Professional Documents

Culture Documents

Lifting Lug Sample

Uploaded by

abdul marpaungCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Lug Sample

Uploaded by

abdul marpaungCopyright:

Available Formats

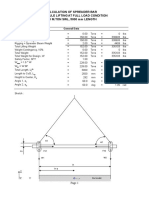

PT.

EJJV-GSB CONSORTIUM

LIFTING LUG CALCULATION

Issued Date : Document No. : PAGE : REVISION

28-Jan-19 2 Of 2 0

Description : Top Lug

5.886 W [lb] Weight of the load

3 Nd Desain Factor

Material :

SA-36 Material of Lug

36.000 Fy [psi] Yieal Strength of Lug

58.000 Fu [psi] Tensile Strength of Lug

29.000.000 E [psi] Modulus of elasticity of Lug

E 7018 Material of Electrode

70.000 Exx [psi] Tensile Strength of Electrode

figure C3-3 Pin-Connected Plate Nation

Dimension :

2,000 Dh [in] Hole Diameter of Lug

3,546 w [in] Width of Lug

0,394 t [in] Thickhness of of lug

1,773 R [in] Outer radius of Lug

0,240 Leg [in] Weld Leg Height

2,000 Lw [in] lenght WeldVertical

Tensile Stress :

Ft [in] = Fy/Nd Allowable tensile Stress (eg. 3-1) = 12.000

A = t*(w-Dh) Area in tension = 0,609

St [psi] = W/A Tensile stress = 9.663

Check St = St < Ft 9.663 < 12.000 = Acceptable

Shear Strength Through Pinhole :

Av [in^2] = 2*(R-(Dh/2)*cos(radians(45)))*t Total area of two planes (eq, 3-51)

= 0,840

Pv [lb] = 0.7*Fu/(1,2*Nd)*Av Double plane Shear Strength (eq. 3-49)

= 9.472

Check Fw = W < Pv 5.886 < 9.472 = Acceptable

Shear Stress in Weld :

Fv [psi] = 0,6*Exx/(1,2*Nd) Allowable weld shear stress (eg. 3-53)

= 11.667

Aw [in^2] = ((2*Lw+w)*t)*(0,707*Leg) Area of the weld

= 0,5044797

Fw [lb] = Fv*Aw Allowable weld load = 5.886

Check Fw = W < Fw 5.886 < 5.886 = Reject

Conclusion: The lifting lug has been designed to ASME BTH-1 and has a maximum lifting capacity of

5000 lb

You might also like

- Pveng: Pressure Vessel Engineering LTDDocument5 pagesPveng: Pressure Vessel Engineering LTDBruno TrujilloNo ratings yet

- Lifting Lug Calculation RefDocument2 pagesLifting Lug Calculation Refmarc_albertoNo ratings yet

- Lifting LugDocument39 pagesLifting LugSasikumar JothiNo ratings yet

- Vessel lifting lug design data and stress analysisDocument3 pagesVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Design of lifting lug for 8MT load capacityDocument2 pagesDesign of lifting lug for 8MT load capacityKeyurNo ratings yet

- Lifting Lug Design and Stress AnalysisDocument2 pagesLifting Lug Design and Stress AnalysisDarkvader0% (1)

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Design Calculation Padeyes Skid Welding MachineDocument19 pagesDesign Calculation Padeyes Skid Welding MachineAbu Al Sayyid100% (1)

- Lifting Lug DesignDocument7 pagesLifting Lug DesignJens SøndergaardNo ratings yet

- Design of Pad Eye Using Check PlatesDocument3 pagesDesign of Pad Eye Using Check Plateshyoung65No ratings yet

- Most Applications, F.S. 5.0) : Calculation ReferenceDocument5 pagesMost Applications, F.S. 5.0) : Calculation ReferenceParthibanNo ratings yet

- Heat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataDocument2 pagesHeat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataSteve MoonNo ratings yet

- Spreader Beam (Planning)Document28 pagesSpreader Beam (Planning)AKSHAY BHATKARNo ratings yet

- 8 Padeye - Spreadsheet Check1Document4 pages8 Padeye - Spreadsheet Check1oluomo1No ratings yet

- Calculation of lift lug on spreader barDocument8 pagesCalculation of lift lug on spreader barrustamriyadiNo ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationAndy Chan100% (1)

- Lifting Lug CalculationDocument2 pagesLifting Lug CalculationDaison Paul63% (8)

