Professional Documents

Culture Documents

Woodsmith Magazine 27

Uploaded by

Ilberto Fortuna0 ratings0% found this document useful (0 votes)

32 views24 pagesExcelente revista com planos para fabricação.

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentExcelente revista com planos para fabricação.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views24 pagesWoodsmith Magazine 27

Uploaded by

Ilberto FortunaExcelente revista com planos para fabricação.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

NO.27.——sSNOTES FROM THESHOP,——s—~i~s~=«éSSD2«CSO

“Woodsmith

PAI © FOURNIMGREg

COMPLETE PLANS FOR:

@ PICNIC TABLE

@ PATIO CHAIRS

@ OUTDOOR BENCH

PLUS. . .A SHOP TEST ON

CARBIDE-TIP SAW BLADES

‘Michae! P. Scott

‘Subscription Manager

‘Sandy J. Baum

‘Subscription Assistants

‘Christel Miner

Vicky Robingon

Jackie Stroud

Shirley Feltman

Pam Dickey

‘Computer Operations

‘Ken Miner

CGreulaton Manager

Jott Farris

‘Administrative Assistant

‘Chery! Seott

ISSN: o16¢-4114

WOODSMITH is published bimonthy (January,

March, May, duly, September, November) by

‘Woodsmith Publishing Company. 1912 Grand

‘Ave, Des Moines, lowa £0309.

WOODSMITH is a regsiered trademark of he

Woodsmith

‘Subscriptions: One year (6 issues) $10, Two

‘yar (12 lees) $18. Sigle copy price, $250

(Canada and Foreign: acd $2 pet yeer.)

Change OF Address: Please be sure io include

‘both your old and new edéress for change of

‘address. Nal 10: Woodsmit, 1912 Grand Ave,

Des Moines, lowa 50309.

Second class postage pald at Dor Meinos,

lowe.

Postmaster: Send change of addiess notice.

Ferm 3570, o Woedemith Publishing Co., 1912

Grand Ave., Des Moines, ona 50308.

BACK ISSUES

A ist ofthe conten of al back issues appears

on the wrapper ofthis issue. I the wrapper is

miscing, you can sond fer a booklet dosciting

the conteris and prices ofall back issues.

SAMPLE COPIES:

"you nave atrienawno woulc tke 0 see copy.

‘of Woodemith just send the name and adcress,

and we'l send a sample (at 10 cos).

sweater with a hole in one sleeve. 1's

thread-bare, and sagging from old age

‘And Tee been told ite time to get id of

hat old hing” and buy a new one.

Bat [lige my cd sweater. Talways fee!

warm in it — even though I know a new

Sweater would really be warmer.

"So what's the point ofall this tall about

aid eweatere? I thought this was a wood:

‘working magazine.

‘Wel, its just that T have almost the

sae lings abot my a lade Fs the

couple of years I've been using a

Freud 30-tooth earbide-tipped com:

bination blade. That biade has cut alot of

‘wood and even though its begianing, to

trear down a hit, I fee comfortable with it

and it always gets the job done

T wouldn't think of getting a new one.

That i until I made the mistake of using

one of Freai’s new LUSGM “Anti gript

blades. Just one eat, that’s ll it took to

completely alter my way of looking at sw

blades and what I should expect of them.

But before I get too excited about this

blade, let me back up aminute and explain

howailofthis started. Steve Kevhmer (ur

aslstant editor) drew the assignment of

writing 4 two-page article about saw

Blades.

‘We agreed that we shoul buy several

typesof Hades and test thom out to soe i

there really was any difference between

one blade and another, Without going

overboard on this project, we settled on

thro brands; Sears and Freud. Then we

Added the “Mr. Sawdust” blade, because [

keep seeing full-page ads for it in Fine

Woodworking and T wanted to know just

hhow good it was.

In the middie of allthis, Ted Kralicek

(oar Design Director) decided we should

get anew tablesaw. Things were getting a

little crowded in the shop — almost to the

point that we had to schedule time on the

‘one table saw we had.

Our new saw ard the collection of saw

blades arrived about the sametime. It was,

then I realized that we were really buying

two separate pieces of equipment. The

table saw by itself is just a way to guide

‘boards through the blade. But i's the saw

blade that's really doing all the work.

left the shop to sign the checks for all

this new equipment. Meanwhile, Steve

started testingthe saw blades. A couple of

‘weeks later, he emerged from the shop and.

announced that the two-page article on

‘saw blades wasnow going tobe six pages. I

agreed — if only to get him out ofthe shop.

0 [could get some time in on the new saw.

Tthought I'd test out the new table saw

by cutting through a piece of serap oak.

That's when it happened. 1 didn’t realize

Steve had left the Freud “Anti-grip” blade

onthe saw. As I trimmed off the end ofthe

ak serap, I noticed something was

ferent.

