Professional Documents

Culture Documents

New Text Document

Uploaded by

N Dhanunjaya Rao BorraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Text Document

Uploaded by

N Dhanunjaya Rao BorraCopyright:

Available Formats

Numerical simulation of composite structures is challenging due to the differences in involved

length scales. While the finite element method could be used to simulate the structural mechanics

of this system (resolving all length scales), it is not practical.

The standard approach to eliminate this problem of scale in finite element analysis for composite

materials is homogenization. An accurate approach is finite element analysis of the microscale

structure of the material, which is the approach implemented in Material Designer. In Material

Designer, the homogenization process starts with modeling the RVE. This requires the creation of

a simplified geometry, as well as the definition of material properties of the constituent materials.

Subsequently, the geometry is meshed for finite element analysis. The RVE is then exposed to

several macroscopic load cases, and its response is computed. The homogenized material data is

computed from the results of these responses.

Using this tool, you can calculate the effective properties of an RVE based on a lattice structure,

UD Composite(UD), Random UD Composite, Chopped Fiber Composite, Woven Composite or

specifyan user defined RVE as shown.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Assembly DrawingsDocument15 pagesAssembly DrawingsN Dhanunjaya Rao BorraNo ratings yet

- Assembly DrawingsDocument15 pagesAssembly DrawingsN Dhanunjaya Rao BorraNo ratings yet

- Advanced NDE Lesson 1Document190 pagesAdvanced NDE Lesson 1N Dhanunjaya Rao BorraNo ratings yet

- Mid 2Document6 pagesMid 2N Dhanunjaya Rao BorraNo ratings yet

- Fundamentals of Machining TechniquesDocument2 pagesFundamentals of Machining TechniquesN Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-2 Mech 3-1 R13Document1 pageMCMT Mid-2 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- MCMT Unit-2 PPQDocument2 pagesMCMT Unit-2 PPQN Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-1 Mech 3-1 R13Document1 pageMCMT Mid-1 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- Robotics Course Objectives and ApplicationsDocument5 pagesRobotics Course Objectives and ApplicationsN Dhanunjaya Rao BorraNo ratings yet

- Mid 2Document6 pagesMid 2N Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-2 Mech 3-1 R13Document1 pageMCMT Mid-2 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- Study of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionDocument1 pageStudy of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionN Dhanunjaya Rao BorraNo ratings yet

- Supplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingDocument5 pagesSupplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingN Dhanunjaya Rao BorraNo ratings yet

- Ucmp QBDocument1 pageUcmp QBN Dhanunjaya Rao BorraNo ratings yet

- Supplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingDocument5 pagesSupplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingN Dhanunjaya Rao BorraNo ratings yet

- Study of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionDocument1 pageStudy of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionN Dhanunjaya Rao BorraNo ratings yet

- Composite Materials QuotationDocument1 pageComposite Materials QuotationN Dhanunjaya Rao BorraNo ratings yet

- New Microsoft Excel WorksheetDocument3 pagesNew Microsoft Excel WorksheetN Dhanunjaya Rao BorraNo ratings yet

- CAMD QuestionsDocument3 pagesCAMD QuestionsN Dhanunjaya Rao Borra100% (1)

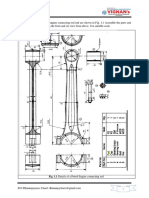

- Part-B1-Petrol Engine Connecting RodDocument5 pagesPart-B1-Petrol Engine Connecting RodN Dhanunjaya Rao BorraNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentN Dhanunjaya Rao BorraNo ratings yet

- Part A4 Keyed JointsDocument8 pagesPart A4 Keyed JointsN Dhanunjaya Rao BorraNo ratings yet

- Part-B-Topic AB 1 CAMD Petrol Engine Connecting - RodDocument8 pagesPart-B-Topic AB 1 CAMD Petrol Engine Connecting - RodN Dhanunjaya Rao BorraNo ratings yet

- Part A5 Cotter JointsDocument6 pagesPart A5 Cotter JointsN Dhanunjaya Rao BorraNo ratings yet

- Part A5 Cotter JointsDocument8 pagesPart A5 Cotter JointsN Dhanunjaya Rao BorraNo ratings yet

- Part A4 Keyed JointsDocument8 pagesPart A4 Keyed JointsN Dhanunjaya Rao BorraNo ratings yet

- Part-A5-Cotter Joints PDFDocument6 pagesPart-A5-Cotter Joints PDFN Dhanunjaya Rao BorraNo ratings yet

- Part A5 Cotter JointsDocument8 pagesPart A5 Cotter JointsN Dhanunjaya Rao BorraNo ratings yet

- Intro To NDTDocument34 pagesIntro To NDTkbldamNo ratings yet