Professional Documents

Culture Documents

Hot Di PDF

Uploaded by

Zahrotul Hayati0 ratings0% found this document useful (0 votes)

29 views5 pagesOriginal Title

HOT DI.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views5 pagesHot Di PDF

Uploaded by

Zahrotul HayatiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

1

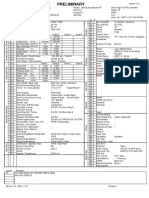

Case Name: C:\WINDOWS\system32\NoName.usc

2

3 Calgary, Alberta Unit Set: EuroSI

4 CANADA

Date/Time: Tuesday Sep 25 2018, 10:37:53

5

6

7 Pipe Segment: LOOP PIPE

8

9

10

CONNECTIONS

11

12

Inlet Stream

13 STREAM NAME FROM UNIT OPERATION

14 HOT DI SUPPLY

15

16

Outlet Stream

17 STREAM NAME TO UNIT OPERATION

18 HOT DI RETURN

19

20

Energy Stream

21 STREAM NAME TO UNIT OPERATION

22 HEAT LOSS

23

24

PARAMETERS

25

26

Pressure Gradient/Pipe Parameters

27 Pipe Flow Correlation Beggs and Brill Pressure Drop: 1.315 bar

28

29

Fittings Parameters

30 Segment Number

31 Fitting Name

32 VH Factor

33 FT Factor

34 Data Source

35

36

Swage Parameters

37 Segment Number

38 Swage Name

39 Swage Angle (deg)

40 Inlet Diameter

41 Outlet Diameter

42 Swage Type

43

44

CALCULATION

45 Pressure Tolerance (bar) 0.0010 Length Step Size (m) 1000

46 Temperature Tolerance (C) 0.0100 Flow Initial Guess (kgmole/h) 360.0

47 Heat Flow Tolerance (kcal/h) 8.604e-002 Flow Step Size (kgmole/h) 252.0

48 Length Initial Guess (m) 5000 Diam. Initial Guess (mm) 80.00

49 Always Use PH Flash Disabled Default Increments 5

50 Do Deposition Calcs Enabled Check Choke Flow Disabled

51 Is Pipe Choked No

52

53

User Variables

54

55

SIZING

56 Segment Number 1

57 Fitting/Pipe Pipe

58 Distance (m) 200.0 *

59 Elevation Change (m) 6.000 *

60 Schedule Schedule 40

61 Nominal Diameter (mm) 76.20

62 Outer Diameter (mm) 88.90

63 Honeywell International Inc. UniSim Design (R390.1 Build 15107) Page 1 of 5

Licensed to: Printed by: Zahro * Specified by user.

1

Case Name: C:\WINDOWS\system32\NoName.usc

2

3 Calgary, Alberta Unit Set: EuroSI

4 CANADA

Date/Time: Tuesday Sep 25 2018, 10:37:53

5

6

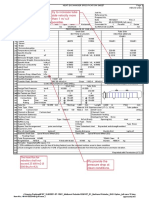

7 Pipe Segment: LOOP PIPE (continued)

8

9

10

SIZING

11 Inner Diameter (mm) 77.93

12 Material Mild Steel

13 Roughness (m) 4.572e-005 *

14 Conductivity (W/m-K) 45.00 *

15 Increments 5*

16

17

HEAT TRANSFER

18 Heat Loss: 2810 kcal/h Ambient Temp: 25.00 C * Overall HTC: 3.516 kJ/h-m2-C

19

20

Inside Heat Transfer Coefficient Estimation

21 Include Inner HTC: Enabled Correlation: UniSim Profes

22

23

Pipe Wall Resistance Estimation

24 Include Pipe Wall Resistance: Enabled

25

26

Insulation Resistance Estimation

27 Include Conduction: Enabled Type: Fiberglass Block Thermal Cond.: 0.0350 W/m-K * Thickness: 0.0500 m *

28

29

Outside Heat Transfer Coefficient Estimation

30 Include Outer HTC Outer Diameter Ambient Medium Velocity

31 Enabled --- Air 1.000 m/s *

32

33

PROFILES

34

35

Data

36 Distance Elevation Increments

37 (m) (m)

