Professional Documents

Culture Documents

Course Outline Djj3213 Dis2018

Uploaded by

Guang Wen Guang WenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Outline Djj3213 Dis2018

Uploaded by

Guang Wen Guang WenCopyright:

Available Formats

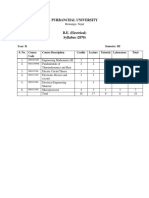

COURSE OUTLINE

Department : Mechanical Engineering Department Class : DKM3A

Programme : Diploma In Mechanical Engineering Semester :3

Academic Session : DIS 2018

Course and Code : Material Science and DJJ3213

Pre-requisite : None

Total Contact Hours : 64 Hours

Lecturer : TAN CHIN CHAI

Room : MECHANICAL ENGINEERING OFFICE (GROUND FLOOR)

Tel. No. : 04-5383322 (ext: 5001)

Synopsis : MATERIAL SCIENCE provides students with an understanding of material

science and engineering which emphasizes on atomic and crystal structure,

material properties and behavior including material classification and its

application in the engineering field. The topic also covers the processes of metal

work used to produce engineering components and apply basic principles of

material testing and processing through practical.

SUMMARY

1.0 INTRODUCTION TO MATERIAL SCIENCE

This topic introduces to material science which explains further about material classification

such as metals, polymers, ceramics, composites and advanced materials.

2.0 MATERIAL STRUCTURE AND BONDING

This topic explains the concepts of material structure and bonding, physical structure of

atoms, and crystal structure. In addition, the topic also covers the interpretation of periodic

table.

3.0 MATERIAL PROPERTIES AND BEHAVIOUR

This topic describes the material properties which are physical, thermal, mechanical and

electrical properties. The material behavior such as creep, fatigue, corrosion and fracture are

also provided.

4.0 SOLID SOLUTION AND EQUILIBRIUM PHASE DIAGRAM

This topic explain solid solution and equilibrium phase for ferrous-carbon.

5.0 METAL ALLOYS

This topic describes the characteristics and application of ferrous alloys and nonferrous

alloys. It also explains the electrochemical corrosion phenomenon includes the differences

between the types of corrosion and their remedial action to metal alloys.

6.0 MATERIAL PROCESSING

This topic explains the fabrication of metal works which focuses on hot and cold work,

forming operation and casting process.

7.0 HEAT TREATMENT

This topic explains the purposes of heat treatment process for steels and the effects of heat

treatment on mechanical properties of steels.

8.0 MATERIAL TESTING

This topic provides an understanding on the materials testing. It also explains on the

definition and principle on destructive and non-destructive tests.

LEARNING OUTCOMES:

Upon completion of this course, students should be able to:

Programme

Learning

Course Learning Outcome (CLO) LD Assessment Methods

Outcome

(PLO)

Explain the fundamental of material

1

science including identification of

Quiz, Test, End of Chapter,

various types of materials, mechanical

PLO 1 LD1 Report of Practical Task and

behavior, metal production processes,

Final Exam

and various principles of material

testing. (C3)

Organize appropriately experiments in

2 group according to the Standard PLO 4 LD2 Practical Task

Operating Procedures. (P4)

Demonstrate ability to work in team to

3 complete assigned tasks during PLO 7 LD9 Practical Task

practical work sessions.(A3)

ASSESSMENT

The course assessment is carried out in two sections:

i. Coursework Assessment (CA) – 50%

Coursework is continuous assessment that measures knowledge, practical skills and generic

skills. Coursework assessment mark comprises of knowledge and practical marks ONLY. It

does not include the mark of generic skills.

ii. Final Examination Assessment (FE) – 50%

Final examination is carried out at the end of the semester.

ASSESSMENT SPECIFICATION TABLE (AST)

Teaching Methods:

Lectures, lectures based on power point presentations, group learning activities such as discussions,

problem solving exercises, and individual/group assignments.

ASSESSMENT:

No Method Quantity Criteria % Total Dates

Week 2

1 Quiz 2 Chapter 1 and 8 10%

Week 15

Chapter 2, 3 and 4 Week 8

2 Test 2 20%

Chapter 5, 6 and 7 Week 16

Chapter 2, 3 and 4 Week 7

3 End-of-Chapter* 1 10%

Chapter 5, 6 and 7 Week 13

Report Report of practical 5% Week 1 - 15

4 4

task

Practical 5% Week 1 - 15

5 4 Practical Task

Cover all lecture

6 Final exam 1 50% Week 17, 18

topics 1 - 8

Overall Total 100%

ATTENDANCE

The student should adhere to the rules of attendance as stated in the Polytechnic Academic Regulations and

Procedures:

a. Student must attend not less than 80% of lecture hours as required for the subject.

b. The student will be prohibited from attending any lecture and assessment activities upon failure to

comply the above requirement. Zero mark will be given to the subject.

