Professional Documents

Culture Documents

Hot Mix Recycling of Asphalt Pavements in India - It's Long Overdue!

Uploaded by

Prof. Prithvi Singh KandhalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Mix Recycling of Asphalt Pavements in India - It's Long Overdue!

Uploaded by

Prof. Prithvi Singh KandhalCopyright:

Available Formats

Asphalt Pavement

Hot Mix Recycling of

Asphalt P avements

Pavements

It’s Long Overdue in India!

Prof. Prithvi Singh Kandhal, Associate Director Emeritus, National Center for Asphalt Technology

Auburn University, Alabama USA.

Introduction In-Place Recycling; and (5) Full made a six-laned highway. Due to

Depth Reclamation. Only hot construction of under passes and

Recycling of existing asphalt

recycling of asphalt pavements at a flyovers a total of about 30 km of

pavement materials to produce new

central plant will be discussed in the existing four lanes of bituminous

pavement materials results in

this article in the context of 4-laning pavement will get buried if not

considerable savings of material,

and 6-laning of India’s state reclaimed and recycled. The total

money, and energy. The specific

highways and national highways tonnage of bitumen, which will be

benefits of recycling can be

wherein road paving bitumen worth buried, is estimated to be about

summarized as follows: (a)

crores of rupees is being buried 7,000 tons which has a value of

substantial savings over the use of

rather than recycled. The cost of more than 22 crore rupees. The

new materials, (b) conservation of

bitumen is about the same as total tonnage of aggregate in the

natural resources, (c) performance

sugar that is: `30-35 per kg. Will bituminous pavement, which will

equal or even better than new

we bury sugar under our highways? also get buried, is estimated to be

materials, (d) pavement geometrics

The “burial” of bitumen which about 165,000 tons which has a

is maintained, and (e) saving of

is our country’s “dharohar” value of over 6 crore rupees. So we

considerable amount of energy

(property) is being done will have a gross savings of over

compared to conventional

indiscriminately on some of our 28 crore rupees. The estimated cost

construction techniques. The last

highways, which are being six-laned of cold milling and transport of RAP

benefit is very important due to the

from the existing four lanes. Existing to hot mix plant for recycling is

recent urgent need for reducing

four lanes of bituminous pavement about 8 crores. Therefore, a net

greenhouse gases that is, reducing

get buried while constructing vehicle savings of rupees 20 crores can

carbon footprint thereby earning

under passes, public under passes, be realized on this six-laning project

carbon credits for India.

and flyovers. In such cases, the if hot mix recycling is implemented

Over the years, recycling has

existing bituminous pavement by the National Highway Authority of

become one of the most attractive

usually consisting of dense India (NHAI). There are many

pavement rehabilitation alternatives

bituminous macadam (DBM) and projects of this nature which can

in developed countries.

bituminous concrete (BC) can be save us hundreds of crores. The

Unfortunately, asphalt pavement

milled off and the reclaimed asphalt one-time cost of modifying an

recycling is yet to take off in India

pavement (RAP) transported to hot existing asphalt batch plant to do

despite the current ambitious road

mix plant for recycling on service hot mix recycling in India is only 20

building programme underway.

roads and/or main line. Asphalt lakhs rupees.

The Asphalt Recycling and

pavement is 100% recyclable. Besides huge savings in cost

Reclaiming Association define five

Here is an example. An existing and earning carbon credits, we will

different types of recycling methods:

four-lane national highway with a also have to obtain less virgin

(1) Cold Planing; (2) Hot Recycling;

total length of 120 km is to be aggregate from our stone quarries

(3) Hot In Place Recycling; (4) Cold

128 NBM&CW MARCH 2012

Asphalt Pavement

and also will have to import less burial. Moreover, inclusion of QC/QA (quality control/quality

crude oil to produce the paving discrete particles of RAP in GSB assurance). This manual can be

bitumen. In some states such as is detrimental to its function as downloaded free at the following

Punjab and Haryana where stone drainage layer in the pavement. internet link:

quarries are prohibited, aggregate Inclusion of discrete sub rounded h t t p : / / w w w. s c r i b d . c o m / d o c /

is transported from the neighboring particles of RAP in WMM 47299513/Pavement-Recycling-

states covering over 150 km that interferes with the interlocking Guidelines-for-State-and-Local-

makes the aggregate very characteristic of the WMM. Governments-Federal-Highway-

expensive. Besides, the cost of bitumen is Administration-Publication-No-

hardly realized from this burial.] FHWA-SA-98-042-December-1997

Common Arguments 4. We do not have an Indian Roads However, training of NHAI

Congress (IRC) specification for engineers, contractors, and

Against Recycling of hot asphalt recycling. [As a consultants in hot mix recycling is

Asphalt Pavements member of the IRC Flexible still needed. The writer is currently

The following arguments are Pavement Committee, last year based in Jaipur and can assist in

commonly encountered as to why the writer had submitted two draft conducting such training workshops.

