Professional Documents

Culture Documents

Strapped Footing Design

Uploaded by

RyanRuceMelvilleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strapped Footing Design

Uploaded by

RyanRuceMelvilleCopyright:

Available Formats

Straped footing design

CE-REF.COM

Home About News Products Services Calendar Contact

Search

Custom Search

Strap footing design Related topics

Contents: Bearing capacity

Introduction Pressure under footing

Reinforced concrete design

Service load design

Spread footing design

Example 3.4. Determine sizes of strap footing

Strap footing design

Structural analysis of strap footing

RC retaining wall design

Example 3.5: Determine moment and shear in a strap footing

Reinforced concrete design of strap footing

Example 3.6 Reinforced concrete design of a strap footing

Introduction

Combined footings and strap footings are normal used when one of columns is subjected to large eccentric loadings. When two

columns are reasonably close, a combined footing is designed for both columns as shown in Figure 3.1. When two columns are far

apart, a strap is designed to transfer eccentric moment between two columns as shown in Figure 3.1. The goal is to have uniform

bearing pressure and to minimize differential settlement between columns.

Figure 3.1 Combined footing and strap footing

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

Design assumptions

1. Strap does not provide bearing.

2. Strap is ridge enough to transfer moment from one footing to the other.

Design procedure

Service load design:

1. Determine the length of exterior footing and its eccentricity, e.

2. Determine eccentric moment, M = Pa*e.

3. Determine shear force, V = M / L

4. Determine footing reaction, Ra = Pa+V, and Rb = Pb -V

5. Determine footing sizes for both A & B.

Structural analysis

1. Calculate factored column loads, Pua & Pub

2. Calculate factored eccentric moment M u = Pua *e

3. Calculate factored shear, Vu = M u / L

4. Determine factored reactions, Rua & Rub.

5. Perform structural analysis, determine factored shear and moment on footings and strap.

Reinforced concrete design

1. Design exterior footing. Check shear stresses and design flexural reinforcement.

2. Design interior footing. Check shear stresses and design flexural reinforcements.

3. Design footing strap as a reinforced concrete beam.

Service load design:

Design procedure:

1. Determine the length of exterior footing and its eccentricity, e.

2. Determine eccentric moment, M = Pa*e.

3. Determine shear force, V = M / L

4. Determine footing reaction, Ra = Pa+V, and Rb = Pb -V

5. Determine footing sizes for both A & B.

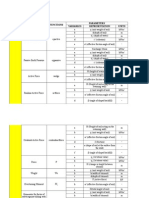

Example 3.4. Determine sizes of strap footing

Given:

Column information:

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

Column A: Live load = 40 kips, Dead load = 50 kips

Column B: Live load = 80 kips, Dead load = 100 kips.

Distance between two columns: 22 ft.

Footing information:

Allowable soil bearing capacity; 3000 psf

Distance from column A to edge of footing: 1 ft.

Allowable soil bearing capacity = 3000 psf

Weight of soil above footing = 120 psf

Depth of footing= 24”

Depth of soil above footing = 12”

Requirements: Determine the size of footing A & B.

Solution:

Assume a footing width of 6 ft, the eccentricity of footing A is e = 6/2-1=2’.

The distance between footing reaction, L = 22-2=20’

The eccentric moment is M = (40+50)*2=180 ft-kips

The shear produced by M is, V = 180/20=9 kips

Reaction at footing A = 40+50+9 =99 kips

Net soil bearing capacity = 3000-2*150-120=2580 psf

Required footing area of A = 99/2.58=38.4 ft2.

Use 6’ by 6.5’ footing, area = 39 ft2.

Reaction at footing B = 100+80-9=171 kips

Required footing area = 171/2.58=66.3 ft2.

Use 8’ by 8.5’ footing, A = 68 ft2.

