards.

work activity. 2. Working area should be

3. Only authorized operator & helper is allowed. cordon off.

4. No workmen should allow in swing area of

Excavator

5. Mobile phones usage are strictly prohibited for

operators.

Sensitivity: LNT Construction Internal Use

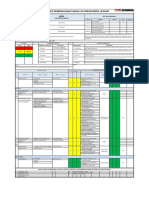

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

Legal Additional Control

Routine/ Consequences /

Activity Hazard Require Evaluation of Existing Control Measures After existing control

Non- Risk ments Hazard measure

Routine /

Emergen Risk

Sl cy Risk

Proba Seve Leve Proba Sever Responsibilit

No Situation Level

(R/NR/E) bility rity l bility ity

M

L=J x

A B C E F G H= F I J K

D K

xG

1. Maintaining angle of repose as per classification of

1. An inspection of the

soil.

excavation site, adjacent

2. Undercutting below the any structure / wall are

areas and protective

avoiding in any situations.

Land slide / system by competent

Fatal 3. Surcharge material/loose material are dumping

side wall person is required. Site Engineer/

NR/E LTA Yes 4 5 20 away from the excavation pit area (At least depth 4 3 12

collapse / 2. Maintained Supervisor

Injury equal to depth of pit)

cave-in shoring/benching of

4. Dewatering arrangement is made available to

excavation pit.

protect from hazards associated with water

accumulation before working in excavations.

5. Work Permit system is adopted.

1. All obstacles which may create hazard are 1. Red light indication

removing to ensure safe access to the workplace. should be installed with

2. No loose materials are stacked near the edge of excavation hazard sign

Material & Fatal excavations. board during night times.

Site Engineer/

worker falling NR Lost time injury Yes 4 3 12 3. Hard Barricading provided at periphery of 4 2 8 2. Hard Barricading to be

Supervisor

into excavation unconscious- ness excavated area. provided at periphery of

4. Safe access to be provided and should ensure that excavated area all times.

the access is being used properly

5. Adequate PPE to be provided

Unauthorised NR Major Accident Yes 4 3 12 1. Checking all equipment’s fitness along with P&M 4 2 8 1. Scope of improvement- P&M Incharge

driving/Operati Property damage staff before deployment Biometric system should Site Engineer/

on 2. Only Licensed / Authorized Operator / Driver be followed. Supervisor

allowed for operating the earth moving equipment.

3. For any type of vehicle helper is not allowed for

Operating/Driving the vehicle.

Sensitivity: LNT Construction Internal Use

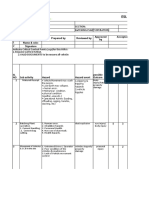

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

Legal Additional Control

Routine/ Consequences /

Activity Hazard Require Evaluation of Existing Control Measures After existing control

Non- Risk ments Hazard measure

Routine /

Emergen Risk

Sl cy Risk

Proba Seve Leve Proba Sever Responsibilit

No Situation Level

(R/NR/E) bility rity l bility ity

M

L=J x

A B C E F G H= F I J K

D K

xG

1. Proper planning shall

be done to execute such

1. Undercutting below the any structure / wall are type of work in a

avoided in any situations. sequence order like one

Collapse of 2. Close supervision by one excavation

building and Major Accident 3. Awareness training is providing through PEP Talk instead of mass Site Engineer/

E Yes 3 5 15 3 3 9

adjoining Property damage and Training program. excavation. Supervisor

structure 2. Shoring, shuttering

and timbering to be done

where the probability of

soil / Structure collapse.

Water R Fatal / Major Yes 4 3 12 1. Dewatering arrangement (like dewater pump) is 4 2 8 1. Continous monitoring Site Engineer/

accumulation accident made available to protect from hazards associated to be ensured for such Supervisor

in pit / with water accumulation. critical job.

Excavated area 2. PPE like gumboots is mandatory. 2. Dewatering pump

should be available all

times (if water seepage is

more)

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

Legal Additional Control

Routine/ Consequences /

Activity Hazard Require Evaluation of Existing Control Measures After existing control

Non- Risk ments Hazard measure

Routine /

Emergen Risk

Sl cy Risk

Proba Seve Leve Proba Sever Responsibilit

No Situation Level

(R/NR/E) bility rity l bility ity

M

L=J x

A B C E F G H= F I J K

D K

xG

1. If the clearance

distance is less than as

per IE rule, it shall be

ensured that the

overhead power lines

shall be shut down and

residual charges

grounded before

commencing to use of

1. Maintained safe clearance distance from live

machinery

cables. As per IE rule

2. If earth moving eqpt.

2. Only authorized personnel are allowed.

comes in contact with

3. Work permit system are adopted.

power lines-

4. Don’t carry any lengthy conductive material near

Electric shock a) If the cabin and the

to power line. Project

Overhead Electrocution controls are well

R/NR Yes 4 5 20 5. Ensuring proper communication facilities with site 4 3 12 Manager/ Site

power lines Emergency insulated, the operator

team. Incharge

Induction can remain inside his

6. PPE like Safety helmet, safety shoes / gumboot,

cabin with touching any

Reflective vest, Hand gloves etc. are provided.

conductive /metallic

7. Body earthing is providing for equipment for avoid

parts.

induction.

b) He should not step on

8. Using FRP ladders

ground having contact

with equipment.

c) Others should keep

away. They should not

touch the load lines,

boom, bucket or any

other part of the

equipment.

