Professional Documents

Culture Documents

01 Structural Notes

Uploaded by

James Pitts0 ratings0% found this document useful (0 votes)

19 views1 pageStructural Notes

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStructural Notes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 page01 Structural Notes

Uploaded by

James PittsStructural Notes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

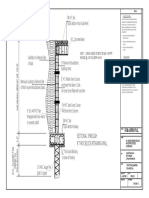

STRUCTURAL STEEL

1. APPLICABLE STRUCTURAL STEEL CODES:

A. AISC SPECIFICATION FOR STRUCTURAL STEEL BUILDINGS, 13TH EDITION

B. AISC CODE OF STANDARD PRACTICE FOR STEEL BUILDINGS AND BRIDGES

2. MATERIALS:

"W" SHAPES ASTM A992, GRADE 50

STEEL TUBING ASTM A500, GRADE B, Fy = 46 KSI

STEEL PIPE ASTM A500, GRADE B, Fy = 42 KSI

ALL OTHER ASTM A36

ANCHOR BOLTS ASTM A307

HIGH STRENGTH BOLTS ASTM A325

ANCHOR RODS ASTM F1554, GRADE 36

WELDING ELECTRODES E70 SERIES

3. ALL STRUCTURAL STEEL FABRICATION SHALL BE PERFORMED BY A QUALIFIED FABRICATOR WHO

PARTICIPATES IN THE AISC CERTIFICATION PROGRAM AND IS DESIGNATED AN AISC CERTIFIED PLANT,

CATEGORY [STD] AT TIME OF BID. METAL FABRICATOR SHALL BE A CERTIFIED SHOP IN ACCORDANCE

WITH THE REQUIREMENTS OF IBC 1704.2.2

4. ALL STRUCTURAL STEEL SHALL BE FABRICATED AND ERECTED ACCORDING TO THE LATEST EDITION OF

AISC "SPECIFICATION, DESIGN, AND ERECTION OF STRUCTURAL STEEL FOR BUILDINGS" AND RELATED

PUBLICATIONS SPECIFIED THEREIN.

5. ALL SHEAR AND TENSION TYPE BOLTED CONNECTIONS SHALL BE MADE WITH ASTM A325X

HIGH STRENGTH BOLTS. DESIGN TORQUE TO BE DEVELOPED USING LOAD INDICATOR WASHERS OR

LOAD INDICATOR TYPE BOLTS. INSTALL AS PER MANUFACTURER'S PUBLISHED INSTRUCTIONS. ALL

OTHER BOLTED CONNECTIONS MAY BE MADE WITH ASTM A325 BOLTS AND WASHERS.

6. STEEL FRAMING ERECTION INCLUDING ALL BOLTED AND WELDED CONNECTIONS, BRACING, AND

ANCHORAGES SHALL BE COMPLETED AND PLUMB PRIOR TO PLACEMENT OF DECK.

7. TOP OF STEEL ELEVATION MEASURED FROM MAIN FINISHED FLOOR UNLESS NOTED

8. NON-SHRINK, NON-METALLIC GROUT WITH A 28 DAY COMPRESSIVE STRENGTH OF 5000 PSI SHALL BE

USED UNDER BASE PLATES.

9. ENGINEER SHALL BE CONTACTED FOR APPROVAL OF ANY FIELD MODIFICATIONS OF ANCHOR BOLTS OR

RODS AND COLUMN BASE PLATES.

10. TEMPORARY BRACING OF STEEL STRUCTURAL ELEMENTS IS THE RESPONSIBILITY OF THE CONTRACTOR.

STRUCTURAL STABILITY SHALL BE MAINTAINED AT ALL TIMES DURING THE ERECTION PROCESS.

11. FRAMING CONNECTIONS NOT DETAILED, OR CONNECTIONS THAT ARE MODIFIED FROM THOSE DETAILED

SHALL BE DESIGNED BY SUPPLIER FOR THE END REACTION SHOWN ON THE PLAN. IF NO REACTION IS

PROVIDED, CONNECTIONS SHALL BE DESIGNED FOR 1/2 THE BEAM MAXIMUM UNIFORM LOAD PER AISC

MANUAL FOR STEEL CONSTRUCTION.