NHAI should not mandate hot specifications to IRC for adoption Hot mix recycling cannot be

recycling of asphalt pavements. The to facilitate hot recycling. One implemented in India until NHAI

writer’s response is given in specification is for cold milling mandates its use on all major

parenthesis. and the other for hot mix recycling. projects. Such a circular should be

1. It is a new technology that we NHAI can use these two draft issued as soon as possible before

cannot implement as we do not standards immediately without the highway fraternity of India is

have the relevant experience. [Hot waiting for IRC’s final approval blamed for squandering our

recycling of asphalt pavements because time is of essence. country’s “dharohar” by burying it

has become a standard, proven These two draft standards can under our national highways. By

practice in many countries of the be downloaded at the following Just issuing a circular to encourage

world in the last 30 years. It is link: recycling is not good enough any

not a US technology but global h t t p : / / w w w. s c r i b d . c o m / d o c / more. Recycling should also be

and not a “rocket science.” We 77469016/Open-Letter-to-the- allowed in existing contracts with

can implement it right away on Chairman-of-the-NHAI-About-Hot- immediate effect.

major NH projects without any Recycling-18-November-2011

experience or experimental field 5. NHAI engineers, contractors, and Hot Mix Asphalt

consultants are not trained in hot

trials just like NHAI has

mix recycling. [The writer had

Recycling

commendably implemented the

use of robust stone matrix asphalt the privilege of developing Technology

(SMA) mix recently on national detailed, easy to understand, Two processes which are essential

highways without any problem.] guidelines for recycling asphalt for carrying out recycling of existing

2. Recycled hot asphalt mix may be pavements; the project was asphalt pavements are (a) cold

inferior in performance to 100% funded by the US Federal milling of existing road and (b) hot

virgin asphalt mix. [Numerous Highway Administration (FHWA). mix recycling at asphalt plant. These

field studies in the developed This manual was used by the are discussed here:

countries have shown time and writer and his associate Dr. Rajib

again that the performance of hot Mallick to conduct field workshops Cold Milling

recycled asphalt mix is equal to throughout the US to train highway Cold milling is described as an

or better than 100% virgin mix. engineers of state and local automatic method of removing

This is because the specification governments, contractors, and asphalt pavement to a desired

requirements are generally the consultants. Twelve workshops depth and restoration of the surface

same for both.] were conducted in different parts to a desired grade and slope and

3. We are already recycling the of the US to train engineers from free of humps, ruts and other

milled RAP in the granular sub all 50 states. This comprehensive distresses. This method can also

base (GSB) and/or wet mix maca- manual addresses all issues be used for the roughening or

dam (WMM) on some national related to recycling such as texturing of a pavement to improve

highway projects. [Use of RAP in construction methods & frictional resistance. Cold milling is

GSB or WMM cannot be called equipment; materials & mix performed with a self-propelled

recycling; it is still a wasteful design; and case histories and rotary drum cold milling machine

130 NBM&CW MARCH 2012

Asphalt Pavement

produce hot mix asphalt (HMA)

mixtures. Both batch and drum type

hot mix plants are used to produce

recycled mix. The RAP material can

be obtained by milling or ripping

and crushing operation.

Batch Plant

Batch type hot mix plants are quite

common in India. Some

modifications are required in the

batch plant to recycle RAP since

attempts to introduce RAP directly

with the virgin aggregates result in

excessive smoke and material

build-up problems in the dryer, hot

elevator, screens and hot aggregate

bins. The most widely used method

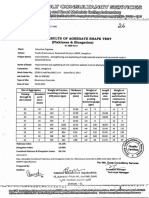

Figure 1: Milling machine loading RAP on truck for transport to hot mix asphalt plant

for batch plant recycling is the

“Maplewood Method.” Figure 2

with the reclaimed asphalt hour in India, where streets in

shows the schematic of this

pavement (RAP) transferred to metropolitan areas have reduced

method.

trucks for removal from the job site curb heights due to repeated

The cold pre-screened RAP

(Figure 1). The rotary drum is fitted overlays. “Mill and fill” should be a

(95% should pass 50 mm sieve) is

with tungsten carbide teeth, which common practice in urban India.

stored in a steep-sided bin. RAP is

can bite through hard rock particles.

Hot Mix Asphalt conveyed from this bin directly into

The resulting pavement can be

the weigh hopper of the batch

used immediately by regular traffic

and overlaid at some future time or

Recycling at Asphalt tower (or to another RAP bin

besides hot bins) through an

left as a textured surface. Plant inclined conveyor having automatic

Cold milling has become a Hot recycling or hot mix recycling is plant control. Superheated

common practice in developed the process in which reclaimed aggregate is discharged first in the

countries in the so-called “mill and asphalt pavement (RAP) material is weigh hopper followed by RAP at

fill” method of resurfacing/ combined with new materials ambient temperature. Since heat

rehabilitating asphalt pavements. (asphalt binder and aggregate) to rises, superheated aggregate heats

For example, it is quite

up the RAP. More heat

common in the US to mill off

transfer takes place during

the top 40-mm asphalt

dry mixing and wet mixing in

wearing course which is

the pugmill. Figure 3 shows

exhibiting surface distress

a batch plant with RAP bin

such as raveling, cracking

and RAP conveyor.

and rutting, and then replace

Generally, 30% RAP in

(fill) it with a new recycled

the recycled mix is

asphalt wearing course. It is

considered to be practical

done on interstate (national)

limit for this type of recycling

highways which are

technique.

otherwise structurally

Therefore, major

adequate so that the paved

modifications to batch plant

shoulders need not be

consist of a separate bin for

upgraded in elevation. It is

RAP and an automated

especially useful and

conveyor system for taking

necessary for urban streets

the RAP from the bin to

where overlay after overlay

weigh hopper. If desired a

would decrease the height

RAP bin can also be

of the roadside curb. This Figure 2: Schematic of hot mix asphalt recycling in a provided near the hot bins

latter use is the need of the batch plant and RAP discharged from

132 NBM&CW MARCH 2012

Asphalt Pavement

(when recycling about 50% RAP). It

then drops through the wall of the

drum and meets the RAP in the

annular space. Since the outer shell

does not rotate, easy access is

available to add virgin asphalt

binder and/or rejuvenating agents.