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

1) Only Authorized operator is allowed to do work.

2) Cutting wheel & Cutting machine RPM have

checked and ensuring cutting wheels RPM always

1. All cutting/ grinding

greater than cutting machine.

Molten particles, machine supply taken

Cutting 3) Ensured cutting machine's Wheel guard, cable not

flying through RCCB only (30mA

of Eye/ face Injury damaged and defects free. Site Incharge/

02 particles/pieces/P R Yes 4 4 16 4 3 12 cut-off sensitivity).

reinforce LTA 4) Collection bins or separate areas to be allocated Engineer

oor 2. Regular Inspection of

ment bar for collection of cut pieces.

ergonomics/Fire power tools should be

5) Training on cutting machine safety given to

done.

workmen.

6) Adequate PPEs provided to workers. (Face, Eye &

Ear protection)

1. Bar bending machine

1) Bar bending shall be carried manually or

shall be inspected by

mechanically depending on availability & nature of

P&M engineer prior start

job.

LTA of the work activity &

Defective machine 2) Ensured all workers are in one direction while

Fitness tag of machine

Bar / Inexperienced Major accident bending / shifting the bars.

should be displayed on

Bending operator/ Slip / Property 3) Bar bending machine double body Site Engineer/

03 NR Yes 4 3 12 4 2 8 machine.

as per Trip / Fall/ Damage earthing/grounding shall provide. Supervisor

2. Bending of bars shall

BBS trapping/ Injury 4) Good Housekeeping is maintained as on regular

be carried as per the

Entanglement basis.

approved drawing and

5) All engaged workers should be skilled &

bending radius, hook

experienced.

lengths, lap length shall

6) Adequate PPEs are provided to workmen.

be strictly followed.

1) Only authorized and trained operators operating

machine. 1) Only inspected and

Fall of steel from

2) Ensuring Machine to be locked when not in use. safe tag provided

Making of hand/ Failure of

LTA 3) SOP to be followed during work. machine to be used.

reinforce equipment / burr Site Engineer/

04 R/NR Major Accident No 4 3 12 4) Body Earthing provided to machine. 4 3 12 2) Weather protection

ment sharp edges/ Supervisor

Fatigue 5) Safe guards to be ensure while using of machine. shed to be provided to

cage/Jali Excessive work

6) Job rotation to be implemented & Workmen are machine.

load/ Bullying

guided/ Trained

7) Adequate PPE provided to workmen.

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

1) Hard barricading at edges of building and

openings on floors.

2) Shoulder pads are provided for workmen.

3) For joining of bars, lapping splicing coupling or 1) Material lifting and

Tying of

Fall of welding may be employed based on the lowering shall be done by

steel

Person/Trip/ Muscular Sprain requirements with engineer in charge approval. crane or rope and pulley

reinforce Site Engineer/

05 Working at R Backache No 4 3 12 4) Surplus rods are removed from workplace and 4 2 8 methods.

ment of Supervisor

height/Repetitive injury/ incident stored at yard. 2) Horizontal Safety nets

the

work 5) All workmen engage in height work under gone to be provided.

structure

height pass test prior working at height.

6) Height work training provided to concern

workmen.

7) Adequate PPEs provided to workmen.

1) Plank to be fixed on

reinforcement steel for

1) Hard barricading provided at edges.

Inspectio safe walk way.

2) Supervision provided to identify unsafe

n of Fall of person/ backache 2) Alternate access to be Site In-charge/

act/conditions.

06 reinforce Trip/ collapse of R/NR Injury/ incident No 4 3 12 4 2 8 ready during concreting Site Engineer/

3) Pre-employment medical checkup with Height

ment structure LTA work. Supervisor

pass test

structure 3) Horizontal Safety nets

4) Adequate PPE's provided to workmen.

to be provided while

working at height.

1) Inspected and approved crane/ Mobile crane &

Lifting tools & tackles are provided for unloading the

steel.

Fall of 2) Competent operators and riggers are engaged in

material/Hit to unloading of steel.

1) Ensure storing distance

the person/ Muscular pain 3) Wooden blocks are provided below the rebar

from live overhead

Unloadin Failure of Injury/Incident bundles to support keep them free from mud/soil Site Engineer/

07 R/E Yes 4 3 12 4 2 electric cable. (as per IE

g of steel slings/Hydraulic Property contact on the job site. Supervisor

rules)

oil leakage/ damage 4) Training provided to workmen engaged in manual

Inadequate space shifting of material.

to work 5) Wooden blocks provided for proper steel storage

and stacking.

