Professional Documents

Culture Documents

Danfoss Erc101

Uploaded by

farazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Danfoss Erc101

Uploaded by

farazCopyright:

Available Formats

EN-Instruction sheet

ERC 101 kit

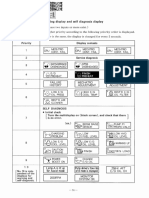

Installation Display / operation

yy Insert the ERC 101 in to the cabinet Press BRIEFLY to defrost

yy Attach the clips to each side of the ^

Press the button

ERC 101 5 seconds to ON/OFF

Press UP/DOWN to

^ adjust setpoint

The green def symbol is list Flasching

when in defrost mode Press any button to acknowlege

Technical highlights Input/output

Press: variable direct function defrost Press: tempearture setpoint

yy Pre-programmed - ready to use Sub function: BACK sub function: UP

yy Compressor protection against instable voltage DO ERC 101

yy High condensing temperature protection 1(o1) DO1: controller

Press: upper left button BACK

yy Compact design - total depth is only 46 mm 2 L UL: 16FLA 72LRA, to return to parameter group ^ Press and hold for 5 seconds

3 N to enter the menu

yy Real 16 A power relay - up to 2.5 HP compressors IEC: 16(16)A ^

To select: press the lower Press: UP/DOWN to scroll

yy Automatically controlled brightness of large-size LED display Input/ Cabinet Evapor. Conden. through the menu

left button (OK)

yy Fully compatible with flammable refrigerants (R290) Sensors Sensors Sensors Sensors

yy Moisture protection (housing & coating) S1

yy Advanced defrost algorithms S2 100-240VAc +/-10% 50/60Hz Press: variable direct functionON/OFF Press: tempearture setpoint

Sub function: OK sub function: DOWN

OT 55

Technical specifications 1 2 3 DO & Input/Sensors

Operation menu

FEATURES DESCRIPTION S1 S2

100 V AC - 240 V AC 50-60 Hertz, automatic switch Press 5 sec both right buttons

Power supply to access the menu

mode power supply

Rated power Less than 0.5 W 1) Parameter groups

Dimensions mm ^

Danfoss NTC Air temperature probes ^

2 analogue inputs Danfoss NTC Condenser ^ Scroll through the

^ menu group

temperature probes (optional)

36.5 mm

^

28 mm

Output compressor 16 (16 A) EN60730; 16 (16 A) CQC; 71 mm

^ 30 mm

relay 16 A (16 A FLA / 72 A LRA) UL60730

LED display, 3 digits, decimal point and 47.25 mm Higher left button to exit

Display rear mounting

multi functionality icons, °C scale 78.25 mm 51.25 mm Lower left button to confirm

Operating

0 °C to 55 °C, 93% rH

conditions 2) Parameter name

Storage conditions -40 °C to 85 °C, 93% rH

Measurement range -40 °C to 85 °C ^ Scroll through the

^ parameters group

Front: IP65 / Rear: water and dust protection

Protection corresponds to IP31, accessibility of connectors limit

rear part rating to IP00

Higher left button to exit

Pollution degree III 3) Parameter value

Environmental (can be mounted inside a refrigerated cabinet), Lower left button to confirm

non-condensing

Resistance to heat

Category D (UL94-V0)

& fire

EMC category Category I

IMPORTANT NOTE

Compressor relay: The inputs are not galvanic separated and are connected directly to

Operating cycles more than 175,000 at full load ((16 A) 16 A) the mains supply! For that reason, door-switches, sensors as well as the cables must fulfil the reinforced

insulation requirements.

R290/R600a: EN/IEC 60079-15:2005,

Glow wire according to EN/IEC 60335-1,

Approvals IEC/EN 60730, UL60730, NSF, CQC, GOST R 60730 Safety info

Note: These approvals are only valid when using the Risk of electrocution!

accessories listed in this document For mounting: do not connect mains power until the controller is correctly mounted.

For unmounting: disconnect the power supply before unmounting.

