Professional Documents

Culture Documents

Despre Lemn Si Caramida

Uploaded by

just_a_userCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Despre Lemn Si Caramida

Uploaded by

just_a_userCopyright:

Available Formats

Scientific Papers Series Management, Economic Engineering in Agriculture and Rural Development

Vol. 15, Issue 3, 2015

PRINT ISSN 2284-7995, E-ISSN 2285-3952

BUILDING A HOUSE - BETWEEN TRADITIONAL MATERIALS AND

PATENTED ORGANIC MATERIALS

Adelaida Cristina HONTUŞ

University of Agronomical Sciences and Veterinary Medicine - Bucharest, Faculty of

Management, Economical Engineering in Agriculture and Rural Developments, 59, Mărăşti

Boulevard, District 1, Bucharest, Zip code 011464, Romania,

E-mail: adelaidahontus@yahoo.com

Corresponding author: adelaidahontus@yahoo.com

Abstract

Ecological and patented a traditional or modern? These are the two options you have at your disposal a beneficiary

when engaging in adventure called "dream house". As usually happens, in this case, opinions are divided, because

in both cases there are advantages and disadvantages. To make the best decision regarding the construction of a

house, it is necessary that each beneficiary to document thoroughly and choose the knowledgeable, the solution that

best suits your needs and, not least Its budget. Other issues that need to be considered are the peculiarities of the

land, which will be located in the building, usable area which will also architectural style they prefer beneficiary.

Lately in our country this type of construction, wood, green, took a considerable boom, leaving behind traditional

methods of building a house. It gained widespread Romanian real estate market demand for people to build or buy a

house on wooden structure that is more resilient and sustainable and earthquakes. In this study we will present the

positive and negative, of building a wooden house or a house brick.

Key words: brick, bearing structure, beams, loading technique, load-bearing walls, masonry, monolithic casting,

wood

INTRODUCTION extremely popular in the Nordic countries,

where effectively fight a cold. About they

In a decision should be known that a wooden need to know they are very functional,

house is cheaper, even with 50% against one because their inner space can easily be

brick, but that maintenance of wooden houses, divided or changed, as have a light structure

in time, generate higher costs. Also, and therefore does not require too many

experience has shown designers and builders, supporting pillars [1]. Regarding benefits, also

that brick house is more lasting and withstand noted a fact: traditional wooden houses can be

unexpected events such as fires, but is less built on weak soil or sandy [8]. If no trump

friendly in terms of creating a thermal the latter failed to convince, we will say only

environment pleasant both in winter, cat and that doctors considered "healthy" because

in the warm. The pros and cons adds that a wood is a 100% natural element, breathe, so it

wooden house is more flexible and has lower made dampness and condensation shelter.

seismic risk, but a brick house is attacked by

decay, ants and humidity. In addition to the MATERIALS AND METHODS

arguments mentioned, must also be taken of

the particularities of the land and the costs that In the study, we used as materials, wood and

can afford a beneficiary. brick, two of construction materials frequently

A wooden construction is clearly a good used in execution of houses. As a research

choice for those who want to move into a new method we used comparative method, the

home in record time, given that it runs Radic advantages and disadvantages of each

in a period of between one and three Monday. construction material. Comparison of the two

In addition, heat losses were calculated by the construction materials, and present certain

specialists as 30-40% lower than in brick specific characteristics, helps in choosing the

houses [3]. As proof, wooden houses are recipient of the construction material for the

167

Scientific Papers Series Management, Economic Engineering in Agriculture and Rural Development

Vol. 15, Issue 3, 2015

PRINT ISSN 2284-7995, E-ISSN 2285-3952

implementation of your own home. The lengths, and provide easy decorating the

construction material, its quality, its usage and walls, exposing only regular wood surfaces.

the costs of each construction material, are Laminated wood framed home. The assembly

very important in the implementation of a of structural elements creates a network of

house. beam-column where all parts are

predimensioned and processed in the factory.

