Professional Documents

Culture Documents

2008 MBE900 Brochure

Uploaded by

ZERO-HOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2008 MBE900 Brochure

Uploaded by

ZERO-HCopyright:

Available Formats

ENGINE MBE 900 ENGINE MBE 900

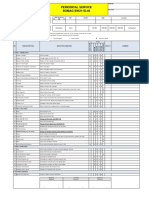

UNALTERED MAINTENANCE SCHEDULES.

UNMATCHED SERVICE AND WARRANTY.

Maintenance Intervals (Miles)

Maintenance Item Severe-Duty Short-Haul Long-Haul

Engine Oil and Filter Change* 6,000 15,000 20,000

Fuel Filter Change 18,000 60,000 60,000

Valve Lash Adjustment 24,000 75,000 80,000

* Based on using Detroit Diesel approved lube oil.

Severe-Duty: Less than 6,000 annual miles. Short-Haul: 6,000 to 60,000 annual miles. Long-Haul: Over 60,000 annual miles.

Parts, Service and Warranty Fire Truck, Bus and RV Warranty 1

Parts and service for the MBE 900 engine

Application Years Miles

are available at more than 800 Detroit Diesel

Fire Truck and EMS 5 150,000

authorized service locations throughout North

School Bus and RV* 5 Unlimited*

America. Factory certified technicians know * Coverage is limited to 6,000 hours of operation.

your MBE 900 inside and out and are ready to

help. For roadside assistance, technical support

or locating the nearest service center, contact

the Detroit Diesel hotline at 1-800-445-1980.

On-Highway Warranty Period for Trucks1

Warranty Limitations

Repair Charge to be Paid by Owner

(Whichever Occurs First)

Item Months Miles / Kilometers Parts Labor

0 - 150,000 mi.

Engine 0 - 36 0 - 240,000 km No Charge No Charge

0 - 100,000 mi.

Accessories 0 - 24 No Charge No Charge

0 - 160,000 km

1

Refer to the Detroit Diesel warranty parchment for full warranty details, terms and conditions.

NO QUESTION ABOUT IT.

The 2007 EPA diesel-emissions mandate was one of the most challenging engineering tasks Detroit Diesel

has confronted, demanding more time, effort and resources than any other single program in the past several

decades. The MBE 900 engine not only is far cleaner than its predecessors, it’s stronger, too.

For more information, call 1-800-445-1980. www.DetroitDiesel.com

DDC-EMC-BRO-0015-0608. Specifications are subject to change without notice. Detroit Diesel Corporation is registered to ISO 9001:2001.

Copyright © Detroit Diesel Corporation. All rights reserved. Detroit Diesel Corporation is a Daimler company.

MBE 900

DETROIT DIESEL: DRIVING TECHNOLOGY. REFINED ENGINE COMPONENTS REFINED EXHAUST SYSTEM

The Mercedes-Benz 900 series engine (MBE 900) has been The MBE 900 Exhaust Gas Recirculation (EGR) High Tech Grid Heater Multi-Functional Fuel Filter Exhaust Aftertreatment System

going strong since we introduced it to the NAFTA medium-duty The MBE 900 has been the premium engine choice for a wide The Exhaust Gas Recirculation system has been optimized to The MBE 900 is capable of starting unassisted in temperatures as The MBE 900 now features an all-new multi-functional fuel filter The biggest change to our engines is the addition of an exhaust

truck market in 1998. With more than 150 years of Detroit Diesel range of medium-duty and vocational vehicle buyers, powering dramatically cut NOx formation by routing a measured amount of low as 10 degrees Fahrenheit. For colder temperature operation, containing primary and secondary filtration, a fuel priming valve Aftertreatment System, which replaces the muffler assembly

and Mercedes-Benz collective experience designing, testing the needs of food and beverage distributors, pick-up and exhaust flow to the cylinders to lower combustion temperatures. down to –13 degrees Fahrenheit, an optional high tech grid heater and a fuel-water separator in one compact assembly as standard in the exhaust system. The unit’s defining components are a

