Professional Documents

Culture Documents

The Effect of Computerized Maintenance Management System (CMMS) in Enhancing The Firm Productivity

Original Title

Copyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

The Effect of Computerized Maintenance Management System (CMMS) in Enhancing The Firm Productivity

Copyright:

Volume 4, Issue 1, January – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

The Effect of Computerized Maintenance Management

System (CMMS) in Enhancing the Firm Productivity

Nabeel Abdulredha Mashhadi, MBA

AMA International University - Bahrain

Abstract:- This study aims to prove that having in case of sudden machine breakdown. Early in the 21th

computerized maintenance management system (CMMS) century, most of the organizations started to consider plans to

within the firm production process will enhance the avoid unwanted break time caused by equipment breakdown.

productivity of the firm and add a valuable step to be Most of the plans are considered to provide spare machines

followed in order to get the best out of the daily and parts to serve as standby machines to replace the running

maintenance activities and the firm productivity as a ones in case of breakdown

whole.

Later on, organizations started to consider maintaining

The study compares data gathered by the use of a some costly parts which have a major impact on the machine

questionnaire for different firms in the Kingdom of and will affect the productivity of the company as a whole. In

Bahrain concentrated before and after implementing the effect, the preventive maintenance becomes an important task

CMMS using three variables such as: Machine efficiency, which will lead to a successful operation of the company.

product quality, and labors productivity which are the This intensive study provides maintenance concepts and

main essential components in the production process that procedures that can be implemented in order to improve

are directly affecting the firm’s productivity. In addition maintenance activities.

to that, the study aims to provide a certainty that having

CMMS involved within firm activities will smooth up the Implementation of a sound maintenance control

process of the maintenance daily activities and create a program is essential to minimize breakdown and maintenance

clean environment in terms of reducing the build-up costs. Machine downtime negatively affects work and results

pressures caused by the delay in such process, as well as to backlog. Accurate implementation of the maintenance

reducing the papers used by the team for the purpose of program will definitely result to attaining on time deliveries

having records filed, checklists, and material/tools and meeting the quality of products and services in any

dispatched. company.

At the end of the study, a statistical analysis is The maintenance group should be knowledgeable and

provided using the weighted mean to analyze the focused on equipment condition and turn the maintenance

numerical data generated from the questionnaire in terms effort into a planning and scheduling machine.

of (Before and After) having CMMS implemented within

the firm, and then the data is compared by the use of T- Interruptions in performing the maintenance are not

TEST tool that shows the different variables between caused by laziness or lack of motivation, but rather by lack of

having CMMS or not. At the end, a recommendation is adequate planning and scheduling techniques. A properly

provided which can be adopted by firms and researchers planned job will have the needed parts, equipment and tools

alike. identified, and the availability of these items confirmed prior

to scheduling the job.

Keywords:- Computerized, Maintenance, CMMS,

Productivity. II. STATEMENT OF THE PROBLEM

I. INTRODUCTION The study focused on the effect of Implementing

Computerized Maintenance Management System (CMMS) in

Until the previous century, preventative maintenance Enhancing the Productivity of the Firm, and specifically it

activities are not considered to be an important task within a aimed to answer the related questions.

working environment. People from the industry tend to think

that as long as the machines are running, there are no reasons What is the status of the firm before the CMMS

for them to check its condition. There was no system or implementation in terms of Machine Efficiency, Product

approach which is being applied on those days. Machines Non Conformance to specification ( Quality) and Labor

only shutdown unexpectedly and this has a huge impact on Productivity.

the time, cost and resources. No contingency plans were set What is the status of the firm after the CMMS

up in order for the operators and the technical teams to follow implementation in terms of, Machine Efficiency, Product

IJISRT19JA251 www.ijisrt.com 282

Volume 4, Issue 1, January – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Non Conformance to specification ( Quality) and Labor The questionnaire been sent to selected people involved

Productivity in the process within the selected companies.(Sample) Each

Is there a significant difference between the firm respondent been asked how they rate the benefits of the

productivity before and after CMMS implementation ? applications. Their perception of using CMMS in their daily

work and to rate it from1 to 5.

A. Research Hypotheses

H01: There is No significant difference between the The goal targeted out of the questionnaire is to find out

firm's productivity before implementation the CMMS and whether or not there is difference in perceived benefits

after the implementations within a firm. between having CMMS and not, and that would be relayed

by answering the question specified in the problem statement.

