Professional Documents

Culture Documents

Grizly de Linkbelt

Uploaded by

Edgar David HuallpamaitaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grizly de Linkbelt

Uploaded by

Edgar David HuallpamaitaCopyright:

Available Formats

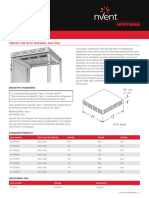

Vibrating Grizzly Bar Screens

Syntron vibrating Grizzly Bar the grizzly section should be In addition to the electromagnetic

Screens are used in the basic suspension mounted. Grizzly bar designs outlined in this catalog,

industries to bypass fine particles that screens with above-deck drive units FMC also manufactures Vibrating

would otherwise clog or slow down are available upon request, and can Grizzly Bar Screens with electro-

crushing or reducing operations. only be suspension mounted. mechanical drive units. For complete

These units are also used for laying a details, contact your FMC Regional

cushion of fines on a belt conveyer to Operation is from either 230.460 or Field Specialist.

protect the belt from damage by the 550 volt, 60 cycle, single phase a-c.

fall of large, abrasive pieces; for

removing large foreign objects from

volume flow; or for any rough scalping SpeciÀcations

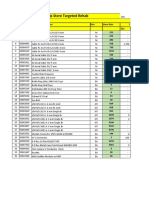

or separating. Model Power Consumption Current Input Bar Spacing Approx Net Wt. Approx Shipping

(watts*) (Amps*) (inches) (Pounds) Wt. (Pounds)

