Professional Documents

Culture Documents

Jack. Pump Head Calculation

Uploaded by

Abarajithan RajendranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jack. Pump Head Calculation

Uploaded by

Abarajithan RajendranCopyright:

Available Formats

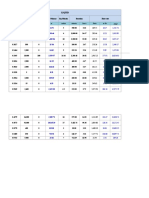

CIP-500L DISTRIBUTION

Pipe size (DN) DN15 DN25 DN40 DN50 DN65 DN80 DN100

Pipe Size (inch) 0.5 1 1.5 2 2.5 3 4 As per ASME BPE

OD mm 12.7 25.4 38.1 50.8 63.5 76.2 101.6

Thk 1.65 1.65 1.65 1.65 1.65 1.65 2.11

ID 9.4 22.1 34.8 47.5 60.2 72.9 97.38

Recom-

mended Minimum Flow in Cu.m/Hr As per the pipe Size And Recommended Velocity(m/s)

Velocity

1 0.25 1.38 3.42 6.38 10.24 15.02 26.80 0

1.5 0.37 2.07 5.13 9.56 15.36 22.53 40.20 0

2 0.50 2.76 6.84 12.75 20.48 30.04 53.60 0

2.5 0.62 3.45 8.56 15.94 25.60 37.55 67.00 0

3 0.75 4.14 10.27 19.13 30.72 45.06 80.40 0

3.5 0.87 4.83 11.98 22.32 35.85 52.56 93.80 0

4 1.00 5.52 13.69 25.50 40.97 60.07 107.19

4.5 1.12 6.21 15.40 28.69 46.09 67.58 120.59

5 1.25 6.90 17.11 31.88 51.21 75.09 133.99

PARAMETERS SUPPLY SUPPLY LINE FITTING

ITEMS Length K EQ LENGNO OF FITTIN

Peak load cumsumption m3/hr 45 Deg Short 0.02603595 0.35 0.03515 0

Line Flow M3/hr 1.380 45 Deg long 0.02603595 0.2 0.03124 0

Total flow in line m3/hr 0.500 90 Deg Short 0.0520719 0.75 0.09113 11

Pipe Diameter in mm 25.4 90 Deg long 0.0520719 0.45 0.0755 0

Pipe Thickness in mm 1.65 180 close Deg long 0.1041438 1.5 0.26036 0

Pipe ID mm 22.1 Tee Std run (non used) 0.0442 0.4 0.06188 2

Angle Seat Valve 0.0442 3.15 0.18343 4

Velocity in Pipe m/s 0.4

Kinematics viscosity in centipoise 0.36

Reynolds NO 22238.3762

Roughness in meter 0.00002

Relative Roughness 0.0007

frictional factor 0.0264

PIPE length(m) 5

Eq. Fitting length 1.86

TOTAL Length 6.86

Head Losses in MWC 0.05

Static Head 0.6

Pressure required at the spray ball 0

Pressre drop plate & frame HE 0.3

HEAD OF PUMP MWC 7.27 0.7269526 BARG

FLOW m3/hr 0.50

er ASME BPE KINEMATIC VISCOSITY IN centipoise.

TEMPERATURE. KV

80 1.2

EQ. LENGTH

0

0

1.00

0

0

0.12376

0.73372

1.86

You might also like

- DPS Calculation SheetDocument133 pagesDPS Calculation SheetKraiwan AranyawatNo ratings yet

- How Much Quantity of Chemical Reuqired For Chilled Water SystemDocument3 pagesHow Much Quantity of Chemical Reuqired For Chilled Water Systemganesh gundNo ratings yet

- How Much Quantity of Chemical Reuqired For Chilled Water SystemDocument3 pagesHow Much Quantity of Chemical Reuqired For Chilled Water SystemRaju Ksn100% (1)

- Low Head Designer v1 1cDocument7 pagesLow Head Designer v1 1cRekha PandeyNo ratings yet

- 6 ResultsDocument2 pages6 ResultsKHAIRUNISANo ratings yet

- Data NYAF 4mm SupremeDocument1 pageData NYAF 4mm SupremeHans JayaNo ratings yet

