Professional Documents

Culture Documents

Standard Equipment/Optional Equipment Features

Uploaded by

liyooooOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Equipment/Optional Equipment Features

Uploaded by

liyooooCopyright:

Available Formats

Load Capacity Diagrams

Standard Equipment/Optional Equipment Features

Linde compact drive axle Linde hydrostatic power steering

E20R E20/600RH

3 Twin drive design with high performance 3 Minimal physical demands

Linde AC technology on the operator

3 Optimum energy efficiency 3 Compact ergonomically

Standard Equipment

3 Maintenance-free oil-bath vane brake designed steering wheel

3 Automatic parking brake 3 Linde combi steer axle for

Standard truck height or comfort version (+ 80 mm) Standard chassis suitable for working in ISO containers with 3 Latest DCB-power moduls are mounted on outstanding manoeuvrability

Hydrostatic power steering appropriate mast (not high comfort version) the drive axle - highest efficiency due to

very compact conductors to the motors

Linde twin accelerator pedals for all vehicle movements Hydraulically cushioned full suspension PVC operator‘s seat

Central lever (joystick control) integrated into the with armrest

Subject to modification in the interest of progress. Illustrations and technical details could include options and not binding for actual construc-

E25R/E25RL E25/600RH, E25/600RHL

adjustable armrest Comprehensive digital instrument display

2 x 9 kW maintenance free AC drive motors Generous storage facilities for writing materials

22 kW AC maintenance free lift motor and miscellaneous items

Different ECO modes providing the perfect combination of Superelastic tyres

performance and efficiency

Graphic display of remaining battery operating time in minutes Mast

Automatic parking brake Clearview standard mast

Linde patented combi axle in all models up to 3.5t Fork carriage width:

E30R/E30RL E30/600RH, E30/600RHL

Linde dual motor drive 1,080 mm for E20, E20/600H, E25, E25L Linde twin accelerator control Linde Load Control Linde Dual Motor Drive

Proportional reduction of travel speed when cornering 1,150 mm for E25/600H, E25/600HL, E30, E30/600H, 3 Seamless, rapid reversing without 3 Small tactile joystick integrated into 3 Two powerful AC drive motors

repositioning the feet the adjustable armrest integrated in the front axle

(Curve Assist) E30/600HL, E30L, E35L, E35HL

3 Short pedal travel 3 Precise and effortless fingertip joystick 3 Infinitely acceleration and

Seamless electronic control of all traction and hydraulic Fork length 1,000 mm

Electric Counterbalanced Trucks

3 Fatigue-free working control of all mast functions variable torque characteristics

movements 3 Increased throughput and performance 3 Safe and highly efficient load handling 3 Extremely quiet in operation

Capacity 2000 - 3500 kg

E20R, E25R, E30R, E35R Series 387

E35RL/E35RHL

tions. All dimensions subject to usual tolerances.

Optional Equipment

Top screen: 20mm armored safety glass & wipe/wash system One or two additional hydraulic circuits for attachments Safety

Windshield: 10mm frameless armored safety glass Working lamps and truck lights with LED technology The world’s first Roadster for counterbalanced trucks is set-

Rear screen Flashing beacon/rotating beacon/BlueSpot™ ting the new standard in terms of visibility and safety. This

Overhead guard sun blind Audible reversing alarm unique design allows for a superb panorama view due to

Single pedal accelerator with forward/reverse selector Electrical socket 12 V removed A-pillars. A steel strutted roof or an optional armo-

Fabric covered comfort seat External, internal and panoramic mirror red glass roof, which is connected at the mast and the tilt Linde operator’s compartment World‘s best visibility Linde energy management

Super-comfort seat with air suspension, heater and Integrated charger unit, optionally with electrolyte cylinder support, forms the new protective zone around the 3 Ergonomically designed for efficient, 3 Removel of the A-pillars for an excel- 3 Optimised energy consumption

fatigue-free working lent view to load and environment 3 Accurate battery condition indicator

backrest extension circulation operator.