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

Structural analysis of strap footing

Procedures

1. Calculate factored column loads, Pua & Pub

2. Calculate factored eccentric moment M u = Pua*e

3. Calculate factored shear, Vu = M u / L

4. Determine factored reactions, Rua & Rub.

5. Determine factored footing reactions.

6. Perform structural analysis; determine factored shear and moment on footings and strap.

Example 3.5: Determine moment and shear in a strap footing

Given: The strap footing in example 3.4

Design code: ACI 318-05

Requirement: Determine maximum factored shears and moment in the footings and strap.

Solution:

Factored column load of A = 1.2*50+1.6*40=124 kips

Factored column load of B = 1.2*100+1.6*80=248 kips

Factored eccentric moment, M u = 124*2=248 ft-kips

Factored shear, Vu = 248/20=12.4 kips

Factored footing reaction at A = 124+12.4= 136.4 kips

Factored footing pressure per linear foot of A = 136.4/6=22.7 k/ft

Factored footing reaction at B = 248-12.4= 235.6 kips

Factored footing pressure per linear foot at B = 235.6/8=29.5 k/ft.

Shear diagram:

At point 1: Vu = 22.7*1.5-124= -90 kips

At point 2: Vu = 22.7*6-124= 12.2 kips

At point 3: Vu = 22.7*6-124=12.2 kips

At point 4: Vu = 12.4+29.5*3.5= 115.7 kips

At point 5: Vu = 29.5*-3.5=-103.5 kips

Moment diagram:

At point 1: M = 22.7*1.52 /2-124*0.5= -36.5 ft-kips

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

At point 2: M u = 22.7*62 /2-124*5= -211.4 ft-kips

At point 3: M u = 22.7*6*(6/2+13)-124*(5+13)=-52.8 ft-kips

At point 4: M u = 22.7*6*(6/2+13+3.5)-124*(5+13+3.5)+29.5*3.52 /2=183 ft-kips

At point 5: M u = 29.5*3.52 /2= 180.7 ft-kips

Reinforced concrete design of strap footing

Design procedure:

1. Design exterior footing. Check shear stresses and design flexural reinforcement.

2. Design interior footing. Check shear stresses and design flexural reinforcements.

3. Design footing strap as a reinforced concrete beam.

Example 3.6 Reinforced concrete design of a strap footing

Given:

A strap footing with loading, shear, and moment as shown in example 3.4 & 3.5

Compressive strength of concrete for footing at 28 days: 3000 psi

Yield strength of rebars: 60 ksi

Design code: ACI 318-05

Requirement: design footing depth and flexural reinforcements.

Solution:

1. Design footing strap

Assume a 2’-6” by 2’ footing strap and the reinforcement is #8 bars, with 2” top cover the effective depth, d = 24-2-1=21”

a. Check direct shear

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

From Example 3.5, the factored shear force on footing strap, Vu = 12.4 kips

Factored shear strength of concrete,

f Vc = f v c*b*d = (0.75 x 2 x 3000)*30*21/1000=51.7 kips

Minimum shear strength of concrete without shear reinforcement.

1/2f Vc =0.5*51.7=25.8 kips > 12.4 kips no shear reinforcement is required

b. Design flexural reinforcement

From Example 3.5, the maximum factored moment at point 2, M u =211.4 ft-kips

Use trail method for reinforcement design

Assume a = 1.8 ".

T = M u /f(d-a/2) = (211.4)(12)/[(0.9)(21-1.8/2)]=140.2 kip

Calculate new a,

a = T/0.85fc'b = 140.2/[(0.85)(3)(30)] = 1.83 in » 1.8” assumed

As = T/fy = 140.2/60 = 2.33 in 2 .

The reinforcement ratio is

r = As /bd = 2.33/[(21)(30)] = 0.0037

Minimum reinforcement ratio,

r min = 0.0033

Use 4#7 bars, As = 0.6*4= 2.4 in 2 .