© Danfoss | DCS (ZA) | 2016.03 DKRCC.EI.RL0.A4.02 | 520H10864 1

EN-Instruction sheet ERC 101 kit

Parameters

Menu Parameters Cod Description Min Max Unit De- Menu Parameters Cod Description Min Max Unit De-

fault fault

Setpoint Stp Setpoint -50 80 C 2 Assignments Assignments of inputs and outputs

Thermostat tHE Thermostat settings S2 Application S2A Application to be controlled with Sensor nC Con - nc

C. (nC=Not Connected, Sco= Temp control,

Setpoint adjustment SPr Current setpoint adjustment value diF * SPr 0.0 1.0 - 0.0 EuA= Evap temp, Con=Cond temp {condenser

ratio cleaning})

Differential diF Thermostat differential 0.0 20.0 K 2.0 DO1 configuration o1C Relay output 1. compressor (CoP) CoP HeT - CoP

Air temperature tAD Air Temp Adjust 0.0 20.0 K 0 2. Heater HeT

adjust Password level1 PS1 Shop owner Most common parameters 0 999 - 0

Alarm ALA Alarm setting Password level2 PS2 Service technician all parameters with read 0 999 - 0

High temperature HAt Alarm is activated above this temperature -50.0 80.0 C 15.0 permission and possibility to change a

alarm (Celsius ) number of parameters

Low temperature LAt Alarm is activated below this temperature -50.0 80.0 C -50.0 Service Service

alarm (Celsius ) Voltage value uAC Current main power supply voltage 0 270 V AC -

Compressor CoP Compressor Setting Relay 1 counter rL1 Thousands of cycles of compressor relay since 0 999 1000 -

Min run time Crt Minimum time compressor must run 0-30 0 30 min 0 manufacture

minutes Interval counter int Compressor run time since last defrost 0 999 min -

Min Stop time CSt Minimum time compressor must idle 0-30 0 30 min 0 Defrost time counter dnt Duration of last defrost cycle [min] 0 999 min -

minutes

Firmware version Fir Danfoss software version number - - - -

Max OFF time Cot Maximum time compressor must idle 0-480 0 480 min 0

minutes Hardware version HAr Danfoss hardware version number - - - -

Error run time Ert Compressor run time if temperature sensor is 0 60 min 0

not working (0-60 minutes )

Error stop time ESt Compressor stop time if temperature sensor is 0 60 min 0 Problem solving

not working (0-60 minutes )

Minimum cut-in uLi When compressor is OFF: 0 270 V AC 0 Problem Probable cause Remedy

voltage lowest compressor start voltage (0-270 V)

Waiting for compressor delay timer Check CoP->CSt

Minimum cut-out uLo When compressor is ON: 0 270 V AC 0 Compressor does not start

voltage lowest operation voltage (0-270 V) Line voltage to compressor too low or too high Check CoP->uLi, uLo, uHi

Maximum voltage uHi When compressor is ON: 0 270 V AC 270 E01: Sensor "S1" defective Replace sensor

E01 or E02 is shown on display

highest operation voltage (0-270 V) E02: Sensor "S2" defective Replace sensor

Power ON delay Pod Delay in seconds between power ON & 0 300 Sec 180 Display alternates between "Con" and Condenser temperature exceeds the Clean condenser,

compressor being activated temperature temperature set in condenser settings menu Check Con->CAL, CbL

Defrost dEF Defrost Setting Display alternates between "Hi" and Temperature too high Check ALA->HAt

Defrost type dFt No: defrost function is disabled, no nat - nat temperature

nat: OFF-cycle defrost (natural defrost) Display alternates between "Lo" and Temperature too low Check ALA-> LAt

Terminating temp dtt Temp at which defrost stop 0 25 C 7 temperature

(evap temperature or cabinet temperature)

Def Min Interval dii The minimum time in hours between the start 0 96 hours 6

of each defrost cycle

Def Max Interval dAi The maximum time in hours between the 0 96 hours 7

start of each defrost cycle

Def Min time dit The minimum duration of a defrost cycle 0 240 min 10

in minutes

Def Max time dAt The maximum duration of a defrost cycle 0 480 min 30

in minutes

Condenser Con Condenser protection settings

Protection

Condenser Alarm CAL If condenser sensor exceeds this temperature, 0 85 C 75

Limit alarm is activated

Condens er Block CbL If this temperature is exceeded, compressor 0 85 C 85

Lim it will be stopped

Condenser OK limit CoL Temperature at which compressor may start 0 85 C 60

after a stop due to exceeding CbL

Condenser Low Temp CLL Temperature below which the compressor is -50 20 C -5

not allowed to start

Display diS Display setting

Lock-time After dLt Display lock time after defrost (0-60 min) 0 60 min 5

defrost

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DCS (ZA) | 2016.03 DKRCC.EI.RL0.A4.02 | 520H10864 2

