Professional Documents

Culture Documents

NOJA-7067-00 OSM15 310 OSM27 310 OSM38 300 Quick Site Installation Guide

Uploaded by

Nhat Nguyen VanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NOJA-7067-00 OSM15 310 OSM27 310 OSM38 300 Quick Site Installation Guide

Uploaded by

Nhat Nguyen VanCopyright:

Available Formats

OSM Series 300/310 and RC10 Controller Quick Site Installation Guide

1. Pole Installation

Fit bracket to OSM Tank (if not already fitted).

Fit Surge Arrestors (recommended prior to OSM installation on pole).

Drill holes through the pole for the bracket (280mm apart, 24mm dia).

On concrete poles use bolt on top hole and steel strap through slots provided in the

bracket.

Lift OSM Tank (use lifting points) and bolt to pole.

Repeat for VT if supplied. Ensure that the LV connection to the VT is sealed with a

gland.

2. HV Cables and Bird Guards

Connect HV cables to line.

Connect HV Connectors on each bushing. For Tunnel Connectors use 8mm Allen Key

to torque the hexagonal socket screws to 30Nm. For Tin-plated Brass NEMA 2-hole

Palm Connectors attach a matching lug using two M12 bolts (torque 30Nm).

Connect each Surge Arrestor to its bushing with a short length of cable.

Fit Bird Guards (recommended) to all bushings. Bird guards should not go below the

first shed on the bushing (see picture on this page).

3. RC10 Installation

Lift and secure RC10 to pole (use steel straps for concrete or coach screws for wood).

4. Earthing

2

Run a single, unbroken 35mm copper conductor from OSM tank earth point

directly to the earth connection at the base of the pole.

2

Use short length 35mm copper conductors for VT and RC10 earth points and bond

to main earth conductor using line taps or crimp connections.

5. Control Cable Connection

Insert and lock Control Cable into OSM Tank.

Run Control Cable along pole and feed Canon Plug into RC10 cubicle. Align notch

correctly before inserting into SIM connection. Rotate locking nut to secure.

Secure control cable plate with wing nuts. Roll up excess length of cable and safely

tie to pole. Ensure there is no tension in the Harting connection.

6. LV Auxiliary Supply

Connect the AC supply (from the pole mounted VT or other source) to the RC10

circuit breaker.

A N

Use a 2 pole isolation point on the LV supply cable. E

7. Installation Checks OK

VT supply correct

RC10 Circuit Breaker turned ON

Current and Voltage Readings on the panel are correct

Trip/Close Test successful E

All holes in cubicle are sealed using glands A N

Conduct Protection and SCADA Tests as Required

ALL CABLE SEPARATION FROM EARTH CONDUCTOR MUST BE MINIMUM 150mm

LENGTH OF TEE-OFF TO THE CUBICLE FROM MAIN EARTH BOND MUST BE < 1.5m

USE CRIMP TYPE CONNECTION LUGS FOR TERMINATION OF EARTH BOND

CONTROL CABLE MINIMUM BEND RADIUS IS 300mm

SECURE CABLES ALONG POLE WITH SADDLES OR STRAPS

USE PARALLEL GROOVE CLAMPS TO CONNECT CABLES TO FEEDER

ALWAYS USE GLANDS FOR ANY CABLE ENTRY TO ENSURE STRAIN RELIEF AND PROTECTION FROM ENVIRONMENT

STEEL POLE CANNOT BE USED AS EARTH. A SEPARATE COPPER CONDUCTOR MUST BE USED

PLEASE REFER TO SECTION 9.4 SITE INSTALLATION IN THE OSM USER MANUAL FOR CORRECT INSTALLATION

1 OSM Recloser NOJA-7067-00 OSM Quick Site Installation Guide

2

VT (Phase to Phase)

OSM Recloser

Bond VT to OSM Earth

Control Cable

Earth Conductor

LV Auxiliary Supply from VT Control Cable

Source Side

(Note Cable separation)

Bond Cubicle to

OSM Earth MINIMUM REQUIREMENT:

All cable separation from Earth Conductor, minimum

150mm.