- Lifting Lug DesignDocument27 pagesLifting Lug Designmramico100% (1)

- LiftingLug TrunnionDocument22 pagesLiftingLug Trunnionrichardchiam100% (2)

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- Design Calculation 4-PadeyesDocument4 pagesDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- Lifting Lug CalculationDocument4 pagesLifting Lug CalculationLokesh PatelNo ratings yet

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- Spreader Beam DesignDocument3 pagesSpreader Beam DesignCHENo ratings yet

- Calculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightDocument14 pagesCalculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightrustamriyadiNo ratings yet

- Lifting Lug Material and Stress CheckDocument1 pageLifting Lug Material and Stress Checkveeru2906No ratings yet

- Spreader Bar For LiftingDocument1 pageSpreader Bar For LiftingTran ThoNo ratings yet

- Spreader Calculation (ISMC-200)Document4 pagesSpreader Calculation (ISMC-200)mechmohan26No ratings yet

- Padeye CheckDocument12 pagesPadeye CheckBen100% (1)

- Lifting LugDocument7 pagesLifting LugSajal KulshresthaNo ratings yet

- Lifting Lug DesignDocument7 pagesLifting Lug DesignadammzjinNo ratings yet

- LIFTING LUG AND LIFTING COVER DESIGN REFERENCEDocument4 pagesLIFTING LUG AND LIFTING COVER DESIGN REFERENCERohith V VNo ratings yet

- Pad EyesDocument12 pagesPad EyesRachmad HidayatNo ratings yet

- Lifting Lug Design (3064)Document37 pagesLifting Lug Design (3064)Ganesh Bhardwaj50% (2)

- Pad Eye Design AnalysisDocument10 pagesPad Eye Design AnalysisRaza AidanNo ratings yet

- Spreader Beam: ASME BTH-1: InputsDocument17 pagesSpreader Beam: ASME BTH-1: InputsGokul AmarnathNo ratings yet

- Sample Section Modulas CalculationDocument18 pagesSample Section Modulas CalculationShamik ChowdhuryNo ratings yet

- Lifting Lug DesignDocument17 pagesLifting Lug Designguravdr100% (2)

- Report SPeaDer BarDocument24 pagesReport SPeaDer BarMochammad Shokeh100% (2)

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Lifting Lug Design SheetDocument6 pagesLifting Lug Design SheetIjaz AhmedNo ratings yet

- Spreader Beam SampleDocument10 pagesSpreader Beam SampleAdi SutardiNo ratings yet

- Engineering Design of Lifting LugsDocument1 pageEngineering Design of Lifting LugsadammzjinNo ratings yet

- Spreader Beam CalculationDocument4 pagesSpreader Beam CalculationMateen KhanNo ratings yet

- Padeye CalculationDocument6 pagesPadeye CalculationKarun DasNo ratings yet

- LIFTING-LUG DESIGN CALCULATIONDocument5 pagesLIFTING-LUG DESIGN CALCULATIONAnisa Rifqi0% (1)

- Aluminium Cladding DesignDocument2 pagesAluminium Cladding DesigntkofaiNo ratings yet

- Aluminium Cladding DesignDocument3 pagesAluminium Cladding Designjatin100% (1)

- Appendix E.1. Pipe Support Calculation - PS-CP-01Document10 pagesAppendix E.1. Pipe Support Calculation - PS-CP-01noto.sugiarto50% (2)

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Spreader Bar Calc REF.Document34 pagesSpreader Bar Calc REF.Gokul AmarnathNo ratings yet

- Reactor Feed/Effluent Exchangers Rajasthan Refinery, Naphtha HDTDocument2 pagesReactor Feed/Effluent Exchangers Rajasthan Refinery, Naphtha HDTAnonymous AyDvqgNo ratings yet

- Steel Column Base - Shear Lug AnalysisDocument1 pageSteel Column Base - Shear Lug AnalysisVega DesNo ratings yet

- LSB-1-0808-02-A2-001 - NewDocument5 pagesLSB-1-0808-02-A2-001 - NewariyaNo ratings yet

- Eng - M - Lifting Lug Cal - 2Document6 pagesEng - M - Lifting Lug Cal - 2Ricardo NapitupuluNo ratings yet

- Strut Waler Connection Design TemplateDocument1 pageStrut Waler Connection Design TemplateArjun Raja100% (1)