3 Spacious operator’s compartment 3 Large and open steel strutted roof ena- 3 Simple horizontal or vertical battery

Swiveling seat Active ventilation for battery charging with generous floor plate area bles superb visibility to the top changing options

Individual or single hydraulic control joystick Alternative tyre types Performance Reliability 3 Cushioned comfort – mast and drive 3 Optional the world‘s largest armored 3 Optional built-in high frequency

axle are isolated from the chassis and glass forklift truck roof for an unob- charger for convenience and

Clipboard with LED illumination Alternative custom paintwork One would expect a high performance truck to have a high An electric forklift truck depends on reliable electronic systems.

cab by a unique resilient suspension structed view flexibility

Alternative fork carriage widths Connected solutions like access control for individual driver performance traction system – and that is exactly what the The Linde electronic control system provides a high level of system that absorbs shock loadings 3 Reduced risk of accidents due to better 3 Record of battery usage and condition

Integrated sideshift authorization, recording and remote transfer of the opera- Linde compact drive axle and lift system delivers. Powerful reliability because of its dual circuit monitoring system and all-around visibility

Integrated fork spreader ting hours and active usage analysis of complete truck fleet motors and intelligent electronic control form an impressive sealed aluminium housings which provides total protection for 3 Integrated access grip for safe and

easy entry

power pack to deliver the highest level of productivity. the electronics from the ingress of dust and moisture.

Other options available on request

Comfort Productivity

Consistently high levels of performance and efficiency for Effective in operation, efficient in reducing costs: The unique

extended periods are only possible if the operator feels Linde energy management system ensures intelligent and

Printed in Germany 119.e.3.0416.IndB.Ki

comfortable. The ergonomic layout of all the controls, the economical consumption of energy. Energy can also be

adjustability of the armrest and seat, Linde Load Control, and obtained quickly utilising the optional built-in charging unit or

twin accelerator pedals provide the best possible intuitive one of the four simple and rapid battery changing methods.

interface between the truck and the operator. Combined The result: more uptime and increased productivity. The unbea-

with the excellent view, the Roadster offers the operator table visibility of the Roadster specially for load and environ-

Linde Material Handling GmbH, Postfach 10 01 36, 63701 Aschaffenburg, Germany

unmatched operating comfort. ment further improves the productivity. Phone +49.60 21.99-0, Fax +49.60 21.99-15 70, www.linde-mh.com, info@linde-mh.com

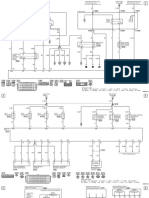

Technical Data according to VDI 2198

1.1 Manufacturer LINDE LINDE LINDE LINDE LINDE LINDE LINDE LINDE LINDE LINDE LINDE LINDE

1.2 Model designation E20R E20/600RH E25R E25/600RH E25RL E25/600RHL E30R E30/600RH E30RL E30/600RHL E35RL E35RHL

1.2a Series 387-00 387-00 387-00 387-00 387-00 387-00 387-00 387-00 387-00 387-00 387-00 387-00

Characteristics

1.3 Power unit Battery Battery Battery Battery Battery Battery Battery Battery Battery Battery Battery Battery

1.4 Operation Seat Seat Seat Seat Seat Seat Seat Seat Seat Seat Seat Seat

1.5 Load capacity/Load Q (t) 2.0 2.0 2.5 2.5 2.5 2.5 3.0 3.0 3.0 3.0 3.5 3.5

1.6 Load centre c (mm) 500 600 500 600 500 600 500 600 500 600 500 500

1.8 Axle centre to fork face x (mm) 445 445 445 468 445 468 471 476 471 476 476 476

1.9 Wheelbase y (mm) 1622 1651 1622 1651 1767 1796 1665 1651 1767 1796 1810 1796

2.1 Service weight (kg) 3951 1) 4601 1) 4437 1) 5030 1) 4365 1) 5055 1) 4937 1) 5581 1) 4980 1) 5459 1) 5356 1) 5639 1)

Weights

2.2 Axle load with load, front/rear (kg) 5333 / 618 5617 / 984 6123 / 814 6611 / 919 6132 / 733 6589 / 966 7125 / 812 7579 / 1002 7131 / 849 7519 / 940 8025 / 831 8152 / 987

2.3 Axle load without load, front/rear (kg) 2168 / 1783 1) 2351 / 2250 1) 2166 / 2271 1) 2494 / 2536 1) 2295 / 2070 1) 2602 / 2453 1) 2375 / 2562 1) 2624 / 2957 1) 2482 / 2498 1) 2722 / 2737 1) 2638 / 2718 1) 2750 / 2889 1)

