Professional Documents

Culture Documents

Annexure - Bolt Torque Calculation

Uploaded by

Darshan PanchalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure - Bolt Torque Calculation

Uploaded by

Darshan PanchalCopyright:

Available Formats

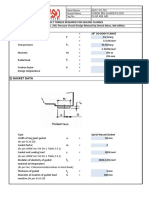

ANNEXURE 3

BOLT TORQUE CALCULATION

TECHFINIX ENGINEERING PVT.LTD.

Customer : JNK India PVT LTD Date: 08.01.19

Item: Bolt Torque Calculation for Piping flanges Rev.No: 0

Project: Cleaning Plant Skid

Doc No: TEM-2017_CPS_BTC_00 Sheet: 1

BOLT TORQUE CALCULATION FOR 4" FLANGE

Remark

DESIGN PRESSURE P Mpa(g) 0.9996

Design Temperature (Max.) Deg,C 150

Ext. Bolt Diameter D mm 19.05 3/4" UNC

Bolt Sectional Area A mm2 194.83832 ( From TEMA for Inch Series)

Bolt Root Diameter Dn mm 15.75

Number of Bolt N 8

Bolt Material SA 193 Gr. B8

Bolt allowable Stress @ design temperature Sy MPa 172.25264 As per ASME Section II, Part D

Operating Bolt Load WM1 Kg 1786.946 As per ASME Sec. VIII, Appendix-2

N 17529.94026

Gasket Seating Bolt Load WM2 Kg 10056.03 As per ASME Sec. VIII, Appendix-2

N 98649.6543

Maximum Load (Max. of Wm1 & Wm2) Wreg N 98649.6543

Safety Factor considered for above calculation 1.3

Force Required = Wreg x SOF / N Freq N 16030.56882 ( For Single Bolt)

Required Bolt Torque (K * D * Freq) T N-mm 61076.5 K= (Bolt constant) 0.2

Induced Stress in Bolt (Freq/A) Sinduced MPa 82.27626282

Bolt allowable Stress @ design temperature Sallowed MPa 172.25264

AS INDUCED STRESS IN THE BOLT IS LESS THAN ALLOWABLE STRESS, THE PROVIDED PRE-STRESS IS ADEQUATE

Thus bolt torque to be provided T N-m 61.08

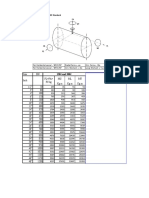

PTA SILO EQPT No. F6951 F 6952 PAGE 3

60 KL tank

TOP LIFTING TRUNNION CALCULATIONS :

MATERIAL : SA 36

L : Moment arm 80.00 mm

d1 : Outside Diameter of Trunnion Pipe 219.10 mm

t : Thickness of Trunnion Pipe = SCH 80 12.70 mm

d2 : Inside Diameter of Trunnion Pipe 193.70 mm

I : Moment Of Inertia = pi * (d1^4 - d2^4) / 64 = 44018358.97 mm4

Z : Section Modulus = I / (d1 / 2) = 401810.67 mm3

sy : Yield stress 227.76 Mpa

S : Allowable stress = 2/3 * yield stress 151.84 Mpa

Maximum longitudinal load per Trunnion = PL = #REF! N

Maximum transverse load per Trunnion = PT = #REF! N

Vessel Vertical

Longitudinal Moment ML = PL x L = #REF! N-mm

Bending stress in trunnion, Sb = ML / Z = #REF! Mpa

Vessel Horizontal

Circumferencial moment, Mc = PT x L = #REF! N-mm

Bending stress in trunnion, Sb = Mc / Z = #REF! Mpa

Maximum Bending Stress = #REF! Mpa

#REF!