B. Conceptual Framework

Most of the prospected respondents were people

actually working on the field like senior level management,

middle level management, and maintenance departmental

staff. in addition to that, information related to the production

line being involved/reviewed in the study which been taken

from the implementation manuals. Ppopulation are to be

considered all people work/Involved in the production field

maintenance within the companies located in the kingdom of

Bahrain 2018 , asample among these people been selected to

be involved in the study , this sample varies from the expert

level to the least level. and they are 50 person their position

varies between first line management all the way to the

implementation team and they been categorized as following:

E. Research Instrument

The main instrument for the data collection in this

research was questionnaire and the process been supported

by the use of interview as of supplementary to the data

collection process.

III. SUMMARY OF FINDINGS

On the Status of the Firm before the CMMS

Implementation

For the Machine Efficiency, the overall weighted mean

score is 3.01, referring this back to the Likert table, it is

Fig 1

found the score indicates that the Machine Efficiency shows

Undecided.

C. Research Design

This paper was descriptive research.Its design to get

For the Product Non Conformance to specification

information related to CMMS from senior level

(Quality), the overall weighted mean score is 3.12, referring

management, middle level management and maintenance

this back to the Likert table, it is found the score indicates

staff, on their preference and perspective on the

that the Product quality shows Undecided.

implementation of CMMS before and after

implementationeffectively on the(Machine Efficiency,

For the Labor Productivity, the overall weighted mean

Product Non Conformance to specification - Quality , Labor

score is 2.84, referring this back to the Likert table, it is

Productivity).

found the score indicates that the Labor productivity shows

Undecided.

D. Population and Sampling

Since CMMS has not yet been popular in term of actual

On the Status of the Firm after the CMMS Implementation

implementation in the kingdom, few of well-known

For the Machine Efficiency, the overall back to the

companies who had been using CMMS and had implemented

Likert table, it is found the score indicates that the Machine

it as a part of their system been selected to be under the scope

efficiency shows Strongly Agree.

of data gathering source in this research .

For the Product Non Conformance to specification

(Quality), the overall weighted mean score is 4.80, referring

IJISRT19JA251 www.ijisrt.com 283

Volume 4, Issue 1, January – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

this back to the Likert table, it is found the score indicates Hypotheses Testing

that the Product quality shows Strongly Agree. Testing the study hypothesis was done through testing

the firm's productivity before and after Implementing

For the Labor Productivity, the overall weighted mean Computerized Maintenance Management System (CMMS)

score is 4.73, referring this back to the Likert table, it is within a Firm.

found the score indicates that the Machine efficiency is

showing Strongly Agree. The findings shows a difference between the firm's

productivity before and after Implementing the CMMS

Summary of Weighted Mean within a firm in terms of (Machine Efficiency, Product Non

Conformance to specification - Quality, Labor

Weighted Productivity).Therefore, the hypothesis testing rejected the

Variable Weighted mean null hypothesis, as there was a positive statistical significant

mean After

Before CMMS

CMMS differences in the result as mentioned, The p-value is .00003

and this indicates that the result is significant at p < .05

A. Machine Efficiency 3.01 4.75

B. Product Non IV. CONCLUSIONS

Conformance to

3.12 4.80 On the Status of the Firm before the CMMS

specification

( Quality) Implementation

2.84 4.73 For the machine Efficiency. Based on the findings, it is

C. Labor Productivity

stated that it cannot be decided whether the machines are

Overall Weighted Mean 2.99 4.76 efficient.

Description Undecided Strongly Agree

Table 1:- Summary of Weighted Mean For the product Non Conformance to specification

(Quality). Based on the findings, it is stated that it cannot be

On the Statues of the Firm Whether there is a Significant decided whether the product is in high quality or not.

difference between the Firm Productivity before and after

CMMS Implementation ? For the labor Productivity. Based on the findings,it is

T-Test been conducted by inserting both results from stated that it cannot be decided whether the labors are

the summary of the weighted mean table summarizing the productive or not.

result of the firm’s productivity before and after the

implementation of CMMSinto online calculator through On the Status of the Firm after the CMMS Implementation

social science statistics website For the machine Efficiency. Based on the findings, it is

(https://www.socscistatistics.com) in order to have an strongly agreed that the machines are efficient and therefore

accurate statics comparison between both results. The result it will lead to: Reducing the down time caused by the

of the T-test was as showed below: breakdowns, Increase the machines efficiency, Increase the

machine utilization And having proper tracked records on the

machines.