2. Design footing for column A

a. Check punching shear

Assume a 16” depth of footing and #6 bars, the effective depth

d = 16" - 3" (bottom cover) – 0.75 (one bar size) = 12.3 " = 1.02’

Factored footing pressure = 22.7/6.5=3.49 kips/ft2 .

The perimeter of punching shear is at one half effective depth from face of column.

Since the distance from exterior face of column to exterior face of footing, 6", is less than effective depth, d,

the perimeter of punching shear is only 3 sides. At the interior face of column the length is column width, 12" plus d.

At the other two faces is column width + d + 6".

P = 2*(6”+12”+12.3”/2)+(12”+12.3”)=72.6”

The punch shear stress can be calculated as

vu = [124-(3.49)(1+1.02)(0.5+1+1.02/2](1000)/[(12.3)(72.6)]= 123 psi

The shear strength of concrete is

f v c = 0.75 x 4 x Ö3000 = 164.3 psi O.K.

b. Check direct shear:

The critical section of direct shear is at one effective depth from the face of column. From Example 3.4, the maximum direction shear

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

is –90 kips at inside face of column.

The factored shear at one effective depth, d, from the face of the column is

Vu = 90*(4.5-1.02)/4.5=69.6 kips

Factored shear strength of concrete,

f Vc = f v c*b*d = (0.75 x 2 x Ö3000)*6.5*12*12.3/1000 = 78.8 kips > 69.6 kips O.K.

c. Determine maximum negative reinforcement in longitudinal direction

The location of zero shear is at

X = 4.5*90/(90+12.2) = 3.96’ from inside face of the column

The maximum negative moment is at zero shear, at 3.96’ from inside face of column, or 5.46’ from exterior end of footing.

M u = 22.7*5.462 /2-124*(0.5+3.96)=-214.7 ft-kips

Use trail method for reinforcement design

Assume a = 1.3".

T = M u /f(d-a/2) = (214.7)(12)/[(0.9)(12.3-1.3/2)]= 245.7 kip

Calculate new a,

a = T/0.85fc'b = 245.7/[(0.85)(3)(6.5*12)] = 1.24 in » 1.3” assumed

As = T/fy = 245.7/60 = 4.1 in 2 .

The reinforcement ratio is

r = As /bd = 4.1/[(78)(12.3)] = 0.0043

Minimum reinforcement ratio,

r min = 0.0033

Use 8-#7 bars, 4#7 extended from footing strap, 2 #7 in each side of footing,

As = 0.6*8=4.8 in 2 . Place reinforcement at top face of footing.

d. Determine reinforcement in transverse direction

The distance from face of column to the edge of the footing is

l = (6.5– 1)/2 =2.75'

The factored moment at the face of the column is

M u = (3.49)(2.75) 2 /2 = 13.2 k-ft. per foot width of footing

Use trail method for reinforcement design

Assume a = 0.5".

T = M u /f(d-a/2) = (14.7)(12)/[(0.9)(12.3-0.5/2)]= 16.3 kip

Calculate new a,

a = T/0.85fc'b = 16.3/[(0.85)(3)(12)] = 0.53 in » 0.5” assumed

As = T/fy = 16.3/60 = 0.27 in 2 . per one foot section.

The reinforcement ratio is

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

r = As /bd = 0.27/[(12)(12.3)] = 0.0018

Minimum reinforcement ratio,

rmin = 0.0033 > rmin =(4/3)*0.0018=0.0024

Use r min =0.0024

As = (0.0024 )(6)(12)(12.3) = 2.1 in2.

Use 5 #6 bars, As = 0.44*5= 2.2 in2.

Place reinforcement at bottom face of footing.