38 0.0000 0.0000 5

39 200.0 6.000

40

41

Pipe Table

42 Length (m) 0.0000 40.00 80.00 120.0

43 Elevation (m) 0.0000 1.200 2.400 3.600

44 Pressure (bar) 4.000 3.737 3.474 3.211

45 Temperature (C) 84.92 84.90 84.89 84.87

46 Vapour Fraction 0.0000 0.0000 0.0000 0.0000

47 Heat Transferred (kJ/h-m) --- 58.82 58.80 58.79

48 Flow Regime Liquid Only Liquid Only Liquid Only Liquid Only

49 Liquid HoldUp 1.000 1.000 1.000 1.000

50 Friction Gradient (kPa/m) 0.3751 0.3751 0.3751 0.3751

51 Static Gradient (kPa/m) 0.2826 0.2826 0.2826 0.2826

52 Accel. Gradient (kPa/m) 0.0000 0.0000 0.0000 0.0000

53 Liq. Reynolds 4.112e+005 4.112e+005 4.111e+005 4.110e+005

54 Vap. Reynolds --- --- --- ---

55 Liquid Velocity (m/s) 1.815 1.815 1.815 1.815

56 Vapour Velocity (m/s) --- --- --- ---

57 Deposit Thickness (mm) --- --- --- ---

58 Deposit Volume (m3) --- --- --- ---

59 Length (m) 160.0 200.0

60 Elevation (m) 4.800 6.000

61 Pressure (bar) 2.948 2.685

62 Temperature (C) 84.86 84.84

63 Honeywell International Inc. UniSim Design (R390.1 Build 15107) Page 2 of 5

Licensed to: Printed by: Zahro * Specified by user.

1

Case Name: C:\WINDOWS\system32\NoName.usc

2

3 Calgary, Alberta Unit Set: EuroSI

4 CANADA

Date/Time: Tuesday Sep 25 2018, 10:37:53

5

6

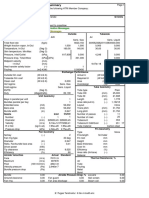

7 Pipe Segment: LOOP PIPE (continued)

8

9

10

PROFILES

11

12

Pipe Table

13 Vapour Fraction 0.0000 0.0000

14 Heat Transferred (kJ/h-m) 58.77 58.76

15 Flow Regime Liquid Only Liquid Only

16 Liquid HoldUp 1.000 1.000

17 Friction Gradient (kPa/m) 0.3751 0.3751

18 Static Gradient (kPa/m) 0.2826 0.2826

19 Accel. Gradient (kPa/m) 0.0000 0.0000

20 Liq. Reynolds 4.109e+005 4.109e+005

21 Vap. Reynolds --- ---

22 Liquid Velocity (m/s) 1.815 1.815

23 Vapour Velocity (m/s) --- ---

24 Deposit Thickness (mm) --- ---

25 Deposit Volume (m3) --- ---

26

27

SLUG OPTIONS

28 Slug Tool Calculation Options

29 Translational Model: Bendikson

30 Velovity Papameter CO: ---

31 Velovity Papameter UO: (m/s) ---

32 Hold Up Model: Gregory et al

33 Hold Up Parameter: ---

34 Friction Factor Model: Colebrook

35 Slug Tool Frequency Options

36 Frequency Model: Hill & Wood

37 Frequency: (1/seconds) ---

38

39

SLUG TOOL RESULTS

40 Position Status Frequency Slug Freq.Text Slug Length Bubble Length

41

42 Position Film Holdup Slug Velocity Pressure Gradient Slug/Bubble Ratio

43

44

45

CONDITIONS

46 Name HOT DI SUPPLY HOT DI RETURN HEAT LOSS

47 Vapour 0.0000 0.0000 ---

48 Temperature (C) 84.9200 * 84.8423 ---

49 Pressure (bar) 4.0000 * 2.6846 ---

50 Molar Flow (kgmole/h) 1661.9158 1661.9158 ---

51 Mass Flow (kg/h) 29939.5807 29939.5807 ---

52 Std Ideal Liq Vol Flow (m3/h) 30.0000 * 30.0000 ---

53 Molar Enthalpy (kcal/kgmole) -6.729e+004 -6.729e+004 ---

54 Molar Entropy (kJ/kgmole-C) 67.98 67.97 ---

55 Heat Flow (kcal/h) -1.1183e+08 -1.1183e+08 2.8101e+03

56

57

PROPERTIES

58 Name HOT DI SUPPLY HOT DI RETURN

59

60

61

62

63 Honeywell International Inc. UniSim Design (R390.1 Build 15107) Page 3 of 5

Licensed to: Printed by: Zahro * Specified by user.