RESULTS AND DISCUSSIONS Fixing the foundation wooden structure is

made by special fixture which isolates total

A very important aspect of building a house is surface of the timber concrete [3]. They can

the choice of construction materials, both be filled with large glass panels or insulated

those related to the achievement of the panels (sandwich).

resistance structure and finishes. Regarding Houses self-supporting (sandwich). This type

the support structure which gives stability and of structural frame houses independent, role

strength of the entire construction, should the being taken over by prefabricated bearing

beneficiary, requiring manufacturers to use walls. Assembly is done with screws. Besides

only approved and certified building the resistance structure includes wall

materials, providing a guarantee of quality sandwich insulation layer, vapor barrier,

and work well done. facilities and routes within and outside layers

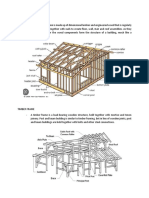

Wood house.Among the oldest green building of finish. You can choose any type of finish as

include wood houses. They are made of wood in standard construction. Among the

in various types of structures (modular, logs, advantages can be mentioned: high resistance

panels, etc.), better withstand earthquakes and to earthquakes, a wide variety of shapes and

foundations require much lower volume and sizes, lower execution costs.

cost. Wooden houses presents a number of

Logs houses. They are made of two types of advantages observable. The production cost is

wood: Roundwood calibrated (ie the log is lower than the housing made of other

processed at the same size) and calibrated logs materials. Then, no air conditioning is not too

(the log has approximate dimensions). Log costly, given that a well-insulated wooden

houses are massive, in fact, traditional houses house proves to be sufficiently cool in

made of rough wood processed manually [3]. summer and warm enough in winter. All this

These amounts generally on concrete leads to reduced consumption of fuel and

foundations, but are made entirely of massive energy, emission of pollutants is therefore

trunks of wood, previously untreated, but diminished.

peeled. The entire building is made of logs A wooden house is cheaper, sometimes by

and shaped by overlapping and joining their almost half, but maintenance is demanding

ends by plane manually, which ensures a very her time [4]. A brick house is more durable

resistant structure of the house mechanically and resistant to fire, but it is colder in winter

(and effective protection against seismic). Is and warmer in summer than in a wooden

inserted between the mating surfaces of house. A wooden house is more flexible and

mineral wool for thermal and sound less dangerous in case of earthquake, but a

insulation. Then the wood is treated to gain brick house is attacked by caries, overrun by

resistance against harmful microorganisms. ants etc. [4].

Laminated wood beams houses. They are The advantages of wooden houses:

made of wooden beams Glulam, namely: - Are cheaper by 30-40% than those of brick;

beams compact timber obtained by combining materials used are cheaper and their degree of

pieces of lumber in the first phase in the form industrialization that can be prefabricated to a

of blades, which in turn are glued together in greater extent and cause the price to be lower;

special conditions of temperature and pressure - Runs fast in a month, more than three

[6] . The advantage is that are more stable months;

over time (not subject to specific deformation - Are flexible and lightweight, and are not

of solid wood) can have large sections and dangerous in case of earthquake;

168

Scientific Papers Series Management, Economic Engineering in Agriculture and Rural Development

Vol. 15, Issue 3, 2015

PRINT ISSN 2284-7995, E-ISSN 2285-3952

- Good thermal insulation is colder in than classical nails, staples and which are also

summer and winter warmer; Heat losses were used in other parts of the builders.

calculated by experts as 30-40% lower than Unfortunately, in our country, do not meet the

brick houses; Nordic people prefer this standards and rules of construction for homes

technology, which demonstrates that they are made of wood.

effective in fighting very low temperatures; The construction of wooden houses using

Norwegian and Swedish houses are made as material and technical and execution

sandwich method; standards already approved in more developed

- Inner space can easily be divided or countries, the price is about 400 € /mp +

modified; the house light, does not require too VAT.

many pillars, making the inner space to be The houses made of wood, various structures

easily modeled. not demanding in terms of and forms can be achieved and cellar, garage.

terrain type that can be placed; being Foundation such a home is like a classic, all

lightweight wooden houses can be built and concrete and reinforced concrete

poor or sandy land, facilities can be hidden in reinforcement. The cost of foundations in a

walls; walls being prefabricated and wooden wooden house, is about 50 € /mp.

houses were built usually by type projects Finally, foreigners say they are healthier.