In this method, the RAP material is

not exposed to the hot gases.

Grade of Virgin

Bitumen Used in

Recycling

Since RAP typically contains hard,

aged asphalt binder (bitumen), the

grade of virgin asphalt binder to be

used in hot mix recycling depends

upon the amount of RAP in the

recycled mix. A study completed by

Figure 3: Typical batch plant with RAP bin and RAP conveyor Kandhal and Foo indicated that the

evaluation of recycled mixture should

that bin to the weigh hopper with a heats up the RAP by conduction be based on a three-tier process.

chute. These modifications can be before mixing with virgin bitumen. Tier 1 included up to 20% RAP and

done easily to existing HMA batch Generally, 50% RAP material is would not require any change in

plants. As mentioned earlier, the considered to be the practical limit the grade of standard bitumen. Tier

estimated one-time cost of such for this type of recycling technique. 2 included from 21 to 30% RAP

modifications is about `20 lakhs in A schematic of the center entry and required that the new bitumen

India. method used in a conventional grade should be softer by one

drum plant is shown in Figure 4. grade. Tier 3 included more than

Drum Plant

A double barrel drum mix plant 30% RAP and required that the

The center entry method is the most

is ideally suited for hot mix asphalt bitumen be recovered from the RAP

widely used method for hot mix

recycling. A schematic of the double and blended with the proposed

recycling in a drum mix plant. In

barrel drum is shown in Figure 5. virgin soft bitumen to produce

this method, RAP is introduced with

The shell of the drum is used as blended bitumen with the desired

a special drum collar into the

the shaft of the coater. The virgin properties of standard bitumen.

downstream of the burner flame to

aggregate is dried in the inner drum Current guidelines for Superpave

mix with superheated virgin (new)

and superheated to 315-340 C mix design are similar to those

aggregate. The hot virgin aggregate

Figure 4: Schematic of hot mix recycling in a drum plant by the Figure 5: Schematic of hot mix recycling in a double barrel

central entry method drum plant

134 NBM&CW MARCH 2012

Asphalt Pavement

recommended by Kandhal and Foo. structural improvement, equal or board, Transportation Research

Since viscosity grading was better performance compared to Record 2051, 2008.

adopted in India in 2006, the above conventional HMA, and capability to

About The Author

recommendations mean that VG- correct most surface defects,

Prof. Prithvi Singh Kandhal is

30 can be used when the RAP is deformation, and cracking.

20% or less. If RAP is 21 – 30%, a

References

softer viscosity grade, that is, VG-

♦ Kandhal, Prithvi S. and Rajib B. Mallick.

20 should be used. Over 30% RAP,

Pavement Recycling Guidelines for

blend of aged and virgin binder State and Local Governments. Federal

should be analyzed. It is quite Highway Administration Publication No.

possible VG-10 may have to be FHWA-SA-98-042, December 1997.

used. ♦ Kandhal, P.S. Open Letter to Chairman,

High RAP mixes are being National Highway Authority of India

developed to further reduce the on Hot Mix Recycling, 18 November

2011. http://www.scribd.com/doc/

carbon footprint as well as

77469016/Open-Letter-to-the-

economize construction. Such Associate Director Emeritus of the

Chairman-of-the-NHAI-About-Hot-

mixes have been made possible National Center for Asphalt

Recycling-18-November-2011

by separating RAP materials ♦ Newcomb, D.E., E.R. Brown, and J.A. Technology (NCAT) based at Auburn

according to size and/or new Epps. Designing HMA Mixtures with University, Alabama, U.S.A. NCAT is

designs of drum mix plants. Warm High RAP Content – A Practical Guide. the largest asphalt (bitumen) road

mix asphalt (WMA) technologies National Asphalt Pavement technology center in the world. Prior

also offer potential for using high Association, Quality Improvement to joining NCAT in 1988, Kandhal

Series 124, March 2007. served as Chief Asphalt Engineer

RAP contents.

♦ Kandhal, P.S., S.S. Rao and B. Young.

of the Pennsylvania Department of

Performance of Recycled Mixtures in

Summary State of Georgia. Federal Highway

Transportation for 17 years. He is

Hot mix recycling should be Administration Report No. FHWA-GA- the first person born outside North

implemented in India especially by 94-9209, 1994. America, who has held the following

NHAI ASAP because besides ♦ Kandhal, P.S. Recycling of Asphalt three very prestigious positions in

reducing carbon footprint, it has Pavements: An Overview. Proceedings the asphalt technology area:

significant economical advantages of the Association of Asphalt Paving ♦ President, Association of Asphalt

Technologists, Vol. 66, 1997. Paving Technologists (with

by reusing very costly asphalt binder

♦ Roberts, F.L., P.S. Kandhal, E.R.