12. SHOP CONNECTIONS SHALL BE WELDED OR HIGH STRENGTH BOLTED. USE FILLET WELD

13. FIELD CONNECTIONS SHALL BE WELDED OR HIGH STRENGTH BOLTED AS DETAILED. NO FIELD WELDING

14. OF HOT-DIPPED GALVANIZED MEMBERS IS ALLOWED. USE FILLET WELD

15. SUBMIT FOR REVIEW SHOP DRAWINGS OF STEEL DETAILS PRIOR TO FABRICATING STRUCTURAL STEEL.

16. ALL BRICK SHELF ANGLES SHALL BE HOT-DIPPED GALVANIZED.

17. ALL EXTERIOR ELEMENTS AND THOSE ELEMENTS NOTED TO BE GALVANIZED SHALL BE HOT-DIPPED

GALVANIZED IN ACCORDANCE WITH ASTM A123 AFTER SANDBLAST CLEANING PER SSPC-SP10. USE ASTM

A325 BOLTS HOT DIPPED GALVANIZED WITH GALVANIZED HARDENED WASHERS AND GALVANIZED HEAVY

HEX NUTS FOR BOLTING OF GALVANIZED ITEMS.

18. STEEL COLUMNS, BASE PLATES, AND ALL STEEL BELOW GRADE SHALL HAVE A MINIMUM 3" CONCRETE

COVER PROTECTION.

You might also like

- Columns Below) Gutter To Be: - Lower Roof PlanDocument1 pageColumns Below) Gutter To Be: - Lower Roof PlanJames PittsNo ratings yet

- Door & Window ScheduleDocument1 pageDoor & Window ScheduleJames PittsNo ratings yet

- Ainsley Brown: Roof Framing LayoutDocument24 pagesAinsley Brown: Roof Framing LayoutJames PittsNo ratings yet

- S-19 - Connection DetailsDocument1 pageS-19 - Connection DetailsJames PittsNo ratings yet

- S-16 - Connection DetailsDocument1 pageS-16 - Connection DetailsJames PittsNo ratings yet

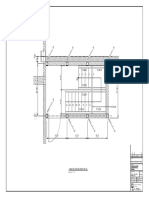

- A08-1 - Section 'B-B'Document1 pageA08-1 - Section 'B-B'James PittsNo ratings yet

- A08-3 - Section 'D-D'Document1 pageA08-3 - Section 'D-D'James PittsNo ratings yet

- S-21 - Connection DetailsDocument1 pageS-21 - Connection DetailsJames PittsNo ratings yet

- S-14 - Roof Framing PlanDocument1 pageS-14 - Roof Framing PlanJames PittsNo ratings yet

- S-18 - Connection DetailsDocument1 pageS-18 - Connection DetailsJames PittsNo ratings yet

- Civpro Engineering Limited: S-22 Miscellaneous DetailsDocument1 pageCivpro Engineering Limited: S-22 Miscellaneous DetailsJames PittsNo ratings yet

- S-20 - Connection DetailsDocument1 pageS-20 - Connection DetailsJames PittsNo ratings yet

- S-17 - Connection DetailsDocument1 pageS-17 - Connection DetailsJames PittsNo ratings yet

- S-23 - Misc DetailsDocument1 pageS-23 - Misc DetailsJames PittsNo ratings yet

- Roof Level: - Fire Escape Stair Section X-XDocument1 pageRoof Level: - Fire Escape Stair Section X-XJames PittsNo ratings yet

- S-04 Framing Back ViewDocument1 pageS-04 Framing Back ViewJames PittsNo ratings yet

- See Hss Base Plate Detail: 5 8 3 4 5 8 3 8 1 4 Scale: 1 "-1'-0"Document1 pageSee Hss Base Plate Detail: 5 8 3 4 5 8 3 8 1 4 Scale: 1 "-1'-0"James PittsNo ratings yet

- S-05 Framing Side ViewDocument1 pageS-05 Framing Side ViewJames PittsNo ratings yet

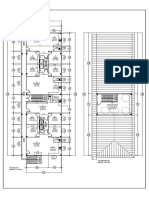

- 02-Freeport Multi Family-2-12-19Document1 page02-Freeport Multi Family-2-12-19James PittsNo ratings yet

- Sectional Through 8" Thick Block Retaining Wall: For-ApprovalDocument1 pageSectional Through 8" Thick Block Retaining Wall: For-ApprovalJames PittsNo ratings yet

- 04-Freeport Multi Family-2-12-19Document1 page04-Freeport Multi Family-2-12-19James PittsNo ratings yet

- S-01 Typical FramingDocument1 pageS-01 Typical FramingJames PittsNo ratings yet

- 01-Freeport Multi Family-2-12-19 PDFDocument1 page01-Freeport Multi Family-2-12-19 PDFJames PittsNo ratings yet

- Laundry Tile Floor Finish: DN To Gr. Floor DN To Gr. FloorDocument1 pageLaundry Tile Floor Finish: DN To Gr. Floor DN To Gr. FloorJames PittsNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Installation and Leakage Testing Method Statement of Drainage Piping (Ground Zero)Document2 pagesInstallation and Leakage Testing Method Statement of Drainage Piping (Ground Zero)Al Mumeen Construction ServicesNo ratings yet