could be envisaged route cable wires or utility Wood is a natural, environmentally friendly;

lines. In a masonry house may appear damp,

(When buying a property looks over which it condensation. It is said that a wooden house

emphasizes is the presence of utilities. It "breathe" and does not suffer from the vapors.

refers to running water, gas, electricity, Disadvantages of wooden houses:

Internet, cable TV and access to the sewage - "Live" less than brick; builders view that

system of a house or possibility to make the the life of a house of wooden panels is 20-

connection to these services for a particular 30% shorter than the one of brick, however,

field.). there are wooden churches and old houses

The wood used to construct the houses would built of wood massive, who resisted while

have to meet some technical conditions of use more than palaces built of stone in the cities;

are not complied with by all manufacturers - Does not ensure a perfect sound-proofing;

and all companies providing building - Maintenance time is painstaking and

materials: demands money; at an interval of five to six

- the wood comes from the provider you have years should be checked carefully and make

a few weeks left to dry any necessary repairs; In addition, all

-wood insert, then in special ovens for drying, elements of structural and nonstructural wood

electronically controlled kilns where wood is should be treated against insects and whether

until you reach the optimal humidity of 14- or log paneling on the outside, they should be

16%. varnished;

-gives wood is planned on all sides in this - Cannot be too high; a wooden house should

phase and you see all hidden defects. Through not have more than two floors, because at a

this process, the wood loses 26% by volume height greater stability is shaky house.

and is the size of 15 × 4.5 cm. Brick house. As it was reminded the wooden

- the wood is cut to the size of the project and houses, a brick house is quite expensive (more

numbered and then to be able to easily build expensive than one made of wood even 50

panels the size of the project. percent), it requires no maintenance expenses

-the wood is completely submerged in the as high as those of wood.

bath where the substance of treatment against Also, a house brick cope better with

insects and fungi. unexpected events such as fires, but is less

The joints should use special fasteners, efficient in terms of creating an environment

galvanized and approved items bearing the CE so pleasant heat in winter and in the warm.

marking. Obviously, the cost of these These buildings can be improved in terms of

engaging elements are 3 times more expensive heat through systems engineering construction

169

Scientific Papers Series Management, Economic Engineering in Agriculture and Rural Development

Vol. 15, Issue 3, 2015

PRINT ISSN 2284-7995, E-ISSN 2285-3952

(creating an air vertically between two layers structure of the supporting walls of brick (the

of masonry, which prevents the transfer of panels of masonry are framed reinforced

energy between inside and outside). In concrete little poles and belts), etc.

addition, these homes can benefit from a There are many structural variants from

classic insulation system. which to choose:

Brick houses are durable, resisting for more - Brick structure houses the bearing (full

years than those made from other materials brick or brick goals); - Houses concrete

(eg wood), but it is not recommended to be structure: columns and beams;

built on weak soil or sand. It should be noted -Monolithic structure houses: pour

that a house of brick is higher seismic risk and reinforced concrete walls (hence the novelty

is less flexible, but is not affected by moisture of those modules that make up the future of

or by pests [5]. expanded polystyrene wall, which lay the

If you want a large house with several floors, rebar and the concrete is poured)

a brick home is a good choice because, if built - Wooden structure wood: pillars and beams

correctly, no problems of stability. (the floors are all wooden beams or concrete

The resistance structure must cope with brio slabs may be);

own weight of the house, and seismic forces, - Metal structure houses: pillars and beams.

weather and vibrations. It takes its own weight The combinations may occur if structures on

plus the payload capacity (people and pillars and beams and have exterior walls of:

furniture) through floors and beams, walls and brick, hollow brick, concrete, sandwich

columns and send that through the foundation, panels, panels of corrugated sheets, panels of

a pass on the ground [2]. wood or PVC, prefabricated and bulkheads in:

Depending on your budget, the architecture brick, hollow brick, concrete, drywall boards.

desired and, not least, personal taste, What is important especially structure and the

Framework, a case can be made either of material it is made it? depending on what you

reinforced concrete frames or frames of wood want to have spaces in new home (openings,

or wooden wall, or the supporting walls of glass surfaces, number of levels, whether or

brick. not a basement), architect and structural

In Romania, the most used system is the engineer will recommend a certain type of

monolithic reinforced concrete frames. This is structure.