WELD CALCULATION

Vessel Vertical

Longitudinal Moment ML = PL x L = #REF! N-mm

Section Modulus of weld Sw = pi * Ro^2 = 37702.889608 mm2

Shear stress in weld due to bending moment fs = ML / Sw = #REF! Mpa

Allowable shear stress = 0.4 * Yield Stress = 91.1 Mpa

Weld Size of trunnion to end plate = W1 > end plate thickness = 30 mm

Min. Weld Size of trunnion to pad = W2 = max {(fs / FS ) , 20mm) #REF! mm

Provided weld thickness at trunnion to pad (total groove + fillet) = w = 20 mm PAGE A4

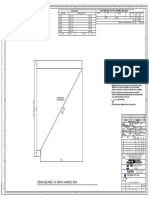

PTA SILO EQPT No. F6951 F 6952 PAGE 4

60 KL tank

TOP LIFTING TRUNNION LOADS

MATERIAL : SA 516 GR. 60

CASE 1 : HORIZONTAL LIFT WITH NO RADIAL LOAD

Maximum transverse load PT = N = #REF! N

Moment = M = PT * Moment Arm L = #REF! N-mm

CASE 2 : HORIZONTAL LIFT WITH RADIAL LOAD

Considering half angle formed by roap = 15 Deg.

Maximum transverse load PT1 = PT * cos 15 = #REF! N

Maximum Radial load PT1 = PT * sin 15 = #REF! N

Moment = M = PT1 * Moment Arm L = #REF! N-mm

CASE 3 : VERTICAL LIFT WITH NO RADIAL LOAD

Maximum Longitudinal load PL = N = #REF! N

Moment = M = PT * Moment Arm L = #REF! N-mm

CASE 4 : VERTICAL LIFT WITH RADIAL LOAD

Considering half angle formed by roap = 15 Deg.

Maximum Longitudinal load PL1 = PL * cos 15 = #REF! N

Maximum Radial load PL = PL * sin 15 = #REF! N

Moment = M = PT1 * Moment Arm L = #REF! N-mm

Above loading is checked for local stresses as per WRC 107 in PVELite and found safe.

PAGE A6

You might also like

- Calculating bolt torque for sealing a 30Document4 pagesCalculating bolt torque for sealing a 30souren1975No ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- U-V-673 - Manual Flange and GussetDocument8 pagesU-V-673 - Manual Flange and GussetDarshan PanchalNo ratings yet

- Bolt torque calculation for sealing flangesDocument6 pagesBolt torque calculation for sealing flangessouren1975No ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- LIFTING LUG Weld Check KGDocument4 pagesLIFTING LUG Weld Check KGjoerijiNo ratings yet

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanNo ratings yet

- Vortex Shedding Load On PipingDocument1 pageVortex Shedding Load On Pipingananyo_sengupta100% (1)

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- Hinge Calculation FormulasDocument2 pagesHinge Calculation FormulasamaNo ratings yet

- Design of Flanges - Loose Hub Type 2010Document58 pagesDesign of Flanges - Loose Hub Type 2010bakellyNo ratings yet

- Design of Flanges - Loose Type 2010Document53 pagesDesign of Flanges - Loose Type 2010bakellyNo ratings yet

- Heat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataDocument2 pagesHeat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataSteve MoonNo ratings yet

- Davit Cal 2251B Davit Arm CalculationDocument4 pagesDavit Cal 2251B Davit Arm Calculationnitin400No ratings yet

- Stress at Junction of Shell & HeadDocument13 pagesStress at Junction of Shell & HeadRey Fiedacan100% (1)

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- Asme BPVC II Part D Material Strengths 01Document7 pagesAsme BPVC II Part D Material Strengths 01bakellyNo ratings yet

- Youngs Modulus b3 2010Document2 pagesYoungs Modulus b3 2010bakellyNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Lug - On - FlangeDocument17 pagesLug - On - Flangeshaishav100% (1)

- Godrej & Boyce calculations for weld strength and size of RIL equipmentDocument10 pagesGodrej & Boyce calculations for weld strength and size of RIL equipmentSajal KulshresthaNo ratings yet

- BuoyancyDocument1 pageBuoyancyLcm TnlNo ratings yet

- Tutorial of WRC 107 For Lifting LugsDocument20 pagesTutorial of WRC 107 For Lifting LugsPeterWayNo ratings yet

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel TorradoNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Structural TrunnionDocument4 pagesStructural TrunnionecsalomNo ratings yet

- Dead Load Only From The PipeDocument5 pagesDead Load Only From The PipeНемања Караклајић100% (1)

- ASME B16.5 Class 150 & 300 Flanges Studbolt LengthDocument3 pagesASME B16.5 Class 150 & 300 Flanges Studbolt LengthbakellyNo ratings yet

