Professional Documents

Culture Documents

Kanban Cheat Sheet PDF

Uploaded by

stewatiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kanban Cheat Sheet PDF

Uploaded by

stewatiaCopyright:

Available Formats

UK.LINKEDIN.

COM/IN/SOLUTIONEER

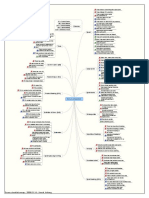

KANBAN CHEAT SHEET

!

!

! @CAZA_NO7

@IANCARROLLUK

!

!

FIRST EDITION

!

07968 399947

Kanban is a highly tactile and visible approach to orchestrating work across IAN@SOLUTIONEERS.CO.UK

organisations. It works at the team level, straddling departmental boundaries (aka

Silo’s) as a highly effective organisational change tool. The ‘Kanban effect’ results in WWW.IANCARROLL.COM

profound changes in the behaviours and interactions of individuals, teams, and

sometimes entire organisations.

PRINCIPLES

1 2 3 6 • Start with what you do now

• Agree to pursue incremental,

evolutionary change

• Respect the current process, roles,

responsibilities & titles

CORE PROPERTIES

• Visualise the workflow, make all work

visible

• Limit Work-In-Process (WIP)

• Measure and Manage Flow

• Make Process Policies Explicit

• Improve Collaboratively (using

5

4 models/scientific method)

1• Visualise the BACKLOG. Organise by demand 4• Use LIMITS to subordinate activities to

type or by product feature area. For multiple bottlenecks and improve flow. For individuals USUAL OUTCOMES

stakeholders some teams organise by new to Kanban, when limits are hit the hardest

stakeholder. For Iteration focused teams thing is to not blow the limit (essentially stopping • Release value earlier

organise the backlog into iterations. work) and going downstream to help unblock • Value discovery through

the pipeline. Limits help you to stop starting and accelarated learning

2• The NEXT column is an extremely powerful start finishing. • Maximise throughput

mechanism for selecting the next items to be • Reduce multi-tasking & task

delivered. Powerful due to the conversations 5• If you use an EXPEDITE lane make sure you have

switching

and clarity on value. Extremely useful when a row limit of 1 card in play at anytime. If you

dealing with multiple stakeholders with don’t limit this guess what will happen? ;) Cards • Reduced variation, improved

conflicting perceptions on priorities. Use this in this lane trump the priority of all other work predictability

mechanism for sustainable long-term items. • Create ‘safety’ for the team

organisation change. • Open up capacity absorbed in

6• In Kanban we visualise the whole pipeline wasteful activity

3• DONE columns are used as queues for two including UAT, DEPLOY, MEASURE. This is often

• Improved collaboration by cutting

main purposes – 1) to remove ‘chuck it over the an effective way to bring together dev and IT

wall syndrome’ and thus drive better Ops teams. Measure is a critical step in through org silo’s

collaboration and induce a pull, and 2) avoid understanding if our anticipated value was • Clarify macro & micro prioritisation

work starvation downstream and thus recognised, or whether we need to feedback

encourage flow. into the backlog. See Eric Ries cycle or Deming

cycle.

CONCEPTS TIPS METRICS

• How we visualise the world dominates how we • Keep the card wall TIDY!!! It’s a system not a • CFD – Cumulative Flow Diagram

perceive the world notice board. Straighten cards, redraw faded • SPC Chart – Statistical Process

• Pull work across the wall, don’t push it lines, refresh tatty icons and avatars. Control Chart aka Control Chart

• Focus on unblocking blocked work instead of • Don’t change the card wall design without

buy-in and support from the team. It’s not your

• Cycle Time, Lead Time, Waiting time

starting more work

• Make all work visible irrespective of ‘type’ card wall it is the team’s card wall. • See http://iancarroll.com for

• Stop starting, start finishing • Use arrow icons to show movement on the templates and samples of these.

• Use column limits to limit work in process to board and ‘reset’ them after each stand-up

increase flow • Laminate, laminate, laminate!