2. Design footing for column B

Assume a footing depth of 20” and #8 bars, the effective depth =20-3-1=16”

The factored footing pressure = 29.5/8.5= 3.47 ksf

a. Check punching shear

The perimeter of punching shear is at d/2 beyond faces of column

P = 4*(12+16)=112”

The punch shear stress can be calculated as

vu = [248-(3.47)(1+1.33) 2 ](1000)/(16)(112) = 127.9 psi <186 psi O.K.

b. Check direct shear:

The critical section of direct shear is at one effective depth from the face of column. From Example 3.4, the maximum direct shear is

115.7 kips at inside face of column.

The factored shear at one effective depth from the face of the column is

Vu = 12.2+(115.7-12.2)*(3.5-1.33)/3.5= 76.3 kips

Factored shear strength of concrete,

f Vc = f v c*b*d = (0.75 x 2 x Ö3000)*8.5*12*16/1000= 134.1 kips > 85 kips O.K.

c. Determine maximum positive reinforcement in longitudinal direction

M u = 180.7 ft-kips

Use trail method for reinforcement design

Assume a = 0.6".

T = M u /f(d-a/2) = (180.7)(12)/[(0.9)(16-0.6/2)]= 153.4 kip

Calculate new a,

a = T/0.85fc'b = 153.4/[(0.85)(3)(8.5*12)] = 0.59 in » 0.6” assumed

As = T/fy = 153.4/60 = 2.6 in 2 .

The reinforcement ratio is

r = As /bd = 2.6/[(8.5*12)(16)] = 0.0016

Minimum reinforcement ratio,

r min = 0.0033 >r min =(4/3)*0.0016=0.0021

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

Use r min =0.0021

As = (0.0021 )(8.5)(12)(16) = 3.5 in 2 .

Use 6-#7 bars, As = 0.6*6= 3.6 in 2 .

d. Determine reinforcement in transverse direction

The distance from face of column to the edge of the footing is

l = (8.5– 1)/2 =3.75'

The factored moment at the face of the column is

M u = (3.47)(3.75) 2 /2 = 24.4 k-ft. per foot width of footing

Use trail method for reinforcement design

Assume a = 0.7".

T = M u /f(d-a/2) = (24.4)(12)/[(0.9)(16-0.7/2)]= 20.8 kip

Calculate new a,

a = T/0.85fc'b = 20.8/[(0.85)(3)(12)] = 0.68 in » 0.7” assumed

As = T/fy = 20.8/60 = 0.35 in 2 per one foot section.

The reinforcement ratio is

r = As /bd = 0.35/[(12)(16)] = 0.0018

Minimum reinforcement ratio,

r min = 0.0033 > r min =(4/3)*0.0018=0.0024

Use r min =0.0024

As = (0.0024)(8)(12)(16) = 3.7 in2.

Use 7 #7 bars, As = 0.6*7= 4.2 in2.

4. Designing column dowels.

The bearing capacity of concrete at column base is

Pc = (0.7)(0.85)(4)(12)(12) = 342.7 kips

Which is greater than factored column loads of both A and B.

The minimum dowel area is

As,min = (0.0005)(12)(12) = 0.72 in2

Use 4 - #4 dowels As = 0.8 in2

The footing is shown in below

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

Straped footing design

Home | About | Calendar | Contact | Employees | Employment | FAQ | Information Links | News | Photo Gallery | Press | Products | Promotions | Services | Site Map

Disclaimer: The content of this website was obtained and edited from various resources. The editor made reasonable effort of editing. Nevertheless, the editor does not warrant, and assume no

liability for accuracy and completeness of its content. The viewer shall use his/her professional knowledge and judgment in use of the web content. Webmaster: www.ce-ref.com

Copyright: www.ce-ref.com. All Rights Reserved.

http://www.ce-ref.com/Foundation/Straped_footing/FTG_Straped.html[31/05/2015 12:27:54 PM]

You might also like

- PRMG6003 - TrustWeb Case StudyDocument72 pagesPRMG6003 - TrustWeb Case StudyRyanRuceMelvilleNo ratings yet

- 300 Solved Problems in Geotechnical EngineeringDocument0 pages300 Solved Problems in Geotechnical Engineeringmote3488% (17)