‘The cut seemed smooth, almost effert-

Jess. Iooked atthe freshly eut end, and to

my surprise, it wasn't smooth . . it was

perfect. The end grain fot like glass. No

tora fibers. No tooth marks. Just a

smooth, almost burnished surface you

couldn't help but touch. . . and beamazed.

took the blade off the saw to see what it

looked like. It looks awesome. The teeth

shine like something straight out of a

‘toothpaste commercial, The bla ise is

coated with black Teflon. (You get the

feeling Darth Vader would use it to cut

‘down his opponents.)

‘Okay, okay. Al of this is beginning to

‘sound like a big public relations effort for

Freud saw biades.

1 will admit that I'm very impressed

with this blade. But in all fairness, Pmoare

there are other saw blades that will pro-

‘duce the same quality of eut. (The Mr.

‘Sawdust blade is one of them.)

‘But the point is this: using a good saw

bladedoes make a difference. If yotexpect

perfection, there are blades that will pre-

Ahacet-Ten ts justamatter ofhow mach

‘money it's wor

T agree with Steve's conclusions that

‘one ofthe best choice for the money isthe

Freud 50-tooth combination blade (my old

favorite). The new Antigrip blade is a

fantastic ade, bat t'sdesuned hey for

cutoff wor

also agree that the Sears bladee will

ccut wood, but they simply aren't up tothe

‘quality of the Freud products.

‘As for the Mr. Sawdust blade, I'm etill

‘not quite convinced that “the only blade

ryoutl ever need” is worth $160.

‘NEW Paces, We've added one more new

face tothe group at Woodsmith. Jeff Far-

ris has joined us to coordinate the eireula-

tion efforts — the business side of this

business, Jeff is from Ava (popalation

2.504), Missouri, where he operated his

‘own hardwood limber company.

"Ashe comes on board here, our cireua-

tion stands at about 130,000, and Jeff wil

bbe responsible for keopingall of thace num-

bers under control. But he's off to a good

start. He's already assured me that cir-

culation will inercase by one new sub-

seriber. Jeff and Marilyn are expecting

their first child August 4th.

NEXT MAILING. The next issue of Wood.

‘smith (Number 28) should be in the mall

‘during the week of July 25th.

2

WoopsMiTH

Tips

& Techniques

STICKY STAVES

‘When it came time to “glue up” the staves

cused for the turned canisters (Woodsmith

No. 25), I came up with an easy way to

keep everything under control. [just used

tape (masking, fbergiass, or whatover) to

secure all the individual pieces until

they're glued together.

‘The first step is to lay out all the staves:

‘edge to edge with the outside face upward.

cua

=

‘Then | applied two or three rows of

the outside face to holi the individual

saves together. Finally, the whole assem-

Dlyis turned over and rolled intoaeylinder

to.check the fit botwoen the staves.

everything fis okay, the next step is

to fatten the assembly oat and brush glue

anthe edges ofeach stave. Then the entire

‘assembly is rolled up, and clamped with

‘web clamps,

Ifthe ft between the staves needs ad-

justing, I don't apply glue to two of the

Joints (opposite each other). Ths produces

two half evlinders after the assernbly has

been clamped. When everything is dry, |

trim the two halves until they mate per-

fectly. Then finaly, the two half cylinders

are glued together.

Perey B. Hansen

Waihatia, North Dakota

‘ORGANIZED DOVETAILS

Recently I constructed a few drawers (14

tobe exact) using adovetail fixture torout

+halfblind dovetails on all four comers. This

involved a total of 36 individual joints, and

about 10 million possible combinations.

‘About the time I was half dane, the

started. All ofa sudden I realized

that I have become confused about where

‘toposition the proper pieces for each joint.

(Repetition doesn’t sharpen my mind, it

djulls it.)

So to eliminate the chance of mounting.

the pieces into the dovetail jig in the

wrong position, I came up with a simple

labeling system for both the drawer sides,

and the jg.

‘The first step is to label the individual

drawer sides using a simple method that

involves marking each drawer side with

letter. The key to this marking system is,

to mark the etter near the bottom edge on

the inside face.

=

Next, I made two labels that are at-

tached to the dovetail jig for identifying

‘both the proper sides, and their locations

for routing each of the four joints. Each

label consists of two separate two-letter

combinations. Each set of letters is posi-

tioned with one letter over the other,

representing the two sides needed to form

each comer joint. The top letter repre-

sents the piaee placed in the top of the jig,

and the bottom letter represents the piece

placed in the front of the jig.

Example: The dovetail between

sides B and A is cut using the let side of

the Jig (two of the joints are eut using the

left side of the jig, and the remaining two

Joints use the right side of the jig). The

label shows side B over side A, so piece B

is inserted in the top ofthe jig, and piece A

is inserted in the front of the fix. Note:

Alwayskeep the labeled face of

sides facing out, away from the jig, and

the labeled edge against the guide pins in

the jg

‘Using this system, Ican tell at a glance

which two sides are joined together, and

where to loeate each individual piece.

Even after 56 joints.

Sue Kortum

Custer, South Dakota

MEASURED CUT OFFS

ve been using a cut off jg you showed in

Woedsmith No. 25 for some time now.

There is one change I've made that might

interest your readers — I added a measur-

ing tape.