6) Adequate PPE's provided. (Hand gloves, Safety

helmet, safety shoes)

Fall of 1) Deployed more than one worker for handling of

Manual 1) Adequate rest

material/Hit to heavy rebar (weight more than 35kg)

Shifting intervals to be monitor

the person/Sharp Ill health 2) Training provided to workmen engaged in manual

of steel/ by supervisor. Site Engineer/

08 edges R Injury/Incident Yes 4 3 12 shifting of material. 3 3 9

Re-bar at 2) Shall be ensured hand Supervisor

(burr)/Manual Backache 3) Adequate PPEs provided to workmen including

steel gloves & Shoulder pads

material shoulder pad & Hand Gloves.

yard. usage

handling/Trapping

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

1) The steel yard is isolated and demarcated; steel

Cuts/ Bruises/ to be barricaded after unloading.

1.Don’t store steel bars

Sprains due to 2) Access/egress is kept clear of unwanted

near live sub-station or

protruding steel materials.

maintain safe clearance

Storage bars / Burns to Ill health 3) Sufficient illumination provided at nights. Site Engineer/

09 R No 3 3 9 3 2 6 from live sub-station

of Steel palms and other Injury/Incident 3) Wooden blocks are provided below the rebar Supervisor

2. Avoid storage of steel

body parts during bundles to support keep them free from mud/soil

in open area in hot

extreme summer contact on the jobsite.

weather.

conditions 4) Workmen are trained

5) Adequate PPE provided to workmen

1) Ensure good housekeeping and systemized

stacking of material is done.

2) Wood cutting machine rotating parts should be 1. Cutting machine supply

fully guarded. connections routed

Slip/trip/fall of 3) Shuttering material are stacked away from the through ELCB/RCCB

person/ edge of the pit not less than 1.5m and stacking not 2. De-shuttering area

Shuttering/

material/ more than 1.5m heights. should be barricaded and

De- Body pain/

Manual 4) Shuttering material should have nail/protruded unauthorized workman Site Incharge/

10 shuttering of R Injury/Incident Yes 4 3 12 3 2 6

handling / free. should not work or enter Engineer

Column/ LTA

Lack of 5) Do not allow to rest near or below shuttering in de-shuttering area.

raft

control/commu 6) Only authorized persons are involved in de 3. Other activity not

nication shuttering activity. permitted while de

7) Use of PP rope to balance & lower the load. shuttering in progress.

8) Horizontal safety nets are provided.

9) Closed Supervision provided to monitoring

10) Adequate PPE's provided to workmen.

1) Lifeline provided for workmen who are going to

De-shutter for slab works.

2) Provided lifeline with double lanyard body

harness. 1) The area should be

Slip, trip and 3) Ensuring tie rods support for put down and demarcated and no

fall/ material body pain/

removing of the Wallers, shuttering material. trespassers should be

De- handling/ Musculoskeletal

4) All nails, protruded & sharp objects removed from allowed. Site Incharge

shuttering of disorder/

11 Inadequate NR No 4 3 12 shuttering material. 4 2 8 2) De-shuttered material Site Engineer/

slab form Injury/Incident

work place/ 5) Around the floor opening and along the along the should be down on floor Supervisor

work Fatal

Physical floor edges temporary guardrails are arranged. by using rope and pulley

violence 6) Manual Material handling training provided to arrangement.

workmen.

7) No person is allowed when de-shuttering work is

in progress.

8) Adequate PPE's provided to workmen.

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

1) Crane/ equipment to

1) Scaffolding/formwork material/pipes and other be used for heavy de-

de-shuttering material shifting by manually. shutter material from

Fall, slip &

2) Heavy load avoiding by manually. floor to ground.

trip/ Manual

3) If being lifted manually ensure the shutter to be 2) Only tested and

handling/

secured with pp-rope and to be raised using rope certified lifting tools & P&M Engineer

Shifting of working at fatigue/Injury/

12 R/NR Yes 4 3 12 pulley system. 4 2 8 tackles to be used for Site Engineer/

material height/ Incident

4) Protruded nails removed from wooden material. Crane. Supervisor

excessive work

5) Loose material not stacking above standard level. 3) Loose and small pieces

load/ uneven

6) After de-shuttering of specific area; all material should not lift between

work platform

removes and housekeeping to be maintained. big size material loads.

7) Adequate PPE's provided to workmen. 4)Good Housekeeping to

be maintained

Fall of

material/ 1) Material not stacking above 1.5m.

injuries due to 2) Material to be stacked as per store stacking plan

scattered nails provided. 1. 5s to be implemented

produced while 3) 5s to be implemented while material storage. while material

Muscular Store

de- 4) Housekeeping at work area with proper access storage.

Stacking of pain/Injury/ Incharge/ Site

13 shuttering/slip R Yes 4 3 12 road. 4 2 8

material Incident/ Engineer/

page due to 5) Scrape and damage nails material shifted in site 2. Should be ensured

allergy Supervisor

oiling of de- store. material stacking as

shuttered 6) Training provided to housekeeping team engaged per plan.

plywood/ in material shifting work.