Use minimum 35mm2 copper for Earth Conductors.

Crimp type Lugs used to connect to Earth Studs.

Parallel Groove Clamps or Line Taps used to bond RC

Controller Earth and VT to the unbroken OSM Earth

Conductor.

Typical Pole Mounting Arrangement For OSM38-300

NOJA-7067-00 OSM Quick Site Installation Guide

You might also like

- SPPG 66kv Ed.7.2 Feb 2012Document155 pagesSPPG 66kv Ed.7.2 Feb 2012landtransport100% (5)

- TES-P-104.05-R1 Cable Installation Reqt.Document28 pagesTES-P-104.05-R1 Cable Installation Reqt.Mohamed Emad100% (1)

- SVL Testing GuideDocument7 pagesSVL Testing GuideNagaraj RamNo ratings yet

- IEC 726 Dry Type PowertransformersDocument45 pagesIEC 726 Dry Type Powertransformersg_nrajaNo ratings yet

- IEC 726 Dry Type PowertransformersDocument45 pagesIEC 726 Dry Type Powertransformersg_nrajaNo ratings yet

- BEF 22903 - Lecture 5 - Unbalanced Three-Phase CircuitsDocument13 pagesBEF 22903 - Lecture 5 - Unbalanced Three-Phase CircuitsJames LiewNo ratings yet

- Im pj944Document16 pagesIm pj944fishdfNo ratings yet

- Schedule of Load: SpecificationDocument1 pageSchedule of Load: SpecificationRojim Asio DilaoNo ratings yet

- Grounding Bonding Fact SheetDocument7 pagesGrounding Bonding Fact SheetMiguel EspinosaNo ratings yet

- Screen BondingDocument38 pagesScreen BondingMoataz Eweda100% (1)

- Liebert Ita2 MBC Quick Start Guide PDFDocument12 pagesLiebert Ita2 MBC Quick Start Guide PDFCarlos PalmaNo ratings yet

- ABB - TechNotes - 2.3 - Overvoltages - Inductive Voltage Drops 1HC0138873 EN AADocument7 pagesABB - TechNotes - 2.3 - Overvoltages - Inductive Voltage Drops 1HC0138873 EN AADeoudrafNo ratings yet

- Installation Guide For Solid State Am TransmittersDocument17 pagesInstallation Guide For Solid State Am TransmittersJohn SchneiderNo ratings yet

- Online Cable Monitor Developed in JapanDocument7 pagesOnline Cable Monitor Developed in JapanelcarmoNo ratings yet

- Technical Session-14 Tower Earthing & Use of LaDocument46 pagesTechnical Session-14 Tower Earthing & Use of LaEPTCL Hazira control roomNo ratings yet

- Synchro Transmitter-Receiver SCL 110ADocument1 pageSynchro Transmitter-Receiver SCL 110AAtul MahajanNo ratings yet

- 13 Temporary Electrical Installations Inspection ChecklistDocument4 pages13 Temporary Electrical Installations Inspection Checklistjohn rajNo ratings yet

- Portable Earthing, Line End Clamps, Earth End Clamps PB WeirDocument40 pagesPortable Earthing, Line End Clamps, Earth End Clamps PB WeirrocketvtNo ratings yet

- Ham Station GroundingDocument33 pagesHam Station GroundingakaNo ratings yet

- Prysmian Separable Connectors v1.03Document12 pagesPrysmian Separable Connectors v1.03Muhammad SyaifulhaqNo ratings yet

- Manual Reconectador NOJA - OSM 15 y OSM 27 Página 77Document1 pageManual Reconectador NOJA - OSM 15 y OSM 27 Página 77cristobal valderramaNo ratings yet

- AN-1149 Switching Power Supplies Guidelines PDFDocument3 pagesAN-1149 Switching Power Supplies Guidelines PDFingenierosunidosNo ratings yet