made up of a network of horizontal elements Each structure has restrictions. Here are a few

(beams) and vertical (columns) monolithic to get an idea about what discussed:

reinforced concrete slabs stiffened by In a supporting structure of brick house you

horizontal reinforced concrete. cannot have large openings - up to 2.5 m,

Concrete is the cheapest building material whether we speak of an empty window, door

resistance and, unlike wood or metal, does not or living space. You cannot "forget" a wall

require special treatment (flame retardant or between the living and dining unless you

antiseptic). In addition, preparation and reduce the total area. And if you want more

application made easy work directly on site levels should thickened walls in order to have

without requiring any additional equipment. stability and strength. If the structure of

One disadvantage is prolonged attain full columns and beams is the most flexible, so I

capacity of the port. showed above and can be combinations.

Fittings, those steel rods embedded in In terms of timber frame house, standardized

concrete, plays a pivotal role in taking the models that bring our demands should be

efforts that occur during an earthquake, resized to seismicity. Do not ignore the fact

increasing in strength and gives it elasticity that Romania is in a seismically active area,

needed to cope with shocks [3]. with a threshold value below that of Japan and

For residential buildings, single-family or the west coast of the United States, this is

duplex, you can choose any type of structural being reflected in a series of conditioning

frame: reinforced concrete frames structure manufacturer.

with wooden frames or wooden walls, the Thus, a structure of reinforced concrete

170

Scientific Papers Series Management, Economic Engineering in Agriculture and Rural Development

Vol. 15, Issue 3, 2015

PRINT ISSN 2284-7995, E-ISSN 2285-3952

pillars and beams appropriately sized for execution, the interior cannot be changed

reinforcement combines the flexibility of easily, because the resistance structure, are

reinforced concrete with compressive strength "cold" and require more power or heating

of concrete [7]. A wood frame house cannot fuel, earthquake fall faster than wood . The

withstand the same loads and mechanical cost of these houses is higher than wooden

stresses as one of the concrete structure unless ones.

resizes or use structural columns and beams of

wood. Every choice and change can bring CONCLUSIONS

added cost, everything is done strictly related

to space travel home. Regarding the implementation of a wooden

The advantages of brick houses: house, building firms which respects the

- They are more durable, have a longer life material runs constructively with European

than a house of wood; resistance structure of standards and the constructive method used is

the house is stronger, while requiring repair quality standards. Engaging elements of the

walls, but less than a house of wood; wood, are very important for the stability and

- Can support any type of roof, including durability of timber frame houses. For this

tiles; tile material is considered "hard", which reason the companies working for foreign

must be supported by a strong house with a beneficiaries, the quality of these elements do

durable structure; even if it seems an not give up, even if the manufacturing cost is

antiquated method, the tile has many higher and execution.

advantages: it takes time, it is good insulator The price of a wooden building can only be

and is resistant to rain; determined on a project basis. In the absence

- Allow a very wide range of finishes; the of any project cost estimate can only be

walls inside and outside, can be painted with approximate due to several factors such as:

lime or washable paint or wallpaper can be • real geometry of the structure can cause

painted or covered with plasterboard and higher or lower consumption of construction

wood paneling; materials, workmanship material additional or

- Are resistant to pests, insects and rodents, different losses;

without the need for special treatments, do not • cannot be considered exact degree of finish

need more maintenance work in the current desired by the customer nor the quality of

time; is painting the walls over two to three construction materials, factors that are

years, repair a chipped corner of the house extremely significant because of the great

that was over ten years, throwing a dash of diversity of building materials market.

lime on exterior walls over 15 years. All these The place where the building will be located

are nothing compared to doping and by influencing its price needs insulation, noise

chemicals every five years; resistance requirements or different

- Are better silencing; in other words, it mechanical stresses (earthquakes, winds,

provides greater privacy of the home, interior snow etc).

space; In general US house prices by type of wood is

- Can be constructed by traditional methods 60-70% of the brick houses.