• Nothing has value until it’s live • Use ‘classes of service’ to service tech debt or

• All work before live is cost with no value other other types of demand such as BAU

than learning • Know the difference between efficiency and BACKGROUND & FURTHER READING

• Walk the wall (right to left) at the daily stand-ups effectiveness – don’t deliver more of the wrong • Theory of Constraints, Eliyahu M.

focusing on finishing work thing quicker! Goldratt

• Value trumps flow, flow trumps waste elimination • Create a ‘super-tribe’ by theming your card • Kanban, David Anderson

• De-coupled cadences – release on demand, wall

• Get your stakeholders to run some stand-ups

• Queuing Theory, Little’s Law

plan on demand, real-time retro’s, real-time

showcase. and rotate on a daily basis who hosts the stand- • Systems Thinking, John Seddon

• Encourage swarming to resolve blockers and up • Lean Software Development – Mary

bottlenecks • For teams new to Kanban stick rigidly to the & Tom Poppendieck

• ‘Stop the line’ defect resolution rules initially in line with Dreyfus Model for skills • Toyota Production System (TPS), W.

• Continuous improvement aquisition

Edwards Deming

• End-to-end flow is more important than individual MYTHS

activity

• The Lean Start-up, Eic Ries

• No need for planning as we now use cycle time

• Use NEXT column to have the right conversations instead of velocity

about value and prioritisation • No need for estimation in Kanban

IANCARROLL.COM

• Items to the right of the card wall have higher • Cards can only go one way (left to right)

priority than cards to the left • Limits cannot be broken – it’s the LAW!

• Kanban overlays on top of your current practices • To the left of the ‘select’ (prioritisation) column

– it doesn’t replace them. is not the delivery team’s concern

• We don’t do iterations in Kanban This work is licensed under the Creative Commons Attribution-

• Kanban is all about eliminating waste NonCommercial-ShareAlike 3.0 Unported License.

To view a copy of this license, visit

http://creativecommons.org/licenses/by-nc-sa/3.0/.

You might also like

- ScrumMaster Training BookDocument125 pagesScrumMaster Training Bookinkafan100% (10)

- Ethereum White Paper Made SimpleDocument29 pagesEthereum White Paper Made SimpleSamir BennaniNo ratings yet

- AmazonDocument13 pagesAmazonMahima Mishra Dubey100% (1)

- Single Code Page Conversion Guide to UnicodeDocument22 pagesSingle Code Page Conversion Guide to Unicodezahid9486No ratings yet

- Doing Agile Versus Being AgileDocument6 pagesDoing Agile Versus Being AgileRefineM Project Management Consulting100% (1)

- Agile Scrum Cheat SheetDocument1 pageAgile Scrum Cheat Sheetashisamk180% (5)

- Effective RetrospectivesDocument50 pagesEffective Retrospectivesopenid_fHmBEkzYNo ratings yet

- Agile Scrum GlossaryDocument5 pagesAgile Scrum GlossaryCarolina Becerra TellezNo ratings yet

- Scaled Agile Exam Study GuideDocument2 pagesScaled Agile Exam Study GuideGeorge MunteanuNo ratings yet

- PMO A Step by Step Guide For Implementing AgileDocument14 pagesPMO A Step by Step Guide For Implementing AgileOkan Cerrah100% (1)

- Descartes Error PDFDocument15 pagesDescartes Error PDFstewatia100% (2)

- V.B Agile Program Management EB043LTRENDocument12 pagesV.B Agile Program Management EB043LTRENSai Sunil Chandraa100% (2)

- Agile Project Excel TemplateDocument37 pagesAgile Project Excel TemplateAlexandruDaniel50% (2)

- Implementing ScrumbanDocument13 pagesImplementing Scrumbankukuduxu100% (2)

- Advanced Roadmaps Vs Jira AlignDocument6 pagesAdvanced Roadmaps Vs Jira AlignfabioosNo ratings yet

- WBS Estimation and Scheduling PDFDocument61 pagesWBS Estimation and Scheduling PDFstewatiaNo ratings yet

- Scrum GuideDocument80 pagesScrum Guidewaznedane1No ratings yet

- Agile & Scrum Cheat SheetDocument1 pageAgile & Scrum Cheat SheetozukecaloNo ratings yet