(bitumen) and aggregates. If “mill members from all continents in

Brown, D. Lee and T.W. Kennedy.

and fill” method is adopted in the world)

Hot Mix Asphalt Materials, Mix Design

metropolitan India, hot mix recycling and Construction. HMA Textbook, ♦ Chairman, American Society for

becomes necessary so that surplus Second Edition, NAPA Education Testing and Materials (ASTM)

RAP is not discarded but recycled Foundation, Lanham, MD 1996. International Committee on Road

back on the road. ♦ Kandhal, P.S. and K.Y. Foo. Hot Mix Paving Standards (responsible for

Hot mix recycling is Recycling Design Using Superpave over 200 highway standards used

Technology. ASTM, Special Technical worldwide)

economically lucrative when existing

Publication 1322, 1997.

bituminous pavements get buried ♦ Chairman, Transportation

♦ McDaniel, R. and Anderson R.M.

while constructing vehicle under Research Board Committee on

Recommended Use of Reclaimed

passes, public under passes, and Asphalt Asphalt Roads, U.S. National

flyovers. This is happening on many ♦ Pavement in the Superpave Mix Academy of Sciences

national highways in India when Design Method: Technicians Manual. Prof. Kandhal has published

six-laning of existing four-lane Transportation Research Board. over 120 technical papers and has

highways is done. In such cases, NCHRP Report 452, 2001. co-authored the first ever textbook

♦ Kandhal, P.S. An Overview of the on asphalt road technology, which

the existing bituminous pavement

Viscosity Grading System Adopted in

usually consisting of Dense is used by more than 25

India for Paving Bitumen. Indian Roads

Bituminous Macadam (DBM) and universities in the U.S. He has

Congress, Indian Highways, April

Bituminous Concrete (BC), can be 2007. traveled to various countries in

milled off and RAP transported to ♦ Mallick, R., P. S. Kandhal, and R. South America, Europe, Middle East,

hot mix plant for recycling and reuse Bradbury. Using Warm Mix Asphalt China, Vietnam, Japan, and

on service roads and the main line. Technology to Incorporate High Australia to provide training and

Besides cost savings, the Percentage of Reclaimed Asphalt consulting services in asphalt

Pavement (RAP) Material in Asphalt (bitumen) technology.

advantages of hot mix asphalt

Mixtures. Transportation Research

recycling include significant

136 NBM&CW MARCH 2012

You might also like

- Why Do Many Roads Constructed in India Fail Prematurely?Document2 pagesWhy Do Many Roads Constructed in India Fail Prematurely?Prof. Prithvi Singh Kandhal100% (1)

- Hot Mix Recycling of Asphalt Pavements It's Long Overdue in India!Document5 pagesHot Mix Recycling of Asphalt Pavements It's Long Overdue in India!Vizag RoadsNo ratings yet

- Recycling of Asphalt Pavements: An OverviewDocument12 pagesRecycling of Asphalt Pavements: An OverviewProf. Prithvi Singh Kandhal100% (1)

- Use of Modified Bituminous Binders in India - Current ImperativesDocument25 pagesUse of Modified Bituminous Binders in India - Current ImperativesProf. Prithvi Singh Kandhal100% (4)

- Third Open Letter To Chairman, National Highway Authority of India On Recycling of Asphalt Roads.Document9 pagesThird Open Letter To Chairman, National Highway Authority of India On Recycling of Asphalt Roads.Prof. Prithvi Singh Kandhal100% (1)

- Proposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalDocument14 pagesProposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalProf. Prithvi Singh KandhalNo ratings yet

- Investigation of Premature Pavement Distresses On Typical National Highway ProjectDocument28 pagesInvestigation of Premature Pavement Distresses On Typical National Highway ProjectProf. Prithvi Singh Kandhal100% (2)

- Durable and Economical Technology For Bituminous Surfacing of Rural Roads in IndiaDocument6 pagesDurable and Economical Technology For Bituminous Surfacing of Rural Roads in IndiaProf. Prithvi Singh Kandhal50% (2)

- Open Letter To Hon. Gadkari MORTH On Savings of Over One Lakh Crores Per Year - 14 August 2021Document6 pagesOpen Letter To Hon. Gadkari MORTH On Savings of Over One Lakh Crores Per Year - 14 August 2021Prof. Prithvi Singh KandhalNo ratings yet

- A Simple Guide For Producing and Placing Readymade Pothole Patching Mix in Accordance With IRC:116-2014Document14 pagesA Simple Guide For Producing and Placing Readymade Pothole Patching Mix in Accordance With IRC:116-2014Prof. Prithvi Singh KandhalNo ratings yet

- A Critical Review of Bituminous Mixes Used in IndiaDocument42 pagesA Critical Review of Bituminous Mixes Used in IndiaProf. Prithvi Singh Kandhal100% (2)

- Review of Practices For Improving Ride Quality and Periodical Renewal of Bituminous Pavements in IndiaDocument26 pagesReview of Practices For Improving Ride Quality and Periodical Renewal of Bituminous Pavements in IndiaProf. Prithvi Singh Kandhal100% (2)