7) Adequate PPE's provided to workmen.

Manual

handling/

Fall of person / 1. Stair tower has provided for access/egress

Inspection of Hit by 2) Only trained and height pass test workman 1) Inspection of form

Shuttering/ protruding part Body pain deployed on height works. work to be carried out as

Site Incharge/

14 formwork of CT prop / R/NR/E Injury No 4 4 16 3) walkway access to be provided during concrete 4 3 12 per std.

Engineer

before Fall of material Incident work 2) Ensured Closed

concreting / collapse of 4) Hard barricading & life line to be provided. supervision all the times.

structure 5) Adequate PPE`s provided.

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

1) Concrete pump shall be set up in level, solid and

obstruction free place.

2) If outriggers are used, adequate timbers to be

1. It shall be ensured

used for the purpose of packing the baseplate.

that the pump is not

3) No person shall stand between the reversing RMC

positioned over or

vehicle and the hopper.

adjacent to:

4) Pipe line is installed as per approved plan with

a) Previously disturbed

clamping support to avoid interference while

ground that has been

working on floor.

back-filled

Fall of person/ 5) Work permit system is used for working at height

b) Excavations, trenches

Installation Fall of Skin irritation 6) All concrete pipe connection should be fitted &

or holes in the ground

of concrete material/ Injury tight with clamps with supports. Site Engineer/

15 NR Yes 4 3 12 4 2 8 c) Inadequately

pump/ pipe collapse of Incident 6) All protruded reinforcement bar has checking and Supervisor

compacted or soft ground

line. structure/Vibra Emergency rebar caps are installing on it.

2) The formwork to be

tion 7) Signal man is deployed at ground and desire level

closely monitored by

of concreting slab to communicate with concrete

supervisor throughout the

pump for concrete.

time.

8) Height Pass is issued to all fit workmen after

3) Only authorized pump

conducting Height Pass test.

operator should operate

9) Training provided to workmen engaged in

the concrete pump.

installation work.

10 Workmen are trained and experienced.

11) Adequate PPE`s provided (Safety Helmet, Safety

Shoes, Hand Gloves etc.

1) Only valid license holder operator can operate TM

in project premises.

2) All the transit mixers shall be provided with a

helper.

Failure of 3) Inspection of Valid insurance, fitness and PUC at

1) Unauthorized driving

vehicle/ security gate.

shall not be permitted

Delivery of unguarded 4) Ensuring guard to be provided to moving /

Headache 2) Wheel chocks to be P&M engineer/

RMC by moving part / rotating part.

16 R/NR Fatal/ Injury Yes 4 4 16 4 3 12 used while TM parked at Site Engineer/

Transit Noise/ 5) Speed limit Instruction (15kmph) given to RMC

Incident site. Supervisor

mixture Reversing/ vehicle driver's & helpers.

3) The TM shall not be

6) Helper provided on site to give direction on site.

Run over moved when chute in

7) Ladders of TM are strong & the rungs shall be

open position

welded properly for safe use.

8) Speed limit signage's displayed on site.

9) Supervision provided for closed monitoring.

10) Adequate PPE`s provided.

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

Skin irritation/

fall of

person

1) Vertical / Horizontal

/edges / 1) No work is carried out unless Inspection is carried

safety net to be

flying of out by authorized persons.

provided. (Work at

particles 2) Life line provided during concreting

height)

concrete/ 3) Stair tower has provided for safe access.

2) Shall be ensured

bullying/ 4) Adequate Illumination provided while night work

Pouring of Skin irritation closing of all ducts and Site Engineer/

17 fatigue to R/NR Yes 4 3 12 hours. 4 2 8

concrete Injury/Incident openings by appropriate Supervisor

weather 5) Inspection of concrete pump and pipe to be

material prior work

conditions/ carried out prior work start by concrete pump.

starts.

6) Hard barricading and supporting barricading

poor 3) Job rotation should be

provided.

illumination / ensured.

7) Adequate PPE`s provided.

manual

handling /

excessive work

load

Fatigue/ Skin 1) Inspection of vibrator before use.

Use of

Irritation/ 2) Exhaust of diesel vibrator engine kept away from 1) Rotating parts should

vibrator P&M Incharge/

Noise / Smoke the direction of workplace. be guarded. (if not)

during Ill health Site In-charge/

18 emission / R/NR Yes 3 3 9 3) Job rotation to avoid fatigue. 3 2 8 2) Avoid concrete

concreting injury/ incident Site Engineer/

vibration / 4) Training provided to workmen engaged in contamination to skin

(Diesel Supervisor

Repetitive concreting work. while concreting work

Vibrator)

work 5) Adequate PPE`s provided.

1) Removal of slurry /

waste concrete on road

Contact with

after wash and used it

concrete/ slip/

Inhalation of 1) Pump washing at identified / allocated / for backfilling.