and manufacturing diesel engines behind it, it’s no wonder. delivery, fire and rescue departments, school bus fleets, tow Lower temperatures result in lower NOx levels without the controlled by DDEC VI is available. The high tech grid heater pre- equipment. The unit also may be ordered with a hand priming pump, Diesel Oxidation Catalyst and a Diesel Particulate Filter that

truck operators, construction companies and others. Nearly negative effects of retarding engine timing. The EGR valve has heats air in the intake system before it enters the engine during a water-in-fuel sensor and/or a fuel heater as optional equipment. oxidize – or burn – soot. During normal highway operation,

Through the years, customers have turned to our engines for

600,000 MBE 900 engines are in service today, more than 100,000 been moved to the top of the engine for improved serviceability. starting and initial warm-up. This device reduces cranking time exhaust temperatures alone usually are high enough to burn off

reliability, fuel economy, weight advantage and ease of service.

in North America alone. in cold weather to increase starter life, reduces white smoke and accumulating soot, a process known as “passive regeneration.”

That’s never changed. But, when Environmental Protection Reusable Air elimination vent

SMART Fuel System offers peace of mind. filter cap In low ambient temperatures, however, or in some stop-and-go

Agency’s ’07 requirements grew more stringent to protect the With the changes required to meet the EPA’s 2007 diesel-

The new SMART Fuel System adds to the performance and Outlet prefiltered applications, the system needs a little help to regenerate or clean

environment, Detroit Diesel combined our long heritage and emissions mandate, the new MBE 900 – now a full 7.2 liters – fuel to pump Standard four micron

cleanliness of the MBE 900. It features electronically controlled Maintenance-Free Electrostatic Breather secondary filter itself. This process is called “active regeneration.”

industry-leading innovation with the resources of our parent continues to serve its diverse customer base, offering a wide

injection nozzles capable of multiple injections per combustion cycle. A new electrostatic breather system removes oil from

range of power ratings. With this broad spectrum of choices, Integrated fuel

company, Daimler – the world’s largest commercial vehicle

crankcase vapor before it’s vented into the atmosphere. Optional priming valve Doser

manufacturer. Together, we did more than just meet emissions buyers can spec the most economical and best matched hand primer (standard)

Detroit Diesel Electronic Control (DDEC®) VI The system sends oil droplets back to the sump, where they The Aftertreatment System uses a “doser” to initiate active

standards. We took our engines to the next level. components to fit their specific applications. Less money invested Detroit Diesel set the benchmark for diesel engine electronics. continue to serve the engine, reducing oil consumption. regeneration. When the amount of soot inside reaches a certain

plus lower operational costs equal a better bottom line. Now, we’re raising the bar with the sixth generation DDEC VI Outlet shut-off valve: Optional 260 watt

With an investment of hundreds of millions of dollars and the And, it requires no maintenance. return fuel to tank and heater PTC level, the doser injects a measured amount of diesel fuel into

work of the world’s top engineers, Detroit Diesel produced electronic engine management system. It employs a more powerful air purge

Inlet non-return valve, the exhaust flow, which reacts with the catalyst to raise the

Tightening Emissions Standards dirty fuel from tank

a new line of engines that are the most advanced and microprocessor, increased memory and enhanced diagnostics. temperature to a point that enables regeneration.

The EPA has been reducing diesel emissions for the past 30

environmentally-friendly generation of Detroit Diesel engines The DDEC VI is capable of monitoring and managing all engine MBE 900 Engine Power Ratings

years. The latest regulations, which took effect in 2007, demand There are two types of active regeneration: in-transit and

ever built. We’ve lowered oil consumption. Increased response functions, including the Aftertreatment Systems required for Inlet return fuel Lever drain with

changes in both fuel and engine technology. The new regulations Standard stationary. In-transit regeneration occurs when the truck is in

from injectors drain hose

times. Reduced emissions. And achieved SMART Fuel Systems. emissions. DDEC VI is a key part of the strategy to achieve greater

will dramatically reduce oxides of nitrogen (NOx) by 190 HP @ 2200 RPM 520 lb-ft @ 1200 RPM motion. When the truck’s driving cycle is insufficient for in-transit

operating efficiency and cleaner exhaust emissions. 210 HP @ 2200 RPM 520 lb-ft @ 1200 RPM

After countless laboratory tests and more 55 percent and particulate matter (soot and ash) Water/contaminant active regeneration, stationary active regeneration is required.