To incorporate the measuring tape into

the cut off sig, ly redesigned the

imply

fence into an “L” shape. This allows the Ys"

wide tape to be attached on the shoulder of |

the fence. Then fray, adjustable siop

bok are out to ft the new fence

Tthe measuring tape i attached to the

fence ofthe ut off ig accurately, you can

save lot of time normaly sed in measr-

ing and marking.

L.A. Snyter

Wyoming, Mickigan

Editor's Note: The only mail onder source

ree've been able to locate for the self stick.

ing counter tapes is Garrett Wade, 161

Avenue of the Amerieas, New York, New

York, 10013. Stock # 30N01.01, $3.90

each,

These tapes are 6 feet long, Ve wide, and.

calibrated in Vos" increments (the first 6”

fare calibrated in Ya" increments). They

can be easily eut to mateh the length ofthe

cutoff jig fence (they're made with .008"

thick steel). The rule is attached by remov-

sooth per ack od eats reengte

in position.

‘One other note: When the tape is set up

for particular blade, it may not be aecn-

rate when wsed with ¢nother blade.

‘nyo a share a woodworking ipwin other

readers of Woodsmith. send your idea to:

Woodsmith, Tips & Techrquos, 1012 Grand

‘Ave, Des Nines, lowe 50308.

‘Wepaya minimum of $10 or tos, and $15 or

ore for special tecriques (that are accepted

{or pubtcaton). Pease gwe acompiet expiana-

‘ion of your idea Ha sketch is needed, send it

_alorg: well draw a new one.

‘WoopsmiTH

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Woodsmith Magazine 160Document54 pagesWoodsmith Magazine 160Ilberto FortunaNo ratings yet

- 1 CabinetMaker+FDM January 2012 PDFDocument64 pages1 CabinetMaker+FDM January 2012 PDFIlberto FortunaNo ratings yet

- Woodsmith Magazine 133Document36 pagesWoodsmith Magazine 133Ilberto FortunaNo ratings yet

- Router JigsDocument2 pagesRouter JigsIlberto Fortuna100% (1)

- Woodsmith Magazine 169Document52 pagesWoodsmith Magazine 169Ilberto Fortuna100% (1)

- Woodsmith Magazine 140Document36 pagesWoodsmith Magazine 140Ilberto FortunaNo ratings yet

- Woodsmith Magazine 132Document36 pagesWoodsmith Magazine 132Ilberto Fortuna100% (1)

- Woodsmith Magazine 150Document36 pagesWoodsmith Magazine 150Ilberto Fortuna100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Woodsmith Magazine 142Document36 pagesWoodsmith Magazine 142Ilberto Fortuna100% (1)

- Woodsmith Magazine 134Document36 pagesWoodsmith Magazine 134Ilberto FortunaNo ratings yet

- Finger Joints: Fast and EasyDocument4 pagesFinger Joints: Fast and EasyIlberto FortunaNo ratings yet

- 32 Jig For Threaded Inserts & Making Raised Panels PDFDocument1 page32 Jig For Threaded Inserts & Making Raised Panels PDFIlberto FortunaNo ratings yet

- Sherwood Creations Winter 2011Document68 pagesSherwood Creations Winter 2011Ilberto FortunaNo ratings yet

- HWHL Router Table PlansDocument9 pagesHWHL Router Table PlansIlberto FortunaNo ratings yet

- 63 Portable Mitre Saw Station PDFDocument1 page63 Portable Mitre Saw Station PDFIlberto FortunaNo ratings yet

- Sherwood Creations Spring 2011Document68 pagesSherwood Creations Spring 2011Jorge ReyesNo ratings yet

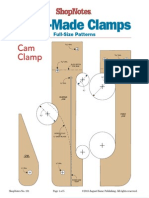

- Clamp PatternsDocument5 pagesClamp PatternsGermanHund100% (3)

- Shop-Made Cam ClampDocument68 pagesShop-Made Cam ClampIlberto Fortuna33% (3)

- Woodsmith Magazine 130Document36 pagesWoodsmith Magazine 130Ilberto FortunaNo ratings yet

- AW Extra - Double-Duty Shop StoolDocument15 pagesAW Extra - Double-Duty Shop StoolIlberto FortunaNo ratings yet

- Woodsmith Magazine 25Document28 pagesWoodsmith Magazine 25Ilberto FortunaNo ratings yet

- Woodsmith Magazine 24Document24 pagesWoodsmith Magazine 24Ilberto FortunaNo ratings yet

- Woodsmith Magazine 23Document24 pagesWoodsmith Magazine 23Ilberto FortunaNo ratings yet

- Woodsmith Magazine 99Document32 pagesWoodsmith Magazine 99Ilberto FortunaNo ratings yet

- Woodsmith Magazine 20Document24 pagesWoodsmith Magazine 20Ilberto FortunaNo ratings yet

- 33 Optional BaseDocument1 page33 Optional Baseapi-3704830No ratings yet

- Shop-Made Router LiftDocument6 pagesShop-Made Router LiftIlberto Fortuna100% (2)