Professional Documents

Culture Documents

Spherical Shells en 13445-3 - 7.4.3

Uploaded by

met-calc100%(1)100% found this document useful (1 vote)

82 views3 pagesThis document summarizes the key parameters for designing and analyzing a spherical shell under pressure. It defines thickness parameters including required, nominal, minimum fabrication, analysis and corrosion thickness. It also defines design stresses and calculates required thicknesses for normal operating and test pressures. The analysis determines the maximum allowable pressures are 6.2 MPa for normal operation and 11.9 MPa for testing based on the defined stresses and thicknesses.

Original Description:

Spherical Shells en 13445-3

Original Title

Spherical Shells en 13445-3_7.4.3

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the key parameters for designing and analyzing a spherical shell under pressure. It defines thickness parameters including required, nominal, minimum fabrication, analysis and corrosion thickness. It also defines design stresses and calculates required thicknesses for normal operating and test pressures. The analysis determines the maximum allowable pressures are 6.2 MPa for normal operation and 11.9 MPa for testing based on the defined stresses and thicknesses.

Copyright:

© All Rights Reserved

100%(1)100% found this document useful (1 vote)

82 views3 pagesSpherical Shells en 13445-3 - 7.4.3

Uploaded by

met-calcThis document summarizes the key parameters for designing and analyzing a spherical shell under pressure. It defines thickness parameters including required, nominal, minimum fabrication, analysis and corrosion thickness. It also defines design stresses and calculates required thicknesses for normal operating and test pressures. The analysis determines the maximum allowable pressures are 6.2 MPa for normal operation and 11.9 MPa for testing based on the defined stresses and thicknesses.

Copyright:

© All Rights Reserved

You are on page 1of 3

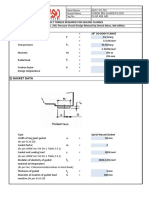

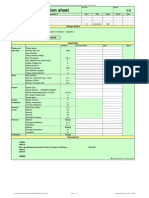

7.4.

3 Spherical shells

The required thickness: e

The nominal thickness: en

The minimum possible fabrication thickness: emin

The analysis thickness: ea

The corrosion allowance: c

The absolute value of the possible negative tolerance de

on the nominal thickness:

The allowance for possible thinning during

dm

manufacturing process:

The extra thickness to make up to the nominal

thickness: eex

The calculation pressure: P 4,4 [Mpa]

The test pressure: Ptest 6 [Mpa]

The inside diameter of shell: Di 864 [mm]

The minimum yield strength or 0,2% proof strength at

calculation temperature: Rp0,2T 355 [Mpa]

The minimum tensile strength at 20°C: Rm/20 470 [Mpa]

Joint coefficient: z 0,7 []

The nominal design stress for normal operating cases:

𝑅 , 𝑅 /

𝑓 = 𝑚𝑖𝑛 ;

1,5 2,4

𝑅 , 𝑅 /

𝑓 = 𝑚𝑖𝑛 ∗ 0,9; ∗ 0,9 : 𝑧 ≤ 0,7

1,5 2,4

fd 176,3 [Mpa]

The nominal design stress for test cases:

𝑅 ,

𝑓 =

1,05

ftest 338,1 [Mpa]

The required thickness for calculation pressure:

𝑃∗𝐷

𝑒=

4𝑓 ∗ 𝑧 − 𝑃

e 7,8 [mm]

The required thickness for test pressure:

𝑃 ∗𝐷

𝑒=

4𝑓 ∗𝑧−𝑃

e 5,5 [mm]

The nominal thickness: en 16 [mm]

The corrosion allowance: c 2 [mm]

The absolute value of the possible negative tolerance

on the nominal thickness (EN 10029): quality C

de1 0 [mm]

Limit values of weld joint defects (EN ISO 5817): quality C

Linear offset between plates (EN 5817):

𝐵 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,1𝑒 ; 3

𝐶 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,15𝑒 ; 4

𝐷 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,25𝑒 ; 5

de2 2,6 [mm]

Defects of welds:

𝐵 → 𝛿 = 0,2𝑒 ∗ 0,04

𝐶 → 𝛿 = 0,3𝑒 ∗ 0,08

𝐷 → 𝛿 = 0,4𝑒 ∗ 0,16

de3 0,4 [mm]

The mean diameter of shell:

𝐷 =𝐷 +𝑒

Dm 880 [mm]

The analysis thickness:

𝑒 =𝑒 −𝛿 −𝛿 −𝛿 −𝑐

ea 11,0 [mm]

Maximum pressure for normal operating loads:

4𝑓 ∗ 𝑧 ∗ 𝑒

𝑃≤𝑃 =

𝐷

Pmax 6,2 [MPa]

Maximum pressure for test loads:

4𝑓 ∗𝑧∗𝑒

𝑃 ≤𝑃 =

𝐷

Pmaxtest 11,9 [MPa]

You might also like

- 3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!From Everand3D Printer Troubleshooting Handbook: The Ultimate Guide To Fix all Common and Uncommon FDM 3D Printing Issues!No ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Design of Large Opening Nozzle by Bulletin WRC-107Document12 pagesDesign of Large Opening Nozzle by Bulletin WRC-107ALONSO GOMEZNo ratings yet

- Horizontal Vessel CalculationDocument24 pagesHorizontal Vessel Calculationjithin.rjn4055100% (1)

- Ref: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionDocument5 pagesRef: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionSivi NallamothuNo ratings yet

- Asme Viii D Table 2aDocument9 pagesAsme Viii D Table 2aHugoNo ratings yet

- 2-CSWIP Practical Plate ExamplesDocument31 pages2-CSWIP Practical Plate Examplesvibinkumars@gmail.com100% (42)

- PV Elite Vessel Analysis Program HorizontalDocument55 pagesPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNo ratings yet

- 1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd EditionDocument6 pages1) Design Data: Ref: Procedure No. 3-4 Pg. No. 169, Pressure Vessel Design Manual by Dennis Moss, 4rd Editionsouren1975No ratings yet

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsNo ratings yet

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- Copper-Brazed Steel Tubing: Standard Specification ForDocument4 pagesCopper-Brazed Steel Tubing: Standard Specification ForSofiaJabadanEspulgar100% (1)

- Design by AnalysisDocument22 pagesDesign by AnalysisJEELE77No ratings yet

- Flat Ends With A Hub For Uniform Thickness ShellDocument5 pagesFlat Ends With A Hub For Uniform Thickness ShellEng-CalculationsNo ratings yet

- Physical Science DLP Q1W3Document7 pagesPhysical Science DLP Q1W3junar asentistaNo ratings yet

- Conical ShellsDocument3 pagesConical ShellsEng-CalculationsNo ratings yet

- Figure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2Document5 pagesFigure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2met-calcNo ratings yet

- Figure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2Document5 pagesFigure 9.5-2 Cylindrical Shell With Nozzle Oblique in The Transverse Cross Section en 13445-3 - Figure 9.5-2met-calcNo ratings yet

- Junction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6Document3 pagesJunction Between The Large End of A Cone and A Cylinder Without A Knuckle en 13445-3 - 7.6.6met-calcNo ratings yet

- Figure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9Document4 pagesFigure 9.4-9 Cylindrical Shell With Isolated Opening, Increased Wall Thickness and Set-In Nozzle en 13445-3 - Figure 9.4-9met-calcNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through-Conduit)Document23 pagesHydrodynamic Calculation Gate Valve (Through-Conduit)met-calcNo ratings yet

- RC Lecture 11 - ColumnsDocument19 pagesRC Lecture 11 - ColumnsShean Berwin GonzalesNo ratings yet

- Flat Ends Welded Directly To The ShellDocument9 pagesFlat Ends Welded Directly To The ShellEng-CalculationsNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Power ScrewsDocument4 pagesPower Screwsmet-calcNo ratings yet

- Pressure Vessel ExampleDocument48 pagesPressure Vessel ExamplemohamedNo ratings yet

- Figure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13Document4 pagesFigure 9.4-13 Conical Shell With Isolated Opening. Combined Reinforcement From Shell and Nozzle en 13445-3 - Figure 9.4-13met-calcNo ratings yet

- Figure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3Document5 pagesFigure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3met-calcNo ratings yet

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocument3 pagesRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNo ratings yet

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocument3 pagesRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Multi-Stage Valve: Pipeline SpeedDocument6 pagesMulti-Stage Valve: Pipeline Speedmet-calcNo ratings yet

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Document2 pagesPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Flat Ends With A Relief GrooveDocument11 pagesFlat Ends With A Relief GrooveEng-CalculationsNo ratings yet

- Articulated Trunnion in The RodDocument5 pagesArticulated Trunnion in The Rodmet-calc100% (1)