- White Paper SAFe-4.6 Introduction-FINAL PDFDocument28 pagesWhite Paper SAFe-4.6 Introduction-FINAL PDFjpalanaNo ratings yet

- The Agile Business Analysis Scrum EBrochure 1Document6 pagesThe Agile Business Analysis Scrum EBrochure 1pritamNo ratings yet

- SBOK Guide Glossary - SCRUMstudyDocument26 pagesSBOK Guide Glossary - SCRUMstudyRomarMroNo ratings yet

- 5 Step Roadmap For Implementing Agile ScrumDocument7 pages5 Step Roadmap For Implementing Agile ScrumKPNo ratings yet

- Enterprise Scrum Definition PDFDocument77 pagesEnterprise Scrum Definition PDFluiskriegNo ratings yet

- SAFe PI Planning Simulation Handout (5.1)Document9 pagesSAFe PI Planning Simulation Handout (5.1)Nadia DolbaraevaNo ratings yet

- ALL Quality Management PPT For MBADocument188 pagesALL Quality Management PPT For MBAsunil kumarNo ratings yet

- SAFe SimplifiedDocument1 pageSAFe SimplifiedCarlos Rosas100% (2)

- Space MathsDocument192 pagesSpace MathsstewatiaNo ratings yet

- Kubectl Commands Cheat Sheet PDFDocument1 pageKubectl Commands Cheat Sheet PDFJade Devin CabatlaoNo ratings yet

- Iteration Planning Guide: What Is It? Right Sizing Backlog ItemsDocument2 pagesIteration Planning Guide: What Is It? Right Sizing Backlog ItemsAdetya Gupta100% (1)

- AgileDocument29 pagesAgileRohit Khurana100% (1)

- Agile Scrum WorkshopDocument7 pagesAgile Scrum WorkshopNitin Singh Rajput100% (2)

- RXCamView-Mobile APP User ManualDocument7 pagesRXCamView-Mobile APP User ManualNigromante_0125% (4)

- ScrumDocument26 pagesScrumfatih kilicNo ratings yet

- Agile Metrics That MatterDocument20 pagesAgile Metrics That Matterbrianhanly100% (1)

- Definition of DoneDocument2 pagesDefinition of Doneprateek_prakash_2100% (1)

- PSPO Sample QuestionsDocument22 pagesPSPO Sample QuestionsJean BaptisteNo ratings yet

- SAFe RTE 5.0 Flashcards - QuizletDocument2 pagesSAFe RTE 5.0 Flashcards - QuizletIero tr0% (1)

- Agile Estimating 2.0 Cheat SheetDocument1 pageAgile Estimating 2.0 Cheat SheetPeter SaddingtonNo ratings yet

- Scrum Mechanical ProjectDocument134 pagesScrum Mechanical Projectpquiroga2No ratings yet

- Agile Maturity Matrix For TeamsDocument45 pagesAgile Maturity Matrix For TeamsJasdev Singh100% (1)

- SIWES ReportDocument23 pagesSIWES ReportDaniel Abara93% (15)

- Whitepaper Agile MetricsDocument9 pagesWhitepaper Agile MetricsFrancisco AyalaNo ratings yet

- The Agile Buddy Guide PDFDocument17 pagesThe Agile Buddy Guide PDFTxokol Karvalhium100% (1)

- Software Architecture in PracticeDocument104 pagesSoftware Architecture in PracticeJuan Sebastián SánchezNo ratings yet

- Estimating Business Value Agile2014Document23 pagesEstimating Business Value Agile2014redpiyoNo ratings yet

- Release Planning Guide ChecklistDocument2 pagesRelease Planning Guide ChecklistEric_J_Danker_9701No ratings yet

- Cisco VPN Client Administrator GuideDocument226 pagesCisco VPN Client Administrator GuideLong NguyễnNo ratings yet

- Agile Methodology: Introduction, ContentsDocument17 pagesAgile Methodology: Introduction, ContentsAMRUTHA RNo ratings yet