Each unit consists of a heavy-duty

F-280 550 11.2 1

/2 to 1 475 600

electromagnetic drive attached to F-330 950 23 1

/2 to 1 1/4 1,075 1,500

a specially constructed grizzly bar F-380 1250 36 1

/2 to 1 1/4 1,340 1,800

trough. The troughs are built with F-440 2200 40 1 1/2 to 3 2,275 2,700

a solid-steel plate area in the rear F-450 2350 48 1 1/2 to 3 3,350 3,700

F-480 3300 ✝ 35 1 1/2 to 3 4,350 4,700

to absorb the impact and shock F-560 2900 ✝ 40 1 to 1 1/2 7,300 7,800

of loading large, heavy chunks F-660 3300 ✝ 35 1 1/2 to 4 8,500 9,000

of materials. F-88 4600 ✝ 60. ✝ 1 1/2 and up 11,500 12,000

*230 volt, 60 cycle. ✝ 460 volt, 60 cycle

Suspension mounting is

recommended for most grizzly bar

screen applications. Units with below-

deck drives can be floor mounted, but

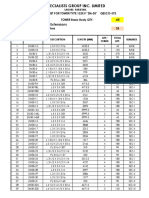

Dimensions in Inches

Trough

Model Size A B C D E F G H J

F-280 10 x 30 10 29 /21

16 /41

6 24 /41

23 30 9 /43

15

F-330 18 x 36 18 35 1/2 21 1/4 6 26 1/2 28 36 11 15

F-380 24 x 36 24 35 1/2 21 1/4 6 29 1/2 29 1/2 36 14 15

F-440 24 x 42 24 41 1/4 31 1/4 8 34 41 38 1/2 15 3/4 15

F-450 30 x 60 30 59 28 1/2 9 40 1/2 41 3/4 54 19 1/4 15

F-450 24 x 60 25 58 3/4 28 1/2 9 40 1/2 41 54 13 3/4 36

F-480 30 x 60 30 58 3/4 28 1/2 9 40 1/2 41 3/4 54 13 3/4 36

F-480 36 x 60 36 58 3/4 28 1/2 9 40 1/2 41 3/4 54 13 3/4 36

F-560 42 x 60 42 59 46 10 44 3/4 68 1/2 60 20 3/4 15

F-560 24 x 72 24 70 1/2 48 10 47 3/4 68 1/2 72 17 3/4 36

F-560 30 x 72 30 70 1/2 48 10 47 3/4 68 1/2 72 17 3/4 36

F-660 48 x 60 48 58 1/2 51 12 51 1/2 68 1/2 63 20 3/4 36

F-660 36 x 72 36 70 1/2 45 12 51 3/4 68 1/2 72 19 3/4 36

F-88 42 x 72 42 70 1/2 54 12 52 1/2 68 1/2 82 20 1/2 36

F-88 48 x 72 48 70 1/2 54 12 52 1/2 68 1/2 82 20 1/2 36

F-88 48 x 96 48 94 1/2 47 1/2 12 55 1/2 68 1/2 109 1/4 22 1/2 36

34

You might also like

- Fan Coil Info YorkDocument1 pageFan Coil Info YorkGEDÉON TVNo ratings yet

- NEMA Explosion-Proof AC Motors: Frame Size Number of Poles Horizontal Vertical Weight of Rotor in Load Direction 143/5TDocument1 pageNEMA Explosion-Proof AC Motors: Frame Size Number of Poles Horizontal Vertical Weight of Rotor in Load Direction 143/5TLymeparkNo ratings yet

- North Corfu Rhodes Crete Manual 27Document11 pagesNorth Corfu Rhodes Crete Manual 27Kostas PetrouNo ratings yet

- OEL Recommended Spare Parts List: Revision 8Document3 pagesOEL Recommended Spare Parts List: Revision 8belinha1234No ratings yet

- FF Parts TP Fuel PumpDocument120 pagesFF Parts TP Fuel PumpLuis Alejandro Faris BurgosNo ratings yet

- SS Invetment Casting Pipe Fittings CF8 (304) : Sr. Item Description 1/4" 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"Document2 pagesSS Invetment Casting Pipe Fittings CF8 (304) : Sr. Item Description 1/4" 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"Sunil BajpaiNo ratings yet

- 1 Detail: Gr. Elettrogeno E 6500 Shhpi LimitedDocument2 pages1 Detail: Gr. Elettrogeno E 6500 Shhpi LimitednpNo ratings yet

- Brochure Bettis m2cp Electric Valve Actuators en 86630Document16 pagesBrochure Bettis m2cp Electric Valve Actuators en 86630Goutham KSNo ratings yet

- Leaflet For PVDF Drum PumpDocument2 pagesLeaflet For PVDF Drum PumpAjay KastureNo ratings yet

- Folleto Tanques ELBIDocument2 pagesFolleto Tanques ELBILuis SanguinettiNo ratings yet

- Beverage Industry 2010Document8 pagesBeverage Industry 2010José Ángel SigüenzaNo ratings yet

- Fire Retardant Cable Tie 1576222614 1Document1 pageFire Retardant Cable Tie 1576222614 1pratik jainNo ratings yet

- 572014-102421-Am - Catalogue Asian Linings - Edition 13 - February 2014Document18 pages572014-102421-Am - Catalogue Asian Linings - Edition 13 - February 2014Aprizal AzisNo ratings yet

- Bti BX30Document1 pageBti BX30AS LO ProveedoresNo ratings yet

- Insulator PDFDocument11 pagesInsulator PDFmanoj_2027100% (1)

- Cable Pasante Al Extremo de VarillaDocument1 pageCable Pasante Al Extremo de VarillaFabian VillaNo ratings yet

- Brook-Crompton-Motor-Catalog-03-31-15-84 24Document1 pageBrook-Crompton-Motor-Catalog-03-31-15-84 24Adewunmi OlufemiNo ratings yet

- Bomba Sumergible DX PDFDocument2 pagesBomba Sumergible DX PDFJuan Carlos Gonzales PreiraNo ratings yet

- Aluminum Triplex Overhead Service Drop CableDocument1 pageAluminum Triplex Overhead Service Drop Cableakib javedNo ratings yet

- UBOLTDocument1 pageUBOLTSuper 7No ratings yet

- Sel 00321Document2 pagesSel 00321roberto Alanis AcevedoNo ratings yet

- Nord GlassDocument386 pagesNord GlassABDELLATIF AITHAMDNo ratings yet

- Electroventilatoare CatalogDocument58 pagesElectroventilatoare CataloggeorgeNo ratings yet

- CTR - Boq (38714)Document12 pagesCTR - Boq (38714)Mehroz KhanNo ratings yet

- Ser & TSRDocument8 pagesSer & TSRSAMO THERMALNo ratings yet

- Reel Craft Hose Reel - Model Fd84000Document1 pageReel Craft Hose Reel - Model Fd84000ibrahimfahadNo ratings yet