- S06&12 CBR 04 August 20161.odsDocument6 pagesS06&12 CBR 04 August 20161.odsAnonymous 0VmQRqfNNo ratings yet

- Diam. (MM) A (CM) (MM)Document12 pagesDiam. (MM) A (CM) (MM)telnajjarNo ratings yet

- NyaDocument1 pageNyaahmat kharisNo ratings yet

- Calculo de Parámetros de Resistencia Con El Ensayo SPT Estudios Geotecnicos Biodigestor CajicaDocument6 pagesCalculo de Parámetros de Resistencia Con El Ensayo SPT Estudios Geotecnicos Biodigestor CajicaMauro DelgadoNo ratings yet

- Pressure Drop CalculationDocument6 pagesPressure Drop CalculationmohamedNo ratings yet

- Return Air Square: Ceiling DiffuserDocument1 pageReturn Air Square: Ceiling DiffuserEnak CenirNo ratings yet

- Charts of Stainless Steel Pipe Fittings' WeightsDocument6 pagesCharts of Stainless Steel Pipe Fittings' WeightsHao ZhouNo ratings yet

- ANSI B16.5 Flanges - JMVDocument24 pagesANSI B16.5 Flanges - JMVJMVNo ratings yet

- Contenido de Humedad: 12 GolpesDocument6 pagesContenido de Humedad: 12 GolpessegundoNo ratings yet

- Amaravati Ducts Paid Vs Unpaidr4Document39 pagesAmaravati Ducts Paid Vs Unpaidr4Srigopi Chand RamineniNo ratings yet

- AC Fans Static Calculation Final-1Document20 pagesAC Fans Static Calculation Final-1Hendrias A.SNo ratings yet

- Return Air Square: Ceiling DiffuserDocument1 pageReturn Air Square: Ceiling DiffuserEnak CenirNo ratings yet

- SUPREME-flexible Cable PDFDocument12 pagesSUPREME-flexible Cable PDFRobert BudiwijayaNo ratings yet

- Transformer Base SL No Item Length Width Depth No Qty/Nos Total Qty UnitDocument4 pagesTransformer Base SL No Item Length Width Depth No Qty/Nos Total Qty UnitKM Mehedi HasanNo ratings yet

- Rodsim:: Open Circuit Grinding SimulatorDocument38 pagesRodsim:: Open Circuit Grinding SimulatorJunior Romero ChavezNo ratings yet

- HT Xlpe PDFDocument3 pagesHT Xlpe PDFrengaramanujanNo ratings yet

- PVC and CPVC Pressure Pipes: PVC Astm D1785 Schedule 80Document33 pagesPVC and CPVC Pressure Pipes: PVC Astm D1785 Schedule 80Muhammad AfzaalNo ratings yet

- Weight CalculationDocument22 pagesWeight Calculationkamaldhar007No ratings yet

- Calculos EléctricosDocument7 pagesCalculos Eléctricosjohn rangelNo ratings yet

- Chiler Water Supply Pump Head CaculationDocument1 pageChiler Water Supply Pump Head CaculationtienNo ratings yet

- Soil Test BasicDocument17 pagesSoil Test BasicSamwailNo ratings yet

- Data Set 3A For CoursesDocument6 pagesData Set 3A For CoursesDlanorNo ratings yet

- Dripnet PC Thin Walled Dripperlines Product SheetDocument2 pagesDripnet PC Thin Walled Dripperlines Product SheetIpanaqveRomeroJordanNo ratings yet

- Weight AreaDocument2 pagesWeight Areaapi-344441811No ratings yet

- Estimates - (09-18-13) Fe Village, Tagum City BY Contract CHB Fabrication, Drainage Phase3.xls New 2-24-17Document378 pagesEstimates - (09-18-13) Fe Village, Tagum City BY Contract CHB Fabrication, Drainage Phase3.xls New 2-24-17xtianNo ratings yet

- Din 2448Document1 pageDin 2448IsaacNo ratings yet

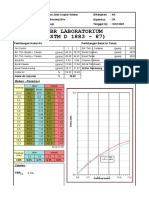

- CBR Laboratorium (ASTM D 1883 - 87) : Proyek Dikerjakan Lokasi Diperiksa Kedalaman Tanggal UjiDocument4 pagesCBR Laboratorium (ASTM D 1883 - 87) : Proyek Dikerjakan Lokasi Diperiksa Kedalaman Tanggal Ujirochmatul anisaNo ratings yet