- Introduction To Scrum: Bob SchatzDocument41 pagesIntroduction To Scrum: Bob SchatzNim Ra100% (1)

- Scrumban DeckDocument10 pagesScrumban DeckSaravanan100% (1)

- Scrum Checklist All PDFDocument1 pageScrum Checklist All PDFvsrajeshvs0% (1)

- Agile Methodology in a NutshellDocument13 pagesAgile Methodology in a NutshellJaiNo ratings yet

- Agile Scaling ModelDocument31 pagesAgile Scaling ModelTan Keng Chow100% (1)

- Scrum Assessments - OpenDocument12 pagesScrum Assessments - OpenMeddah MehdiNo ratings yet

- A Consultant's Perspective by Javad AhmadDocument19 pagesA Consultant's Perspective by Javad AhmadAgilePK100% (1)

- Master MoSCoW Prioritisation and Protect Delivery QualityDocument13 pagesMaster MoSCoW Prioritisation and Protect Delivery QualityPercy SuarezNo ratings yet

- Agile (SCRUM) : Basics & Adaption: Prepared by Helen IoffeDocument29 pagesAgile (SCRUM) : Basics & Adaption: Prepared by Helen IoffeavintasNo ratings yet

- Scrum Revealed by International Scrum InstituteDocument55 pagesScrum Revealed by International Scrum InstituteWalter MacuadaNo ratings yet

- Kanban cheat sheet for optimizing workflowDocument2 pagesKanban cheat sheet for optimizing workflowGG DNo ratings yet

- Agile Tools Whitepaper: The Good, the Bad and the UglyDocument21 pagesAgile Tools Whitepaper: The Good, the Bad and the UglySatish987No ratings yet

- 10 Tips For Your Scrum Master InterviewDocument14 pages10 Tips For Your Scrum Master Interviewegarciac77100% (1)

- Agile Maturity Model Applied To Building and Releasing SoftwareDocument8 pagesAgile Maturity Model Applied To Building and Releasing SoftwareCarlos CambraNo ratings yet

- Agile Way of ThinkingDocument12 pagesAgile Way of ThinkingNilofer ShaikNo ratings yet

- Introduction To Agile and Scrum: Simon BakerDocument73 pagesIntroduction To Agile and Scrum: Simon BakerachilleslawNo ratings yet

- RACI in ScrumDocument3 pagesRACI in ScrumMario Bryan RodzNo ratings yet

- Joe's Unofficial Scrum CheckList V11Document9 pagesJoe's Unofficial Scrum CheckList V11Raluca Andreea TurcuNo ratings yet

- Darshan Institute of Engineering & Technology: History of Wireless CommunicationDocument30 pagesDarshan Institute of Engineering & Technology: History of Wireless CommunicationabcdefgNo ratings yet

- Securing Web Services With Mod Security 2.0Document17 pagesSecuring Web Services With Mod Security 2.0chn5800inNo ratings yet

- Coach Survival Guide PDFDocument62 pagesCoach Survival Guide PDFstewatiaNo ratings yet

- PVPDocument12 pagesPVPstewatiaNo ratings yet

- Darshan Institute of Engineering & Technology: History of Wireless CommunicationDocument30 pagesDarshan Institute of Engineering & Technology: History of Wireless CommunicationabcdefgNo ratings yet

- StudyGuide Ver BSG4 ORIGINAL PDFDocument44 pagesStudyGuide Ver BSG4 ORIGINAL PDFstewatiaNo ratings yet

- 3d2b Salesforce Partneredition Overview enDocument25 pages3d2b Salesforce Partneredition Overview enstewatiaNo ratings yet

- Artofdatascience Sample PDFDocument20 pagesArtofdatascience Sample PDFstewatiaNo ratings yet

- HaidtEmotionalDog PDFDocument21 pagesHaidtEmotionalDog PDFstewatiaNo ratings yet

- User ManualDocument13 pagesUser ManualsitiNo ratings yet

- Artofdatascience SampleDocument20 pagesArtofdatascience SamplechrischovNo ratings yet

- Top 35 Mitigations 2012Document3 pagesTop 35 Mitigations 2012stewatiaNo ratings yet