- 300 Solved Problems in Geotechnical EngineeringDocument0 pages300 Solved Problems in Geotechnical Engineeringmote3488% (17)

- A Short Course in Geotechnical Site Investigation PDFDocument369 pagesA Short Course in Geotechnical Site Investigation PDFFrapint100% (17)

- Lu & Likos - Unsaturated Soil Mechanics (Solutions Manual) PDFDocument108 pagesLu & Likos - Unsaturated Soil Mechanics (Solutions Manual) PDFnearmonkey100% (3)

- Slab Designer As Per IS 456-2000Document7 pagesSlab Designer As Per IS 456-2000mofizahmed64% (11)

- Biogas Generation From Rice Cooking WastewaterDocument3 pagesBiogas Generation From Rice Cooking WastewaterProyectos Plantas De Tratamiento De AguaNo ratings yet

- Analysis and Design of Cantilever SlabDocument9 pagesAnalysis and Design of Cantilever SlabOscarKonzultNo ratings yet

- Design of DomeDocument5 pagesDesign of DomeAmarjeet SinghNo ratings yet

- Method of RCC Slab Design As Per Is 456Document2 pagesMethod of RCC Slab Design As Per Is 456Shruti Shah67% (3)

- Anchor Bolt DesignDocument26 pagesAnchor Bolt Designdwicahyo_as100% (1)

- Proposed Research Laboratory Center Soil Investigation ReportDocument51 pagesProposed Research Laboratory Center Soil Investigation ReportAHMED SOHEL67% (6)

- NFM Annual Report and Financial AnalysisDocument44 pagesNFM Annual Report and Financial AnalysisRyanRuceMelvilleNo ratings yet

- Som MCQDocument14 pagesSom MCQVignesh Vicky0% (2)

- Structural Masangkay ExamDocument34 pagesStructural Masangkay ExamMary Lenilie Candare VenganoNo ratings yet

- Design of Underground Water TankDocument6 pagesDesign of Underground Water TankAlfred PatrickNo ratings yet

- 5.3 Slab 5.3.1 Slab: Office Area: Ref. Calculation OutputDocument27 pages5.3 Slab 5.3.1 Slab: Office Area: Ref. Calculation OutputNH SyzlnNo ratings yet

- Pile Cap DesignDocument28 pagesPile Cap Designpwd2007No ratings yet

- Load Combination and Flexural Design of Roof Deck BeamsDocument123 pagesLoad Combination and Flexural Design of Roof Deck BeamsMarkNo ratings yet

- Reinforced ConcreteDocument12 pagesReinforced ConcreteluckywaysNo ratings yet

- Presentation On Analysis and Design of Small Reinforced Concrete BuildingsDocument29 pagesPresentation On Analysis and Design of Small Reinforced Concrete BuildingsPuneeth H GowdaNo ratings yet

- Excel Template For Strap Footing Using ES en CodeDocument9 pagesExcel Template For Strap Footing Using ES en CodeJim JamNo ratings yet

- Two Way Slab (First Slab Level Slabs)Document15 pagesTwo Way Slab (First Slab Level Slabs)Anjali DudhyalNo ratings yet

- RC-Cantiliver Slab DesignDocument2 pagesRC-Cantiliver Slab DesignJerielle Annika GetuabanNo ratings yet

- Analysis and Design of SlabsDocument3 pagesAnalysis and Design of Slabsdhanya1995100% (1)

- Mathcad - 03-Design of Singly Reinforced BeamsDocument3 pagesMathcad - 03-Design of Singly Reinforced BeamsMrAlittle FingerNo ratings yet

- Stair Case Design Single FlightDocument3 pagesStair Case Design Single Flightrahul100% (1)

- RCC51 Column Load Take-Down & DesignDocument8 pagesRCC51 Column Load Take-Down & Designعصام السامرائيNo ratings yet