T-Value P-Value

-21.05552 0.00003 For the product Non Conformance to specification

(Quality). Based on the findings, it is strongly agreed that the

product is in high quality and therefore it will result to the

This indicates that the result is significant at p < .05

below :Reducing the number of non-conformities;

which means there is a difference between the two inserted

results which conclude that there is a different in the firm

Enhance the delivering time to the end users; and

productivity in term of Machine Efficiency, Product Non

Conformance to specification – Quality, and Labor

Improved the integration between the required and the

Productivity Before and after implementing the CMMS.

produced quantity. Or the Labor Productivity, based on the

findings its strongly agreed that the labors are very

In general, the firm's productivity shows Strongly

productive and therefore it will led to:

Agree after implementing CMMS and Undecided before

implementing CMMS, this result shows a big difference in

Increasing the labors motivation because of the number

improving the firm's productivity after implementing the

of output has increased as a result of CMMS implementation

CMMS.

Enhance the flexibility of releasing materials and tools from

the store. Availability of a maintenance standard task

database to be used for recurring planned jobs.

IJISRT19JA251 www.ijisrt.com 284

Volume 4, Issue 1, January – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

On the Statues of the Firm withier there is a Significant On the Status of the Firm Whether there is a Significant

difference between the Firm Productivity before and after difference between the Firm Productivity before and after

CMMS Implementation ? CMMS Implementation ?

Base on the findings that compared the statuse of the Based on the conclusions, it is positively agreed that

firm before and after the implementation of CMMS . Its there is a significant difference between before and after the

agreed that there is a significant difference between the implementation of CMMS. Therefore, It is highly

compared result and therefore we counclude that having recommended to implement CMMS within the firm process

CMMS implemented within the firm process will positively which will led to gaining the reliability among the rivals as a

enhance the firm productivity . result of a stable standard reliable procedures being

implemented within a firm policy.

Furthermore, it will led to gaining the reliability among

the rivals as a result of a stable standard reliable procedure For the Firms

being implemented within a firm policy. Since the result of the statistics analysis shows the

positive effect of having CMMS within the firm process,It is

RECOMMENDATION highly recommended for the firms to implement the CMMS

in order have issues related to the machines efficiency,

On the Status of the Firm before the CMMS product quality and labors’ productivity to consider having

Implementation CMMS onboard which will definitely enhance the process of

Based on the conclusions its stated that its can’t be the mentioned issues and will increase the level of the

decided whether the machines are efficient and reliable. professionalism that the firm aimed for.

Therefore, there should be a way to enhance the efficiency of

the machines. For the Researches

It is recommended for interested researches planning to

Based on the conclusions its stated that its can’t be implement some research subjected to CMMS for the

decided whether the product is in high quality . Therefore, following:

there should be a way to enhance the product quality.

To look into the available versions of CMMS software

Based on the conclusions its stated that its can’t be and compare among them in term of its suitability to the

decided whether the labors are productive. Therefore, there firm’s activities, to come up with a report containing

should be a way to enhance the labor productivity. which version is more effective and in which field.

To conduct a study subjected to a comparison of “Dose

On the Status of the Firm after the CMMS CMMS work with both services field maintenance and

Implementation: production field maintenance “, and how does it reflect on

Based on the conclusions it’s strongly agreed that the both in term of efficiency.

machines are efficient and reliable. I, therefore, highly

recommend the implementation of CMMS in order to: REFERENCES

Reduce the down time caused by the break downs. Increase

the machines efficiency increase the machine utilization [1]. American Society for Quality. (2017, April 10).

Having proper tracked records on the machines. Retrieved from ASQ: http://asq.org/learn-about-

quality/auditing/

Based on the conclusions, it is strongly agreed that the [2]. Bertolini, D. (2015). CMMS Explained Made Simple

product is in a high quality. It is highly recommended to 2nd Edition. Reliabilityweb.com; 2nd edition (June 22,

implement the CMMS in order to: Reduce the number of 2015).

non-conformities; Enhance the delivering time to the end [3]. bizmanualz. (2017, April 6). Retrieved from

users, Improved the integration between the required and the bizmanualz.com: https://www.bizmanualz.com/save-

produced quantity. time-writing-procedures/what-are-policies-and-

procedures-sop.html

Based on the conclusions it’s strongly agreed that the [4]. CEBOS. (2017, April 10). Retrieved from CEBOS.com:

labours are highly productive. It is highly recommended to http://www.cebos.com/understanding-layered-process-

implement the CMMS in order to: audit/

[5]. Floridi, L. (2013). Information quality. Philosophy and

Increase the labors’ motivation as of the number of Technology. 56-62.

output has increased as a result of CMMS implementation; [6]. Gualberto, R. D. (2015). Asia Pacific Journal of

Enhance the flexibility of releasing materials and tools from Multidisciplinary Research. APJM, Vol. 3, No. 5.