1

Case Name: C:\WINDOWS\system32\NoName.usc

2

3 Calgary, Alberta Unit Set: EuroSI

4 CANADA

Date/Time: Tuesday Sep 25 2018, 10:37:53

5

6

7 Pipe Segment: LOOP PIPE (continued)

8

9

10

DYNAMICS

11

12

Parameters

13 Pipe Flow Model 'Quick'n Dirty' Methods Pipe Friction Model turbulent Pipe Holdup Type one holdup per segment

14 Model Holdup Volume Off Base Elevation of Inlet Relative to Ground 0.0000 m *

15

16

DEPOSITION

17

18

Methods

19 Method None Time Step 4.320e+004 seconds

20 Max. Time 6.048e+005 seconds Simulation Time ---

21

22

Properties

23 Density 881.0 kg/m3 Yield Strength 2.068e-002 bar

24 Thermal Conductivity 0.2596 W/m-K

25

26

Profile

27 Cell 1 2 3 4 5

28 Cum. Length (m) 40.0000 80.0000 120.000 160.000 200.000

29 Init. Dep. Thick. (mm) --- --- --- --- ---

30 Calc. Dep. Thick. (mm) --- --- --- --- ---

31 Dep. Volume (m3) --- --- --- --- ---

32 Dep. Rate (kg/s-m2) --- --- --- --- ---

33 Film Coefficient (kJ/h-m2-C) 39830.0 39824.8 39819.7 39814.5 39809.3

34 Wall Temperature (C) --- --- --- --- ---

35 Fluid Temperature (C) --- --- --- --- ---

36 Critical Deposition Temperature (C) --- --- --- --- ---

37

38

Limits

39 Allowable Max. Deposit Thickness --- Max. Deposit Thickness ---

40 Allowable Overall Pressure Drop --- Overall Pressure Drop 1.31536 bar

41 Allowable Deposit Volume --- Deposit Volume ---

42 Allowable Plug Pressure Drop --- Plug Pressure Drop ---

43

44

NOTES

45

46

47 Workbook: Case (Main)

48

49

50

Streams Fluid Pkg: All

51 Name HOT DI SUPPLY HOT DI RETURN HEAT LOSS

52 Vapour Fraction 0.0000 0.0000 ---

53 Temperature (C) 84.92 * 84.84 ---

54 Pressure (bar) 4.000 * 2.685 ---

55 Molar Flow (kgmole/h) 1662 1662 ---

56 Mass Flow (kg/h) 2.994e+004 2.994e+004 ---

57 Std Ideal Liq Vol Flow (m3/h) 30.00 * 30.00 ---

58 Heat Flow (kcal/h) -1.118e+008 -1.118e+008 2810

59 Molar Enthalpy (kcal/kgmole) -6.729e+004 -6.729e+004 ---

60

61

62

63 Honeywell International Inc. UniSim Design (R390.1 Build 15107) Page 4 of 5

Licensed to: Printed by: Zahro * Specified by user.

1

Case Name: C:\WINDOWS\system32\NoName.usc

2

3 Calgary, Alberta Unit Set: EuroSI

4 CANADA

Date/Time: Tuesday Sep 25 2018, 10:37:53

5

6

7 Workbook: Case (Main) (continued)

8

9

10

Unit Ops

11 Operation Name Operation Type Feeds Products Ignored Calc Level

12 HOT DI SUPPLY HOT DI RETURN

LOOP PIPE Pipe Segment No 500.0 *

13 HEAT LOSS

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63 Honeywell International Inc. UniSim Design (R390.1 Build 15107) Page 5 of 5

Licensed to: Printed by: Zahro * Specified by user.