3.1 Tyres rubber, SE, pneumatic, polyurethane SE SE SE SE SE SE SE SE SE SE SE SE

250/60-12 (23x10- 250/60-12 (23x10-

3.2 Tyre size, front 225/75-10 (23x9-10) 225/75-10 (23x9-10) 225/75-10 (23x9-10) 225/75-10 (23x9-10) 225/75-10 (23x9-10) 225/75-10 (23x9-10) 225/75-10 (23x9-10) 225/75-10 (23x9-10) 315/45-12 315/45-12

Wheels/Tyres

12) 12)

3.3 Tyre size, rear 180/60-10 180/60-10 200/50-10 200/50-10 200/50-10 200/50-10 200/50-10 200/50-10 200/50-10 200/50-10 200/50-10 200/50-10

3.5 Wheels, number front/rear (x = driven) 2x / 2 2x / 2 2x / 2 2x / 2 2x / 2 2x / 2 2x / 2 2x / 2 2x / 2 2x / 2 2x / 2 2x / 2

3.6 Track width, front b10 (mm) 942 942 942 942 942 942 942 980 942 980 1028 1028

3.7 Track width, rear b11 (mm) 900 900 886 886 886 886 886 886 886 886 886 886

4.1 Mast/fork carriage tilt, forward/backward a/b (°) 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0 5.0 / 5.0

4.2 Height of mast, lowered h1 (mm) 2223 2273 2223 2269 2223 2269 2270 2272 2269 2271 2267 2267

4.3 Free lift h2 (mm) 150 150 150 150 150 150 150 150 150 150 150 150

4.4 Lift h3 (mm) 3130 3230 3130 3195 3130 3195 3195 3195 3195 3195 3195 3195

4.5 Height of mast, extended h4 (mm) 3793 3893 3793 3956 3793 3956 3957 3959 3956 3958 3954 3954

4.7 Height of overhead guard (cabin) h6 (mm) 2128 2) 2293 3) 2128 2) 2293 3) 2128 2) 2293 3) 2128 2) 2293 3) 2128 2) 2293 3) 2128 2) 2293 3)

4.8 Height of seat/stand on platform h7 (mm) 1002 1160 1002 1160 1002 1160 1002 1160 1002 1160 1002 1160

4.12 Towing coupling height h10 (mm) 621 656 621 658 624 659 623 656 622 661 626 659

4.19 Overall length l1 (mm) 3318 3352 3318 3375 3463 3520 3444 3383 3539 3528 3594 3528

Dimensions

4.20 Length to fork face l2 (mm) 2318 2352 2318 2375 2463 2520 2444 2383 2539 2528 2594 2528

4.21 Overall width b1/b2 (mm) 1150 / 1148 1150 / 1146 1150 / 1148 1150 / 1146 1150 / 1148 1150 / 1146 1150 / 1178 1228 / 1146 1150 / 1148 1228 / 1146 1322 / 1178 1322 / 1146

4.22 Fork dimensions s/e/l (mm) 45 x 100 x 1000 45 x 100 x 1000 45 x 100 x 1000 45 x 100 x 1000 45 x 100 x 1000 45 x 100 x 1000 45 x 100 x 1000 50 x 120 x 1000 45 x 100 x 1000 50 x 120 x 1000 50 x 120 x 1000 50 x 120 x 1000

4.23 Fork carriage to ISO 2328, class/type A, B 2A 2A 2A 2A 2A 2A 3A 3A 3A 3A 3A 3A

4.24 Width of fork carriage b3 (mm) 1080 1080 1080 1150 1080 1150 1150 1150 1150 1150 1150 1150

4.31 Ground clearance, below mast m1 (mm) 130 130 129 127 130 127 136 136 136 136 129 129

4.32 Ground clearance, centre of wheelbase m2 (mm) 120 120 120 120 120 120 120 120 120 120 120 120

4.33 Aisle width with pallet 1000 x 1200 across forks Ast (mm) 3638 4) 3672 4) 3638 4) 3693 4) 3783 4) 3838 4) 3762 4) 3700 4) 3857 4) 3845 4) 3911 4) 3845 4)