- Annexure 2Document2 pagesAnnexure 2Anoop DamodaranNo ratings yet

- PGCILDocument50 pagesPGCILsataveerNo ratings yet

- Everyday Electronics 1975 03Document7 pagesEveryday Electronics 1975 03marcosscarato0% (1)

- Module 4: Substation Equipment's Details and Operations: July 2021Document21 pagesModule 4: Substation Equipment's Details and Operations: July 2021Gundeboyina GopiNo ratings yet

- IEEE Guide For Grounding of Instrument Transformer Secondary Circuits and CasesDocument53 pagesIEEE Guide For Grounding of Instrument Transformer Secondary Circuits and Casessyed Mujtaba hassanNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-2Document1 pagePages From SIMABUS Tubular Busbar Accesories-2asi midobarNo ratings yet

- Temporary Electrical Installations Inspection Checklist For Construction and Building SitesDocument5 pagesTemporary Electrical Installations Inspection Checklist For Construction and Building SitesqweNo ratings yet

- Product Dimensions (MM) : DescriptionDocument2 pagesProduct Dimensions (MM) : Descriptionboubakeur atouiNo ratings yet

- NOJA-7424-00 Application Note - Surge ArrestersDocument2 pagesNOJA-7424-00 Application Note - Surge Arrestersenriq7No ratings yet

- Prok ManualDocument8 pagesProk ManualaymaanfkNo ratings yet

- IR Vs DMRCDocument28 pagesIR Vs DMRCAnubhav Hem Kumar JainNo ratings yet

- Erintesvedelmi Muszerek2Document2 pagesErintesvedelmi Muszerek2lincoln9003198No ratings yet

- Chanlee Electrical Plan2Document1 pageChanlee Electrical Plan2Bai Samrah Kenti PalampongNo ratings yet

- 2.CP For Potable & Fire Water Tanks - TrainingDocument82 pages2.CP For Potable & Fire Water Tanks - TrainingRaja Prathap Singh Gopal100% (1)

- 10012020-50MW-220-33KV PSS BoqDocument4 pages10012020-50MW-220-33KV PSS BoqHari HaranNo ratings yet

- Wi 10758Document2 pagesWi 10758Estefania Giraldo GuzmanNo ratings yet

- As Per Exccution Qty 6 7 8 Rate Per in Rs - Ps Amount in RsDocument9 pagesAs Per Exccution Qty 6 7 8 Rate Per in Rs - Ps Amount in RspudurbhaskarNo ratings yet

- Csh120Andcsh200 Corebalancects: SensorsDocument1 pageCsh120Andcsh200 Corebalancects: Sensorsshoham985No ratings yet

- Earthing SystemDocument3 pagesEarthing SystemKhyle Laurenz DuroNo ratings yet

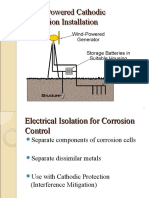

- Cathodic ProtectionDocument6 pagesCathodic ProtectionOmar DhiebNo ratings yet

- LRC099-04BT1G: 4-Channel Low Capacitance Esd Protection Diodes ArrayDocument5 pagesLRC099-04BT1G: 4-Channel Low Capacitance Esd Protection Diodes ArrayAndy Díaz MorenoNo ratings yet

- Yaesu FL-2100Z UserDocument15 pagesYaesu FL-2100Z Userjos34800No ratings yet

- File 126 6298ac2e4afbdDocument2 pagesFile 126 6298ac2e4afbdRobério FariaNo ratings yet

- Earthing PracticesDocument58 pagesEarthing Practicessubbaiah54100% (1)

- Antune Build InstructionsDocument4 pagesAntune Build InstructionsmvannierNo ratings yet

- Layout ConsiderationsDocument18 pagesLayout ConsiderationsZabrina Maika AbadNo ratings yet

- P0050S MGPSDocument21 pagesP0050S MGPSDmytro 1No ratings yet

- CalculationDocument33 pagesCalculationSwagat Pradhan100% (1)

- Project Subject DateDocument68 pagesProject Subject DateMohammad SaquibNo ratings yet