with cheap labor; almost every man knows In France, as in other European countries,

how to do a brick wall and do not know yet, there are standards, rules and regulations in

can learn quickly, running only on a worker respect of the implementation of wood falls.

such work. Such builders and manufacturers of building

- Can be built as high; house in the project do materials must meet all these standards and

not have height restrictions due to the chosen regulations.

material; homes may have only one level, but Unfortunately, in our country, did not engage

five-six floors or blocks can turn into anyone to regulate rules and standards for the

skyscrapers, they have a resistance structure execution of a wooden house. Likewise, for

of reinforced concrete. companies producing materials and wooden

Disadvantages brick houses: take a long time construction elements, there is a standard of

171

Scientific Papers Series Management, Economic Engineering in Agriculture and Rural Development

Vol. 15, Issue 3, 2015

PRINT ISSN 2284-7995, E-ISSN 2285-3952

quality in this area.

In our country, we can build a wooden house,

under any circumstances, even if executed in

own or with a company. Only working for

foreign firms comply with the rules and

standards but the costs are higher.

On the other hand, brick homes remain the

most cherished of Romanian, as the

Europeans. Each year, according to statistics,

in Europe, more than two million new

buildings for housing are constructed of brick,

which represents 60% of all new housing. The

most ardent supporters of this way of building

houses are Latins, particularly Italians and

Spaniards, who rarely They make a house of

different materials. Brick homes are built with

more weight, take more time, but they have a

longer life.

REFERENCES

[1]Bia, C., Ille, V., Sun, M.V., 1983, Strength of

materials and elasticity theory, Didactic and Pedagogic

Publishing House, Bucharest

[2]Honţuş Adelaida Cristina, 2005, Agrotouristic

Building, Publishing CERES, Bucharest

[3]Honțuș Adelaida Cristina, 2014, Agrotouristic

Building - the Second edition revised and enlarged,

CERES Publishing, Bucharest

[4]Honţuş Adelaida Cristina, 2014, New trends of

achievement of ecological lightweight wooden

material, Scientific Papers Series Management,

Economic Engineering in Agriculture and Rural

Development, Vol. 14, Issue 4

[5]Honţuş Adelaida Cristina, 2014, Comparative study

on the choice of building materials for constructing a

house, Scientific Papers Series Management ,

Economic Engineering in Agriculture and Rural

Development, Vol. 14, Issue 4

[6]Stan Daniel, 2004, Building and Environment,

Matrix Rom Publishing House, Bucharest

[7]Suman, R., Ghibu, M., N. Gheorghiu, Oană, C.,

Oţel, A., 1988, Modern technologies in construction,

Technical Publishing House, Bucharest

[8]Șerban Liliana, 1998, , Building Materials, Matrix

Rom Publishing House, Bucharest

[9]STAS 3451-73. Statics, dynamics and stability of

structures

[10]STAS 1963-73. Strength of Materials.

Terminology and symbols

[11] The Law. 10/1995 on construction quality

[12]Normative P100-2006. Seismic design code.

Design provisions for buildings

172

You might also like

- Cutting A GemDocument18 pagesCutting A Gemmobsivac100% (1)

- GuidewireClaimCenter Performance TestPlanDocument18 pagesGuidewireClaimCenter Performance TestPlanshanthan117No ratings yet

- Framing PDFDocument5 pagesFraming PDFKenneth Ignacio ArcillaNo ratings yet

- Steel and TimberDocument3 pagesSteel and TimberKate Nazareno FlorendoNo ratings yet

- Timber Construction MaterialsDocument42 pagesTimber Construction MaterialsNUR ALYA IRDINA SAZALINo ratings yet

- Timber HouseDocument7 pagesTimber HouseMinh Tu NguyenNo ratings yet

- The 7 Best Eco-Friendly Materials For Building: Taken From: WWW - Broadsword-Group - Co.ukDocument5 pagesThe 7 Best Eco-Friendly Materials For Building: Taken From: WWW - Broadsword-Group - Co.ukFigo Catur PalusaNo ratings yet

- Wood-Concrete Hybrid Construction GuideDocument24 pagesWood-Concrete Hybrid Construction Guidefastreturn67% (3)

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocument3 pagesScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNo ratings yet