- Calculator - U Tubes - HSA & QtyDocument4 pagesCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping Forcejosediaz141No ratings yet

- Weld Neck Flange Design - As Per Denis MorisDocument2 pagesWeld Neck Flange Design - As Per Denis Morissouren1975No ratings yet

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocument10 pagesFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiNo ratings yet

- Wind Calculation SheetDocument32 pagesWind Calculation SheetaauppalNo ratings yet

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocument4 pagesDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastav50% (2)

- Bolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Document2 pagesBolt Torque Calculation for Girth Flange-T-13311 - D2/D3: G * b * π * 2 g A Manoj MulikNo ratings yet

- Calculation sheet for M20 and M16 bolts torque and tensionDocument2 pagesCalculation sheet for M20 and M16 bolts torque and tensionUmesh ChamaraNo ratings yet

- Platform Cleat CalculationDocument1 pagePlatform Cleat Calculationmiteshpatel191No ratings yet

- Flat Plate - Roark & YoungDocument15 pagesFlat Plate - Roark & YoungPrasad Pingle0% (1)

- BlindDocument3 pagesBlindSajal KulshresthaNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Design of Tail LugDocument34 pagesDesign of Tail LugPrajwal Shetty100% (1)

- Design of Flanges - Weld Neck Type 2010Document58 pagesDesign of Flanges - Weld Neck Type 2010bakellyNo ratings yet

- Tailing Lug - 173004-05Document1 pageTailing Lug - 173004-05shazan100% (1)

- Trunnion Check Calculation (Onsite) : Page No: Contract No: System NoDocument2 pagesTrunnion Check Calculation (Onsite) : Page No: Contract No: System NoJ A S JAS0% (1)

- New - Reinforcement of NozzleDocument24 pagesNew - Reinforcement of NozzleVaniya GoelNo ratings yet

- Trunnion load calcsDocument4 pagesTrunnion load calcsChirag Shah50% (2)

- Annexure - Bolt Torque CalculationDocument4 pagesAnnexure - Bolt Torque CalculationDarshan Panchal100% (1)

- TRUNNION CALCULATION SHEETDocument1 pageTRUNNION CALCULATION SHEETAtty Atty100% (1)

- TRUNNION CHECK CN-0xxDocument2 pagesTRUNNION CHECK CN-0xxAkashNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- Hanger Clamp DesignDocument10 pagesHanger Clamp DesignVenkat gopalakrishna P100% (1)

- General Data: Bending StessesDocument8 pagesGeneral Data: Bending Stessesprajakt_pieNo ratings yet

- TrunnionDocument5 pagesTrunnionTanvirNo ratings yet

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit0% (1)

- Saddle Calc PD5500Document6 pagesSaddle Calc PD5500Vamsi SNo ratings yet

- Saddle Calc PD5500Document4 pagesSaddle Calc PD5500rsubramaniNo ratings yet

- Vanillin Crude B Column Mechanical DatasheetDocument3 pagesVanillin Crude B Column Mechanical DatasheetDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDocument4 pagesVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNo ratings yet

- Transportation - Bearing LoadDocument3 pagesTransportation - Bearing LoadDarshan PanchalNo ratings yet

- Pressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDocument3 pagesPressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDocument130 pagesVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDocument4 pagesVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDocument270 pagesVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDocument130 pagesVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNo ratings yet

- IBIC Nozzle Local LoadDocument1 pageIBIC Nozzle Local LoadDarshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalNo ratings yet

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDocument270 pagesVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Document1 pageLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- VDU Lift Stair Tower 302 - Material Summary - ListDocument4 pagesVDU Lift Stair Tower 302 - Material Summary - ListDarshan PanchalNo ratings yet

- Calculate Hertz Contact Stresses SafelyDocument5 pagesCalculate Hertz Contact Stresses SafelyDarshan PanchalNo ratings yet

- G8 en La Evaluación GeriátricaDocument12 pagesG8 en La Evaluación GeriátricaMIGUEL MORENONo ratings yet

- Castrol Molub Alloy 860Document3 pagesCastrol Molub Alloy 860tribolasNo ratings yet

- Jobs and OccupationsDocument2 pagesJobs and OccupationsSofia GaviriaNo ratings yet