- Depth vs. Disharge/Unit WidthDocument9 pagesDepth vs. Disharge/Unit Widthdannyd193No ratings yet

- Lab Computations TemplateDocument12 pagesLab Computations TemplateBenjamin DagbeyNo ratings yet

- Table - 8 Conductor PropertiesDocument1 pageTable - 8 Conductor PropertiesMichael DarmstaedterNo ratings yet

- Sewer Design On Excel 2009Document117 pagesSewer Design On Excel 2009ashe zinabNo ratings yet

- Power Cables With Their Electricals Characteristics, Overall Length and WeightDocument6 pagesPower Cables With Their Electricals Characteristics, Overall Length and WeightRoumya Darshan RayNo ratings yet

- Blance Con Nueva CapacidadDocument7 pagesBlance Con Nueva Capacidadmarc0scpNo ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius ElbowsDocument3 pagesDimensions (Based On ASME/ANSI B16.9) and Example Weights For Long Radius Elbowswenfang leeNo ratings yet

- Sieve and Hydrometer Results of Dry Bin Crosby Till: Particle Size (MM)Document2 pagesSieve and Hydrometer Results of Dry Bin Crosby Till: Particle Size (MM)AJR365No ratings yet

- Single Core 105°C PVC Tri-RatedDocument1 pageSingle Core 105°C PVC Tri-RatedanuradhaNo ratings yet

- Potable 3Document5 pagesPotable 3Juan Fernando Hernandez TorresNo ratings yet

- Nya Sni IecDocument1 pageNya Sni IecekasandiawanNo ratings yet

- Steel Quantity For Hexane Storage TankDocument2 pagesSteel Quantity For Hexane Storage TankTom JosephNo ratings yet

- Jis g3444-1 PDFDocument1 pageJis g3444-1 PDFRokhmatuSivaNo ratings yet

- Jis g3444-1 PDFDocument1 pageJis g3444-1 PDFbkprodhNo ratings yet

- Statement of BeddingDocument18 pagesStatement of BeddingNiks RathoreNo ratings yet

- Bolt, Nut, WasherDocument9 pagesBolt, Nut, WasherAndri EkoNo ratings yet

- National Highways Authority of India: DIRECT SHEAR TEST (IS 2720 Part-13: 2009)Document2 pagesNational Highways Authority of India: DIRECT SHEAR TEST (IS 2720 Part-13: 2009)DeepakNo ratings yet

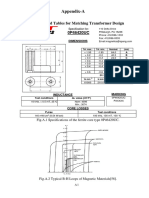

- Appendix ADocument3 pagesAppendix ANaeemo IraqiNo ratings yet

- Streamline PlusDocument8 pagesStreamline PlusWayne SeamanNo ratings yet

- Dhaka University of & Technology: EngineeringDocument17 pagesDhaka University of & Technology: EngineeringSujon AhmmedNo ratings yet

- Criterios de DiseñoDocument8 pagesCriterios de DiseñoKARITO SUAREZNo ratings yet

- AASHTO T 307-99: Resilient Modulus of Subgrade Soils and Untreated Base/Subbase MaterialsDocument1 pageAASHTO T 307-99: Resilient Modulus of Subgrade Soils and Untreated Base/Subbase MaterialsJuan Camilo Pérez CantorNo ratings yet

- Direct Shear Test: For EPC Contractor For Concessionaire RepresentativeDocument1 pageDirect Shear Test: For EPC Contractor For Concessionaire RepresentativeshreNo ratings yet

- Roofdek D32S: Ultimate Section Properties To EurocodeDocument1 pageRoofdek D32S: Ultimate Section Properties To EurocodeVolodymyr ShchurNo ratings yet

- Proyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Document4 pagesProyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Ikhromul Khoirul AqshomNo ratings yet

- Stud Bolts DIN 976-1: 2002-12: 1. ScopeDocument6 pagesStud Bolts DIN 976-1: 2002-12: 1. ScopejayNo ratings yet