- Design of combined footingDocument6 pagesDesign of combined footingEric John PedrosoNo ratings yet

- Isolated footing design example step-by-step guideDocument6 pagesIsolated footing design example step-by-step guidetopukuet100% (1)

- Detailed Longitudinal Section Through RCC Deep BeamDocument1 pageDetailed Longitudinal Section Through RCC Deep BeamShaikh ImranNo ratings yet

- Design of Isolated Footing with Moment CalculationsDocument28 pagesDesign of Isolated Footing with Moment CalculationsmeenuNo ratings yet

- Problem LossesDocument5 pagesProblem LossesArvee GavinoNo ratings yet

- Design of Combined Footing (CFDocument12 pagesDesign of Combined Footing (CFp_ignatiusNo ratings yet

- Combine Footing FinallDocument227 pagesCombine Footing FinallKhalid BanafaNo ratings yet

- Strap Footing Eqns PDFDocument6 pagesStrap Footing Eqns PDFaldert_path100% (2)

- Sepakat Setia Perunding SDN BHD: Design InformationDocument6 pagesSepakat Setia Perunding SDN BHD: Design InformationAfiq SyahmiNo ratings yet

- Design of Critical Two-Way SlabDocument8 pagesDesign of Critical Two-Way SlabBevelyn Manalo100% (1)

- Beam Design ExcelDocument3 pagesBeam Design Excelprashanth palaniNo ratings yet

- DESIGN of Combined-FootingDocument2 pagesDESIGN of Combined-FootingsPringShockNo ratings yet

- Column DesignDocument56 pagesColumn DesignSakar ShresthaNo ratings yet

- Wall Footing DesignDocument102 pagesWall Footing DesignAUNGPSNo ratings yet

- Strip Footing Load Analysis For Rajendra Prasad Kharel: Grid 1-1Document3 pagesStrip Footing Load Analysis For Rajendra Prasad Kharel: Grid 1-1Er Saroj PaudelNo ratings yet

- RCC Beams: Doubly Reinforced BeamDocument2 pagesRCC Beams: Doubly Reinforced BeamSandeep ChavanNo ratings yet

- Calculation NoteDocument10 pagesCalculation NoteJay EvansNo ratings yet

- Handout 4: Design of Slabs A. ONE-WAY SLABS - Supported On Two Edges and Bends in Only One Direction. Please ReadDocument7 pagesHandout 4: Design of Slabs A. ONE-WAY SLABS - Supported On Two Edges and Bends in Only One Direction. Please ReadKevin MedinaNo ratings yet

- Design of Combined FootingDocument12 pagesDesign of Combined FootingAhmmed Muhsee100% (2)

- Strap FootingDocument30 pagesStrap Footinganon_140586866No ratings yet

- Slab Design As Per IS 456Document7 pagesSlab Design As Per IS 456RitaBiswas100% (1)

- Two-way Restrained Slab Design CheckDocument3 pagesTwo-way Restrained Slab Design CheckBasandharaAdhikariNo ratings yet

- Design of Reinforced Concrete Shear WallDocument15 pagesDesign of Reinforced Concrete Shear WallAnonymous nwByj9L0% (1)

- ACI SLAB DESIGN FOR TWO-WAY RECTANGULAR EDGE SUPPORTED SLABDocument1 pageACI SLAB DESIGN FOR TWO-WAY RECTANGULAR EDGE SUPPORTED SLABMuhammad FaisalNo ratings yet

- Admin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Document3 pagesAdmin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Saifulazreen Mahyan100% (1)

- Design of Isolated Mat FootingDocument5 pagesDesign of Isolated Mat FootingYAROFENo ratings yet

- Design of Beams - BS 8110Document3 pagesDesign of Beams - BS 8110thanigai veluNo ratings yet

- Isolated Footing Design Example and Excel SheetDocument8 pagesIsolated Footing Design Example and Excel Sheetosama prog100% (1)