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Case study of subsea piping systemDocument8 pagesCase study of subsea piping systemRaseuki MahadinaNo ratings yet

- Subsea piping case studyDocument16 pagesSubsea piping case studyRaseuki MahadinaNo ratings yet

- E 104DKXBNWKDNXKDocument1 pageE 104DKXBNWKDNXKkeyNo ratings yet

- Output Summary: SI UnitsDocument14 pagesOutput Summary: SI UnitsEduardoNo ratings yet

- Output Summary for Refrigerant CondenserDocument30 pagesOutput Summary for Refrigerant Condenserahmad santosoNo ratings yet

- E 103djwebkdDocument1 pageE 103djwebkdkeyNo ratings yet

- 100-Mc-417-Ra3-Hx-Ra3 - HDC Condensador Reactor PDFDocument2 pages100-Mc-417-Ra3-Hx-Ra3 - HDC Condensador Reactor PDFSonya LoveraNo ratings yet

- Heat Exchanger Specification Sheet for Renewable Naphtha Product CoolerDocument2 pagesHeat Exchanger Specification Sheet for Renewable Naphtha Product Coolershahbaz akramNo ratings yet

- Lab 2 (I) 3Document6 pagesLab 2 (I) 3SchaieraNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Expander: K-100: Stream Name 3Document1 pageExpander: K-100: Stream Name 3Sebastian Camilo Garcia PradaNo ratings yet

- Case 1 e 002 D - H Rev 0Document16 pagesCase 1 e 002 D - H Rev 0Oswaldo GuerraNo ratings yet

- 23-HA-103 - Rating Case - 1Document11 pages23-HA-103 - Rating Case - 1yadav yadavNo ratings yet

- 0208 79 Aa00Document1 page0208 79 Aa00rezarossNo ratings yet

- HE Inputs RequiredDocument1 pageHE Inputs RequireddinakaranpatelNo ratings yet

- Heat exchanger specification sheetDocument1 pageHeat exchanger specification sheetSonya LoveraNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- Electric Heater Datasheet BreakdownDocument3 pagesElectric Heater Datasheet BreakdownSonNguyenNo ratings yet

- Lab 2 (Ii) FlashDocument3 pagesLab 2 (Ii) FlashSchaieraNo ratings yet

- Electric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Document3 pagesElectric Heater Datasheet: Case 1A Case 1B Case 2 Case 3 Case 4 Case 5Tuấn VũNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Heat exchanger specification sheet vibration analysisDocument3 pagesHeat exchanger specification sheet vibration analysisSRINo ratings yet

- 7854-Hds-2e2301 Rev 8Document3 pages7854-Hds-2e2301 Rev 8SonNguyenNo ratings yet

- FS22-002-Process Calculation For Chiller - Rev.A-Bundle OptionDocument3 pagesFS22-002-Process Calculation For Chiller - Rev.A-Bundle OptionJason DoNo ratings yet

- See Runtime Message Report For Warning MessagesDocument1 pageSee Runtime Message Report For Warning MessagesainunNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- Preliminary Control Valve Specification SheetDocument5 pagesPreliminary Control Valve Specification SheetElias EliasNo ratings yet

- HTRI Output Summary for Biogas Cooler DesignDocument1 pageHTRI Output Summary for Biogas Cooler Designkindi76_153423792No ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Chocolatos 2Document1 pageChocolatos 2Hariyono Rudi NovantoNo ratings yet

- SE230701184 - Heater & Panel DatasheetsDocument18 pagesSE230701184 - Heater & Panel DatasheetsVivek SavaliyaNo ratings yet

- Credit Suise All the ReportsDocument5 pagesCredit Suise All the ReportsvheoncygracenNo ratings yet

- Datasheet Motor Faj 7 y 9Document7 pagesDatasheet Motor Faj 7 y 9Danny Javes PeredaNo ratings yet

- Apron FeederDocument8 pagesApron FeederBruce QuareNo ratings yet

- RicisDocument1 pageRicisHariyono Rudi NovantoNo ratings yet

- Dawn of War II Manual - ENDocument45 pagesDawn of War II Manual - ENelmarcusIINo ratings yet

- Sekiro: See Runtime Message Report For Warning MessagesDocument1 pageSekiro: See Runtime Message Report For Warning MessagesĐinh Hoàng ViệtNo ratings yet

- 8670 HAP3125 - HDS - REV 1 (150NB #600 U Stamp)Document3 pages8670 HAP3125 - HDS - REV 1 (150NB #600 U Stamp)SonNguyenNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- Simulation Summary of Horizontal EconomizerDocument1 pageSimulation Summary of Horizontal EconomizerHariyono Rudi NovantoNo ratings yet