230 HP @ 2200 RPM 620 lb-ft @ 1200 RPM Optional integrated collection bowl

than 24 million miles in testing across by

by 90 percent. We achieved the first bracket allows

This is performed when the truck is parked and monitored by the

250 HP @ 2200 RPM 660 lb-ft @ 1200 RPM engine or frame mounting

our three engine targett

ta by optimizing the existing driver or a service technician.

100 micron primary

lines, one thing iss Exhaust Gas Recirculation prefilter/water separator

esel

clear: Detroit Diesel isn’

is n’t just

isn’t juss t

ju system

syst

sy sstteem

m and the second by adding Intake Throttle

Water-in-fuel sensor

ds.

meeting standards. an Aftertreatment System, The intake throttle also assists in the regeneration process.

We’re driving comprised of a Diesel When necessary, this device limits the amount of air entering

Engine Brakes

technology. Oxidation Catalyst and a the engine, raising the exhaust temperature and facilitating

The MBE 900 engine has two engine brake options available:

Diesel Particulate Filter. regeneration.

a compression brake and an exhaust brake. Both engine brake

FPO REFINED FUELS AND LUBRICANTS

options offer quiet operation, increased service brake life,

improved driver safety and increased resale value.

ULTRA LOW SULFUR DIESEL (ULSD) Fuel and CJ-4 Oil MBE 900 Engine Brake Options

The MBE 900 is designed to run on ULSD fuel, which can contain CJ-4, a low ash oil formulation, is recommended in current Single Stage

no more than 15 PPM sulfur. Previously the sulfur content for engines. CJ-4 oil contains less than 1.0 wt. % sulfated ash. Compression Brake 155 HP @ 2500 RPM

on-highway diesel fuel was 500 PPM. ULSD fuel is necessary to Use of high ash engine oils reduce the cleaning interval on the Exhaust Brake 140 HP @ 2500 RPM

avoid fouling the engine’s Aftertreatment System. Diesel Particulate Filter (DPF) system. Both 180 HP @ 2500 RPM

www.DetroitDiesel.com

You might also like

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (5)

- Mbe 4000 Brochure PDFDocument2 pagesMbe 4000 Brochure PDFJose juliNo ratings yet

- Detroit Diesel Series 60Document2 pagesDetroit Diesel Series 60Héctor Perez SNo ratings yet

- VT Oil Specifications & Service Notes - FinalDocument3 pagesVT Oil Specifications & Service Notes - FinalZeko AmeenNo ratings yet

- BMW Motorrad F 650 / F 650 ST Maintenance ScheduleDocument1 pageBMW Motorrad F 650 / F 650 ST Maintenance ScheduleGaltNo ratings yet

- C12 Engine and PumpsDocument2 pagesC12 Engine and PumpsSankar SNo ratings yet

- 2014 Bombardier Global 6000 SN 9526 Available Through Jetcraft 1Document15 pages2014 Bombardier Global 6000 SN 9526 Available Through Jetcraft 1badamkadam9No ratings yet

- Sales quotation for 60kVA diesel generatorDocument1 pageSales quotation for 60kVA diesel generatorAdeelNo ratings yet

- F650GS-CS Maintenance ScheduleDocument2 pagesF650GS-CS Maintenance ScheduleBrotherwolf2010No ratings yet

- Vol 15033b-22x34 Mack Service at A Glance Poster v8 PDFDocument1 pageVol 15033b-22x34 Mack Service at A Glance Poster v8 PDFJenMicMarAguNo ratings yet