- SV SpanishCatalog 2011 12 CompleteDocument72 pagesSV SpanishCatalog 2011 12 CompleteJohann Alexander Caballero BohorquezNo ratings yet

- Selection of Engg Materials of Equipment and Piping SystemDocument17 pagesSelection of Engg Materials of Equipment and Piping SystemNiraj PandyaNo ratings yet

- MSS SP-117 (1996) PDFDocument11 pagesMSS SP-117 (1996) PDFadprim100% (1)

- Calculation Dilute Phase Pressure Drop Zenz Othmer MethodDocument8 pagesCalculation Dilute Phase Pressure Drop Zenz Othmer MethodGeorgi Mitkov SavovNo ratings yet

- Engine Oil Cooler LC9028-02Document3 pagesEngine Oil Cooler LC9028-02Victor RamirezNo ratings yet

- Geet PlansDocument5 pagesGeet PlansbyenterNo ratings yet

- A 249 - A 249M - 16a PDFDocument10 pagesA 249 - A 249M - 16a PDFأسامة وحيد الدين رمضانNo ratings yet

- Single Data Sheet Linear Luminaire With LED GRP - 6402-4128-6100-152-2222-22-8500 - 267053 - en-GBDocument6 pagesSingle Data Sheet Linear Luminaire With LED GRP - 6402-4128-6100-152-2222-22-8500 - 267053 - en-GBAlla Naveen KumarNo ratings yet

- Duze Cooling and Fire Extinguishing Systems For Tanks - EnglishDocument18 pagesDuze Cooling and Fire Extinguishing Systems For Tanks - EnglishstroiebogdanNo ratings yet

- As 1528.3-2001 Tubes (Stainless Steel) and Tube Fittings For The Food Industry Butt Weld Tube FittingsDocument7 pagesAs 1528.3-2001 Tubes (Stainless Steel) and Tube Fittings For The Food Industry Butt Weld Tube FittingsSAI Global - APACNo ratings yet

- GenusDocument68 pagesGenussmokefieldNo ratings yet

- Material Submittal HANDRAILDocument6 pagesMaterial Submittal HANDRAILManu Mohan0% (1)

- Valour Alloys CatalogueDocument20 pagesValour Alloys Cataloguesales2No ratings yet

- SH3532 95石油化工换热设备施工及验收规范Document30 pagesSH3532 95石油化工换热设备施工及验收规范aung_lwinNo ratings yet

- Before You Select A Fitting, Keep in Mind:: Tubing Material Compatibility Temperature and PressureDocument1 pageBefore You Select A Fitting, Keep in Mind:: Tubing Material Compatibility Temperature and PressureNicolas AguilarNo ratings yet

- Heat Pipe - Scientific AmericanDocument10 pagesHeat Pipe - Scientific AmericanEduardo Ocampo HernandezNo ratings yet

- Manual de Operaciones (ZKV-ZKP)Document20 pagesManual de Operaciones (ZKV-ZKP)danielNo ratings yet

- 15 18 128 0R - Catalogue - 12M26.3Document187 pages15 18 128 0R - Catalogue - 12M26.3Raymond100% (1)

- Method Statement of Hydraulic Pressure Test For Transmission Pipe Line-1Document10 pagesMethod Statement of Hydraulic Pressure Test For Transmission Pipe Line-1gawtomNo ratings yet

- Abacus Software WorkDocument6 pagesAbacus Software WorkJunaid AshrafNo ratings yet

- Dp&T-Sup Centrifugal Pumps Specification: 0 Original IssueDocument19 pagesDp&T-Sup Centrifugal Pumps Specification: 0 Original IssueAllyson LisboaNo ratings yet

- General Information: Thermaflex Installation ManualDocument44 pagesGeneral Information: Thermaflex Installation ManualAgus Riyono989 HvacNo ratings yet

- PFD & P&idDocument22 pagesPFD & P&idRajeshSahuNo ratings yet

- MS 06 16 PDFDocument4 pagesMS 06 16 PDFPrateek RajNo ratings yet

- Sizing Asme b31.3 2008Document12 pagesSizing Asme b31.3 2008Enamul KhanNo ratings yet

- Rust Veto MPDocument3 pagesRust Veto MPSubrata DasNo ratings yet

- CableInstallation PDFDocument8 pagesCableInstallation PDFJAY PARIKHNo ratings yet

- Equipo Carrier 38aks028-044Document82 pagesEquipo Carrier 38aks028-044sybreed88No ratings yet

- Erosional Gas VelocityDocument21 pagesErosional Gas VelocityWil Vasquez CNo ratings yet