- Lab 2 (I) 4Document3 pagesLab 2 (I) 4SchaieraNo ratings yet

- Process Design Report SummaryDocument3 pagesProcess Design Report Summarymuhd.qasimNo ratings yet

- Practica 4-ReporteDocument13 pagesPractica 4-ReporteLIZETH MANUEL CELAYANo ratings yet

- 1007 Ac Hex 001 R0Document5 pages1007 Ac Hex 001 R0züheyir nuralNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- Data SpesitxfikasiDocument4 pagesData Spesitxfikasidede rizkiNo ratings yet

- Chiller Data SheetDocument3 pagesChiller Data SheetMoriyasuNguyenNo ratings yet

- Control Valve Data SheetDocument6 pagesControl Valve Data SheetsisesetNo ratings yet

- E 105jewkbdjdDocument2 pagesE 105jewkbdjdkeyNo ratings yet

- Đánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDocument1 pageĐánh giá hệ thống hiện hữu tăng công suất khí Saint-GobainDuy Nguyễn VănNo ratings yet

- PramonnoDocument1 pagePramonnoHariyono Rudi NovantoNo ratings yet

- Sekiro: See Runtime Message Report For Warning MessagesDocument1 pageSekiro: See Runtime Message Report For Warning MessagesĐinh Hoàng ViệtNo ratings yet

- Heat Exchanger: E-107: Connections Tube Side Shell SideDocument2 pagesHeat Exchanger: E-107: Connections Tube Side Shell SidekeyNo ratings yet

- TT 453Document3 pagesTT 453Manuel Rodriguez CNo ratings yet

- Output Summary: SI UnitsDocument1 pageOutput Summary: SI Unitsdaboo sanatNo ratings yet

- Pump: P-100: Stream Name Liq-1Document2 pagesPump: P-100: Stream Name Liq-1Sebastian Camilo Garcia PradaNo ratings yet

- ChocolatosDocument1 pageChocolatosHariyono Rudi NovantoNo ratings yet

- HTRI Output Summary for Multipass Shell and Tube Heat ExchangerDocument1 pageHTRI Output Summary for Multipass Shell and Tube Heat ExchangerGiulliano Enrique MucciNo ratings yet

- WWTP Process Flow ChartDocument1 pageWWTP Process Flow ChartGalih SaputraNo ratings yet

- Auto Cad 20042 D TutorialDocument358 pagesAuto Cad 20042 D TutorialRakman EndRo HutaBaratNo ratings yet

- P&ID HandoutDocument18 pagesP&ID HandoutVu Hoang VoNo ratings yet

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- 2b0035dd2d 23f2e6f3bfDocument99 pages2b0035dd2d 23f2e6f3bfZahrotul HayatiNo ratings yet

- Fluidized BedDocument24 pagesFluidized BedZahrotul HayatiNo ratings yet

- AbstrakDocument2 pagesAbstrakZahrotul HayatiNo ratings yet

- Singh B 1960 PHD ThesisDocument285 pagesSingh B 1960 PHD ThesisMarcoTacoNo ratings yet

- Franz Diffusion Cell Approach For Pre-Formulation Characterisation of Ketoprofen Semi-Solid Dosage FormsDocument8 pagesFranz Diffusion Cell Approach For Pre-Formulation Characterisation of Ketoprofen Semi-Solid Dosage FormsHEMANo ratings yet

- JEE (Advanced) 2015 - A Detailed Analysis by Resonance Expert Team - Reso BlogDocument9 pagesJEE (Advanced) 2015 - A Detailed Analysis by Resonance Expert Team - Reso BlogGaurav YadavNo ratings yet

- ESAS Objectives 1Document15 pagesESAS Objectives 1Jayven VillamaterNo ratings yet

- Namma Kalvi 10th Science Public Exam Model Question Papers 2020 em 217957Document9 pagesNamma Kalvi 10th Science Public Exam Model Question Papers 2020 em 217957biopharmacyNo ratings yet

- Peñon MineralizacionDocument4 pagesPeñon MineralizacionramondiaznNo ratings yet