the store, and Availability of a maintenance standard task [7]. Indonesia, B. (2017, April 10). business dictionary.

database to be used for recurring planned jobs. Retrieved from businessdictionary.com:

IJISRT19JA251 www.ijisrt.com 285

Volume 4, Issue 1, January – 2019 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

http://www.businessdictionary.com/definition/process.h

tml

[8]. Labib, A., Kobbacy, K. A., & Murthy, P. D. (2008,

January). researchgate. Retrieved from

researchgate.net:

https://www.researchgate.net/publication/226606398_C

omputerised_Maintenance_Management_Systems

[9]. Morse, N., & Bailey, E. H. (2017). Guidance for

Preparing Standard Operating Procedures (SOPs). EPA,

48-59.

[10]. Muyengwa, G., & Marowa, Y. N. (2015). Analysing

Adoption Of Maintenance Strategies In Manufacturing

Companies. International Association for Management

of Technology, 1-6.

[11]. OEE. (2017, May 4). Retrieved from oee.com:

http://www.oee.com/oee-six-big-losses.ht

[12]. Peycheva, R. (2017, December). mobility-work.

Retrieved from mobility-work.com:

https://www.mobility-work.com/blog/6-elements-

successful-preventive-maintenance-program

[13]. Prabowo, N. (2015). 5S:Workplace Organization and

Standardization.

[14]. Reeve, J., & Burley, D. (2017). Failure Modes to

Failure Codes. Reliabilityweb.com (2017).

[15]. Sittsamer, M. J. (2015). Best Practices to Make Layered

Process Audits Meaningful. pp. 1-6.

[16]. Sittsamer, M. J. (2015). Layered Process Audits…

Don’t Believe They’re Just Audits. pp. 1-4.

[17]. Software, F. (2017, November 16). Preventive

maintenance (PM). Retrieved from fiixsoftware.com:

https://www.fiixsoftware.com/maintenance-

strategies/preventative-maintenance/

[18]. WBDG. (2016, December 9). Retrieved from wbdg.org:

https://www.wbdg.org/facilities-operations-

maintenance/computerized-maintenance-management-

systems-cmms

[19]. Wireman, T. (2013). Successfully Utilizing

CMMS/EAM Systems. Reliabilityweb.com Press.

IJISRT19JA251 www.ijisrt.com 286

You might also like

- Journal of Engineering and Technology For Industrial ApplicationsDocument10 pagesJournal of Engineering and Technology For Industrial ApplicationsJohn MendozaNo ratings yet

- Jurnal Cmms Faffa FoodDocument13 pagesJurnal Cmms Faffa FoodMalik RosidiNo ratings yet

- Identification of Total Productive Maintenance Barriers in Indian Manufacturing IndustriesDocument7 pagesIdentification of Total Productive Maintenance Barriers in Indian Manufacturing IndustriesJuancalos catacoraNo ratings yet

- 2020 - An Integrated Simulation Fuzzy Model For Preventive Maintenance Optimization in Multi Product Production FirmsDocument19 pages2020 - An Integrated Simulation Fuzzy Model For Preventive Maintenance Optimization in Multi Product Production FirmsAli Akbar NaqviNo ratings yet

- Maintenance Management System For Upstream Operations in Oil and Gas Industry Case Study PDFDocument7 pagesMaintenance Management System For Upstream Operations in Oil and Gas Industry Case Study PDFPearl RayNo ratings yet

- The Computerized Maintenance Management System An Essential Tool For World Class MaintenanceDocument8 pagesThe Computerized Maintenance Management System An Essential Tool For World Class MaintenanceVictor ImehNo ratings yet

- Admin 2552 6047 1 LeDocument8 pagesAdmin 2552 6047 1 LeJoseph RiverosNo ratings yet

- Maintenance management system for oil and gas upstream operationsDocument7 pagesMaintenance management system for oil and gas upstream operationslucas ronaldo coronel mendozaNo ratings yet

- HMIS Project ProposalDocument17 pagesHMIS Project ProposalManal KhanNo ratings yet

- Modern Company Maintenance Management Based On The Principle Computerized Maintenance Management System (CMMS) ImplementationDocument8 pagesModern Company Maintenance Management Based On The Principle Computerized Maintenance Management System (CMMS) ImplementationVictor Imeh100% (1)

- Improvement of Industrial Performamce With TPM Implementation-1Document18 pagesImprovement of Industrial Performamce With TPM Implementation-1Joned David Chica LlamasNo ratings yet