- Kandhal Asphalt Literature For India Rev. 3 January 2019Document27 pagesKandhal Asphalt Literature For India Rev. 3 January 2019Prof. Prithvi Singh Kandhal100% (1)

- Blog "Asphalt For India" by Prof. Prithvi Singh KandhalDocument73 pagesBlog "Asphalt For India" by Prof. Prithvi Singh KandhalProf. Prithvi Singh Kandhal100% (2)

- Quality Control Requirements For Using Crumb Rubber Modified Bitumen (CRMB)Document21 pagesQuality Control Requirements For Using Crumb Rubber Modified Bitumen (CRMB)Prof. Prithvi Singh Kandhal100% (3)

- Guidelines For Long Lasting Bituminous Pavements in IndiaDocument36 pagesGuidelines For Long Lasting Bituminous Pavements in IndiaProf. Prithvi Singh Kandhal100% (2)

- Is Premix Carpet Really Good For Roads in India?Document9 pagesIs Premix Carpet Really Good For Roads in India?Prof. Prithvi Singh Kandhal100% (2)

- Kandhal Q and A Part 6 On Marshall Mix Design - Letter To Highway Colleagues - 15 September 2019Document5 pagesKandhal Q and A Part 6 On Marshall Mix Design - Letter To Highway Colleagues - 15 September 2019Prof. Prithvi Singh Kandhal100% (1)

- Readymade Kandhal Pothole Patching Mix Adopted As Indian Roads Congress Standard SpecificationDocument19 pagesReadymade Kandhal Pothole Patching Mix Adopted As Indian Roads Congress Standard SpecificationProf. Prithvi Singh KandhalNo ratings yet

- Kandhal Q and A Part 4 On Bitumen Content of Bituminous Paving Mixes in India - Letter To Highway Colleagues - 9 August 2018Document6 pagesKandhal Q and A Part 4 On Bitumen Content of Bituminous Paving Mixes in India - Letter To Highway Colleagues - 9 August 2018Prof. Prithvi Singh KandhalNo ratings yet

- Roads in India - Designed To Fail ?Document36 pagesRoads in India - Designed To Fail ?Prof. Prithvi Singh Kandhal100% (6)

- Pothole Repair Technology During Monsoon - by Prof. Prithvi Singh Kandhal, Jaipur, RajasthanDocument3 pagesPothole Repair Technology During Monsoon - by Prof. Prithvi Singh Kandhal, Jaipur, RajasthanVizag Roads100% (1)

- IRC 82 2015 Maintenance of Bitumen Surface PDFDocument82 pagesIRC 82 2015 Maintenance of Bitumen Surface PDFanant11235100% (7)

- Do We Need To Add Mineral Filler in Bituminous Mixtures?Document6 pagesDo We Need To Add Mineral Filler in Bituminous Mixtures?Prof. Prithvi Singh Kandhal100% (2)

- Open Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsDocument6 pagesOpen Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsProf. Prithvi Singh KandhalNo ratings yet

- Flexible Pavement Design SK RaoDocument62 pagesFlexible Pavement Design SK Raokrishnarao krishnarao329100% (2)

- An Overview of The Viscosity Grading System Adopted in India For Paving BitumenDocument20 pagesAn Overview of The Viscosity Grading System Adopted in India For Paving BitumenProf. Prithvi Singh Kandhal100% (6)

- BITUMINOUS ROAD-finalDocument447 pagesBITUMINOUS ROAD-finalFaruquemasud0% (1)

- Letter To Highway Colleagues On New PG Specification For PMB IS 15462:2019 - 4 July 2019Document4 pagesLetter To Highway Colleagues On New PG Specification For PMB IS 15462:2019 - 4 July 2019Prof. Prithvi Singh Kandhal100% (6)

- Kandhal Keynote 1 - Paving Bitumen For Bituminous Road Construction in IndiaDocument49 pagesKandhal Keynote 1 - Paving Bitumen For Bituminous Road Construction in IndiaProf. Prithvi Singh Kandhal50% (4)

- Modified BitumenDocument26 pagesModified BitumenVizag Roads100% (2)

- Pavement DesignDocument74 pagesPavement Designafifa kausar50% (2)

- Are Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerDocument5 pagesAre Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerProf. Prithvi Singh KandhalNo ratings yet

- QIP-123 Heavy Duty MixesDocument44 pagesQIP-123 Heavy Duty Mixesਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟNo ratings yet

- Open Letter To Honourable Shri Ashok Gehlot, Chief Minister of Rajasthan 31 May 2009Document3 pagesOpen Letter To Honourable Shri Ashok Gehlot, Chief Minister of Rajasthan 31 May 2009Prof. Prithvi Singh KandhalNo ratings yet

- Applying Tack Coat Over Prime Coat: Fundamentally Not Necessary and Gross Waste of India's Resources !Document3 pagesApplying Tack Coat Over Prime Coat: Fundamentally Not Necessary and Gross Waste of India's Resources !Prof. Prithvi Singh Kandhal100% (5)

- Irc 16 2008Document20 pagesIrc 16 2008LokeshNo ratings yet

- Significance of Restricted Zone in Superpave Aggregate Gradation SpecificationDocument23 pagesSignificance of Restricted Zone in Superpave Aggregate Gradation SpecificationProf. Prithvi Singh KandhalNo ratings yet