- Design of Footing For Edge Column1Document6 pagesDesign of Footing For Edge Column1sivakumarNo ratings yet

- Design of Doubly Reinforced BeamDocument2 pagesDesign of Doubly Reinforced BeamZnake Von LucasNo ratings yet

- Column-Footing Size 3Document8 pagesColumn-Footing Size 3Anonymous HJ7hmihhNo ratings yet

- Combined Footing Edge-Interior ColumnDocument35 pagesCombined Footing Edge-Interior ColumnReuben James BangaoilNo ratings yet

- Combined Footing Design ES en 2015Document24 pagesCombined Footing Design ES en 2015Dino AbdelaNo ratings yet

- Admin - Mission: Design of Footing F4Document6 pagesAdmin - Mission: Design of Footing F4nishusainiNo ratings yet

- Eccentric Footing Design 4Document10 pagesEccentric Footing Design 4Murthy Guna100% (1)

- TR.28.2.1 Soft Story CheckingDocument2 pagesTR.28.2.1 Soft Story CheckingsvnNo ratings yet

- One Way Slab DesignDocument4 pagesOne Way Slab DesignMario FeghaliNo ratings yet

- Strap Footing DesignDocument19 pagesStrap Footing DesignMainali Ishu100% (1)

- Strap footing design analysisDocument16 pagesStrap footing design analysisWaqar Ahmed75% (4)

- Combined Footing Design PDFDocument10 pagesCombined Footing Design PDFmido medoNo ratings yet

- Combined Footing DesignDocument10 pagesCombined Footing Designmido medoNo ratings yet

- Design of Strap FootingDocument6 pagesDesign of Strap FootingEdgar Arana JNo ratings yet

- Correlations of Soil Properties PDFDocument68 pagesCorrelations of Soil Properties PDFRyanRuceMelvilleNo ratings yet

- Manual For Design and Detailing of RCCDocument340 pagesManual For Design and Detailing of RCCimranmehfoozNo ratings yet

- 4 Combined FootingDocument22 pages4 Combined FootingKamel Jamal BesharahNo ratings yet

- Drilled ShaftDocument186 pagesDrilled ShaftRyanRuceMelvilleNo ratings yet

- (Hugh Brooks) Basics of Retaining Wall Design, 8thDocument229 pages(Hugh Brooks) Basics of Retaining Wall Design, 8thOctavio Castro CamachoNo ratings yet

- Site Investigation 2010 - Master - Chapter 2.0Document135 pagesSite Investigation 2010 - Master - Chapter 2.0RyanRuceMelvilleNo ratings yet

- ACI - 318 - 05 Design of Slab PDFDocument24 pagesACI - 318 - 05 Design of Slab PDFtaz_taz3No ratings yet

- Wastewater Study ManualDocument111 pagesWastewater Study ManualRyanRuceMelvilleNo ratings yet

- Combined Footing 1Document7 pagesCombined Footing 1RyanRuceMelvilleNo ratings yet

- Table of The FunctionsDocument20 pagesTable of The FunctionsRyanRuceMelvilleNo ratings yet

- Steel Spreadsheet ChristelleDocument18 pagesSteel Spreadsheet ChristelleRyanRuceMelvilleNo ratings yet

- Beam Design MylesDocument1,278 pagesBeam Design MylesRyanRuceMelvilleNo ratings yet

- Activity Magnitude and IntensityDocument3 pagesActivity Magnitude and Intensityrobelyn valenzuelaNo ratings yet

- Design of Structure For Earthquake Resistance Part 1Document53 pagesDesign of Structure For Earthquake Resistance Part 1Ng JialinNo ratings yet

- Ce 481 Shear Strength 3Document103 pagesCe 481 Shear Strength 3phan phucNo ratings yet

- Buckling of Woven Fabric - NewDocument27 pagesBuckling of Woven Fabric - NewShovan Das100% (3)