- Development of Computer-Aided Maintenance Resources Planning (CAMRP) : A Case of Multiple CNC Machining CentersDocument10 pagesDevelopment of Computer-Aided Maintenance Resources Planning (CAMRP) : A Case of Multiple CNC Machining Centerssurekha dobaleNo ratings yet

- Total Productive Maintenance: The Evolution in Maintenance and EfficiencyDocument7 pagesTotal Productive Maintenance: The Evolution in Maintenance and Efficiencylaukik_rautNo ratings yet

- f7f1 PDFDocument8 pagesf7f1 PDFAnurag JaiswarNo ratings yet

- 10.1108@ijqrm 07 2020 0232Document33 pages10.1108@ijqrm 07 2020 0232Ricardo Piero Esteban NúñezNo ratings yet

- Performance MeasureDocument15 pagesPerformance MeasureCamilo ZuletaNo ratings yet

- Articulo 4 TPMDocument13 pagesArticulo 4 TPMastrid abigail blas sanchezNo ratings yet

- Total Productive Maintenance (TPM) Implementation Practice A Literature Review and DirectionsDocument8 pagesTotal Productive Maintenance (TPM) Implementation Practice A Literature Review and DirectionsafmzzulfmzbxetNo ratings yet

- IJMRBS_586cc2c1ebf4a -Eficacia de las prácticas de TPM TQM adoptadas en la industria del cemento un estudio empíricoDocument10 pagesIJMRBS_586cc2c1ebf4a -Eficacia de las prácticas de TPM TQM adoptadas en la industria del cemento un estudio empíricoEDMER ALBERTO MAITA AVILANo ratings yet

- A Study On Usage of Total Productive MaiDocument9 pagesA Study On Usage of Total Productive MaigmNo ratings yet

- Revista Internacional de Ingeniera Transacciones A FundamentosDocument14 pagesRevista Internacional de Ingeniera Transacciones A FundamentosCristian GomezNo ratings yet

- Literature Review of The Implementation of Total Productive Maintenance (TPM) in Various Industries in IndonesiaDocument19 pagesLiterature Review of The Implementation of Total Productive Maintenance (TPM) in Various Industries in IndonesiaStefannyNo ratings yet

- Evaluating 8 Pillars of Total Productive Maintenance (TPM) Implementation and Their Contribution To Manufacturing PerformanceDocument9 pagesEvaluating 8 Pillars of Total Productive Maintenance (TPM) Implementation and Their Contribution To Manufacturing PerformanceFrank CordovaNo ratings yet

- Paper The - Impact - of - Total - Productive - Maintenan PDFDocument2 pagesPaper The - Impact - of - Total - Productive - Maintenan PDFFrancis ParedesNo ratings yet

- A Systematic Literature Review of Total Productive Maintenance On IndustriesDocument13 pagesA Systematic Literature Review of Total Productive Maintenance On IndustriesCEA MARKETNo ratings yet

- Integrative Total Productive Maintenance: Lean Practices: Mark A. JohnsonDocument24 pagesIntegrative Total Productive Maintenance: Lean Practices: Mark A. Johnsonerkin gulerNo ratings yet

- Benefits of Maintenance Management SoftwareDocument5 pagesBenefits of Maintenance Management Softwaregranados.saderNo ratings yet

- Condition Monitoring Within Enterprise Information SystemsDocument12 pagesCondition Monitoring Within Enterprise Information SystemsJHON ANGEL VARGAS HUAHUASONCCONo ratings yet

- Total Productive MaintenanceDocument21 pagesTotal Productive Maintenancenajieyuya100% (2)

- Total Productive Maintenance Thesis PDFDocument7 pagesTotal Productive Maintenance Thesis PDFafkojbvmz100% (2)

- RCM On Service SectorDocument5 pagesRCM On Service SectorSourabh GoyalNo ratings yet

- Production Monitoring System For Monitoring The Industrial Shop Oor PerformanceDocument9 pagesProduction Monitoring System For Monitoring The Industrial Shop Oor PerformanceAlex TecnokemNo ratings yet

- Production Monitoring System For Monitoring The Industrial Shop Oor PerformanceDocument9 pagesProduction Monitoring System For Monitoring The Industrial Shop Oor PerformanceAlex TecnokemNo ratings yet

- Production Monitoring System For Monitoring The Industrial Shop Oor PerformanceDocument9 pagesProduction Monitoring System For Monitoring The Industrial Shop Oor PerformanceAlex TecnokemNo ratings yet

- Production Monitoring System For Monitoring The Industrial Shop Oor PerformanceDocument9 pagesProduction Monitoring System For Monitoring The Industrial Shop Oor PerformanceAlex TecnokemNo ratings yet