- 2 Piles Cap Design ExampleDocument3 pages2 Piles Cap Design ExampleSilvanus ChepkocheiNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Foundation Design Analysis of A Three Storey Commercial BuildingDocument54 pagesFoundation Design Analysis of A Three Storey Commercial BuildingJoshua Lacaña SaltivanNo ratings yet

- SI500.11r5e - GrafoilDocument5 pagesSI500.11r5e - GrafoilHumayun NawazNo ratings yet

- Wire Rope GuideDocument30 pagesWire Rope GuideAnonymousNo ratings yet

- 28 Jan 2016 130451497MIDC9A4GAdditionalInformationDocument84 pages28 Jan 2016 130451497MIDC9A4GAdditionalInformationSankhyaNo ratings yet

- Factors Affecting Durability PDFDocument5 pagesFactors Affecting Durability PDFApoorvaAppiNo ratings yet

- Primavera Engineer To Order (ETO)Document9 pagesPrimavera Engineer To Order (ETO)ShriNo ratings yet

- WRE - 412 - Lec01 - Introduction To Hydraulic StructuresDocument40 pagesWRE - 412 - Lec01 - Introduction To Hydraulic StructuresAzwad Abeer100% (1)

- Method Statement For Laying of MCC Duct and Civil Works For MCC NetworkDocument26 pagesMethod Statement For Laying of MCC Duct and Civil Works For MCC NetworkVenkadesh PeriathambiNo ratings yet

- Optimal Foundation Solution For Storage Terminal in MangaloreDocument4 pagesOptimal Foundation Solution For Storage Terminal in MangalorelingamkumarNo ratings yet

- EQ04Document121 pagesEQ04chandan naiduNo ratings yet

- Boiler Basics, Operation and MaintenanceDocument121 pagesBoiler Basics, Operation and MaintenanceCosmin IulianNo ratings yet

- Deaf School Business Plan PDFDocument18 pagesDeaf School Business Plan PDFVovNo ratings yet

- No Fines Conc SpecsDocument3 pagesNo Fines Conc Specsway2saleemNo ratings yet

- Local Buckling Tests On Cold-Formed Steel Beams by Yu 2003Document11 pagesLocal Buckling Tests On Cold-Formed Steel Beams by Yu 2003fahmi aballiNo ratings yet

- Copy of Pending Pos MetalDocument112 pagesCopy of Pending Pos MetalVijay OfficialNo ratings yet

- Experiment 6 Forces in A Roof TrussDocument5 pagesExperiment 6 Forces in A Roof Trusshafiey89No ratings yet

- Model of Tender SpecificationDocument15 pagesModel of Tender SpecificationRishi KathirNo ratings yet

- Design of Rigid Pavement CC Road With M25Document5 pagesDesign of Rigid Pavement CC Road With M25pravincs_007No ratings yet

- Welded Connections DesignDocument35 pagesWelded Connections DesignBelkacem AchourNo ratings yet

- Stock Register StoreDocument1,218 pagesStock Register StoreSantanu Kumar SahuNo ratings yet

- TechnipFMC Project MobilizationDocument9 pagesTechnipFMC Project MobilizationJobJob100% (8)

- VILLA 430: Hyderabad, TelanganaDocument27 pagesVILLA 430: Hyderabad, TelanganaH A I K U S T U D I ONo ratings yet

- Memo RA 9514Document351 pagesMemo RA 9514VergillerMisaGomezNo ratings yet

- Five Steps To Resolving Construction Disputes - Without Litigation (Sheen, 1994)Document3 pagesFive Steps To Resolving Construction Disputes - Without Litigation (Sheen, 1994)Kimmy LeeNo ratings yet

- Bim Module EpflDocument105 pagesBim Module EpflMúÑír PåhôrêNo ratings yet

- ETABS LearningDocument8 pagesETABS LearningSai TarunNo ratings yet

- Standard Method of Measurement for Building Works in QatarDocument158 pagesStandard Method of Measurement for Building Works in Qatarizac007No ratings yet

- Cross-Section Properties of IPN 300 Steel BeamDocument2 pagesCross-Section Properties of IPN 300 Steel BeamFilip StojkovskiNo ratings yet

- Research Portals for Construction Project ManagementDocument9 pagesResearch Portals for Construction Project ManagementrajnishatpecNo ratings yet

- Power Plant Best Practices 2015 PDFDocument107 pagesPower Plant Best Practices 2015 PDFFairoza AmalinnaNo ratings yet