You might also like

- Elmeasure Basic Meter Alphanor Programming GuideDocument1 pageElmeasure Basic Meter Alphanor Programming GuideP.p. Arul IlancheeranNo ratings yet

- HP11 Manual 4.0Document1 pageHP11 Manual 4.0Mauricio Plaza SalinasNo ratings yet

- Motorola/Symbol Terminal Cold and Warm Boot GuideDocument7 pagesMotorola/Symbol Terminal Cold and Warm Boot GuideHilber Ricardo MoyanoNo ratings yet

- SB53 Service ManualDocument26 pagesSB53 Service ManualpieterNo ratings yet

- Tork 1101 ManualDocument1 pageTork 1101 ManualJose Antonio Cortes LopezNo ratings yet

- Print Section 2 Yamatake SFC For DSTJ TransmittersDocument8 pagesPrint Section 2 Yamatake SFC For DSTJ TransmittersaloordominicNo ratings yet

- Mypin: Resistance Controller User ManualDocument1 pageMypin: Resistance Controller User ManualMarcos Luiz AlvesNo ratings yet

- NEC SV9100 Basic User GuideDocument2 pagesNEC SV9100 Basic User Guidefaizan4033No ratings yet

- MYPIA Weight IndicatorDocument2 pagesMYPIA Weight IndicatorGrey MouseNo ratings yet

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptionnajdo1No ratings yet

- Kanto Seiki Support ManualDocument1 pageKanto Seiki Support Manualsunhuynh67% (3)

- GigasetDocument32 pagesGigasetLokesh NamdeoNo ratings yet

- ts20 enDocument2 pagests20 enbobNo ratings yet

- ts20-enDocument2 pagests20-enbobNo ratings yet

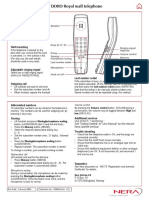

- Using DORO Royal Wall Telephone: ConnectionDocument1 pageUsing DORO Royal Wall Telephone: ConnectionBhavin DoshiNo ratings yet

- Series: Ise4 Zse4Document10 pagesSeries: Ise4 Zse4Josu UriarteNo ratings yet

- FT-891 Quick Manual: (PWR/LOCK) Key RF/SQL KnobDocument2 pagesFT-891 Quick Manual: (PWR/LOCK) Key RF/SQL KnobLoop AntenasNo ratings yet

- Chapter 3: Keys and Displays: 1/32 DIN (PM3)Document2 pagesChapter 3: Keys and Displays: 1/32 DIN (PM3)Henry WildNo ratings yet

- Owner's Manual: Electronic Hand DrumDocument22 pagesOwner's Manual: Electronic Hand Drummiguel_núñez_54No ratings yet

- ContentDocument22 pagesContentNemesio LopezNo ratings yet

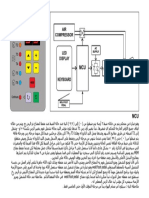

- AIR Compressor: Power T1 T2 T3 T4 T5 T6Document1 pageAIR Compressor: Power T1 T2 T3 T4 T5 T6Mouhanad HalabiNo ratings yet

- Mypin LM PDFDocument2 pagesMypin LM PDFRennan Henrique0% (1)

- Gigaset A59H: The Handset at A GlanceDocument20 pagesGigaset A59H: The Handset at A Glanceriusu2No ratings yet

- Smartouch User ManualDocument14 pagesSmartouch User ManualGregNo ratings yet

- 6.M - Georgin F - IngDocument4 pages6.M - Georgin F - IngclauNo ratings yet

- Quick Manual: SupplementsDocument2 pagesQuick Manual: SupplementsMarcos ChioratoNo ratings yet

- Install and use MrCool remote controlDocument14 pagesInstall and use MrCool remote controlPintilie IonNo ratings yet

- FCM Parameter ListDocument28 pagesFCM Parameter ListAdnanNo ratings yet

- Replay XD User Manual WebDocument12 pagesReplay XD User Manual Webmooseman1980No ratings yet

- Caution: defrost functions inhibited if C-H=HEA or DFR=0Document2 pagesCaution: defrost functions inhibited if C-H=HEA or DFR=0Iulian DobrinNo ratings yet