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Ab FFLDDocument184 pagesAb FFLDNikhilesh MuraleedharanNo ratings yet

- Field Remote Instrument Enclosure: JB-001 MR02Document1 pageField Remote Instrument Enclosure: JB-001 MR02suhailfarhaanNo ratings yet

- AKSS ASDM-2022: - Internal Safety OrientationDocument3 pagesAKSS ASDM-2022: - Internal Safety OrientationAbarajithan RajendranNo ratings yet

- Field Remote Instrument Enclosure: JB-001 MR02Document1 pageField Remote Instrument Enclosure: JB-001 MR02suhailfarhaanNo ratings yet

- Scheduled Courses in 2019 (Singapore) : Course Title Code JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC Duration (DAYS)Document1 pageScheduled Courses in 2019 (Singapore) : Course Title Code JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC Duration (DAYS)Abarajithan RajendranNo ratings yet

- Field Remote Instrument Enclosure: JB-001 MR02Document1 pageField Remote Instrument Enclosure: JB-001 MR02suhailfarhaanNo ratings yet

- TFF (Design Cal)Document1 pageTFF (Design Cal)Abarajithan RajendranNo ratings yet

- Bala ResumeDocument4 pagesBala ResumeAbarajithan RajendranNo ratings yet

- Field Instrument Installation ChecklistDocument1 pageField Instrument Installation ChecklistAbarajithan RajendranNo ratings yet

- Trinkets Season 2 - Google SearchDocument1 pageTrinkets Season 2 - Google SearchAbarajithan Rajendran0% (1)

- Naveen ResumeDocument4 pagesNaveen ResumeAbarajithan RajendranNo ratings yet

- DFVDocument1 pageDFVAbarajithan RajendranNo ratings yet

- Sanjay ResumeDocument4 pagesSanjay ResumeAbarajithan RajendranNo ratings yet

- Displacer: Calibration and Maintenance ProcedureDocument6 pagesDisplacer: Calibration and Maintenance ProcedureAbarajithan RajendranNo ratings yet

- B.3.12 - Impulse Piping & TubingDocument5 pagesB.3.12 - Impulse Piping & TubinggdfsndhgfdvhjzdNo ratings yet

- Agitator Calculation. - SPLDocument2 pagesAgitator Calculation. - SPLAbarajithan RajendranNo ratings yet

- HP To WattDocument4 pagesHP To WattAbarajithan RajendranNo ratings yet

- General Specifications: Daqstation DX1000Document20 pagesGeneral Specifications: Daqstation DX1000Abarajithan RajendranNo ratings yet

- Chp8 3edition PDFDocument21 pagesChp8 3edition PDFAbarajithan RajendranNo ratings yet

- Design Criteria - External Spin FilterDocument2 pagesDesign Criteria - External Spin FilterAbarajithan RajendranNo ratings yet

- Compact Valve Terminal (16-Valves Profibus Master)Document2 pagesCompact Valve Terminal (16-Valves Profibus Master)Abarajithan RajendranNo ratings yet

- DasaDocument2 pagesDasaAbarajithan RajendranNo ratings yet

- MTP 1 Impulse LineDocument4 pagesMTP 1 Impulse LineAbarajithan RajendranNo ratings yet

- Sarathi New ResumeDocument6 pagesSarathi New ResumeAbarajithan RajendranNo ratings yet

- 23Document1 page23Abarajithan RajendranNo ratings yet

- 12Document1 page12Abarajithan RajendranNo ratings yet

- AD Vigano: 110/127 V and 220/240 V Bi-Pin Fluorescent Luminaires For Non-Armoured CableDocument1 pageAD Vigano: 110/127 V and 220/240 V Bi-Pin Fluorescent Luminaires For Non-Armoured CableAbarajithan RajendranNo ratings yet

- Custom Ex Control Stations Stainless SteelDocument17 pagesCustom Ex Control Stations Stainless SteelAbarajithan RajendranNo ratings yet

- Redapt Hazardous Area GuideDocument11 pagesRedapt Hazardous Area GuidekarthipetroNo ratings yet