4.34 Aisle width with pallet 800 x 1200 along forks Ast (mm) 3766 4) 3800 4) 3766 4) 3822 4) 3911 4) 3967 4) 3891 4) 3830 4) 3986 4) 3975 4) 4041 4) 3975 4)

4.35 Turning radius Wa (mm) 1873 1907 1873 1907 2018 2052 1973 1907 2068 2052 2118 2052 E20R/E20R* E25-600RH

E20R/E20R* E20-600RH E20R, E20R*, E20-600RH, E20-600R* E30R/E30R* E25-600RHL E25-600RH*, E25-600RHL*

4.36 Minimum pivoting point distance b13 (mm) 0 0 0 0 0 0 0 0 0 0 0 0 Standard mast E25R/E25R* E25R/E25R* E25R, E25R*, E25RL, E25RL* E30RL/E30RL* E30-600RH E30-600RH*, E30-600RHL*

E25RL/E25RL* E25RL/E25RL* E35RL/E35RL* E30-600RHL E35RHL*

5.1 Travel speed, with/without load (km/h) 20 / 20 20 / 20 20 / 20 20 / 20 20 / 20 20 / 20 20 / 20 20 / 20 20 / 20 20 / 20 20 / 20 20 / 20

5.2 Lifting speed, with/without load (m/s) 0.45 / 0.56 0.45 / 0.56 0.45 / 0.56 0.44 / 0.53 0.45 / 0.56 0.44 / 0.53 0.42 / 0.51 0.42 / 0.51 0.42 / 0.51 0.42 / 0.51 0.39 / 0.51 0.39 / 0.51 Lift h3 3130 3230 3430 3730 4030 4530 5030 3095 3195 3495 3695 3995 4495 4995

Mast retracted h1# 2225 2275 2375 2525 2675 2925 3175 2224 2274 2424 2524 2674 2924 3174

5.3 Lowering speed, with/without load (m/s) 0.54 / 0.54 0.54 / 0.54 0.54 / 0.54 0.56 / 0.56 0.54 / 0.54 0.56 / 0.56 0.56 / 0.56 0.56 / 0.56 0.56 / 0.56 0.56 / 0.56 0.56 / 0.56 0.56 / 0.56

Mast extended h4 3795 3895 4095 4395 4695 5195 5695 3853 3953 4253 4453 4753 5253 5753

Performance

5.5 Tractive force, with/without load (N) 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600 4600 / 4600

Free lift h2 150 150 150 150 150 150 150 150 150 150 150 150 150 150

5.6 Maximum tractive force, with/without load (N) 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000 15000 / 15000

5.7 Climbing ability, with/without load (%) 8.2 / 12.2 7.5 / 10.6 7.1 / 10.8 6.4 / 9.4 7.2 / 11.2 6.4 / 9.4 6.1 / 9.6 5.8 / 8.7 6.1 / 9.5 5.8 / 8.8 5.5 / 9.0 5.4 / 8.5 E25-600RH E25-600RH*

E20R* E20R* E25-600RHL E25-600RHL*

5.8 Maximum climbing ability, with/without load (%) 25.4 / 39.0 23.0 / 33.4 21.6 / 34.1 19.7 / 29.3 22.1 / 35.4 19.6 / 29.3 18.7 / 30.0 17.5 / 27.0 18.6 / 29.7 17.6 / 27.2 16.8 / 27.8 16.3 / 26.4 E20R/E20R* E20-600RH E20-600RH E25R/E25RL E30R* E25R-E30RL*

Duplex mast E25R/E25R* E25R* E25R* E30R/E30RL E30RL* E30-600RH*

5.9 Acceleration time, with/without load (s) 4.1 / 4.0 4.1 / 4.0 4.1 / 4.0 4.1 / 4.0 4.1 / 4.0 4.2 / 4.0 4.2 / 4.0 4.2 / 4.0 4.2 / 4.0 4.2 / 4.0 4.3 / 4.1 4.3 / 4.1 E25RL/E25RL* E25RL* E25RL* E35RL E30-600RH E30-600RHL*

E30-600RHL E35RL*/E35RHL*

5.10 Service brake hydr./mech. hydr./mech. hydr./mech. hydr./mech. hydr./mech. hydr./mech. hydr./mech. hydr./mech. hydr./mech. hydr./mech. hydr./mech. hydr./mech. E35RL*/E35RHL*