Main:

Callister, W.D., Material Science and Engineering an Introduction

Other:

K.G. Budinski & M.K Budinski (1999). Engineering Materials, 6th Edition. New Jersey, US : Prentice-Hall.

R.L Timings. (1998). Engineering Material, 2nd Edition, Singapore : Longman.

William F. Smith & Javad Hashemi (2009). Foundations of Materials Science and Engineering, 5th Edition.

McGraw-Hill, USA.

Prepared by:

................................................................

Signature: TAN CHIN CHAI

Date: 06.12.2018

Note: (*) ASSIST/TEAM TEACHING

PPL-04(2) (27-11-18)

You might also like

- Ship Corrosion - Cathodic Protection and Sacrificial AnodesDocument17 pagesShip Corrosion - Cathodic Protection and Sacrificial Anodese. barajas100% (1)

- TCET FE Chemistry Resource Book (2020-2021)Document219 pagesTCET FE Chemistry Resource Book (2020-2021)KevinNo ratings yet

- Plain Bearings Failure Mode and RectificationDocument13 pagesPlain Bearings Failure Mode and RectificationengrsurifNo ratings yet

- BS 5950-4-1994 (Englezesc) PDFDocument38 pagesBS 5950-4-1994 (Englezesc) PDFYannis Alexandru100% (4)

- EE2003 Semiconductor Fundamentals - OBTLDocument6 pagesEE2003 Semiconductor Fundamentals - OBTLAaron TanNo ratings yet

- DNV Os F101Document166 pagesDNV Os F101Rakesh Sundaramurthy100% (2)

- Material Data Sheet: Ultrachrome® High CR, Low CDocument3 pagesMaterial Data Sheet: Ultrachrome® High CR, Low CfendixNo ratings yet

- CRE Lab ManualDocument26 pagesCRE Lab ManualNaeem Ashraf0% (2)

- Instron Universal Testing Machine SOPDocument12 pagesInstron Universal Testing Machine SOPGuang Wen Guang WenNo ratings yet

- 335 CoflexipDocument40 pages335 Coflexipforajistu100% (1)

- CPC 18 2 CarbonationDocument3 pagesCPC 18 2 Carbonationheidi333No ratings yet

- Base Station Antennas1Document66 pagesBase Station Antennas1redha_rebaiNo ratings yet

- Anodic ProtectionDocument30 pagesAnodic ProtectionLuis Eduardo PereiraNo ratings yet

- Course Outline - DJJ3213 Material ScienceDocument4 pagesCourse Outline - DJJ3213 Material Sciencenya46100% (1)

- 4thyear Course Plan2013ed.Document4 pages4thyear Course Plan2013ed.hsnaterNo ratings yet

- MTCC5008 Soil Mechanics and GeoSciencesv2.3Document4 pagesMTCC5008 Soil Mechanics and GeoSciencesv2.3Morsaleen ChowdhuryNo ratings yet

- Fluid Mechanics Course OutlineDocument3 pagesFluid Mechanics Course OutlineZariff AnizanNo ratings yet

- Andhra Pradesh B.Sc. Physics Syllabus under CBCSDocument39 pagesAndhra Pradesh B.Sc. Physics Syllabus under CBCShareeshNo ratings yet

- MECH 2262 OutlineDocument4 pagesMECH 2262 OutlineSantiago GarcíaNo ratings yet

- Probability Methods in Engineering Spring 2018Document3 pagesProbability Methods in Engineering Spring 2018Chaudry Arshad MehmoodNo ratings yet

- MA505-N-C Modern Manufacturing ProcessesDocument3 pagesMA505-N-C Modern Manufacturing Processeshrana287No ratings yet

- Control Systems EBB320: School of Engineering Department of Electrical, Electronic and Computer EngineeringDocument13 pagesControl Systems EBB320: School of Engineering Department of Electrical, Electronic and Computer Engineeringspam1250 alotNo ratings yet

- Fluid Mechanics Laboratory Manual-Feb t17 AmendedDocument30 pagesFluid Mechanics Laboratory Manual-Feb t17 AmendedRaihanNo ratings yet

- Course Profile Lab RefeDocument11 pagesCourse Profile Lab RefesatishNo ratings yet