- 3Ph Installation2016 m25Document5 pages3Ph Installation2016 m25Rohan SandesaraNo ratings yet

- 15-11-2022 " Ohk Brand "Document1 page15-11-2022 " Ohk Brand "Lucy ElevenNo ratings yet

- Asif WorkDocument2 pagesAsif WorkkrishanNo ratings yet

- Updated MachineDocument56 pagesUpdated MachineAliNo ratings yet

- Iso DWG No S/F Joint Size SCH B/FDocument40 pagesIso DWG No S/F Joint Size SCH B/FAnonymous rYZyQQot55No ratings yet

- Aqua Signal Fixture LampsDocument4 pagesAqua Signal Fixture LampsLuis Perez0% (1)

- Yale Winch Trolley EWDocument97 pagesYale Winch Trolley EWAl7amdlellahNo ratings yet

- Tricosal Katalogas - en - P04 of 09Document4 pagesTricosal Katalogas - en - P04 of 09Adam Michael GreenNo ratings yet

- FILTAIREspecsheet 2Document2 pagesFILTAIREspecsheet 2Anonymous S9qBDVkyNo ratings yet

- Gear BoxDocument6 pagesGear Boxprashant mishra100% (1)

- 2010 Master Parts Book Rain BIrdDocument190 pages2010 Master Parts Book Rain BIrdguinnessNo ratings yet

- Qesco 132KV ZM30 392 Packing ListDocument3 pagesQesco 132KV ZM30 392 Packing ListFarhan IlyasNo ratings yet

- 8038014P 2Document3 pages8038014P 2swarajNo ratings yet

- End Yoke Application GuidelinesDocument44 pagesEnd Yoke Application GuidelinesAndreea BoacaraNo ratings yet

- MOTOVARIO Ha H Series Data Package Cover PDFDocument17 pagesMOTOVARIO Ha H Series Data Package Cover PDFsolihinsjNo ratings yet

- 1014 Graha Paramita II Bintaro, Tangerang (r.12) Jaga - Citra - Inti Fans Mar21 250321Document3 pages1014 Graha Paramita II Bintaro, Tangerang (r.12) Jaga - Citra - Inti Fans Mar21 250321imam wardhanaNo ratings yet

- Reel Craft GS3050Document5 pagesReel Craft GS3050kherlambangNo ratings yet

- Lubricación Fittings & AccesoriosDocument1 pageLubricación Fittings & AccesoriosRafael JaraNo ratings yet

- L Series BrochureWebDocument16 pagesL Series BrochureWebmadhavikNo ratings yet

- Comparison LADocument1 pageComparison LAPanchoo GuerreroNo ratings yet

- General Electronics RacksDocument20 pagesGeneral Electronics RacksAbhijith S. MenonNo ratings yet

- Pernos Huck C50LDocument4 pagesPernos Huck C50LAngelina Santiago JimenezNo ratings yet

- U-Match GOOD R410A SpecificationsDocument20 pagesU-Match GOOD R410A SpecificationsmiguelNo ratings yet

- MRF Sheave SectionsDocument1 pageMRF Sheave SectionsAlberto LobonesNo ratings yet

- Inertia Dynamic TypeFL SpecsheetDocument3 pagesInertia Dynamic TypeFL SpecsheetElectromateNo ratings yet

- New Catalogue 202009Document42 pagesNew Catalogue 202009Ofer GardenNo ratings yet

- Warrior 500i With Warrior Feed 304: Ordering InformationDocument4 pagesWarrior 500i With Warrior Feed 304: Ordering InformationcarlosNo ratings yet

- Eaton YugosDocument44 pagesEaton YugosSolrac Nauj OgaitnasNo ratings yet

- 150lb Style T (316ss) StrainerDocument1 page150lb Style T (316ss) StrainerLuis GarciaNo ratings yet

- Preview 92103Document4 pagesPreview 92103Almir RodriguesNo ratings yet

- HeavydutyDocument12 pagesHeavydutyAndrés Tuesca Clase de inglesNo ratings yet

- Toyota 8 Series Pneu 1-3.5 TonDocument8 pagesToyota 8 Series Pneu 1-3.5 TonCarlos SalazarNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Math - Snowflake With ProtractorsDocument4 pagesMath - Snowflake With Protractorsapi-347625375No ratings yet