6.1 Drive motor, 60 minute rating (kW) 2x 9 2x 9 2x 9 2x 9 2x 9 2x 9 2x 9 2x 9 2x 9 2x 9 2x 9 2x 9 Lift h3 3200 3300 3500 3800 4100 2965 3265 3765 4065

6.2 Lift motor, rating at S3 15% (kW) 22 22 22 22 22 22 22 22 22 22 22 22 Mast retracted h1 2176 2226 2326 2476 2626 2075 2225 2475 2625

6.3 Battery according to DIN 43531/35/36 A,B,C,no 43 536 / A 43 536 / A 43 536 / A 43 536 / A 43 536 / A 43 536 / A 43 536 / A 43 536 / A 43 536 / A 43 536 / A 43 536 / A 43 536 / A Mast extended h4 3870 3927 4170 4470 4770 3745 4045 4545 4845

Drive

Free lift h2 1505 1555 1655 1805 1955 1295 1445 1695 1845

6.4 Battery voltage/rated capacity (5h) (V/Ah) 80 / 460/500 80 / 560/620 80 / 460/500 80 / 560/620 80 / 575/625 80 / 700/775 80 / 460/500 80 / 560/620 80 / 575/625 80 / 700/775 80 / 575/625 80 / 700/775

6.5 Battery weight (± 5%) (kg) 1210 1558 1210 1558 1458 1863 1210 1558 1458 1863 1458 1863 E20R E20R* E20R* E20R* E25/E25RL E25R*/E25RL* E25-600RH E25-600RH*/E25-600RHL*

Triplex mast E25R E25R* E20-600RH E20-600RH* E20R* E30R/E30RL E30R*/E30RL* E25-600RHL E30-600RH*/E30-600RHL*

6.6 Power consumption according to VDI cycle (kWh/h) 6.4 7 7.4 7.9 7.3 7.9 8.6 8.7 8.6 8.7 9.5 9.8 E25RL E25RL* E25R* E25R* E20-600RH E35RL E35RL* E30-600RH E35RL*/E35RHL*

E25RL* E25RL* E30-600RHL

8.1 Type of drive control Digital/stepless Digital/stepless Digital/stepless Digital/stepless Digital/stepless Digital/stepless Digital/stepless Digital/stepless Digital/stepless Digital/stepless Digital/stepless Digital/stepless

Lift h3 4460 4760 4910 5210 5560 6010 6660 4380 4680 4830 4980 5330 5930 6430

8.2

Others

Operating pressure for attachments (bar) 170 170 170 170 170 170 170 170 170 170 170 170

Mast retracted h1 2075 2175 2225 2325 2475 2625 2875 2074 2174 2224 2274 2424 2624 2824

8.3 Oil flow for attachments (l/min) 50 50 50 50 50 50 50 50 50 50 50 50

Mast extended h4 5130 5430 5580 5880 6230 6680 7330 5150 5450 5600 5750 6100 6700 7200

8.4 Noise level at operator‘s ear (dB(A)) < 65 < 65 < 65 < 65 < 65 < 65 < 65 < 65 < 65 < 65 < 65 < 65 Free lift h2 1405 1505 1555 1655 1805 1955 2205 1295 1395 1445 1495 1645 1845 2045

1) Figures with battery, see line 6.4/6.5. 3) Comfort Version h6=2373 mm (*) = Comfort version + 80mm

2) Comfort Version h6=2208 mm 4) Including a 200 mm (min.) operating aisle clearance. Figures in mm

Figures for other equipments and masts on request

You might also like

- Allison - Technical Documents 157 - Cooling Test - UpdateDocument29 pagesAllison - Technical Documents 157 - Cooling Test - Updateangie michell paccini rodriguezNo ratings yet

- Neo Power PAX Product Concept and SpecificationsDocument166 pagesNeo Power PAX Product Concept and SpecificationsHerbert M. Zayco83% (36)

- Diagrama Eletrico Motor AsxDocument6 pagesDiagrama Eletrico Motor AsxAlberto Valenzuela Urzúa0% (1)

- Ahp-01 Edf V2 eDocument72 pagesAhp-01 Edf V2 eChristiaan HellemansNo ratings yet

- BCBP Implementation Guide PDFDocument65 pagesBCBP Implementation Guide PDFCsaba Nagy100% (2)