Washing of trip/ water

dust designated area is strictly avoided. 2) Concrete pump / RMC Site Engineer/

19 Pump/RMC stagnation and R/E Yes 4 3 12 4 2 8

Injury 2) Adequate PPE's are provided to workmen engaged vehicle should only have Supervisor

vehicle. breeding of

Incident in the work. allowed for washing in its

mosquitos or

concrete plant or

larvae

dedicated place.

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

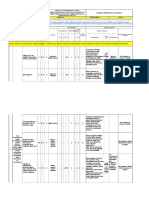

1. Access/ Egress routes are clearly marked.

2. Ensuring Heavy vehicle operator has valid license 1. Signal Man or helper to

Heavy and authorization certificate for operate the be deployed with red

Property Damage

vehicle vehicle. color hand flag. Site Engineer/

E Major accident Yes 4 4 16 4 3 12

toppling / 3. Reverse horn are checked & ensured it is in Supervisor

fatal 2. Don’t park any vehicle

collision working condition.

4. Overloading of vehicle is avoided. near the excavated pit.

5. Backfilling is done by layer by layer.

1. Adequate and well-

1. Ensuring Vehicle/ Equipment are stopped far anchored stop block shall

Backfilling & away from the edge of excavated area at least 1m. be provided on the

20 Falling into

levelling 2. Excavated area is hard barricaded and for night surface to prevent

Excavated

works red light signal to be provided. operating vehicles from

pit

3. Safety Signage’s are displayed at excavated pit falling accidently into

(material/pe Major Accident Site Engineer/

E Yes 4 3 12 area. 4 2 8 excavation pit.

rsons), Property Damage Supervisor

4. Inspection shall be carried out prior to start of 2. Area of backfilling

Rolling of

the job. should be cordon off.

boulders,

5. Pep-talk & training has been conducted to 3. Workmen should Keep

stones

workmen on Excavation safety. away & shall be warned

from Rolling boulders or

other falling objects

1. Plate compactor/ Rollers are fit for deployment &

Rotating inspected by P&M staff.

1. Vibratory

parts of 2. Using rigid platform arrangement for lowering

LTA roller's/static roller's P&M Staff/

compactor / small machines.

N/R Major Accident Yes 4 4 16 4 3 12 rotating parts should be Site Engineer/

Vibrator / 3. Never allowing use of loose clothes of operator.

Fatigue guarded. Supervisor

Excessive 4. Job rotation to be ensured.

work load 5. Safety goggles, Hand gloves, Safety Hemet, Safety

Soil shoes/gumboots are provided to workmen.

21

Compaction

1. Compactor should be

fit for use.

Emission of 1. To be make an arrangement for water sprinkling P&M Staff/

2. Regular/periodic

dust/ gases/ R Health Problem Yes 4 3 12 against dust. 4 2 8 Site Engineer/

maintenance should be

noise 2. Ear plug/ ear muff are using. Supervisor

done.

3. Nose mask are provided to workmen.

Mr. Satyajit Parija Mr. K. V Rami Reddy.

PM / CM / Section Head EHSO

Sensitivity: LNT Construction Internal Use

L&T CONSTRUCTION

POWER TRANSMISSION & DISTRIBUTION

Ref: IM 6.1.2 A Rev 05

HAZARD IDENTIFICATION AND RISK ASSESSMENT- Retaining Wall Construction Work

*E=Elimination *S=Substitution *EC=Engineering controls *AC=Administrative controls *PPE=Personal Protective Equipment

Sensitivity: LNT Construction Internal Use

You might also like

- Risk Assessment For Concrete WorksDocument3 pagesRisk Assessment For Concrete WorksMario Marasigan86% (35)

- Risk Assesment For Formwork ActivityDocument8 pagesRisk Assesment For Formwork ActivityIbrahim Naguib85% (13)

- Revised Risk Assessment-Concrete Coring-1Document5 pagesRevised Risk Assessment-Concrete Coring-1riyazkader82% (11)

- Batching Plant Method Statement PDFDocument4 pagesBatching Plant Method Statement PDFStraus Waseem67% (3)

- Risk Assessment - Grouting WorksDocument5 pagesRisk Assessment - Grouting Worksabhinav dj100% (5)

- Jsa For Road WorksDocument11 pagesJsa For Road Worksyc safety75% (12)

- Risk Assessment For Excavation and BackfillingDocument3 pagesRisk Assessment For Excavation and BackfillingSreyleap Nhet88% (16)

- Excavation Method Statement PDFDocument10 pagesExcavation Method Statement PDFMohammad Bader Al-Dein100% (13)

- IMS 9001/14001/45001 Requirements ComparisonDocument1 pageIMS 9001/14001/45001 Requirements ComparisonCentauri Business Group Inc.95% (20)

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisQin Qin63% (8)

- Stone Masonary Method Statement and Risk AssessmentDocument8 pagesStone Masonary Method Statement and Risk AssessmentTAHER AMMAR0% (1)