- Unit Iv-Pumps: PART - A (2 Marks) (NOV-02)Document1 pageUnit Iv-Pumps: PART - A (2 Marks) (NOV-02)mohanrajmeed2012No ratings yet

- 512 Model DDX Deluge Valves, 2", SmallDocument8 pages512 Model DDX Deluge Valves, 2", SmallM Kumar MarimuthuNo ratings yet

- Operation Manual FOR SKT140 Series of Pneumatic Hydraulic Test-BedDocument12 pagesOperation Manual FOR SKT140 Series of Pneumatic Hydraulic Test-BedAlex RamirezNo ratings yet

- Hansgrohe Product Specification 2023-02-06Document2 pagesHansgrohe Product Specification 2023-02-06ginlemon86No ratings yet

- Eurobrass 146: Pressure Reducing ValveDocument5 pagesEurobrass 146: Pressure Reducing ValveNicolas Fuentes Von KieslingNo ratings yet

- Skip Handling: TP501 Festo DidacticDocument7 pagesSkip Handling: TP501 Festo DidacticHossam AbdelhameedNo ratings yet

- D1wwef01 Eng PDFDocument100 pagesD1wwef01 Eng PDFHugo Valdes BarriosNo ratings yet

- 5.a19a PMSDocument5 pages5.a19a PMSS.selvakumarNo ratings yet

- Form QT4 (B)Document2 pagesForm QT4 (B)Bonaventure NzeyimanaNo ratings yet

- Positive Displacement PumpsDocument20 pagesPositive Displacement PumpspavijayaNo ratings yet

- Hydraulics - Fluid Mechanics - Modi-Seth PDFDocument528 pagesHydraulics - Fluid Mechanics - Modi-Seth PDFAmit SinghNo ratings yet

- 353Document2 pages353Ckaal74No ratings yet

- Valves PresentationDocument36 pagesValves PresentationFareedee100% (1)

- Rig 350 Ipn SpecificationDocument8 pagesRig 350 Ipn SpecificationBambang PermanaNo ratings yet

- Portable Concrete Pump LiugongDocument2 pagesPortable Concrete Pump LiugongsumardiNo ratings yet

- PLC CaterpillarDocument3 pagesPLC CaterpillarAmanda TaylorNo ratings yet

- Kerovit Catalogue PDFDocument86 pagesKerovit Catalogue PDFDharmin Kansara0% (1)

- Operating ACE For Downhole BlendersDocument187 pagesOperating ACE For Downhole BlendersFrank N100% (3)

- GAER Double Disc Check Valve EngDocument2 pagesGAER Double Disc Check Valve EngCarlos Rovello GandoNo ratings yet

- Valve Symbols, Pump and MotorsDocument23 pagesValve Symbols, Pump and MotorsKristian Ureta100% (1)

- TFP1420 09 2004 PDFDocument14 pagesTFP1420 09 2004 PDFPhuNguyenHoangNo ratings yet

- Slow Moving Ready Stock - Hose & O-Ring - 02.15Document30 pagesSlow Moving Ready Stock - Hose & O-Ring - 02.15Cuma QoNo ratings yet

- Detail Produksi (Factry)Document2 pagesDetail Produksi (Factry)hernantoNo ratings yet

- Et33 - Piping Class Anexo Rev BDocument22 pagesEt33 - Piping Class Anexo Rev BAiskel PazNo ratings yet

- Ball Valves KH ParkerDocument7 pagesBall Valves KH Parkerkocho79No ratings yet

- Spray Nozzle Data Sheet 1/2N4@7Document2 pagesSpray Nozzle Data Sheet 1/2N4@7Danel GonzalezNo ratings yet

- Cat 320D Hyd - And.elec Diagram PDFDocument28 pagesCat 320D Hyd - And.elec Diagram PDFluis angel ruiz gomez100% (4)

- Rishabh Steel IndustriesDocument25 pagesRishabh Steel IndustriesNico RoisnerNo ratings yet

- Carga de Nitrógeno - BajaDocument13 pagesCarga de Nitrógeno - BajaBrayan Sánchez ParedesNo ratings yet

- Mainline PPR LT.21.DDocument1 pageMainline PPR LT.21.DVictor AfandiNo ratings yet