- Log Book Pemeliharaan Kendaraan AvanzaDocument2 pagesLog Book Pemeliharaan Kendaraan AvanzaumumdkhkedungwaringNo ratings yet

- M2-112 Mbe 4000 Epa 98-04Document29 pagesM2-112 Mbe 4000 Epa 98-04Julio Ruminot AguileraNo ratings yet

- 2021 B6.7 Maintenance Intervals: Up To 3% Lifetime TCO Reduction Compared To 2017 ModelDocument2 pages2021 B6.7 Maintenance Intervals: Up To 3% Lifetime TCO Reduction Compared To 2017 ModelferraryNo ratings yet

- JCB Rough Terrain Fork Lift 926, 930, 940Document4 pagesJCB Rough Terrain Fork Lift 926, 930, 940DarrenNo ratings yet

- BMW r1150 RT Service ScheduleDocument1 pageBMW r1150 RT Service ScheduleSebastian DinescuNo ratings yet

- Tailor-Made Solution.: Item Vocational Severe 3.0 - 4.9 MPG Shorthaul 5.0 - 5.9 MPG Normal 6.0 - 6.9 MPG Light 7.0 MPGDocument2 pagesTailor-Made Solution.: Item Vocational Severe 3.0 - 4.9 MPG Shorthaul 5.0 - 5.9 MPG Normal 6.0 - 6.9 MPG Light 7.0 MPGOscar Campo100% (1)

- Two Week Maintenanace Activity ReportDocument2 pagesTwo Week Maintenanace Activity ReportHaftom TekluNo ratings yet

- MG Hector Maintenance ScheduleDocument4 pagesMG Hector Maintenance SchedulericlifeNo ratings yet

- Jakson DG CatalogDocument3 pagesJakson DG CatalogNishant Singh Chauhan100% (3)

- K100-K75 Scheda ManutenzioneDocument1 pageK100-K75 Scheda ManutenzionesdfbidzbfiduNo ratings yet

- 6 Cylinder MBE906: Engine PerformanceDocument2 pages6 Cylinder MBE906: Engine Performanceguillermo meza huamanNo ratings yet

- Maruti Wagon R Service Schedule and Maintenance Cost Review in IndiaDocument5 pagesMaruti Wagon R Service Schedule and Maintenance Cost Review in IndiaAjit Shivaji MokalNo ratings yet

- High-speed marine engines from MAN MarineDocument24 pagesHigh-speed marine engines from MAN MarineEDEN SARMENTONo ratings yet

- GS400 Complete ManualDocument139 pagesGS400 Complete ManualJason TierNo ratings yet

- 161 Sanman 5000Document2 pages161 Sanman 5000Choudhary Vikrant GurjarNo ratings yet

- Caterpillar C7.1Document2 pagesCaterpillar C7.1Andre STANo ratings yet

- LE Training 2020Document24 pagesLE Training 2020Neoteric Industrial100% (2)

- Ficha Tecnica Rodillo Bicilindro Operador A PieDocument2 pagesFicha Tecnica Rodillo Bicilindro Operador A PieJorgearmandopico203gmail.com PicoNo ratings yet

- Superliner Specsheet NZ 2022Document4 pagesSuperliner Specsheet NZ 2022SanBre ChannelNo ratings yet

- MTU Marine Flyer 4000M55N GasDocument5 pagesMTU Marine Flyer 4000M55N GasAmin GuiNo ratings yet

- Himsen Gas EngineDocument6 pagesHimsen Gas EngineArieWBNo ratings yet

- DVR Construction CasestudydragasurcavenezuelaDocument2 pagesDVR Construction CasestudydragasurcavenezuelaPablo Luis Ojeda PaezNo ratings yet

- Large Engine Lubricants: OutlineDocument17 pagesLarge Engine Lubricants: OutlineJahmia CoralieNo ratings yet

- 1 DesDocument1 page1 DesSteven Kuang01No ratings yet

- MAN Alpha FP PropellerDocument2 pagesMAN Alpha FP PropellerSea Man MktNo ratings yet