- Architecture: Spotters GuideDocument37 pagesArchitecture: Spotters GuideSarabandBooks100% (2)

- Lecture-4 Timber Frame StruturesDocument50 pagesLecture-4 Timber Frame StruturesAleena AsifNo ratings yet

- Ecofriendly MaterialsDocument8 pagesEcofriendly MaterialsGénie Civil2122No ratings yet

- Cargo Work !Document345 pagesCargo Work !Grecianu Cosmin100% (2)

- Green Building Materials GuideDocument9 pagesGreen Building Materials GuideRushika KothuruNo ratings yet

- Alternative Materials: Prepared By: Agcaoili, Louella Bs-Architeture 4A Orence, Fhirsky Junhe Salvilla, Ma. YlleanoreDocument14 pagesAlternative Materials: Prepared By: Agcaoili, Louella Bs-Architeture 4A Orence, Fhirsky Junhe Salvilla, Ma. YlleanoreRoque CapaqueNo ratings yet

- Juan Arellano - Influential Filipino ArchitectDocument43 pagesJuan Arellano - Influential Filipino ArchitectSmart Plan100% (1)

- Advantages and Disadvantages of Timber ConstructionDocument12 pagesAdvantages and Disadvantages of Timber ConstructionAD Parinas100% (2)

- Interpretations of Organic ArchitectureDocument15 pagesInterpretations of Organic Architecturejust_a_user100% (1)

- Part # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalDocument1 pagePart # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalmnvijaybabuNo ratings yet

- How Wood Outperforms Other Building Materials for SustainabilityDocument4 pagesHow Wood Outperforms Other Building Materials for SustainabilityKraemond Francis ManaloNo ratings yet

- Engineered Wood and Slate Roofing Materials StudyDocument46 pagesEngineered Wood and Slate Roofing Materials StudySusnata ChandaNo ratings yet

- Presentation of Materials finalFINALDocument10 pagesPresentation of Materials finalFINALShahil SadoolNo ratings yet

- En Flagship24-25 WEB CompressedDocument132 pagesEn Flagship24-25 WEB Compressed董思辰No ratings yet

- Alternate Building MaterialsDocument36 pagesAlternate Building MaterialsramNo ratings yet

- Woodframe housing benefits in cold climatesDocument5 pagesWoodframe housing benefits in cold climatesvalistaNo ratings yet

- Figure 1 Glulam BeamDocument7 pagesFigure 1 Glulam Beamrukesh104No ratings yet

- Sustainable Building Materials GuideDocument4 pagesSustainable Building Materials GuideDougs HardNo ratings yet

- Lightweight, Insulating Autoclaved Aerated Concrete MaterialDocument5 pagesLightweight, Insulating Autoclaved Aerated Concrete Materialgouri hooliNo ratings yet

- TRADITIONAL BUILDING MATERIALS - DocumentDocument5 pagesTRADITIONAL BUILDING MATERIALS - DocumentAnja M.No ratings yet

- Michael Murunga Ndwiga Cat 2Document21 pagesMichael Murunga Ndwiga Cat 2Duncan KiokoNo ratings yet

- Wood Frame Home Earthquake RisksDocument28 pagesWood Frame Home Earthquake RisksVenus Gjervie Yu - AlvarezNo ratings yet

- Wood As A Building MaterialDocument34 pagesWood As A Building Materialayesha zahraNo ratings yet

- 7 Best Environmentally Friendly Materials For Buildings RioTy 61200543Document5 pages7 Best Environmentally Friendly Materials For Buildings RioTy 61200543Rio TampatyNo ratings yet

- Alternative Wood Construction Systems, Pre-Cast & Cast-In-Place ConcreteDocument7 pagesAlternative Wood Construction Systems, Pre-Cast & Cast-In-Place ConcreteRojun AranasNo ratings yet

- Sustainable MaterialsDocument9 pagesSustainable Materialsdani.angovNo ratings yet

- 7 Best Eco-Friendly Building MaterialsDocument4 pages7 Best Eco-Friendly Building MaterialsRiksan SueNo ratings yet

- Own Notes. Timber ConstructionDocument23 pagesOwn Notes. Timber ConstructionGraham BennettNo ratings yet