- Nozzles Which Encroach Into The Knuckle Region For Korbbogen Type EndDocument6 pagesNozzles Which Encroach Into The Knuckle Region For Korbbogen Type EndEng-CalculationsNo ratings yet

- Figure 9.5-1 Cylindrical Shell With Nozzle Oblique in The Longitudinal Cross Section en 13445-3 - Figure 9.5-1Document5 pagesFigure 9.5-1 Cylindrical Shell With Nozzle Oblique in The Longitudinal Cross Section en 13445-3 - Figure 9.5-1met-calcNo ratings yet

- Figure 9.5-1 Cylindrical Shell With Nozzle Oblique in The Longitudinal Cross Section en 13445-3 - Figure 9.5-1Document5 pagesFigure 9.5-1 Cylindrical Shell With Nozzle Oblique in The Longitudinal Cross Section en 13445-3 - Figure 9.5-1met-calcNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Threaded Holes (11.4.3.3) EN 13445-3Document1 pageThreaded Holes (11.4.3.3) EN 13445-3met-calcNo ratings yet

- Threaded Holes (11.4.3.3) EN 13445-3Document1 pageThreaded Holes (11.4.3.3) EN 13445-3met-calcNo ratings yet

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- FlangeCalculationASMEVIII Version5Document3 pagesFlangeCalculationASMEVIII Version5alvinchuan100% (2)

- AD 2000 Flange Design Calculation DIN 2505Document2 pagesAD 2000 Flange Design Calculation DIN 2505mechengg01100% (1)

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Document5 pagesFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNo ratings yet

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Document5 pagesFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lenticular Disc)Document28 pagesHydrodynamic Calculation Butterfly Valve (Lenticular Disc)met-calcNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul Adli100% (1)

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNo ratings yet

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNo ratings yet

- Weld Shear Stress Check For FAVID Clips Welded On CladDocument3 pagesWeld Shear Stress Check For FAVID Clips Welded On CladrsubramaniNo ratings yet

- Hydrodynamic Calculation Needle ValveDocument23 pagesHydrodynamic Calculation Needle Valvemet-calcNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- U-Shaped Reinforced Bellows (Austenitic Steel)Document10 pagesU-Shaped Reinforced Bellows (Austenitic Steel)met-calcNo ratings yet

- Paints and Varnishes - General Tests Methods - Vol 1.1 - IndexDocument5 pagesPaints and Varnishes - General Tests Methods - Vol 1.1 - IndexGilberto ManhattanNo ratings yet

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Howell-Jet ValveDocument17 pagesHydrodynamic Calculation Howell-Jet Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNo ratings yet

- Advances in Materials Technology For Fossil Power PlantsDocument1,121 pagesAdvances in Materials Technology For Fossil Power Plantsadadamovicines100% (5)

- Typical List of Chemicals Used in Dyeing MillDocument6 pagesTypical List of Chemicals Used in Dyeing MillMohammed Atiqul Hoque Chowdhury0% (1)

- Contact Stress of The Cylinder in The Cylindrical SocketDocument3 pagesContact Stress of The Cylinder in The Cylindrical Socketmet-calcNo ratings yet

- Nozzle ProDocument3 pagesNozzle Projojo_323No ratings yet

- EN13480-3 Chap12 ModificationsDocument37 pagesEN13480-3 Chap12 ModificationsPrashant ChauhanNo ratings yet

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDocument23 pagesHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNo ratings yet

- Contact Stress of Cylinder On Flat SurfaceDocument3 pagesContact Stress of Cylinder On Flat Surfacemet-calcNo ratings yet

- Hydrodynamic Calculation Spherical ValveDocument40 pagesHydrodynamic Calculation Spherical Valvemet-calcNo ratings yet

- Uhde Dual-Pressure Process For Large-Scale Ammonia Plants: - Saskferco Ammonia-Urea Complex, CanadaDocument6 pagesUhde Dual-Pressure Process For Large-Scale Ammonia Plants: - Saskferco Ammonia-Urea Complex, CanadaMUHAMMAD USMAN0% (1)

- U-Shaped Unreinforced Bellows (Austenitic Steel)Document9 pagesU-Shaped Unreinforced Bellows (Austenitic Steel)met-calc100% (1)

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document19 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Howell-Bunger ValveDocument34 pagesHydrodynamic Calculation Howell-Bunger Valvemet-calcNo ratings yet

- Conical Shells (7.6.4) EN 13445-3Document3 pagesConical Shells (7.6.4) EN 13445-3met-calcNo ratings yet