- Teaching Notes On Track CircuitsDocument12 pagesTeaching Notes On Track CircuitsRamij MujawarNo ratings yet

- Grounded Electrical Power Distribution: Excerpt From G4 Invercharge Series ManualDocument7 pagesGrounded Electrical Power Distribution: Excerpt From G4 Invercharge Series ManualMohammad HamamdNo ratings yet

- TX14B4 TC14B4 Z185 ChassisDocument14 pagesTX14B4 TC14B4 Z185 ChassisDragan StojkovicNo ratings yet

- 041170b Ecosystem - Hi-Lume 3d Instr SheetDocument1 page041170b Ecosystem - Hi-Lume 3d Instr SheetFABIAN PRUNEDANo ratings yet

- Electrical MethodlogyDocument8 pagesElectrical MethodlogyQuerty1234567No ratings yet

- Section 3A Transmission Lines PackageDocument10 pagesSection 3A Transmission Lines PackagealfredomatiasrojoNo ratings yet

- E 929048Document5 pagesE 929048Tariq ZuhlufNo ratings yet

- Earthing Philosophy: Dept./Section: - Electrical Engineering & DesignDocument6 pagesEarthing Philosophy: Dept./Section: - Electrical Engineering & DesignKamila WehbeNo ratings yet

- Universal Ac&dc Power Supply Em-30-09-08Document2 pagesUniversal Ac&dc Power Supply Em-30-09-08Scienscope SDN BHDNo ratings yet

- Typical Rod Gap ArresterDocument11 pagesTypical Rod Gap ArresterMuhammad Asif Iqbal100% (1)

- CBC Expander-160 UserDocument11 pagesCBC Expander-160 UserGerardo HernándezNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Acad AcrDocument2,458 pagesAcad AcrJames JamNo ratings yet

- Release Notes SYS600 9 4 FP2 Hotfix 1Document9 pagesRelease Notes SYS600 9 4 FP2 Hotfix 1PhuongNo ratings yet

- SYS600 94 254027 RNen A PDFDocument64 pagesSYS600 94 254027 RNen A PDFNhat Nguyen VanNo ratings yet

- SYS600 v. 9.4 Release AnnouncementDocument3 pagesSYS600 v. 9.4 Release AnnouncementNhat Nguyen VanNo ratings yet

- Tutorial AutoCad 2010 PDFDocument600 pagesTutorial AutoCad 2010 PDFSeptian Anggoro100% (1)

- SYS600 94 254027 RNen A PDFDocument64 pagesSYS600 94 254027 RNen A PDFNhat Nguyen VanNo ratings yet

- SYS600 v. 9.4 Release AnnouncementDocument3 pagesSYS600 v. 9.4 Release AnnouncementNhat Nguyen VanNo ratings yet

- Mach Do LuongDocument1 pageMach Do LuongNhat Nguyen VanNo ratings yet

- NOJA-5002-08 OSM15 310, OSM27 310, OSM38 300 and RC10 Controller User Manual - Print (Adobe) PDFDocument208 pagesNOJA-5002-08 OSM15 310, OSM27 310, OSM38 300 and RC10 Controller User Manual - Print (Adobe) PDFNhat Nguyen Van100% (1)

- TC Mba EvnDocument58 pagesTC Mba EvnNhat Nguyen VanNo ratings yet

- Neptune Ducati Rego Power Factor Controller ManualDocument15 pagesNeptune Ducati Rego Power Factor Controller ManualKu Bô0% (2)

- IEC 60726 Dry Type Power TransmformersDocument9 pagesIEC 60726 Dry Type Power TransmformersNhat Nguyen VanNo ratings yet

- Retrofit Nulec PDFDocument40 pagesRetrofit Nulec PDFNhat Nguyen VanNo ratings yet

- Siemens 3af 01Document24 pagesSiemens 3af 01Nhat Nguyen VanNo ratings yet

- Retrofit Nulec PDFDocument40 pagesRetrofit Nulec PDFNhat Nguyen VanNo ratings yet

- Engine ImmobilizerDocument51 pagesEngine ImmobilizerYargen Gonzalez100% (4)