- Etabs SoftwareDocument14 pagesEtabs SoftwareD.RamyasreeNo ratings yet

- Diltancy AngleDocument7 pagesDiltancy AngleGopal PNo ratings yet

- 10 1 1 703 8121 PDFDocument41 pages10 1 1 703 8121 PDFFrans van der MerweNo ratings yet

- Tension Test of Low Carbon SteelDocument7 pagesTension Test of Low Carbon SteelUsman ishaqNo ratings yet

- Strain and Stress in Continuum MechanicsDocument15 pagesStrain and Stress in Continuum MechanicsMuhammad Irfan KhanNo ratings yet

- Effect of Fiber Length and Placement Method On Flexural BehaviorDocument15 pagesEffect of Fiber Length and Placement Method On Flexural BehaviorHanumaNo ratings yet

- Torsion, Bending and Buckling of Steel Beams by Trahair 1997Document6 pagesTorsion, Bending and Buckling of Steel Beams by Trahair 1997fahmi aballiNo ratings yet

- Euler Bernoulli PDFDocument2 pagesEuler Bernoulli PDFJoshuaNo ratings yet

- Freyssinet - Freyssibar Plus 1200Document2 pagesFreyssinet - Freyssibar Plus 1200QuangKhảiNo ratings yet

- Earthquake-Resistant Design of StructuresDocument36 pagesEarthquake-Resistant Design of Structures연민민No ratings yet

- A New Codified Design Theory of Second-Order Direct Analysis For Steel A...Document7 pagesA New Codified Design Theory of Second-Order Direct Analysis For Steel A...Luis MartinsNo ratings yet

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 11 PDFDocument82 pagesPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 11 PDFCarlos Alberto Pacheco Sierra100% (1)

- Seaoc Vol 4 2018Document335 pagesSeaoc Vol 4 2018EngrDebashisMallickNo ratings yet

- 1050 HidveghyDocument4 pages1050 HidveghyAdityaNo ratings yet

- STABILTY ASSESSMENT OF HEADRACE TUNNEL SYSTEM FOR PUNATSANGCHHU II HYDROPOWER PROJECT, BHUTAN - Estimation of Seepage and Water Leakage in Underground TunnelsDocument4 pagesSTABILTY ASSESSMENT OF HEADRACE TUNNEL SYSTEM FOR PUNATSANGCHHU II HYDROPOWER PROJECT, BHUTAN - Estimation of Seepage and Water Leakage in Underground TunnelsSudeep SharmaNo ratings yet

- CEEN 3160 - Geotechnical Engineering Example Exam 2 Questions - Fall 2012Document3 pagesCEEN 3160 - Geotechnical Engineering Example Exam 2 Questions - Fall 2012Devendrasinh PadhiyarNo ratings yet

- TCC42 Post Tensioned Analysis & DesignDocument17 pagesTCC42 Post Tensioned Analysis & Designhala_azhariNo ratings yet

- Steel Ch4 - Beams MoviesDocument80 pagesSteel Ch4 - Beams Moviesomar45No ratings yet

- Som-I - Ii Mid Subjective Q.BDocument4 pagesSom-I - Ii Mid Subjective Q.BB VAMSI KRISHNANo ratings yet

- Understanding Viscosity: Newton's Law of ViscosityDocument2 pagesUnderstanding Viscosity: Newton's Law of ViscosityMufeesNo ratings yet

- Direct Shear Test S 30 1Document10 pagesDirect Shear Test S 30 1jems patel0% (1)

- Statically Indeterminate Structures & Thermal StressesDocument24 pagesStatically Indeterminate Structures & Thermal StressesBuddy SinghNo ratings yet

- Nut & Bolt Connection DesignDocument16 pagesNut & Bolt Connection DesignChandana KumaraNo ratings yet

- Beam Design and Vibration AnalysisDocument9 pagesBeam Design and Vibration AnalysisjatinNo ratings yet