- Module (Course Syllabus) Catalogue For All Degree Rawshan Oil and Gas Technology EveningDocument6 pagesModule (Course Syllabus) Catalogue For All Degree Rawshan Oil and Gas Technology EveningOsama MohsinNo ratings yet

- Module SpecificationDocument3 pagesModule Specificationomar zizoNo ratings yet

- CIE AS-Level Chemistry Course StructureDocument3 pagesCIE AS-Level Chemistry Course StructureNur AlyshaNo ratings yet

- WMCIE JU Syllabus 2021 2022Document26 pagesWMCIE JU Syllabus 2021 2022Rajesh RoyNo ratings yet

- Third MVE GuidebookDocument3 pagesThird MVE GuidebookmuhaNo ratings yet

- FEA NEW Lession PlanDocument4 pagesFEA NEW Lession Planbalusharma1212No ratings yet

- Module (Course Syllabus) Catalogue For 2nd StageDocument5 pagesModule (Course Syllabus) Catalogue For 2nd StageJOHAN JOHANNo ratings yet

- Clir15 Introduction To Chemical EngineeringDocument3 pagesClir15 Introduction To Chemical EngineeringKonain Raza AnsariNo ratings yet

- MEng6302 Advanced Mechanics Course OutlineDocument7 pagesMEng6302 Advanced Mechanics Course OutlineKKDhNo ratings yet

- Mat201 PDFDocument4 pagesMat201 PDFVICTORLEGEND100% (1)

- EE 424 Integrated Circuits FabricationDocument7 pagesEE 424 Integrated Circuits FabricationKhalil AlluhaybiNo ratings yet

- Lab Sheet: Faculty of Engineering & TechnologyDocument9 pagesLab Sheet: Faculty of Engineering & TechnologyJohn RajNo ratings yet

- 3395Msc Physics Syllabus 2017-18Document49 pages3395Msc Physics Syllabus 2017-18KEERTHANA RAJAN L100% (1)

- Introducción A Los Procesos de ManufacturaDocument9 pagesIntroducción A Los Procesos de ManufacturaLuis EstebanNo ratings yet

- COURSE OUTLINE FOR STRUCTURAL ENGINEERING LABDocument6 pagesCOURSE OUTLINE FOR STRUCTURAL ENGINEERING LABAsyrieNo ratings yet

- Thermodynamics Course SyllabusDocument4 pagesThermodynamics Course SyllabusSEn SEnNo ratings yet

- Unit Outline Material and Manufacturing 2Document9 pagesUnit Outline Material and Manufacturing 2Bassam MansourNo ratings yet

- Course Syllabus Physical CheDocument7 pagesCourse Syllabus Physical CheOsama MohsinNo ratings yet

- EME1226 Lab Sheet Tri2-2016 - 7aDocument9 pagesEME1226 Lab Sheet Tri2-2016 - 7aDavid LimNo ratings yet

- Essential Electrical and Electronics SyllabusDocument7 pagesEssential Electrical and Electronics SyllabusfarizanNo ratings yet

- MENG 201-Course Specificatio Revised LatestDocument5 pagesMENG 201-Course Specificatio Revised LatestHasan AliNo ratings yet

- De ZG513Document8 pagesDe ZG513inderNo ratings yet

- Corrosion in The Oil and Gas IndustryDocument3 pagesCorrosion in The Oil and Gas IndustryBis HopNo ratings yet

- DR - KB - OFC OutlineDocument6 pagesDR - KB - OFC OutlineEngr SayedNo ratings yet

- Course Plan LNG For Upes Session 2020Document10 pagesCourse Plan LNG For Upes Session 2020kushagra guptaNo ratings yet

- ECA-1 Course Analysis Electric Circuits (39Document4 pagesECA-1 Course Analysis Electric Circuits (39Shahmeer KhanNo ratings yet

- UE Durabilité Des Matériaux en Industrie: Course SyllabusDocument3 pagesUE Durabilité Des Matériaux en Industrie: Course SyllabuswatsopNo ratings yet

- Chapter 1Document6 pagesChapter 1Ashwin MNo ratings yet

- ECE1201 Engineering Lab IIDocument6 pagesECE1201 Engineering Lab IIbelkhair ahmedNo ratings yet

- MCT 3423Document6 pagesMCT 3423abdio89No ratings yet

- Master of Technology Programme Solid State MaterialsDocument56 pagesMaster of Technology Programme Solid State MaterialsdeepanshuNo ratings yet

- BITS Pilani FEM Course Covers Finite Element AnalysisDocument7 pagesBITS Pilani FEM Course Covers Finite Element AnalysisAdil RasheedNo ratings yet