- External Wiring Diagram: Alarm Annunciator Microcontroller VersionDocument1 pageExternal Wiring Diagram: Alarm Annunciator Microcontroller VersionVinay KumarNo ratings yet

- Tps 77501Document23 pagesTps 77501Nur Ihsan AsariNo ratings yet

- Kenwood KE-7090 Instruction Manual (Page 7 of 26) - ManualsLibDocument2 pagesKenwood KE-7090 Instruction Manual (Page 7 of 26) - ManualsLibmikelreyes18No ratings yet

- E510 Compact QuickstartDocument2 pagesE510 Compact QuickstartEduardo LegorretaNo ratings yet

- EWPX 190 (.E) 6.97 IngDocument4 pagesEWPX 190 (.E) 6.97 Ingroby72No ratings yet

- Training-Mechatr Electrics-9 Exc (Fault Codes)Document48 pagesTraining-Mechatr Electrics-9 Exc (Fault Codes)q26n65hvfsNo ratings yet

- Ornaments + Crime Cheat SheetDocument6 pagesOrnaments + Crime Cheat SheetBrett BranningNo ratings yet

- P-Type - Separation System - Parameter List - 2008Document26 pagesP-Type - Separation System - Parameter List - 2008Centrifugal SeparatorNo ratings yet

- Timer ManualDocument60 pagesTimer ManuallvictimNo ratings yet

- Manual Danfoss Erc211 PDFDocument152 pagesManual Danfoss Erc211 PDFSanllyNo ratings yet

- 7E1 OperatingManualDocument2 pages7E1 OperatingManualSanjib NathNo ratings yet

- Rs22hd Fast TrackDocument9 pagesRs22hd Fast Trackdan themanNo ratings yet

- VAV Pneumatic ControllerDocument1 pageVAV Pneumatic ControllerNdia2007No ratings yet

- IFS-15H Quick Reference Guide v.1.0Document2 pagesIFS-15H Quick Reference Guide v.1.0smnguyenNo ratings yet

- Emcp3.1 SinopticoDocument1 pageEmcp3.1 SinopticoAdolfo Dario SaavedraNo ratings yet

- MSP74JA Differential Pressure Switch Controls System PressureDocument1 pageMSP74JA Differential Pressure Switch Controls System PressureChhomNo ratings yet

- Ematma Ematla: Tubular MotorDocument16 pagesEmatma Ematla: Tubular MotorSanduAnduNo ratings yet

- Programming Guide ACS 100: Control PanelDocument6 pagesProgramming Guide ACS 100: Control PanelPabloAlvNo ratings yet

- Factory Reset Procedures, Reset SequencesDocument25 pagesFactory Reset Procedures, Reset SequencesRendy Adam FarhanNo ratings yet

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptiondiab aliNo ratings yet

- Ac1-5 Instruction For Use: PAR Range DescriptionDocument2 pagesAc1-5 Instruction For Use: PAR Range Descriptionhisham falousNo ratings yet

- ALNICO ELECTRONICS DJS-41 UHF FM MINI TRANSCEIVERDocument4 pagesALNICO ELECTRONICS DJS-41 UHF FM MINI TRANSCEIVERQuasiNo ratings yet

- Digitech Digitech Element XP Quick Start Guide PDFDocument2 pagesDigitech Digitech Element XP Quick Start Guide PDFLeandro FariasNo ratings yet

- 祖Low 1輸 祖Low 1過: Sk200 (Lc) Ⅶ Sk210 (Lc) Ⅶ Sk230 (Lc) Ⅶ Sk250 (Lc) Ⅶ ●Sk320 (Lc) Ⅶ Sk330 (Lc) ⅦDocument1 page祖Low 1輸 祖Low 1過: Sk200 (Lc) Ⅶ Sk210 (Lc) Ⅶ Sk230 (Lc) Ⅶ Sk250 (Lc) Ⅶ ●Sk320 (Lc) Ⅶ Sk330 (Lc) ⅦchungNo ratings yet

- Refri Chico WordDocument20 pagesRefri Chico WordgustavoNo ratings yet

- HFO Purifier ParameterDocument33 pagesHFO Purifier ParameterPhan Cao An TruongNo ratings yet

- Gigaset A120/A120A/A220/A220A: eVU eVU " U TDocument16 pagesGigaset A120/A120A/A220/A220A: eVU eVU " U TimalettinNo ratings yet