- Hirac - Batching Plant Erection of PlantDocument8 pagesHirac - Batching Plant Erection of Plantanant sahay100% (2)

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie100% (1)

- Hazard Identification and Risk Assessment: Yes 1 5 Nanayesyesna 1 3Document3 pagesHazard Identification and Risk Assessment: Yes 1 5 Nanayesyesna 1 3Ruchin Jain100% (24)

- C&C-EHS-F-002 HIRARC Eraction and Use of Scaffolding PDFDocument4 pagesC&C-EHS-F-002 HIRARC Eraction and Use of Scaffolding PDFNajman Hamdi100% (3)

- JSA For Concrete Pouring Using Crane and Bucket3Document8 pagesJSA For Concrete Pouring Using Crane and Bucket3Mohammed Minhaj100% (1)

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- Safe Formwork Erection ProcedureDocument1 pageSafe Formwork Erection ProcedureSiti Norsyazana Abd Majid100% (1)

- Concrete Pouring (Risk Assessment)Document3 pagesConcrete Pouring (Risk Assessment)Ri Oz80% (5)

- Risk Assessment Matrix ExplainedDocument28 pagesRisk Assessment Matrix ExplainedAlif Shahril100% (1)

- Excavation Method for Slope StabilizationDocument9 pagesExcavation Method for Slope StabilizationJoseph NGNo ratings yet

- Lifting Plan For Equipment - MMSPDocument14 pagesLifting Plan For Equipment - MMSPClifford100% (1)

- Hazards of Piling WorksDocument6 pagesHazards of Piling Worksjoaonunes.40544364% (11)

- Method Statement Excavation Works: Page 1 of 13Document13 pagesMethod Statement Excavation Works: Page 1 of 13J. Kumar Infraprojects Ltd100% (1)

- Risk Assessment Tower Erection WorkDocument4 pagesRisk Assessment Tower Erection WorkAnonymous ExWAN2xjFJ83% (6)

- Open Excavation MethodDocument2 pagesOpen Excavation MethodSam Wong86% (7)

- Risk Assesment For CompactionDocument12 pagesRisk Assesment For CompactionAzhar MushtaqNo ratings yet

- Deep Excavation Method StatementDocument5 pagesDeep Excavation Method Statementmoytabura9650% (2)

- Risk Assessment Construction SiteDocument9 pagesRisk Assessment Construction SiteJuned Hamid Khan100% (2)

- Backfilling Method StatementDocument7 pagesBackfilling Method StatementMohammad Bader Al-DeinNo ratings yet

- JSA NO 8-Roof WorkDocument6 pagesJSA NO 8-Roof WorkknabpshoNo ratings yet

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document7 pagesHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- 006 - Building Demolition - Rev 1Document5 pages006 - Building Demolition - Rev 1satti50% (2)

- Risk Assessment For Repair of ManholeDocument5 pagesRisk Assessment For Repair of Manholeflmm09No ratings yet

- Environmental, Health and Safety Risk AssessmentDocument2 pagesEnvironmental, Health and Safety Risk AssessmentAdnan100% (2)

- Eurocoalash 2021 Program 20211028Document3 pagesEurocoalash 2021 Program 20211028eurocoal ash2021No ratings yet

- GroutingDocument1 pageGroutingraphael damanikNo ratings yet

- Erection of Col - and Beam, StairDocument3 pagesErection of Col - and Beam, StairChandru100% (1)

- Method Statement For Repair of Bulged Concrete UsingDocument8 pagesMethod Statement For Repair of Bulged Concrete Usingbureau servicesNo ratings yet

- Piling Hazards and RisksDocument4 pagesPiling Hazards and RisksAbhishek Gupta100% (2)

- Hazard Identification and Risk Assessment for Temporary Structure Erection and DismantlingDocument8 pagesHazard Identification and Risk Assessment for Temporary Structure Erection and DismantlingMD AbdullahNo ratings yet

- Activity A.3 - Pilling, Pile Cap & Pier WorksDocument3 pagesActivity A.3 - Pilling, Pile Cap & Pier Worksbhaskar100% (2)

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Batching of Concrete Method StatementDocument4 pagesBatching of Concrete Method Statementmechajay2002100% (1)

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- Deshuttering WorkDocument2 pagesDeshuttering WorkChandru100% (1)

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Document14 pagesRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee ChingNo ratings yet

- Risk Assessment For Back FillingDocument6 pagesRisk Assessment For Back FillingBhargav BbvsNo ratings yet

- Hirac (Piping Installation (Open Cut Trench)Document7 pagesHirac (Piping Installation (Open Cut Trench)tana100% (1)

- 6.0 ISOLATION JSA CONCRETE WORK HanesDocument7 pages6.0 ISOLATION JSA CONCRETE WORK HanesMc Loki100% (3)

- A Typical Method Statement For Roofing WorksDocument2 pagesA Typical Method Statement For Roofing Worksngian196250% (4)