- Jaipur Leads India in Pothole Repair Technology During MonsoonDocument17 pagesJaipur Leads India in Pothole Repair Technology During MonsoonProf. Prithvi Singh KandhalNo ratings yet

- Warm Mix Asphalt Technologies - An OverviewDocument21 pagesWarm Mix Asphalt Technologies - An OverviewProf. Prithvi Singh Kandhal100% (1)

- 09 - VV - Pavement Design IRC37-2018 - 29jan2020 - Admin KHRI PDFDocument24 pages09 - VV - Pavement Design IRC37-2018 - 29jan2020 - Admin KHRI PDFAmit Rajendra Phadatare100% (1)

- Letter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatDocument4 pagesLetter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatProf. Prithvi Singh Kandhal100% (1)

- Aggregate Tests Related To Asphalt Concrete Performance in PavementsDocument114 pagesAggregate Tests Related To Asphalt Concrete Performance in PavementsProf. Prithvi Singh Kandhal100% (2)

- Perpetual PavementsDocument26 pagesPerpetual PavementsRehan Ravi0% (1)

- Guidelines for Using Modified Bitumen in Road ConstructionDocument36 pagesGuidelines for Using Modified Bitumen in Road ConstructionAnant75% (8)

- Pavement Design, Construction and Maintenance For Bituminous RoadsDocument47 pagesPavement Design, Construction and Maintenance For Bituminous RoadsMadhavpokaleNo ratings yet

- List of IRCDocument31 pagesList of IRCPrapulla RameshNo ratings yet

- Asphalt Mix Design With Using Plastic Waste.Document51 pagesAsphalt Mix Design With Using Plastic Waste.Akash YadavNo ratings yet

- IRC-94-1986 Dense Bituminous MacadamDocument12 pagesIRC-94-1986 Dense Bituminous MacadamAshok Rajanavar67% (3)

- Kandhal Lecture 2 On Grading of Bitumen and Polymer Modified Bitumen (PMB) - Handouts OnlyDocument10 pagesKandhal Lecture 2 On Grading of Bitumen and Polymer Modified Bitumen (PMB) - Handouts OnlyProf. Prithvi Singh Kandhal100% (3)

- IRC SP 80 - Corrosion Prevention - 2008Document90 pagesIRC SP 80 - Corrosion Prevention - 2008Palash Damle70% (10)

- IRC Guidelines for Dense Graded Bituminous MixesDocument33 pagesIRC Guidelines for Dense Graded Bituminous MixesSelvi M100% (1)

- Draft IRC SP 53 Guidelines On Use of PolymerDocument4 pagesDraft IRC SP 53 Guidelines On Use of PolymerVizag Roads100% (2)

- White ToppingDocument42 pagesWhite ToppingVinamraMishraNo ratings yet

- Irc - 109-1997 Wet Mix MacadamDocument20 pagesIrc - 109-1997 Wet Mix MacadamNeeraj Dubey100% (2)

- Research and Application of Hot In-Place Recycling Technology for Asphalt PavementFrom EverandResearch and Application of Hot In-Place Recycling Technology for Asphalt PavementNo ratings yet

- Open Letter To The Chairman of The NHAI About Hot Recycling 18 November 2011Document11 pagesOpen Letter To The Chairman of The NHAI About Hot Recycling 18 November 2011Prof. Prithvi Singh KandhalNo ratings yet

- CECR RecyclingofPavemets PDFDocument6 pagesCECR RecyclingofPavemets PDFMILENKA YSABEL UCEDA PUICONNo ratings yet

- CECR RecyclingofPavemetsDocument6 pagesCECR RecyclingofPavemetsMILENKA YSABEL UCEDA PUICONNo ratings yet

- Emulsion Cold Mix Asphalt in The UK A Decade of SiDocument7 pagesEmulsion Cold Mix Asphalt in The UK A Decade of SiDiab BENKAYANo ratings yet

- Letter to Hon. PM Narendra Modi to ban undesirable bituminous mixes on Indian roadsDocument8 pagesLetter to Hon. PM Narendra Modi to ban undesirable bituminous mixes on Indian roadsProf. Prithvi Singh KandhalNo ratings yet

- Q and A with a highway engineer about roads developing potholes during monsoons in India - 12 April 2024Document7 pagesQ and A with a highway engineer about roads developing potholes during monsoons in India - 12 April 2024Prof. Prithvi Singh KandhalNo ratings yet

- Open Letter To Hon. Gadkari MORTH On Savings of Over One Lakh Crores Per Year - 14 August 2021Document6 pagesOpen Letter To Hon. Gadkari MORTH On Savings of Over One Lakh Crores Per Year - 14 August 2021Prof. Prithvi Singh KandhalNo ratings yet

- Blog "Asphalt For India" by Prof. Prithvi Singh KandhalDocument73 pagesBlog "Asphalt For India" by Prof. Prithvi Singh KandhalProf. Prithvi Singh Kandhal100% (2)

- Proposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalDocument14 pagesProposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalProf. Prithvi Singh KandhalNo ratings yet

- Kandhal Q and A Part 6 On Marshall Mix Design - Letter To Highway Colleagues - 15 September 2019Document5 pagesKandhal Q and A Part 6 On Marshall Mix Design - Letter To Highway Colleagues - 15 September 2019Prof. Prithvi Singh Kandhal100% (1)