- 02 - Motor PDFDocument80 pages02 - Motor PDFRenato Assis da SilvaNo ratings yet

- PID Symptoms, Causes, Diagnosis and TreatmentDocument13 pagesPID Symptoms, Causes, Diagnosis and TreatmentAnandila MaulinaNo ratings yet

- How Silence Affected Rivers During WWIDocument4 pagesHow Silence Affected Rivers During WWIAnthonyNo ratings yet

- Design MilestonesDocument1 pageDesign MilestonesRajNo ratings yet

- Respiratory Distress SyndromeDocument30 pagesRespiratory Distress SyndromeDennis MiritiNo ratings yet

- Afr - E100 Service ManualDocument84 pagesAfr - E100 Service ManualMatija Ritoša0% (1)

- Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument6 pagesSafety Data Sheet: 1. Chemical Product and Company IdentificationNguyễn Thị ThúyNo ratings yet

- CompassionDocument1 pageCompassionmina bacayNo ratings yet

- LO Grade 11 Term 3 Week 6 - 2020Document4 pagesLO Grade 11 Term 3 Week 6 - 2020NoluthandoNo ratings yet

- Electrol Roll 2010Document209 pagesElectrol Roll 2010Shanawaj AlamNo ratings yet

- Relationship between cytokines and hazards in waste workersDocument8 pagesRelationship between cytokines and hazards in waste workersSalsa BilaNo ratings yet

- Certificate of Electrical Inspection For Temporary Power ConnectionDocument1 pageCertificate of Electrical Inspection For Temporary Power ConnectionKierbien Kile GarciaNo ratings yet

- Service News: Installation of Stage 2 Long MK Ii Onzr4 Priority: Iv Gac: 48 Ecb Aif 1357/C1 Date: 17/07/2004Document30 pagesService News: Installation of Stage 2 Long MK Ii Onzr4 Priority: Iv Gac: 48 Ecb Aif 1357/C1 Date: 17/07/2004Muhammad HardiusNo ratings yet

- Enhanced Hybrid English 10 Q1 M2Document13 pagesEnhanced Hybrid English 10 Q1 M2VNo ratings yet

- Preparing Equipment CalibrationDocument1 pagePreparing Equipment CalibrationGlobal QualityNo ratings yet

- User Manual of YKD-9122-2022.6Document18 pagesUser Manual of YKD-9122-2022.6Dr Ibrahima BaldeNo ratings yet

- First Aid Basics and Vital Signs EssentialsDocument18 pagesFirst Aid Basics and Vital Signs EssentialsJoyce Anne Tuala YabutNo ratings yet

- 290 Sunaura TaylorDocument9 pages290 Sunaura Taylorapi-249278978No ratings yet

- Business Plan: Virgin of Carmel High School, Inc. Tiwi AlbayDocument12 pagesBusiness Plan: Virgin of Carmel High School, Inc. Tiwi AlbayCamille JerusalemNo ratings yet

- Sharp r-203bw 209bk 220bwDocument40 pagesSharp r-203bw 209bk 220bwNeida MorenoNo ratings yet

- Obw - Jeeves - and - Friends - Short - Stories 2Document13 pagesObw - Jeeves - and - Friends - Short - Stories 2Victoria AvisNo ratings yet

- Chemical and Enzymatic Synthesis of LanthioninesDocument15 pagesChemical and Enzymatic Synthesis of LanthioninesSam SonNo ratings yet

- An Overview of The Rabbit Industry in The PhilippinesDocument3 pagesAn Overview of The Rabbit Industry in The Philippinesallan variasNo ratings yet

- 1 - A Framework For Maternal and Child Health NursingDocument3 pages1 - A Framework For Maternal and Child Health NursingShanealle Athaliah Magsalay CuaNo ratings yet

- 0083 B 95 A 0 CF 2 D 5157 B 98 F 2 D 9Document2 pages0083 B 95 A 0 CF 2 D 5157 B 98 F 2 D 9RutChristinNo ratings yet

- Brain TheoryDocument41 pagesBrain TheoryNikhil NigamNo ratings yet

- Student Risk Assessment Music RoomDocument7 pagesStudent Risk Assessment Music RoomAS Media Column BNo ratings yet