- Developing an MPM Framework Using ANP for Maintenance Performance Indicator SelectionDocument14 pagesDeveloping an MPM Framework Using ANP for Maintenance Performance Indicator SelectionAlejandro100% (1)

- Optimizing Maintenance Spare Parts Re-Ordering Process Using Computerized Maintenance Management SystemDocument5 pagesOptimizing Maintenance Spare Parts Re-Ordering Process Using Computerized Maintenance Management SystemGopi SubramaniamNo ratings yet

- Implementation of Total Productive MaintenanceDocument17 pagesImplementation of Total Productive MaintenanceChinmay DalviNo ratings yet

- MSEC2018-6492: Developing Maintenance Key Performance Indicators From Maintenance Work Order DataDocument9 pagesMSEC2018-6492: Developing Maintenance Key Performance Indicators From Maintenance Work Order DataNurazizul HishamNo ratings yet

- Unit 1Document26 pagesUnit 1bhargav kotadiyaNo ratings yet

- Maintenance Performance Measurement: Methods, Tools and ApplicationsDocument4 pagesMaintenance Performance Measurement: Methods, Tools and ApplicationsŊô ĦâNo ratings yet

- Literature Review On Total Productive MaintenanceDocument7 pagesLiterature Review On Total Productive MaintenancefvhacvjdNo ratings yet

- Proceedings of the World Congress on Engineering 2015 Vol II Preventive Maintenance Development Case StudyDocument6 pagesProceedings of the World Congress on Engineering 2015 Vol II Preventive Maintenance Development Case StudyRonil TrujilloNo ratings yet

- Computerized Maintenance Management SystemDocument8 pagesComputerized Maintenance Management SystemMarwan AljalalNo ratings yet

- Ahuja 2007Document16 pagesAhuja 2007Maria Fernanda Hilfreich GuzmánNo ratings yet

- Manufacturing Operational Intelligence Ge DigitalDocument10 pagesManufacturing Operational Intelligence Ge DigitalFran jimenezNo ratings yet

- Pap 1Document12 pagesPap 1jabir.ali.usainNo ratings yet

- Effective Preventive Maintenance Scheduling: A Case StudyDocument9 pagesEffective Preventive Maintenance Scheduling: A Case StudyHa M ZaNo ratings yet

- The Practice of Business Process Re Engineering at Bottom Line and Its Impact On Productivity An Experimental Study of BSNLDocument13 pagesThe Practice of Business Process Re Engineering at Bottom Line and Its Impact On Productivity An Experimental Study of BSNLAnima AgarwalNo ratings yet

- Thesis On Maintenance Management SystemsDocument4 pagesThesis On Maintenance Management Systemsbeckiroymanchester100% (2)

- Design For Quality in Agile Manufacturing Environment Through Modified Orthogonal Array-Based ExperimentationDocument22 pagesDesign For Quality in Agile Manufacturing Environment Through Modified Orthogonal Array-Based ExperimentationRasgullah PhaniNo ratings yet

- Abuzar CIM Assignment No 01Document5 pagesAbuzar CIM Assignment No 01Abuzar AliNo ratings yet

- The Strategy of Successful Total ProductDocument10 pagesThe Strategy of Successful Total ProductPham GHNo ratings yet

- Barriers in TPM Implementation in Industries PDFDocument6 pagesBarriers in TPM Implementation in Industries PDFFran JimenezNo ratings yet

- A Data Analytics Model For Improving Process Control I 2022 Decision AnalytiDocument12 pagesA Data Analytics Model For Improving Process Control I 2022 Decision AnalytiVikash KumarNo ratings yet

- Industrial Maintenance - 2020: Status, Trends + Forecasts ReportDocument13 pagesIndustrial Maintenance - 2020: Status, Trends + Forecasts ReportJohn AngelopoulosNo ratings yet

- Borjalilu Ghambari 2018 Optimal Maintenance Strategy Selection Based On A Fuzzy Analytical Network Process A Case StudyDocument10 pagesBorjalilu Ghambari 2018 Optimal Maintenance Strategy Selection Based On A Fuzzy Analytical Network Process A Case StudyteddiyfentawNo ratings yet

- Lean Manufacturing Implementation in Zimbabwean Industries: Impact On Operational PerformanceDocument12 pagesLean Manufacturing Implementation in Zimbabwean Industries: Impact On Operational PerformanceMatthew MhlongoNo ratings yet