- Linde RT Catalogue 2019Document2 pagesLinde RT Catalogue 2019anupthattaNo ratings yet

- ATR 72 DescriptionDocument8 pagesATR 72 DescriptionJohn SmithsNo ratings yet

- Standard/Optional Equipment FeaturesDocument2 pagesStandard/Optional Equipment FeaturesAdmir BašićNo ratings yet

- Linde e 16 02 - 335Document2 pagesLinde e 16 02 - 335Eryx0% (1)

- Thermite Welding MetallurgyDocument3 pagesThermite Welding MetallurgyDarryl007No ratings yet

- Productspecificaties Linde H100 H180 Zware HeftrucksDocument2 pagesProductspecificaties Linde H100 H180 Zware HeftrucksJan Hendriks50% (2)

- Drive Light Vehicle Using Traffic RulesDocument43 pagesDrive Light Vehicle Using Traffic RulesTesda Ptc Malilipot86% (14)

- Standard Equipment/Optional Features for Linde ForkliftsDocument2 pagesStandard Equipment/Optional Features for Linde ForkliftsManuel Castillo Fernandez0% (1)

- NR-EA/NDR-EA Reach TrucksDocument6 pagesNR-EA/NDR-EA Reach TrucksConitos Outlet FactoryNo ratings yet

- JT Assembly English A4Document2 pagesJT Assembly English A4kutikuppalaNo ratings yet

- Administrative Law, Rolando A. Suarez, 2001Document37 pagesAdministrative Law, Rolando A. Suarez, 2001nikkibeverly73No ratings yet

- Aisle Width E15 386Document6 pagesAisle Width E15 386Jankovski22 MaksNo ratings yet

- SACHS TengelykapcsoloDocument36 pagesSACHS TengelykapcsoloniloblueNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesBruno VazNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesAttouch AmarNo ratings yet

- Load capacity diagrams and features of Linde electric counterbalanced trucksDocument2 pagesLoad capacity diagrams and features of Linde electric counterbalanced trucksashielanieNo ratings yet

- Features Equipment: Electric Pallet Stackers Capacity 1400 and 1600 KG L14, L16/L14i, L16iDocument6 pagesFeatures Equipment: Electric Pallet Stackers Capacity 1400 and 1600 KG L14, L16/L14i, L16iBruno VazNo ratings yet

- 115 - R10CS, R12CS, R14CS - D-03 - 201212-EnDocument2 pages115 - R10CS, R12CS, R14CS - D-03 - 201212-EnUdayNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesAndrés RojasNo ratings yet

- Linde H30d ManualDocument2 pagesLinde H30d ManualEmadNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesMax K.No ratings yet

- Electric Counterbalanced Trucks Capacity 6000 - 8000 KGDocument2 pagesElectric Counterbalanced Trucks Capacity 6000 - 8000 KGwill wuNo ratings yet

- Strada 4WD Brochure 1 PDFDocument3 pagesStrada 4WD Brochure 1 PDFRes Erzel DuanneNo ratings yet

- T20 and T24 SP and APDocument2 pagesT20 and T24 SP and APLima PereiraNo ratings yet

- Reach Truck 1 4 2tonDocument2 pagesReach Truck 1 4 2tonanupthattaNo ratings yet

- Electric Reach Trucks Capacity 1000 - 2500 KGDocument2 pagesElectric Reach Trucks Capacity 1000 - 2500 KGwill wuNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesBoy ScoutNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesMarcio SilveiraNo ratings yet

- Features: Diesel and LPG Forklift Trucks Capacity 8000, 9000 and 10000 LB H40D/T, H45D/T, and H50D/TDocument4 pagesFeatures: Diesel and LPG Forklift Trucks Capacity 8000, 9000 and 10000 LB H40D/T, H45D/T, and H50D/TLuis Barrera RamirezNo ratings yet

- Linde EN Ds w20 br127 04 en B 0111Document2 pagesLinde EN Ds w20 br127 04 en B 0111Nadeem AhmedNo ratings yet

- Robbins 34RH: Low Profile Raiseboring Machine For Holes Ranging From 0.6 To 1.5 M in DiameterDocument5 pagesRobbins 34RH: Low Profile Raiseboring Machine For Holes Ranging From 0.6 To 1.5 M in DiameterIng del PeleNo ratings yet