- 004 Piling JSADocument5 pages004 Piling JSAmidozotyNo ratings yet

- Mivan Risk AssessmentDocument3 pagesMivan Risk AssessmentBineeshNo ratings yet

- Konstruksi Pembangunan Tangki LPG Pressurized 1X300 MTDocument1 pageKonstruksi Pembangunan Tangki LPG Pressurized 1X300 MTWidya PrasetyaNo ratings yet

- Concrete Pour Risk AssessmentDocument3 pagesConcrete Pour Risk Assessmentridminj0% (1)

- Method Statement for Excavation & BackfillingDocument28 pagesMethod Statement for Excavation & BackfillingRepl microsoft, PuneNo ratings yet

- JHA ConcretePlacingOperationDocument3 pagesJHA ConcretePlacingOperationAnonymous XJ9663C6N4No ratings yet

- HAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBDocument7 pagesHAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBCharles LambNo ratings yet

- HIRA Batching PlanDocument9 pagesHIRA Batching Plannitish tiwariNo ratings yet

- HIRA 4r Utility Identification CMRL 09.05.17Document3 pagesHIRA 4r Utility Identification CMRL 09.05.17mahesh naikNo ratings yet

- List of Identification & Assessment For Environmental Aspect and Impact - Okt 2012Document3 pagesList of Identification & Assessment For Environmental Aspect and Impact - Okt 2012asephidayat042No ratings yet

- Site Ehs RulesDocument1 pageSite Ehs RulesRohit SinghNo ratings yet

- S.No Description of Work Action PlanDocument3 pagesS.No Description of Work Action PlanRohit SinghNo ratings yet

- HelloDocument78 pagesHelloRohit SinghNo ratings yet

- Overhead Crane Safety TrainingDocument71 pagesOverhead Crane Safety TrainingGovarthanan Gopalan100% (8)

- EHS PlanDocument37 pagesEHS PlanVishal TiwariNo ratings yet

- Maintaining Solar PV SystemsDocument44 pagesMaintaining Solar PV SystemsSuresh KumarNo ratings yet

- Why Workers Fail To Report Hazards & InjuriesDocument4 pagesWhy Workers Fail To Report Hazards & InjuriesRohit SinghNo ratings yet

- The Motor Vehicles (Amendment) Bill, 2019: Bill No. 154-C of 2019Document45 pagesThe Motor Vehicles (Amendment) Bill, 2019: Bill No. 154-C of 2019PintuSarangiNo ratings yet

- The Motor Vehicles (Amendment) Bill, 2019Document5 pagesThe Motor Vehicles (Amendment) Bill, 2019Rohit SinghNo ratings yet

- Safety 2Document3 pagesSafety 2Rohit SinghNo ratings yet

- Safety Spectacles PDFDocument1 pageSafety Spectacles PDFRohit SinghNo ratings yet

- Motor Vehicle Act9279Document52 pagesMotor Vehicle Act9279dineshvhavalNo ratings yet

- SafetyDocument2 pagesSafetyRohit SinghNo ratings yet

- Medical Tieup LetterDocument1 pageMedical Tieup LetterRohit SinghNo ratings yet

- Safety SpectaclesDocument1 pageSafety SpectaclesRohit SinghNo ratings yet

- Prevent Hypothermia and Frostbite with Proper Cold Weather Clothing P2Document1 pagePrevent Hypothermia and Frostbite with Proper Cold Weather Clothing P2Rohit SinghNo ratings yet

- BOCW Act RequirementsDocument11 pagesBOCW Act RequirementsRohit SinghNo ratings yet

- Snow RemovalDocument1 pageSnow RemovalRohit SinghNo ratings yet

- Preventing Hypothermia and FrostbiteDocument1 pagePreventing Hypothermia and FrostbiteRohit SinghNo ratings yet

- Blood Borne PathogensDocument29 pagesBlood Borne PathogensRohit SinghNo ratings yet

- Week Topic: Seismology and The Earth's Deep InteriorDocument49 pagesWeek Topic: Seismology and The Earth's Deep InteriorRohit SinghNo ratings yet

- Blasting Regulations: Regulatory Requirements For Blasting OperationsDocument14 pagesBlasting Regulations: Regulatory Requirements For Blasting OperationsRohit SinghNo ratings yet

- Running Nip Point OperationDocument1 pageRunning Nip Point OperationRohit SinghNo ratings yet

- Feeding The Ejection MethodsDocument1 pageFeeding The Ejection MethodsRohit SinghNo ratings yet

- Conveyor SafetyDocument2 pagesConveyor SafetyRohit SinghNo ratings yet

- Tool Box Talk - Requirements of Machine GuardingDocument1 pageTool Box Talk - Requirements of Machine GuardingRohit SinghNo ratings yet

- TBT-Heat Disorders - Heat ExhaustionDocument1 pageTBT-Heat Disorders - Heat ExhaustionRohit SinghNo ratings yet