- BMW Service Inclusive & Repair Inclusive Packages: 330i SedanDocument1 pageBMW Service Inclusive & Repair Inclusive Packages: 330i SedanaditiNo ratings yet

- Qa10 PS BW211D-40Document1 pageQa10 PS BW211D-40Andaru GunawanNo ratings yet

- BMW Full Workshop ManualDocument20 pagesBMW Full Workshop Manualkenneth100% (54)

- 01JUNIDocument1 page01JUNISteven Kuang01No ratings yet

- CAT C32 RNY Series Overhaul Recommendation - JPG PDFDocument6 pagesCAT C32 RNY Series Overhaul Recommendation - JPG PDFharikrishnanpd3327100% (1)

- High-torque 6-cylinder Isuzu FXL 240-350 6x2 rigid truckDocument4 pagesHigh-torque 6-cylinder Isuzu FXL 240-350 6x2 rigid truckSPINHRNo ratings yet

- POP TEMPLATE - HEXINDO - MX-FinalDocument2 pagesPOP TEMPLATE - HEXINDO - MX-Finaldhavit wijayantoNo ratings yet

- 2021-08-05 H-D Maintenance Schedules + Sportster SDocument29 pages2021-08-05 H-D Maintenance Schedules + Sportster SFred LakeNo ratings yet

- Train.Man.06.03.part.3Document79 pagesTrain.Man.06.03.part.3StormNo ratings yet

- MY18 S Class Sedan MaintenanceDocument103 pagesMY18 S Class Sedan MaintenanceccdanNo ratings yet

- 05.02.2b - Maintenance New AXOR - PreparationDocument71 pages05.02.2b - Maintenance New AXOR - Preparationptsi rekrutNo ratings yet

- Cascadia Warranty CoverageDocument1 pageCascadia Warranty CoverageSsNo ratings yet

- Car Maintenance ScheduleDocument1 pageCar Maintenance ScheduleIbrahim KashmNo ratings yet

- Detroit S60 SpecsDocument2 pagesDetroit S60 Specsgrgramm50% (2)

- Service at A Glance Maintenance Intervals: EngineDocument1 pageService at A Glance Maintenance Intervals: EngineDadangNo ratings yet

- 5 TC Update by S Koblenz PDFDocument25 pages5 TC Update by S Koblenz PDFg arvNo ratings yet

- 5th Gen Vocational Model GuideDocument34 pages5th Gen Vocational Model GuideKieran Ryan100% (1)

- Maintenance ScheduleDocument8 pagesMaintenance ScheduleArun KumarNo ratings yet

- Dokumen - Tips Yamaha Virago Xv535 Owners ManualDocument98 pagesDokumen - Tips Yamaha Virago Xv535 Owners ManualLucas FernándezNo ratings yet

- Lube Oil Change Intervals.: The Engine CompanyDocument1 pageLube Oil Change Intervals.: The Engine CompanyJose FavaNo ratings yet

- E06-001-R0 - Lube Oil and OperationDocument1 pageE06-001-R0 - Lube Oil and OperationSert AriNo ratings yet

- Actros MP4 Water RetarderDocument13 pagesActros MP4 Water RetarderAlexandru Nicola75% (4)

- Nissan Genuine Service - Pulsar SedanDocument2 pagesNissan Genuine Service - Pulsar SedanrajNo ratings yet

- ISM Vs ISL ComparisonDocument6 pagesISM Vs ISL ComparisonRZ Emi50% (2)

- Mercury-Mariner Service Manual 2 5 To 275hp 1990-2000-17350802Document403 pagesMercury-Mariner Service Manual 2 5 To 275hp 1990-2000-17350802Marco Diaz100% (2)

- Volatile Organic Compounds Removal Methods - A Review (2012)Document10 pagesVolatile Organic Compounds Removal Methods - A Review (2012)Chai Ming DengNo ratings yet

- RRLDocument7 pagesRRLAtasha MacatangayNo ratings yet

- Excessive Crankcase PressureDocument8 pagesExcessive Crankcase PressureabelNo ratings yet