- Contact Stress Two CylindersDocument3 pagesContact Stress Two Cylindersmet-calcNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through Conduit)Document14 pagesHydrodynamic Calculation Gate Valve (Through Conduit)met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document24 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Reinforcement For Multi OpeningsDocument1 pageReinforcement For Multi OpeningsSajal KulshresthaNo ratings yet

- Bolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Document2 pagesBolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Manoj MulikNo ratings yet

- Pressure & Temperature ClassificationDocument1 pagePressure & Temperature Classificationkeo85100% (1)

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Mo ZeroNo ratings yet

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocument9 pagesCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNo ratings yet

- Ellipsoidal Ends en 13445-3 - 8.8.3Document2 pagesEllipsoidal Ends en 13445-3 - 8.8.3met-calcNo ratings yet

- Junction Between The Large End of A Cone and A Cylinder With A Knuckle en 13445-3 - 7.6.7Document4 pagesJunction Between The Large End of A Cone and A Cylinder With A Knuckle en 13445-3 - 7.6.7met-calcNo ratings yet

- Multi-Hole CageDocument7 pagesMulti-Hole Cagemet-calcNo ratings yet

- Anne Marie Helmenstine, PH.D.: Black Powder Composition Chemical Composition of Black Powder or GunpowderDocument5 pagesAnne Marie Helmenstine, PH.D.: Black Powder Composition Chemical Composition of Black Powder or GunpowderRara Aoi100% (1)

- BERKLEY - Catalogo Caà As 2011Document8 pagesBERKLEY - Catalogo Caà As 2011dondepescasNo ratings yet

- A Review On Reference StandardsDocument12 pagesA Review On Reference StandardsjyothiNo ratings yet

- Theoretical Framework: Compressive Strength TestDocument11 pagesTheoretical Framework: Compressive Strength TestqwertasdfgNo ratings yet

- THE IDEAL GAS (Topic6)Document17 pagesTHE IDEAL GAS (Topic6)ch0k3 iiiNo ratings yet

- BPSC APS WMO Solved Question Paper 02Document5 pagesBPSC APS WMO Solved Question Paper 02Purushottam SinghNo ratings yet

- Sulfate AttackDocument1 pageSulfate AttackbozarromegustaNo ratings yet

- Failure Analysis Question BankDocument29 pagesFailure Analysis Question BankAbd-Elaleem Abdallah SosaNo ratings yet

- MasterTemp 125 High Performance Heater Installation and Users Guide EnglishDocument56 pagesMasterTemp 125 High Performance Heater Installation and Users Guide Englishjesus javier ceme kooNo ratings yet

- Worksheet Ch1Document36 pagesWorksheet Ch1Shazia FarheenNo ratings yet

- 4 Combustion Problems With SolutionsDocument25 pages4 Combustion Problems With SolutionsMunawar Lal JoshiNo ratings yet

- Poly Tetra Flu Oro EthyleneDocument15 pagesPoly Tetra Flu Oro Ethylenevinod.veeranki6129No ratings yet

- Exam Steel DesignDocument2 pagesExam Steel DesignAndrew PortugalNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Sampling Procedure For Impact Testing of Structural SteelDocument4 pagesSampling Procedure For Impact Testing of Structural Steeljoy gultom100% (1)

- Schematic Diagram of Qualitative Tests For Elements in Organic CompoundsDocument5 pagesSchematic Diagram of Qualitative Tests For Elements in Organic CompoundsChristine DomingoNo ratings yet

- Mullion Transom Connector BS-EN-1991-1-1 V2.0Document2 pagesMullion Transom Connector BS-EN-1991-1-1 V2.0Giri DharanNo ratings yet

- Intro To Methyl Chloride Plant 1Document57 pagesIntro To Methyl Chloride Plant 1Kimberly ConleyNo ratings yet

- Alcohols, Phenols and Ethers - MCQs Test - 3Document3 pagesAlcohols, Phenols and Ethers - MCQs Test - 3Prasant KumarNo ratings yet

- Adiabatic Dryers PresentationDocument27 pagesAdiabatic Dryers PresentationJunaid IqbalNo ratings yet

- Chemsheets GCSE 1032 More Group 7Document2 pagesChemsheets GCSE 1032 More Group 7Cheuk Him Ngai0% (1)

- Origin of Color in Complex IonsDocument5 pagesOrigin of Color in Complex IonsThya efeNo ratings yet