- Jqme 01 2013 0003Document22 pagesJqme 01 2013 0003tafesse afeworkNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightDocument4 pagesComparatively Design and Analyze Elevated Rectangular Water Reservoir with and without Bracing for Different Stagging HeightInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Explorning the Role of Machine Learning in Enhancing Cloud SecurityDocument5 pagesExplorning the Role of Machine Learning in Enhancing Cloud SecurityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Review: Pink Eye Outbreak in IndiaDocument3 pagesA Review: Pink Eye Outbreak in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design, Development and Evaluation of Methi-Shikakai Herbal ShampooDocument8 pagesDesign, Development and Evaluation of Methi-Shikakai Herbal ShampooInternational Journal of Innovative Science and Research Technology100% (3)

- Studying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaDocument5 pagesStudying the Situation and Proposing Some Basic Solutions to Improve Psychological Harmony Between Managerial Staff and Students of Medical Universities in Hanoi AreaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Survey of the Plastic Waste used in Paving BlocksDocument4 pagesA Survey of the Plastic Waste used in Paving BlocksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Electro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyDocument7 pagesElectro-Optics Properties of Intact Cocoa Beans based on Near Infrared TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Auto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETDocument6 pagesAuto Encoder Driven Hybrid Pipelines for Image Deblurring using NAFNETInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentDocument7 pagesCyberbullying: Legal and Ethical Implications, Challenges and Opportunities for Policy DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Navigating Digitalization: AHP Insights for SMEs' Strategic TransformationDocument11 pagesNavigating Digitalization: AHP Insights for SMEs' Strategic TransformationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Hepatic Portovenous Gas in a Young MaleDocument2 pagesHepatic Portovenous Gas in a Young MaleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsDocument5 pagesReview of Biomechanics in Footwear Design and Development: An Exploration of Key Concepts and InnovationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Automatic Power Factor ControllerDocument4 pagesAutomatic Power Factor ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formation of New Technology in Automated Highway System in Peripheral HighwayDocument6 pagesFormation of New Technology in Automated Highway System in Peripheral HighwayInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Drug Dosage Control System Using Reinforcement LearningDocument8 pagesDrug Dosage Control System Using Reinforcement LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicDocument7 pagesThe Effect of Time Variables as Predictors of Senior Secondary School Students' Mathematical Performance Department of Mathematics Education Freetown PolytechnicInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaDocument2 pagesMobile Distractions among Adolescents: Impact on Learning in the Aftermath of COVID-19 in IndiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Securing Document Exchange with Blockchain Technology: A New Paradigm for Information SharingDocument4 pagesSecuring Document Exchange with Blockchain Technology: A New Paradigm for Information SharingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Perceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaDocument5 pagesPerceived Impact of Active Pedagogy in Medical Students' Learning at the Faculty of Medicine and Pharmacy of CasablancaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIDocument14 pagesIntelligent Engines: Revolutionizing Manufacturing and Supply Chains with AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enhancing the Strength of Concrete by Using Human Hairs as a FiberDocument3 pagesEnhancing the Strength of Concrete by Using Human Hairs as a FiberInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Clinical Characteristics, Chromosomal Analysis, and Emotional and Social Considerations in Parents of Children with Down SyndromeDocument8 pagesExploring the Clinical Characteristics, Chromosomal Analysis, and Emotional and Social Considerations in Parents of Children with Down SyndromeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Supply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesDocument11 pagesSupply Chain 5.0: A Comprehensive Literature Review on Implications, Applications and ChallengesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Teachers' Perceptions about Distributed Leadership Practices in South Asia: A Case Study on Academic Activities in Government Colleges of BangladeshDocument7 pagesTeachers' Perceptions about Distributed Leadership Practices in South Asia: A Case Study on Academic Activities in Government Colleges of BangladeshInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Opthalmic Diagnostics: U-Net for Retinal Blood Vessel SegmentationDocument8 pagesAdvancing Opthalmic Diagnostics: U-Net for Retinal Blood Vessel SegmentationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsDocument7 pagesThe Making of Self-Disposing Contactless Motion-Activated Trash Bin Using Ultrasonic SensorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Natural Peel-Off Mask Formulation and EvaluationDocument6 pagesNatural Peel-Off Mask Formulation and EvaluationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Beyond Shelters: A Gendered Approach to Disaster Preparedness and Resilience in Urban CentersDocument6 pagesBeyond Shelters: A Gendered Approach to Disaster Preparedness and Resilience in Urban CentersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Handling Disruptive Behaviors of Students in San Jose National High SchoolDocument5 pagesHandling Disruptive Behaviors of Students in San Jose National High SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Megawide Construction CorporationDocument2 pagesMegawide Construction CorporationKersy Mere FajardoNo ratings yet