- TBT-Heat Disorders - DehydrationDocument2 pagesTBT-Heat Disorders - DehydrationRohit SinghNo ratings yet

- How to Calculate the Heat Index and Stay Safe in High HumidityDocument1 pageHow to Calculate the Heat Index and Stay Safe in High HumidityRohit SinghNo ratings yet

- Checklist Installation enDocument4 pagesChecklist Installation enamansaxena9208No ratings yet

- PG 1 3 AES2.1 QuarterlyAnnualWetPipe2013 FSCDocument3 pagesPG 1 3 AES2.1 QuarterlyAnnualWetPipe2013 FSCesgarNo ratings yet

- Aluminium Tape: Lightning ProtectionDocument4 pagesAluminium Tape: Lightning ProtectionPradipa Aisyah Tri SyakinaNo ratings yet

- Monarch's Waterproofing PDFDocument31 pagesMonarch's Waterproofing PDFMonarch DigitalNo ratings yet

- 016-08 - (GA) 002 - 1220mm Wide X 1165mm Coping StoneDocument1 page016-08 - (GA) 002 - 1220mm Wide X 1165mm Coping StoneKelvin bongNo ratings yet

- High-tech Architecture: Steel and Glass StructuresDocument17 pagesHigh-tech Architecture: Steel and Glass StructuresChetasi KothiwalaNo ratings yet

- 0215 Pip 00 Ec 0007 - 000 - 02 - PDF PDFDocument86 pages0215 Pip 00 Ec 0007 - 000 - 02 - PDF PDFkasvikrajNo ratings yet

- TDS - Mastertop 1710Document2 pagesTDS - Mastertop 1710Venkata RaoNo ratings yet

- 2 Weeks Look Ahead Schedule (Submitted On 10 Dec 2021)Document1 page2 Weeks Look Ahead Schedule (Submitted On 10 Dec 2021)Syazu StylzerNo ratings yet

- First Floor RCPDocument9 pagesFirst Floor RCPmohd shirazNo ratings yet

- CRSI Manual To Design RC Diaphragms - Part22Document4 pagesCRSI Manual To Design RC Diaphragms - Part22Adam Michael GreenNo ratings yet

- GEDA-036 - PH7000 - Single - Left - High Speed - BookletDocument8 pagesGEDA-036 - PH7000 - Single - Left - High Speed - BookletfsijestNo ratings yet

- Ecr58d - 20032818-B CHNDocument572 pagesEcr58d - 20032818-B CHNDiego MontenegroNo ratings yet

- Construction Work at The Au Medical CenterDocument6 pagesConstruction Work at The Au Medical CenterafeworkNo ratings yet

- Volume II Part II TS 1Document276 pagesVolume II Part II TS 1RAMASHISH KUMARNo ratings yet

- Extension 1Document23 pagesExtension 1Resources WTE PHASE2No ratings yet

- Excavator Mounted Drill: Innovative Piling EquipmentDocument2 pagesExcavator Mounted Drill: Innovative Piling EquipmentGabriel AmorimNo ratings yet

- Historic Masonry StructuresDocument155 pagesHistoric Masonry Structuresp jNo ratings yet

- CE Module 29 - StaticsDocument13 pagesCE Module 29 - StaticsAngelice Alliah De la CruzNo ratings yet

- Engg - Drawing 1st Year LMDocument167 pagesEngg - Drawing 1st Year LMPRIYABRATA JENANo ratings yet

- Design of Tie Beam (TB)Document3 pagesDesign of Tie Beam (TB)Khael Angelo Zheus JaclaNo ratings yet

- 903 Assignment PDFDocument13 pages903 Assignment PDFabikeerthuNo ratings yet

- Homework No.1 - CEE 351 RCI - Fall 2022Document3 pagesHomework No.1 - CEE 351 RCI - Fall 2022Elvis KarayigaNo ratings yet

- FEM1 - 007 EnglishDocument20 pagesFEM1 - 007 Englishmssm_sNo ratings yet

- Behaviour Based Safety AuditDocument16 pagesBehaviour Based Safety AuditOsama IftikharNo ratings yet

- Design of Prestressed Concrete Structures (3rd Edition) - T. Y. Lin & Ned H. Burns - 2Document326 pagesDesign of Prestressed Concrete Structures (3rd Edition) - T. Y. Lin & Ned H. Burns - 2Ahmed Al-Amri96% (23)

- Rectification of Accident Black Spot Preparation of Proposal and Sanction Approval Regarding On 26th August 2019.-MinDocument11 pagesRectification of Accident Black Spot Preparation of Proposal and Sanction Approval Regarding On 26th August 2019.-MinAshok Kumar SahaNo ratings yet

- Pages From Ashrae 1997 Hvac Fundamentals HandbookDocument21 pagesPages From Ashrae 1997 Hvac Fundamentals HandbookAnkurNo ratings yet

- Finalproject MergedDocument85 pagesFinalproject MergedMICHAELDANE SALANGUITNo ratings yet