- Course Outline - DJJ2093 - Latest PDFDocument1 pageCourse Outline - DJJ2093 - Latest PDFThaneswaran BaluNo ratings yet

- Fracture Mechanics - Simulation Lab Course HandoutDocument2 pagesFracture Mechanics - Simulation Lab Course Handoutraaspoy2007No ratings yet

- Syllabus Summary DMV4242Document2 pagesSyllabus Summary DMV4242muhamadsaidiNo ratings yet

- Mining Syl LDocument163 pagesMining Syl LAKSHAY KARMANKARNo ratings yet

- Third Semester1571374736Document15 pagesThird Semester1571374736miraazNo ratings yet

- Course Outline DJJ 5062Document5 pagesCourse Outline DJJ 5062Munisprasad MuniandyNo ratings yet

- Centurion University of Technology & Management, Odisha School of Applied Sciences, ParalakhemundiDocument5 pagesCenturion University of Technology & Management, Odisha School of Applied Sciences, ParalakhemundiSadhan PadhiNo ratings yet

- Nino EMA 6445 Syllabus S17Document4 pagesNino EMA 6445 Syllabus S17Shin NguyenNo ratings yet

- Materials for Engineering ApplicationsDocument3 pagesMaterials for Engineering Applicationsمحمد فائزNo ratings yet

- 02 Course Structure - Fea - 19-20 - VelDocument6 pages02 Course Structure - Fea - 19-20 - Velrajamanickam sNo ratings yet

- Course Description Form: Marks DistributionDocument6 pagesCourse Description Form: Marks DistributionpradeeperukullaNo ratings yet

- ChE 426N OBE Course Syllabus Ver 2016-2017Document3 pagesChE 426N OBE Course Syllabus Ver 2016-2017EmmanuelDalesAlquizolaNo ratings yet

- 22PHYM12Document5 pages22PHYM12SRIKUMAR BIRADARNo ratings yet

- Computer-Assisted Instruction at Stanford, 1966-68: Data, Models, and Evaluation of the Arithmetic ProgramsFrom EverandComputer-Assisted Instruction at Stanford, 1966-68: Data, Models, and Evaluation of the Arithmetic ProgramsNo ratings yet

- SoalanDocument1 pageSoalanGuang Wen Guang WenNo ratings yet

- Piano NameDocument1 pagePiano NameGuang Wen Guang WenNo ratings yet

- ע�� 1. б � ��� 2.�����Ǯ�����ͻ��� ڣ�����һ�������壩 3. ֻ������4���� online Search the Search buttonDocument1 pageע�� 1. б � ��� 2.�����Ǯ�����ͻ��� ڣ�����һ�������壩 3. ֻ������4���� online Search the Search buttonGuang Wen Guang WenNo ratings yet

- Need A BNC Adapter Solution, SMA ConnectorDocument1 pageNeed A BNC Adapter Solution, SMA ConnectorGuang Wen Guang WenNo ratings yet

- PasswordDocument1 pagePasswordGuang Wen Guang WenNo ratings yet

- LicenseDocument1 pageLicenseGuang Wen Guang WenNo ratings yet

- Readme eDocument2 pagesReadme eGuang Wen Guang WenNo ratings yet

- PasswordDocument1 pagePasswordGuang Wen Guang WenNo ratings yet

- NameDocument1 pageNameGuang Wen Guang WenNo ratings yet

- Preparing Journal Entries: Account Increase DecreaseDocument4 pagesPreparing Journal Entries: Account Increase Decreasebharat100% (1)

- Journal EntriesDocument70 pagesJournal EntriesGuang Wen Guang WenNo ratings yet

- PasswordDocument1 pagePasswordGuang Wen Guang WenNo ratings yet

- PasswordDocument1 pagePasswordGuang Wen Guang WenNo ratings yet

- PasswordDocument1 pagePasswordGuang Wen Guang WenNo ratings yet

- PasswordDocument1 pagePasswordGuang Wen Guang WenNo ratings yet

- Password bl.v10.0.1Document1 pagePassword bl.v10.0.1Guang Wen Guang WenNo ratings yet

- PasswordDocument1 pagePasswordGuang Wen Guang WenNo ratings yet

- Sheet DataDocument63 pagesSheet DataGuang Wen Guang WenNo ratings yet

- NVIDIA System Information 08-29-2016 11-41-59Document2 pagesNVIDIA System Information 08-29-2016 11-41-59Guang Wen Guang WenNo ratings yet