- Diesel and LPG Forklift Trucks Capacity 5000 - 8000 KGDocument2 pagesDiesel and LPG Forklift Trucks Capacity 5000 - 8000 KGwill wuNo ratings yet

- Standard Equipment/Optional Equipment Features: Electric Straddle Stacker Capacity 1000 - 1200 KG L10AS, L12ASDocument2 pagesStandard Equipment/Optional Equipment Features: Electric Straddle Stacker Capacity 1000 - 1200 KG L10AS, L12ASIker BasqueAdventureNo ratings yet

- Standard and Optional Equipment Features: ActiveDocument6 pagesStandard and Optional Equipment Features: Activemike petersNo ratings yet

- GENOS M e E - 15a - 300 - Aug2019Document11 pagesGENOS M e E - 15a - 300 - Aug2019cosminNo ratings yet

- C99 Mitsubishi L06055engfDocument40 pagesC99 Mitsubishi L06055engfNguyen Danh HuyNo ratings yet

- Standard Equipment /optional Equipment FeaturesDocument2 pagesStandard Equipment /optional Equipment FeaturesNadeem AhmedNo ratings yet

- Linde EN Ds 131 p50 0206 ADocument6 pagesLinde EN Ds 131 p50 0206 ANadeem AhmedNo ratings yet

- Boomer L2: Hydraulically Controlled Face Drilling Rig With A Coverage Area Up To 104 MDocument5 pagesBoomer L2: Hydraulically Controlled Face Drilling Rig With A Coverage Area Up To 104 MJesus Manuel MendozaNo ratings yet

- Linde 1293 E20-25B-01 - 202204 - ENDocument2 pagesLinde 1293 E20-25B-01 - 202204 - ENtiencdtiNo ratings yet

- Linde EN Ds t20 25sr br1154 en A 0517Document2 pagesLinde EN Ds t20 25sr br1154 en A 0517Nadeem AhmedNo ratings yet

- Forklift LoadingsDocument2 pagesForklift LoadingsmilovanstanojevNo ratings yet

- SP22C031GB-00 1685459245241Document4 pagesSP22C031GB-00 1685459245241Athul LalNo ratings yet

- ELEMAX® - Elemax SH7600EX ModelDocument1 pageELEMAX® - Elemax SH7600EX Modelاختر بلوچNo ratings yet

- Linde Diesel DE - Typ - en - 1218 - ht25 - ht30Document2 pagesLinde Diesel DE - Typ - en - 1218 - ht25 - ht30murshed audatallaNo ratings yet

- 175-Ton - 150 MT All Terrain Crane: Lattice Attachment Available in Hydraulic or Manual OffsetDocument4 pages175-Ton - 150 MT All Terrain Crane: Lattice Attachment Available in Hydraulic or Manual OffsetMatheus Pires PereiraNo ratings yet

- Linde 392 H20Document6 pagesLinde 392 H20Mustafa SabryNo ratings yet

- Linde 1219 Technical SpecificationsDocument2 pagesLinde 1219 Technical SpecificationsEmadNo ratings yet

- PS 12l / PS 16l / PS 20l: Electric Pedestrian Stacker With Capacities of 1200/ 1600/ 2000kgDocument5 pagesPS 12l / PS 16l / PS 20l: Electric Pedestrian Stacker With Capacities of 1200/ 1600/ 2000kgEWERTONNo ratings yet

- Urban Electric Pallet Truck Capacity 500 KG CiTi OneDocument2 pagesUrban Electric Pallet Truck Capacity 500 KG CiTi Onewill wuNo ratings yet

- Minetruck MT42: Underground Truck With 42-Tonne Load CapacityDocument5 pagesMinetruck MT42: Underground Truck With 42-Tonne Load CapacityLucas Loyola GuzmanNo ratings yet

- SC-350S/D, SC - 350S/D, SC - 600S/D: All-Axis Servo Driven Type Take-Out RobotDocument1 pageSC-350S/D, SC - 350S/D, SC - 600S/D: All-Axis Servo Driven Type Take-Out Robotbagas prakosoNo ratings yet

- Machine EpirocDocument5 pagesMachine Epirochenrymejiam100% (1)