- Instinct: Machine ConsciousnessDocument3 pagesInstinct: Machine ConsciousnessstewatiaNo ratings yet

- De Waal PDFDocument12 pagesDe Waal PDFstewatiaNo ratings yet

- Itsm Soa SampleDocument18 pagesItsm Soa SamplestewatiaNo ratings yet

- MS SQL ServerDocument36 pagesMS SQL ServerstewatiaNo ratings yet

- ADDM Datacenter OptimizationDocument16 pagesADDM Datacenter OptimizationstewatiaNo ratings yet

- BMC Remedy SolutionsDocument4 pagesBMC Remedy SolutionsstewatiaNo ratings yet

- Load Balancing 101 Nuts BoltsDocument6 pagesLoad Balancing 101 Nuts BoltsMartin SaucierNo ratings yet

- Engineering Seminar TopicsDocument4 pagesEngineering Seminar Topicsmahek19579328No ratings yet

- A Comparative Study On Machine Learning Techniques Using Titanic DatasetDocument6 pagesA Comparative Study On Machine Learning Techniques Using Titanic Datasetfitoj akaNo ratings yet

- Digital Innovation and Transformation - An Institutional PerspectiveDocument10 pagesDigital Innovation and Transformation - An Institutional PerspectiveGabriele12No ratings yet

- JAVA UNIT-1 Question BankDocument4 pagesJAVA UNIT-1 Question BankAmaan ShaikhNo ratings yet

- Ancient God Deadlift RoutineDocument2 pagesAncient God Deadlift Routinebasuthker raviNo ratings yet

- A.V AidsDocument19 pagesA.V AidsRohini RaiNo ratings yet

- ZTE Cam PDFDocument2 pagesZTE Cam PDFmarsudi.kisworo7533No ratings yet

- ZTE UMTS Cell Selection and ReselectionDocument83 pagesZTE UMTS Cell Selection and Reselectionsudhir_gsrc100% (1)

- Pointers To Study 2nd Grading Grade 78 1Document8 pagesPointers To Study 2nd Grading Grade 78 1Val Alec TuballaNo ratings yet

- Francis - Onyemem - SAP FICO SMEDocument4 pagesFrancis - Onyemem - SAP FICO SMEMohammedNo ratings yet

- RC4 Basics PresentationDocument14 pagesRC4 Basics PresentationKiruthikaBalasubramanianNo ratings yet

- Unit-3 Activity Planning and Risk Management The Objectives of Activity Planning Feasibility AssessmentDocument21 pagesUnit-3 Activity Planning and Risk Management The Objectives of Activity Planning Feasibility AssessmentzoeNo ratings yet

- The Advantages of Online Shopping PlatformDocument2 pagesThe Advantages of Online Shopping PlatformNor SyahirahNo ratings yet

- Arduboy API ReferenceDocument72 pagesArduboy API ReferencejossjxmNo ratings yet

- CFD LectureDocument19 pagesCFD LectureRobi Afrizal100% (1)

- COMO LIMPIAR CP PM CS 5.5Document10 pagesCOMO LIMPIAR CP PM CS 5.5Franco AlarcónNo ratings yet

- Model-3631 GWS2 C1410Document2 pagesModel-3631 GWS2 C1410wsorucoNo ratings yet

- Experiment No.5Document11 pagesExperiment No.5Kshitij DudheNo ratings yet

- IC Block Diagrams & SpecsDocument14 pagesIC Block Diagrams & SpecsChaitanya ParaskarNo ratings yet

- UM - RAN-15 - RNC-08 ZXWR RNC (V3.11.10) Test Management Operation Guide V1.0Document95 pagesUM - RAN-15 - RNC-08 ZXWR RNC (V3.11.10) Test Management Operation Guide V1.0ahmad alsheik ahmadNo ratings yet

- Reactor FuncionamientoDocument24 pagesReactor FuncionamientoDaniel BahamondesNo ratings yet

- The Grillage Analogy Method for Bridge AnalysisDocument12 pagesThe Grillage Analogy Method for Bridge AnalysisKashiPrakash DambalNo ratings yet