- Network 15756C3FDocument1 pageNetwork 15756C3FGuang Wen Guang WenNo ratings yet

- PasswordDocument1 pagePasswordGuang Wen Guang WenNo ratings yet

- Nguoi Tinh Mua Dong - Piano Music SheetsDocument5 pagesNguoi Tinh Mua Dong - Piano Music SheetsGuang Wen Guang WenNo ratings yet

- Nguoi Tinh Mua Dong - Piano Music SheetsDocument5 pagesNguoi Tinh Mua Dong - Piano Music SheetsPriscilla TranNo ratings yet

- Unit 1. Banks, Central Bank and RegulationsDocument40 pagesUnit 1. Banks, Central Bank and RegulationsGuang Wen Guang WenNo ratings yet

- Malaysian Debt Market OverviewDocument45 pagesMalaysian Debt Market OverviewGuang Wen Guang WenNo ratings yet

- Malaysian Debt Market OverviewDocument45 pagesMalaysian Debt Market OverviewGuang Wen Guang WenNo ratings yet

- T A 3 1 1 4 2 F N G: Ta31142fg, Ta31142fngDocument13 pagesT A 3 1 1 4 2 F N G: Ta31142fg, Ta31142fngGuang Wen Guang WenNo ratings yet

- T A 3 1 1 4 2 F N G: Ta31142fg, Ta31142fngDocument13 pagesT A 3 1 1 4 2 F N G: Ta31142fg, Ta31142fngGuang Wen Guang WenNo ratings yet

- Prospectus EnglishDocument20 pagesProspectus EnglishMilan GašićNo ratings yet

- Monel Data SheetDocument16 pagesMonel Data SheetElias KapaNo ratings yet

- Astm G 139Document10 pagesAstm G 139Lichi leonNo ratings yet

- Interline 967+ds+eng PDFDocument4 pagesInterline 967+ds+eng PDFMohamed NouzerNo ratings yet

- Introduction To Corrosion ScienceDocument11 pagesIntroduction To Corrosion ScienceFrancois BornmanNo ratings yet

- Higt Temp Failure Case LanceDocument2 pagesHigt Temp Failure Case LanceDevin Trianda PutraNo ratings yet

- H5139 PDFDocument1 pageH5139 PDFAndyNo ratings yet

- Gantrex Mk90 Raillok Pad Data Sheet MetricDocument2 pagesGantrex Mk90 Raillok Pad Data Sheet MetricZar Ka ZiNo ratings yet

- The Phase Stability of Cerium Species in Aqueous SystemsDocument9 pagesThe Phase Stability of Cerium Species in Aqueous SystemsHoracio Piña SpeziaNo ratings yet

- AMIF Sanitary Design ChecklistsDocument12 pagesAMIF Sanitary Design ChecklistsGustavoNo ratings yet

- MOD 005 Stainless SteelsDocument6 pagesMOD 005 Stainless SteelsDu Xuan BinhNo ratings yet

- Ultra Cote 101 PrimerDocument3 pagesUltra Cote 101 PrimerGilbert Dela Serna IINo ratings yet

- CTS Essentials 09.2020 en LRDocument4 pagesCTS Essentials 09.2020 en LRChicago PneumaticNo ratings yet

- Guided Waves Pipe Inspection: Teletest Focus+ Pipe Screening SystemDocument2 pagesGuided Waves Pipe Inspection: Teletest Focus+ Pipe Screening Systemshahbaz akramNo ratings yet

- Carlan (Serban) - Beatrice - Adriana - Art7Document9 pagesCarlan (Serban) - Beatrice - Adriana - Art7Liviu BadeaNo ratings yet

- SWORD Escalator Travolater S900E S900T GiantliftslimitedDocument12 pagesSWORD Escalator Travolater S900E S900T GiantliftslimitedSazzad Hossan RaselNo ratings yet

- Jadwal Tentative INDOCOR 2019Document1 pageJadwal Tentative INDOCOR 2019Aswin Lorenzo GultomNo ratings yet

- The Corrosion Module User's GuideDocument340 pagesThe Corrosion Module User's GuideFelipe Cepeda SilvaNo ratings yet

- Electrochemical Chloride Extraction Impact on ConcreteDocument10 pagesElectrochemical Chloride Extraction Impact on ConcreteLeonardo Medina RosarioNo ratings yet

- Atea-Composite Presentation Aug-09Document41 pagesAtea-Composite Presentation Aug-09thanakomNo ratings yet

- Introduction To CorrosionDocument35 pagesIntroduction To CorrosionmdrizwanuddinNo ratings yet