- Letter To Niti Aayog - 21 Indian Cities Will Run Out of Groundwater by 2020 - What To Do?Document2 pagesLetter To Niti Aayog - 21 Indian Cities Will Run Out of Groundwater by 2020 - What To Do?Prof. Prithvi Singh Kandhal100% (1)

- Gross Wastage of Over 10,000 Crores Per Year in Construction and Maintainance of Rural Roads - 23 July 2019Document5 pagesGross Wastage of Over 10,000 Crores Per Year in Construction and Maintainance of Rural Roads - 23 July 2019Prof. Prithvi Singh KandhalNo ratings yet

- Letter To Highway Colleagues On New PG Specification For PMB IS 15462:2019 - 4 July 2019Document4 pagesLetter To Highway Colleagues On New PG Specification For PMB IS 15462:2019 - 4 July 2019Prof. Prithvi Singh Kandhal100% (6)

- Investigation of Premature Pavement Distresses On Typical National Highway ProjectDocument28 pagesInvestigation of Premature Pavement Distresses On Typical National Highway ProjectProf. Prithvi Singh Kandhal100% (2)

- Kandhal Asphalt Literature For India Rev. 3 January 2019Document27 pagesKandhal Asphalt Literature For India Rev. 3 January 2019Prof. Prithvi Singh Kandhal100% (1)

- Potholes Killed 3,597 People Across India in 2017 Who Is Responsible?Document8 pagesPotholes Killed 3,597 People Across India in 2017 Who Is Responsible?Prof. Prithvi Singh KandhalNo ratings yet

- Are Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerDocument5 pagesAre Two Separate Test Samples Are Used in India To Determine The Flaky (Flat) and Elongated Particles in Each Aggregate Size Fraction? AnswerProf. Prithvi Singh KandhalNo ratings yet

- Quality Control and Quality Assurance in Bituminous Road Construction in IndiaDocument21 pagesQuality Control and Quality Assurance in Bituminous Road Construction in IndiaProf. Prithvi Singh Kandhal100% (4)

- Kandhal Q and A Part 2 On Why We Have Potholes On Bituminous Roads Especially During Monsoons With Picture - 23 November 2017Document7 pagesKandhal Q and A Part 2 On Why We Have Potholes On Bituminous Roads Especially During Monsoons With Picture - 23 November 2017Prof. Prithvi Singh KandhalNo ratings yet

- Durable and Economical Technology For Bituminous Surfacing of Rural Roads in IndiaDocument6 pagesDurable and Economical Technology For Bituminous Surfacing of Rural Roads in IndiaProf. Prithvi Singh Kandhal50% (2)

- Open Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaDocument3 pagesOpen Letter To Hon. Nitin Gadkari On Pothole Problem On National and Other Highways in IndiaProf. Prithvi Singh KandhalNo ratings yet

- Kandhal Q and A Part 4 On Bitumen Content of Bituminous Paving Mixes in India - Letter To Highway Colleagues - 9 August 2018Document6 pagesKandhal Q and A Part 4 On Bitumen Content of Bituminous Paving Mixes in India - Letter To Highway Colleagues - 9 August 2018Prof. Prithvi Singh KandhalNo ratings yet

- Open Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsDocument6 pagesOpen Letter To Hon. Narendra Modi On Gross Wastage of Public Funds On Bituminous Resurfacing of Rural RoadsProf. Prithvi Singh KandhalNo ratings yet

- A Simple Guide For Producing and Placing Readymade Pothole Patching Mix in Accordance With IRC:116-2014Document14 pagesA Simple Guide For Producing and Placing Readymade Pothole Patching Mix in Accordance With IRC:116-2014Prof. Prithvi Singh KandhalNo ratings yet

- Letter To Hon. Narendra Singh Tomar About Wastage of Funds in Blacktopping Rural Roads in IndiaDocument6 pagesLetter To Hon. Narendra Singh Tomar About Wastage of Funds in Blacktopping Rural Roads in IndiaProf. Prithvi Singh KandhalNo ratings yet

- Letter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatDocument4 pagesLetter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatProf. Prithvi Singh Kandhal100% (1)

- Kandhal Q and A Part 3 On Quality of Bitumen Emulsions Supplied On Highway Projects in IndiaDocument5 pagesKandhal Q and A Part 3 On Quality of Bitumen Emulsions Supplied On Highway Projects in IndiaProf. Prithvi Singh KandhalNo ratings yet

- An Open Letter To Mr. Deepak Kumar, Chairman NHAI, On Monster Signs Near NHAI Toll Booths Depicting VIP Culture in IndiaDocument3 pagesAn Open Letter To Mr. Deepak Kumar, Chairman NHAI, On Monster Signs Near NHAI Toll Booths Depicting VIP Culture in IndiaProf. Prithvi Singh KandhalNo ratings yet

- Review of Practices For Improving Ride Quality and Periodical Renewal of Bituminous Pavements in IndiaDocument26 pagesReview of Practices For Improving Ride Quality and Periodical Renewal of Bituminous Pavements in IndiaProf. Prithvi Singh Kandhal100% (2)

- Kandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyDocument8 pagesKandhal Lecture 3 On Aggregate For Bituminous Road Construction - Handouts OnlyProf. Prithvi Singh KandhalNo ratings yet

- Kandhal Lecture 2 On Grading of Bitumen and Polymer Modified Bitumen (PMB) - Handouts OnlyDocument10 pagesKandhal Lecture 2 On Grading of Bitumen and Polymer Modified Bitumen (PMB) - Handouts OnlyProf. Prithvi Singh Kandhal100% (3)

- A Seminar On Automobile SafetyDocument23 pagesA Seminar On Automobile SafetyJash PatelNo ratings yet

- HD1500-7 (A) Parts Book PDFDocument487 pagesHD1500-7 (A) Parts Book PDFRenier van Rooyen100% (1)

- Traffic EngineeringDocument2 pagesTraffic Engineeringsuganthi1711No ratings yet

- Direct Injection Test (Voltage Vs Current) (Picoscope)Document7 pagesDirect Injection Test (Voltage Vs Current) (Picoscope)Toni JuanNo ratings yet

- Diagrama 4 AMBIENT AIR TEMPER..Document1 pageDiagrama 4 AMBIENT AIR TEMPER..Gustavo PérezNo ratings yet

- MSC ThesisDocument140 pagesMSC ThesisGopi C ShresthaNo ratings yet

- Parts Number Movement 2022 (New Parts Number, Subtitution, Discontinue, Etc)Document3,138 pagesParts Number Movement 2022 (New Parts Number, Subtitution, Discontinue, Etc)gudang baruNo ratings yet

- In Rail: Advances Wagon DesignDocument10 pagesIn Rail: Advances Wagon DesignGermán GoñiNo ratings yet

- Transmision r5m3 MitsubishiDocument155 pagesTransmision r5m3 MitsubishiVictorDjChiqueCastilloNo ratings yet

- Komatsu Wheel Loaders Wa150pz 5 Shop ManualDocument20 pagesKomatsu Wheel Loaders Wa150pz 5 Shop Manualjoan100% (46)

- Te Lab ManualDocument25 pagesTe Lab ManualshakeelwaseemNo ratings yet

- XD PROT 20180622 1514 Turismos253946 WDC0G4GB4HF220545 PCZ3859PROTINGLESDocument9 pagesXD PROT 20180622 1514 Turismos253946 WDC0G4GB4HF220545 PCZ3859PROTINGLESfausto_titoNo ratings yet

- Checklist Submission Drawing Report UTTIPECDocument2 pagesChecklist Submission Drawing Report UTTIPECanimeshoct100% (1)

- Learner Driver Quiz 3 SurveyDocument11 pagesLearner Driver Quiz 3 SurveyJay Ryan SantosNo ratings yet

- Catalago STX 200 PDFDocument77 pagesCatalago STX 200 PDFjadenyNo ratings yet

- Yamaha Tricity 125 Handleiding Engels PDFDocument92 pagesYamaha Tricity 125 Handleiding Engels PDFAiko Timmer0% (1)

- Valve Guides EngDocument35 pagesValve Guides EngKaiser IqbalNo ratings yet

- Attachment New Price TGP 20190709.shareDocument202 pagesAttachment New Price TGP 20190709.shareImran Al Imran0% (1)

- IRSE ARTICLE Signalling RelaysDocument23 pagesIRSE ARTICLE Signalling Relaysmaxxand100% (1)

- Pripps R.N., Sanders R.W.-Classic Farm Tractors 200 of The Best, Worst, and Most Fascinating Tractors of All Time-Voyageur Press (2014) PDFDocument307 pagesPripps R.N., Sanders R.W.-Classic Farm Tractors 200 of The Best, Worst, and Most Fascinating Tractors of All Time-Voyageur Press (2014) PDFEnrique SuárezNo ratings yet

- Parts ListDocument2 pagesParts ListmetanirvanaNo ratings yet

- Memorandum: TO: DateDocument7 pagesMemorandum: TO: Datethe next miamiNo ratings yet

- One Piece Forged Wheel & Ruck Forged Aluminum WheelDocument23 pagesOne Piece Forged Wheel & Ruck Forged Aluminum WheelMichael HwangNo ratings yet

- Maxon GS 16 ADocument1 pageMaxon GS 16 AElectromateNo ratings yet

- Spec FTS 139 260 4x4 2303RDocument4 pagesSpec FTS 139 260 4x4 2303Rmaddoginc.01No ratings yet

- Portuario - CS7 - 5S6 - Porta - Contenedor Terex PDFDocument2 pagesPortuario - CS7 - 5S6 - Porta - Contenedor Terex PDFMarco Guachun100% (1)

- L3300DTDocument350 pagesL3300DTrop703406No ratings yet

- Automobile Transmission System Solved Papers PDFDocument52 pagesAutomobile Transmission System Solved Papers PDFSyedJavedAli100% (9)

- Advanced Lubricants Guide for Improved Fuel Efficiency & Lower EmissionsDocument28 pagesAdvanced Lubricants Guide for Improved Fuel Efficiency & Lower EmissionstradehouseNo ratings yet

- Tractor Safety EssentialsDocument40 pagesTractor Safety EssentialsHannah Crystal Agravante-Tampus Capacio-jurolanNo ratings yet