- Thermodynamic Process Problems and SolutionsDocument4 pagesThermodynamic Process Problems and SolutionsAlex AndersNo ratings yet

- Chapter 24 Molecular Absorption Spectrometry Molecular Spectrometry Uv / Vis / Ir Widely Used Identification Inorganic Organic Biochemical SpeciesDocument42 pagesChapter 24 Molecular Absorption Spectrometry Molecular Spectrometry Uv / Vis / Ir Widely Used Identification Inorganic Organic Biochemical Species陳奕廷go.thuNo ratings yet

- Classical MechanicsDocument3 pagesClassical MechanicsMr. BaiGNo ratings yet

- Budget of Work Sci5Document1 pageBudget of Work Sci5Jhoy Angeles PinlacNo ratings yet

- Myanmar Climate Report Final 11 Oct 2017Document104 pagesMyanmar Climate Report Final 11 Oct 2017Moe yeik mayNo ratings yet

- Leica TCS SP8 HyD-Flyer - ENDocument2 pagesLeica TCS SP8 HyD-Flyer - ENhisto.haritNo ratings yet

- Design For Wear Resistance: Raymond G. Bayer, Tribology ConsultantDocument12 pagesDesign For Wear Resistance: Raymond G. Bayer, Tribology Consultanttolentino.jason1222No ratings yet

- UntitledDocument395 pagesUntitledvaishnavi sharmaNo ratings yet

- Group Members: Assignment 2 - Report Writing LGB 10503 Engineering ScienceDocument11 pagesGroup Members: Assignment 2 - Report Writing LGB 10503 Engineering ScienceAfiq AbidinNo ratings yet

- Foundations of Classical ElectrodynamicsDocument414 pagesFoundations of Classical ElectrodynamicsAnonymous UrVkcdNo ratings yet

- MS - Hyprene L1200 7-25-08Document1 pageMS - Hyprene L1200 7-25-08Abe KobNo ratings yet

- Quantum Reality May Be Incomplete, Einstein Argument ShowsDocument4 pagesQuantum Reality May Be Incomplete, Einstein Argument ShowsAndy HoNo ratings yet

- Oregon Geology Map and Report DetailsDocument24 pagesOregon Geology Map and Report DetailskctreeNo ratings yet

- Lubricants in Refrigerant Systems: Related Commercial ResourcesDocument29 pagesLubricants in Refrigerant Systems: Related Commercial ResourcesAndrés Felipe NaranjoNo ratings yet

- Chemguard 3% x 6% AR-AFFF for hydrocarbon and polar solvent fuelsDocument2 pagesChemguard 3% x 6% AR-AFFF for hydrocarbon and polar solvent fuelsTri Cahyono YuniantoNo ratings yet

- Snay Soler Part3Document3 pagesSnay Soler Part3jajceNo ratings yet

- Alkalinity and Acidity ExperimentDocument4 pagesAlkalinity and Acidity ExperimentSaivenkateshBantupalliNo ratings yet

- 7 - Toxic Organic ChemicalsDocument35 pages7 - Toxic Organic ChemicalsBruno MelNo ratings yet

- Electron Diffraction Lab Report - KatzerDocument7 pagesElectron Diffraction Lab Report - Katzerapi-489811472No ratings yet

- Yaws - Chemical Properties Handbook Physical, Thermodynamics, Engironmental Transport, Safety & Health Related Properties For Organic & Inorganic ChemicalDocument2 pagesYaws - Chemical Properties Handbook Physical, Thermodynamics, Engironmental Transport, Safety & Health Related Properties For Organic & Inorganic ChemicalRanny NovellaNo ratings yet

- Lecture RF 10Document39 pagesLecture RF 102021ETB006 RITANKARDASNo ratings yet

- 60 - BS 13577 2007Document12 pages60 - BS 13577 2007mazos77No ratings yet

- Nobel Laureates in Chemistry: by Prof. Pahup Singh Department of Chemistry University of Rajasthan Jaipur-302004Document118 pagesNobel Laureates in Chemistry: by Prof. Pahup Singh Department of Chemistry University of Rajasthan Jaipur-302004Deepak PainulyNo ratings yet

- Physics homework solutions for chapter 23 problemsDocument12 pagesPhysics homework solutions for chapter 23 problemsSandeep BadigantiNo ratings yet