- Timbercrete Offers Highest Fire ResistanceDocument4 pagesTimbercrete Offers Highest Fire Resistanceblah blehNo ratings yet

- Plywood Usage in Passive HouseDocument4 pagesPlywood Usage in Passive HouseEmir TrakoNo ratings yet

- Diy Uk 2013 14Document60 pagesDiy Uk 2013 14Cotul Daniel MihaiNo ratings yet

- 628 1014 1 SM PDFDocument6 pages628 1014 1 SM PDFCella JuwitaNo ratings yet

- MTPDF4 - Module 4 Main PDF LessonDocument35 pagesMTPDF4 - Module 4 Main PDF LessonEunnicePanaliganNo ratings yet

- 10th May-Mongla ResearchDocument11 pages10th May-Mongla Researchsameer hussainNo ratings yet

- Clay building products provide sustainable building solutionsDocument13 pagesClay building products provide sustainable building solutionsPaulo AlmeidaNo ratings yet

- Thine and MingDocument12 pagesThine and Ming高铭徽No ratings yet

- Unit 1: Introduction To Structural WoodDocument6 pagesUnit 1: Introduction To Structural WoodCzelsi Carlos NavarroNo ratings yet

- Types of Cladding "HPL (High Pressure Laminate Cladding) Is The New Trend"Document14 pagesTypes of Cladding "HPL (High Pressure Laminate Cladding) Is The New Trend"Sunil Gavaskar100% (1)

- Indoor Air Quality: Wood As A Sustainable Building MaterialDocument8 pagesIndoor Air Quality: Wood As A Sustainable Building MaterialEmil JamesNo ratings yet

- Construction Supplies For Buildings and FurnituresDocument6 pagesConstruction Supplies For Buildings and FurnituresMarata Steve60% (5)

- Alternative Building MaterialsDocument12 pagesAlternative Building Materialslakshmi achayathNo ratings yet

- Low Cost Assignment 1Document3 pagesLow Cost Assignment 1Netsanet AyalewNo ratings yet

- TechnologyDocument36 pagesTechnologyCrazy KingNo ratings yet

- CarpentryDocument21 pagesCarpentryAshish SinghNo ratings yet

- TIMBER CONSTRUCTION: A VERSATILE BUILDING MATERIALDocument17 pagesTIMBER CONSTRUCTION: A VERSATILE BUILDING MATERIALyeabsira mulukenNo ratings yet

- Sandwich PanelDocument23 pagesSandwich Panel1DC20AT033 Kaarthik N.No ratings yet

- Contribution429 A FinalDocument9 pagesContribution429 A FinalIrene AldayaNo ratings yet

- KNS1042 Timber Part3 W12Document17 pagesKNS1042 Timber Part3 W12justine2109No ratings yet

- Why Do We Need Alternative Building Materials?Document4 pagesWhy Do We Need Alternative Building Materials?Charles Immanuel TolosaNo ratings yet

- Workshop Technology - IDocument183 pagesWorkshop Technology - Iايهاب عبدالعظيمNo ratings yet

- Poly WoodDocument31 pagesPoly WoodLuqman Yusof100% (1)

- Alternative Building MaterialsDocument18 pagesAlternative Building MaterialsShiela Louisianne AbañoNo ratings yet

- NhungPham - Assigment 3Document3 pagesNhungPham - Assigment 3phamNo ratings yet

- Panel Sandwich Properties and AdvantagesDocument6 pagesPanel Sandwich Properties and AdvantagesJustina Saharaim Vargas AcostaNo ratings yet

- Rigid Foam (R-3.8 To R-8.7 Per In.)Document4 pagesRigid Foam (R-3.8 To R-8.7 Per In.)Raine ReyesNo ratings yet

- Act 6-1Document4 pagesAct 6-1PAULINE CECILLE BARRAMEDANo ratings yet

- Murray Grove Case StudyDocument7 pagesMurray Grove Case Studyabiel_guerraNo ratings yet

- Foundatition MaterialDocument40 pagesFoundatition Materialprakriti goyalNo ratings yet