- Air Cooled Chillers: Direct ExpansionDocument27 pagesAir Cooled Chillers: Direct ExpansionIstvan MadacsyNo ratings yet

- Using the PMR seconds counter and troubleshooting guideDocument2 pagesUsing the PMR seconds counter and troubleshooting guidebmbobNo ratings yet

- Probeta JiskootDocument2 pagesProbeta JiskootFrank Mathews GNo ratings yet

- 50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFDocument19 pages50 Chemical Injection System Access Fitting Assemblies - 50-DS Revc PDFChemkhiNo ratings yet

- Aegi ClampsDocument12 pagesAegi ClampssssydorenkoNo ratings yet

- PO format-ACCDocument17 pagesPO format-ACCSpace designNo ratings yet

- How 2 - Build A MIDGE Stove PDFDocument6 pagesHow 2 - Build A MIDGE Stove PDFpimar2008No ratings yet

- Biomass Gasification For Hydrogen ProductionDocument9 pagesBiomass Gasification For Hydrogen ProductionCris CrisNo ratings yet

- Refrigeration Theory PDFDocument48 pagesRefrigeration Theory PDFValentin LupascuNo ratings yet

- SMT Vacuum PlusDocument2 pagesSMT Vacuum PlusEerik-Hannes MatsinaNo ratings yet

- Paper On Plastic To RoadDocument6 pagesPaper On Plastic To RoadSumskrutha Kosgi ShroffNo ratings yet

- Evaluating Gas Turbine TestingDocument27 pagesEvaluating Gas Turbine TestingReshmi Vinu100% (2)

- Laboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)Document17 pagesLaboratory Apparatus For Evaluating Slurry Pipeline Wear (Cooke, Johnson & Goosen)Engr Sakher100% (1)

- Steris Amsco V-Pro PDFDocument8 pagesSteris Amsco V-Pro PDFVictor BlancoNo ratings yet

- Advantages and Disadvantages of Lathe Chuck WorkholdingDocument2 pagesAdvantages and Disadvantages of Lathe Chuck WorkholdingRatna PermatasariNo ratings yet

- PMS Sheet GRE PipeDocument3 pagesPMS Sheet GRE PipeSOPANNo ratings yet

- Composite Cement Retainer Technical DatasheetDocument2 pagesComposite Cement Retainer Technical DatasheetEvolution Oil ToolsNo ratings yet

- AS 2187 - Terminology PDFDocument29 pagesAS 2187 - Terminology PDFkrainaoz2011No ratings yet

- KURADDocument1 pageKURADbeto pagoadaNo ratings yet

- Cold Storage Design GuideDocument5 pagesCold Storage Design GuideMihuler Yordy Romero RojasNo ratings yet

- Foreign MatterDocument6 pagesForeign MatterAnonymous XuiUo2ThNo ratings yet

- Saes B 008Document5 pagesSaes B 008Anonymous a4Jwz14WNo ratings yet

- Seminar Presentation PPT On Reactive Powder Concrete Civil EngineeringDocument39 pagesSeminar Presentation PPT On Reactive Powder Concrete Civil Engineeringshreekanth bapatNo ratings yet

- Building Material Rate in MiriDocument18 pagesBuilding Material Rate in MiriJoanne WongNo ratings yet

- Keywords: Consumer, Packing, RecycleDocument8 pagesKeywords: Consumer, Packing, RecycleDr.K.BaranidharanNo ratings yet

- HSE Directive 1 Work PermitsDocument33 pagesHSE Directive 1 Work PermitsakubestlahNo ratings yet

- UK SP MB Kingspan Multibeam Brochure PDFDocument144 pagesUK SP MB Kingspan Multibeam Brochure PDFhemendraengNo ratings yet

- A Lucas Alternator and Zener Charging CircuitDocument8 pagesA Lucas Alternator and Zener Charging CircuitderryukNo ratings yet

- ADAPT TN388 Vibration Footfall ExampleDocument11 pagesADAPT TN388 Vibration Footfall ExampleMohammadreza MollaeiNo ratings yet

- Annexure C Cost EstimateDocument35 pagesAnnexure C Cost EstimateAnonymous WaXq9sYSQNo ratings yet

- Scope of Work (Plumbing)Document1 pageScope of Work (Plumbing)Mochammad Waris S100% (1)

- 6055 DB 1402Document4 pages6055 DB 1402edgardNo ratings yet