- Week 1-2 Module 1 Chapter 1 Action RseearchDocument18 pagesWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanNo ratings yet

- Unit 6B - PassiveDocument18 pagesUnit 6B - PassiveDavid EstrellaNo ratings yet

- Agile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)Document67 pagesAgile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)j.paulo.mcNo ratings yet

- Gender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected PlaysDocument6 pagesGender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected Playsতন্ময়No ratings yet

- -4618918اسئلة مدني فحص التخطيط مع الأجوبة من د. طارق الشامي & م. أحمد هنداويDocument35 pages-4618918اسئلة مدني فحص التخطيط مع الأجوبة من د. طارق الشامي & م. أحمد هنداويAboalmaail Alamin100% (1)

- The Innovator - S SolutionDocument21 pagesThe Innovator - S SolutionKeijjo Matti100% (1)

- Project Success - Stakeholders 1 PDFDocument7 pagesProject Success - Stakeholders 1 PDFMoataz SadaqahNo ratings yet

- Infor Mashup DesignerDocument95 pagesInfor Mashup DesignerBalayogesh Alagesan100% (1)

- YS1700 Drum Level ControlDocument2 pagesYS1700 Drum Level ControlIdriss BarçaNo ratings yet

- Feature Glance - How To Differentiate HoVPN and H-VPNDocument1 pageFeature Glance - How To Differentiate HoVPN and H-VPNKroco gameNo ratings yet

- 3114 Entrance-Door-Sensor 10 18 18Document5 pages3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaNo ratings yet

- New Client QuestionnaireDocument13 pagesNew Client QuestionnairesundharNo ratings yet

- Invenio Flyer enDocument2 pagesInvenio Flyer enErcx Hijo de AlgoNo ratings yet

- As I Lay Writing How To Write Law Review ArticleDocument23 pagesAs I Lay Writing How To Write Law Review ArticleWalter Perez NiñoNo ratings yet

- New KitDocument195 pagesNew KitRamu BhandariNo ratings yet

- Yuzu InstallerDocument3 pagesYuzu InstallerJohnnel PrietosNo ratings yet

- Datasheet of STS 6000K H1 GCADocument1 pageDatasheet of STS 6000K H1 GCAHome AutomatingNo ratings yet

- High Intermediate 2 Workbook AnswerDocument23 pagesHigh Intermediate 2 Workbook AnswernikwNo ratings yet

- Deep Sea 500 Ats ManDocument18 pagesDeep Sea 500 Ats ManLeo Burns50% (2)

- The Story of An Hour QuestionpoolDocument5 pagesThe Story of An Hour QuestionpoolAKM pro player 2019No ratings yet

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Document8 pagesTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmNo ratings yet

- Sip Poblacion 2019 2021 Revised Latest UpdatedDocument17 pagesSip Poblacion 2019 2021 Revised Latest UpdatedANNALLENE MARIELLE FARISCALNo ratings yet

- Rfis On Formliners, Cover, and EmbedmentsDocument36 pagesRfis On Formliners, Cover, and Embedmentsali tahaNo ratings yet

- Characteristics: Our in Vitro IdentityDocument4 pagesCharacteristics: Our in Vitro IdentityMohammed ArifNo ratings yet

- Supreme Court Case Analysis-Team ProjectDocument5 pagesSupreme Court Case Analysis-Team ProjectJasmineA.RomeroNo ratings yet

- Green ProtectDocument182 pagesGreen ProtectLuka KosticNo ratings yet

- CMS156Document64 pagesCMS156Andres RaymondNo ratings yet

- Top Survival Tips - Kevin Reeve - OnPoint Tactical PDFDocument8 pagesTop Survival Tips - Kevin Reeve - OnPoint Tactical PDFBillLudley5100% (1)

- Theory of Construction of The Giza Plateau Pyramids (Original Title Hypothesis of Construction of The Pyramids of The Valley of Gizeh (Giza)Document15 pagesTheory of Construction of The Giza Plateau Pyramids (Original Title Hypothesis of Construction of The Pyramids of The Valley of Gizeh (Giza)International Journal of Innovative Science and Research TechnologyNo ratings yet