- Electric Heating and WeldingDocument61 pagesElectric Heating and Weldingshuva rajNo ratings yet

- High Voltage PartsDocument80 pagesHigh Voltage PartsLollipopsuckerNo ratings yet

- MicrostripDocument51 pagesMicrostripbhakta_babiNo ratings yet

- 3KC ATC6300 and 6500 Transfer Control Device - Product OverviewDocument38 pages3KC ATC6300 and 6500 Transfer Control Device - Product Overviewcristhian mejiaNo ratings yet

- Annex 2 - Delivery Format - Task 2Document10 pagesAnnex 2 - Delivery Format - Task 2Diego Alejandro Cardona GiraldoNo ratings yet

- Ria 250Document8 pagesRia 250nebojsa_maletin100% (2)

- Space Radiant Energy ReceiverDocument5 pagesSpace Radiant Energy ReceiverfghjhgfNo ratings yet

- Connectors: Installation InstructionsDocument4 pagesConnectors: Installation InstructionsRenzzo Gomez ReatigaNo ratings yet

- Magnetic Moment: Classical Concept Review 27Document2 pagesMagnetic Moment: Classical Concept Review 27Md Rizwan AhmadNo ratings yet

- Device Electronics For Integrated Circuits 3rd Edition 1 PDFDocument270 pagesDevice Electronics For Integrated Circuits 3rd Edition 1 PDFKidane Kebede0% (1)

- A.02.612 FaeDocument8 pagesA.02.612 FaeFahmi IndrawanNo ratings yet

- UC3848Document9 pagesUC3848Sergio Daniel BarretoNo ratings yet

- Apxvf18s C A20Document2 pagesApxvf18s C A20Francisco RevecoNo ratings yet

- 4500 LM 36 W 840 FO L1277mm IP66: Dimension PhotometryDocument1 page4500 LM 36 W 840 FO L1277mm IP66: Dimension Photometryvino5evrNo ratings yet

- Chapter2 - AC To DC ConvertersDocument36 pagesChapter2 - AC To DC ConvertersYee Yen AppleNo ratings yet

- Rane Fpm44 Mixer ManualDocument4 pagesRane Fpm44 Mixer ManualtubegeekNo ratings yet

- KQ-330 Power Line Carrier Communication ModuleDocument3 pagesKQ-330 Power Line Carrier Communication Moduleservio2009No ratings yet

- ACT - 1 - Paper 1 ResonanceDocument27 pagesACT - 1 - Paper 1 ResonanceTridipta MishraNo ratings yet

- CATALOG SmartronDocument16 pagesCATALOG Smartronmuhamad noferdiNo ratings yet

- HP-PN71400-1 - Lightwave Signal Analyzers Measure Relative Intensity NoiseDocument24 pagesHP-PN71400-1 - Lightwave Signal Analyzers Measure Relative Intensity Noisesirjole7584100% (1)

- Transit Time EffectDocument16 pagesTransit Time EffectAshish SharmaNo ratings yet

- MCQDocument28 pagesMCQkrishgkkd3339No ratings yet

- Battery Sizing SS 06Document6 pagesBattery Sizing SS 06aanouar77No ratings yet

- Gordon Woodward: City of Coventry Single and Two Phase Generation and DistributionDocument4 pagesGordon Woodward: City of Coventry Single and Two Phase Generation and DistributionkodandaramNo ratings yet

- Electrical Wiring Diagram Rev 1 0 en 65022 4045504Document36 pagesElectrical Wiring Diagram Rev 1 0 en 65022 4045504nizarNo ratings yet

- Derek Pletcher, Frank C. Walsh (Auth.) - Industrial Electrochemistry-Springer Netherlands (1993) (005-075)Document71 pagesDerek Pletcher, Frank C. Walsh (Auth.) - Industrial Electrochemistry-Springer Netherlands (1993) (005-075)Fabi PerezNo ratings yet

- Thesis Proposal2Document8 pagesThesis Proposal2RynNo ratings yet