- RMX 2018 ManualDocument82 pagesRMX 2018 ManualvicmagucasNo ratings yet

- Sustainable Ephemeral Temporary Spaces With Lasting ImpactDocument97 pagesSustainable Ephemeral Temporary Spaces With Lasting Impactjust_a_userNo ratings yet

- Wright Organic ArchitectureDocument3 pagesWright Organic ArchitecturehutamielimartaNo ratings yet

- Peristaltic Transport of A Viscous Fluid in An Asymmetric Channel With Permeable WallsDocument13 pagesPeristaltic Transport of A Viscous Fluid in An Asymmetric Channel With Permeable WallsRakeshconclaveNo ratings yet

- Variable Frequency Drive Using IR215xDocument7 pagesVariable Frequency Drive Using IR215xartyomNo ratings yet

- Stop Motion Pre Production - Negotiated BriefDocument10 pagesStop Motion Pre Production - Negotiated Briefp4nd3m0n1c100% (1)

- Hybrid or Standard?: Why The Urge To "Go Green"Document20 pagesHybrid or Standard?: Why The Urge To "Go Green"Tyler McPhersonNo ratings yet

- Final Defence 2078Document43 pagesFinal Defence 2078XxxNo ratings yet

- Manual Huawei Hg655bDocument36 pagesManual Huawei Hg655bAnonymous nJm0Ff8z0sNo ratings yet

- Instructions For Installation, Operating and Maintenance InstructionDocument30 pagesInstructions For Installation, Operating and Maintenance InstructionmilacronNo ratings yet

- Zimbabwe Engineer ITDG Small Scale Production of Fired Clay BricksDocument8 pagesZimbabwe Engineer ITDG Small Scale Production of Fired Clay BricksdkataleNo ratings yet

- Elink For Windows: List of Pages in This Trip KitDocument130 pagesElink For Windows: List of Pages in This Trip KitAhmed GvNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument12 pagesFM Global Property Loss Prevention Data Sheets: List of Figuresdaniela hritucNo ratings yet

- What Is AmplifierDocument18 pagesWhat Is AmplifierEbayLunaNo ratings yet

- Implementing A Maintenance Strategic Plan Using TPM MethodologyDocument13 pagesImplementing A Maintenance Strategic Plan Using TPM MethodologyJeyson Lendro ParedesNo ratings yet

- Mycom Nims ProptimaDocument4 pagesMycom Nims ProptimasamnemriNo ratings yet

- Whatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Document6 pagesWhatsapp, Viber and Telegram: Which Is The Best For Instant Messaging?Kuningan NesiaNo ratings yet

- GEC - Sample Resume For StudentsDocument2 pagesGEC - Sample Resume For StudentsNiketNo ratings yet

- Revit Domoty 1Document1 pageRevit Domoty 1SAN RAKSANo ratings yet

- Sennheiser MD 441Document2 pagesSennheiser MD 441ndujaNo ratings yet

- High Voltage Grease Reduces Wear and ArcingDocument2 pagesHigh Voltage Grease Reduces Wear and ArcingtlnferreiraNo ratings yet

- Custom Validation ExampleDocument4 pagesCustom Validation ExampleAbdul Bais StanikzaiNo ratings yet

- PI Digital Panel Indicator - B0Document7 pagesPI Digital Panel Indicator - B0dtoxidNo ratings yet

- Vacuum Chill BlockDocument2 pagesVacuum Chill BlockAditheya Varthan MNo ratings yet

- Address Book in JAVADocument18 pagesAddress Book in JAVAmelyfony100% (1)

- Indian Standards As On 17.01.2004 LatestDocument19 pagesIndian Standards As On 17.01.2004 LatestSaravana KumarNo ratings yet

- NM Group Plumbing WorkDocument33 pagesNM Group Plumbing WorkNM GROUPNo ratings yet

- Using Semi Circular Bending Test To Evaluate Low Temperature Fracture Resistance For Asphalt ConcreteDocument10 pagesUsing Semi Circular Bending Test To Evaluate Low Temperature Fracture Resistance For Asphalt Concreteappu140688No ratings yet

- BRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualDocument28 pagesBRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualLuis Daniel ContrerasNo ratings yet