- Railway Applications - Welding of Railway Vehicles and Components - Part 3: Design RequirementsDocument14 pagesRailway Applications - Welding of Railway Vehicles and Components - Part 3: Design Requirementsram venkatNo ratings yet

- P+B Hy Wet SDocument34 pagesP+B Hy Wet SatakanNo ratings yet

- Chapter 7Document16 pagesChapter 7YvesExequielPascua100% (2)

- Greener Energy With Syntek SolarDocument21 pagesGreener Energy With Syntek SolarirvanNo ratings yet

- Advanced e-Voting Project ReportDocument7 pagesAdvanced e-Voting Project ReportEducation Tech PoolNo ratings yet

- A Look Inside Computer SystemDocument12 pagesA Look Inside Computer SystemAbhishek 54No ratings yet

- MID Back End Developer (Python)Document3 pagesMID Back End Developer (Python)ram pradeepNo ratings yet

- Actividad 3 Modulo 6Document7 pagesActividad 3 Modulo 6Daniela Jiménez SeguraNo ratings yet

- Labnet Mini Microcentrifuge User Manual-0218Document8 pagesLabnet Mini Microcentrifuge User Manual-0218Gustavo MuñozNo ratings yet

- Chapter 7 - Communication ElementsDocument12 pagesChapter 7 - Communication ElementsKhizerNo ratings yet

- Geothermal Energy ProjectDocument13 pagesGeothermal Energy ProjectalawyNo ratings yet

- Iso 20000-1Document4 pagesIso 20000-1Dr-MohamedLashinNo ratings yet

- FINAL REPORT (Uswatun Saliha)Document76 pagesFINAL REPORT (Uswatun Saliha)Uthman Lokman100% (1)

- Basics of Java Programming LanguageDocument5 pagesBasics of Java Programming LanguageNATALIA ALEJANDRA ORTIZ JACOMENo ratings yet

- Atari Lynx - Jaguar / CD: Jaguar System & Accessories World Wide WebDocument1 pageAtari Lynx - Jaguar / CD: Jaguar System & Accessories World Wide WebGame DudeNo ratings yet

- Father of Indonesian EducationDocument9 pagesFather of Indonesian EducationFarah Fatimatuz ZahraNo ratings yet

- Kam CSM: PER API 8.3, ASTM D5854Document2 pagesKam CSM: PER API 8.3, ASTM D5854SaputraNo ratings yet

- PCS 931SDocument773 pagesPCS 931SMuhamad YasrinNo ratings yet

- Spare List - Caterpillar-3512: PLOT NO-103Document5 pagesSpare List - Caterpillar-3512: PLOT NO-103Balar PrakashNo ratings yet

- LearningMaterial ICT4 v6 2 Bai5Document13 pagesLearningMaterial ICT4 v6 2 Bai5Đoàn Tiến ĐạtNo ratings yet

- SECTION 2-TRANSCRIPTS-225 CâuDocument7 pagesSECTION 2-TRANSCRIPTS-225 CâuvipseceNo ratings yet

- BS 46-1-1958Document36 pagesBS 46-1-1958Hans SchwabNo ratings yet

- 3.2. SurveyCTO Quick Start - Desktop With WorkspacesDocument22 pages3.2. SurveyCTO Quick Start - Desktop With WorkspacesDominique KasongoNo ratings yet

- Grade 7/8 Math Circles Continued Fractions A Fraction of Our HistoryDocument23 pagesGrade 7/8 Math Circles Continued Fractions A Fraction of Our HistoryJaydeep GhoshNo ratings yet

- Amada Operators ManualDocument110 pagesAmada Operators ManualJeff Dunn86% (7)

- Dynamic-Link Library (DLL)Document2 pagesDynamic-Link Library (DLL)Ivniaz Zoref DeysNo ratings yet

- Evaluation of Grade 4 Science Learning Packet #4Document2 pagesEvaluation of Grade 4 Science Learning Packet #4GLENDA OLIQUINONo ratings yet

- Guru Nanak Dev UniversityDocument17 pagesGuru Nanak Dev UniversityAnimesh salhotraNo ratings yet

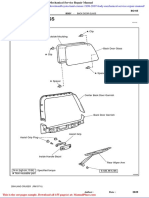

- Toyota Land Cruiser 1998 2007 Body Mechanical Service Repair ManualDocument10 pagesToyota Land Cruiser 1998 2007 Body Mechanical Service Repair Manualhector100% (47)