- EU Stage V Engine: Wheel LoaderDocument24 pagesEU Stage V Engine: Wheel LoaderAnur WakhidNo ratings yet

- MTU Gendrive Diesel Engine Sales ProgramDocument55 pagesMTU Gendrive Diesel Engine Sales ProgramEdutamNo ratings yet

- Carbon Monoxide PDFDocument4 pagesCarbon Monoxide PDFFarzadNo ratings yet

- Example Aircraft Design ProcedureDocument106 pagesExample Aircraft Design ProcedureVijay GorfadNo ratings yet

- Boiler Safe OperationDocument9 pagesBoiler Safe OperationMARISSA DINLASANNo ratings yet

- Normativas Obdbr2Document16 pagesNormativas Obdbr2adrianramonNo ratings yet

- PIV Exhaust Generic V11Document18 pagesPIV Exhaust Generic V11Alireza AameriNo ratings yet

- CAT - 3516H Diagnostic Trouble CodesDocument20 pagesCAT - 3516H Diagnostic Trouble Codeswagner_guimarães_1100% (1)

- Mitsui 2021 ARDocument65 pagesMitsui 2021 ARZakaria AbdessadakNo ratings yet

- Excavator PC210-8 - UESS11008 - 1209Document28 pagesExcavator PC210-8 - UESS11008 - 1209Reynaldi TanjungNo ratings yet

- Jenny Compressor ManualDocument53 pagesJenny Compressor ManualrfelsburgNo ratings yet

- Analysis of Exhaust Gas Emissions From Gasoline Engine-Powered Passenger Vehicles in NigeriaDocument5 pagesAnalysis of Exhaust Gas Emissions From Gasoline Engine-Powered Passenger Vehicles in NigeriaSanthosh KumarNo ratings yet

- Guidelines Spray BoothsDocument6 pagesGuidelines Spray Boothszahid_497No ratings yet

- Checklist For Commercial Kitchen Exhaust Filtration SystemsDocument6 pagesChecklist For Commercial Kitchen Exhaust Filtration Systemsaskara25No ratings yet

- 00 Ytc MR - Tre 001 EngDocument81 pages00 Ytc MR - Tre 001 EngJessica RodriguezNo ratings yet

- Seminar TopicsDocument3 pagesSeminar TopicsPragati ChimangalaNo ratings yet

- GPCDOC GTDS Shell Rimula R4 X 15W-40 (CI-4 E7 DH-1) (En) TDS PDFDocument2 pagesGPCDOC GTDS Shell Rimula R4 X 15W-40 (CI-4 E7 DH-1) (En) TDS PDFLeonardo Da Cao Quy100% (1)

- Transportation Energy Data BookDocument429 pagesTransportation Energy Data BookSeyedNo ratings yet

- Important Manual InformationDocument1 pageImportant Manual InformationJorjNo ratings yet

- Case Study 1Document7 pagesCase Study 1Muhammad AtifNo ratings yet

- Emission Testing, Emission Failures and RepairsDocument5 pagesEmission Testing, Emission Failures and RepairsdilanNo ratings yet

- Exhaust System and Intake Manifold: Exhaust Ball Joint CouplingDocument26 pagesExhaust System and Intake Manifold: Exhaust Ball Joint CouplingSry SantosNo ratings yet

- MR - KVRBabu HD EngineDocument16 pagesMR - KVRBabu HD EngineSantosh TrimbakeNo ratings yet

- Mb900 Trouble GuideDocument427 pagesMb900 Trouble GuideCarlos Chzs100% (10)

- Carbon Footprint Calculator: Formulas, Assumptions and SourcesDocument5 pagesCarbon Footprint Calculator: Formulas, Assumptions and SourcesAzeemuddinNo ratings yet

- Recommended Practices For CNG Fueling Station Design, Construction and OperationDocument35 pagesRecommended Practices For CNG Fueling Station Design, Construction and OperationStefan GhNo ratings yet