- Nexon EV MAX BrochureDocument18 pagesNexon EV MAX BrochureJiten Kumar MahatoNo ratings yet

- En SynRM Brochure 3AUA00000120962 RevEDocument8 pagesEn SynRM Brochure 3AUA00000120962 RevEmitulNo ratings yet

- MAN Marine Propulsion SystemsDocument3 pagesMAN Marine Propulsion SystemsJereszNo ratings yet

- Porter2 Catalog EngDocument13 pagesPorter2 Catalog EngChea KimHeangNo ratings yet

- Series 1216 Data SheetDocument2 pagesSeries 1216 Data SheetSenthilKumarNo ratings yet

- Hitachi ZX 330Document15 pagesHitachi ZX 330fucla100% (1)

- Zund PN Series PrecisionCuttingDocument6 pagesZund PN Series PrecisionCuttingjajjjNo ratings yet

- Kia Sorento BrochureDocument2 pagesKia Sorento BrochureFodil ZouNo ratings yet

- Tier 4 Interim Engine: Net Horsepower Gross Horsepower Maximum GVWDocument16 pagesTier 4 Interim Engine: Net Horsepower Gross Horsepower Maximum GVWdeadbirdsNo ratings yet

- BaeS RG-41Document2 pagesBaeS RG-41engelbrechtwjNo ratings yet

- Destination B1 Özbekcha Tarjimasi Bilan.Document12 pagesDestination B1 Özbekcha Tarjimasi Bilan.Kharezmi67% (3)

- Cohesive Devices List of Items For Writing A CompositionDocument5 pagesCohesive Devices List of Items For Writing A CompositionSaeed FarajiNo ratings yet

- Hazard-Specific Annex - Winter Weather 3-13-18Document42 pagesHazard-Specific Annex - Winter Weather 3-13-18Nayelii CampuzanoNo ratings yet

- R8 Rings@ 200 Concrete Cover of 25mm at The Other 3 Sides 2Y12 Concrete Cover of 40mm at The BottomDocument1 pageR8 Rings@ 200 Concrete Cover of 25mm at The Other 3 Sides 2Y12 Concrete Cover of 40mm at The BottomWanNo ratings yet

- Philips Infraphil HP3609Document13 pagesPhilips Infraphil HP3609Mehmet UstaNo ratings yet

- Wicc Amdt 121Document19 pagesWicc Amdt 121agung cahyaNo ratings yet

- SMDGDocument39 pagesSMDGsalehaNo ratings yet

- AJM ProfileDocument12 pagesAJM ProfileHifzan ShafieeNo ratings yet

- Procedures For Approval of Service Suppliers - v01!05!13Document43 pagesProcedures For Approval of Service Suppliers - v01!05!13_LuisErnesto_No ratings yet

- Selection of Authority's Engineer for EPC Mode ProjectsDocument2 pagesSelection of Authority's Engineer for EPC Mode ProjectspvijayabharathiNo ratings yet

- Garage Smart Menu - January 2022Document176 pagesGarage Smart Menu - January 2022kevalNo ratings yet

- Report - Software Bug Led To Death in Uber's Self-Driving Crash - Ars TechnicaDocument5 pagesReport - Software Bug Led To Death in Uber's Self-Driving Crash - Ars TechnicaMac Norhen E. BornalesNo ratings yet

- 2022 07 20 - AutocarDocument84 pages2022 07 20 - Autocarmario hernandezNo ratings yet

- Oic Grasp BrochureDocument8 pagesOic Grasp BrochureAbid HassaanNo ratings yet

- SO3 - B2+ - Unit Test - U1BDocument5 pagesSO3 - B2+ - Unit Test - U1BirishacrobatNo ratings yet

- b3540v Leanburn Gas GensetDocument2 pagesb3540v Leanburn Gas GensetDexterous EngineeringNo ratings yet

- California High-Speed Rail Authority Seeks Expressions of Interest for Tier III TrainsetsDocument4 pagesCalifornia High-Speed Rail Authority Seeks Expressions of Interest for Tier III Trainsetsjackson michaelNo ratings yet

- Flight Fleet ForecastDocument6 pagesFlight Fleet ForecastdapdanielNo ratings yet

- Conditional Sentences PaperDocument16 pagesConditional Sentences PaperNursalamah putriNo ratings yet