Professional Documents

Culture Documents

Piping Construction

Uploaded by

Anonymous dSFbLxc90 ratings0% found this document useful (0 votes)

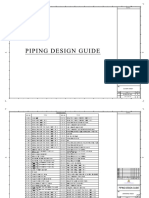

735 views31 pagesMICLYN SHIPBUILDING and ENGINEERING PTE LTD DRAWN HULL NO : MSE 101 and MSE 102 DWG. NO. REV. CHECKED NOTED TOTAL 31 SHEETS PIPING CONSTRUCTION STANDARDS CONTENTS SKETCH TITLE PAGE GENERAL NOTES 3 TANK VENTING 4-6 AP-1 General Details (1/ 3) Typical Details (2 / 3) Vent Head Detail (3

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMICLYN SHIPBUILDING and ENGINEERING PTE LTD DRAWN HULL NO : MSE 101 and MSE 102 DWG. NO. REV. CHECKED NOTED TOTAL 31 SHEETS PIPING CONSTRUCTION STANDARDS CONTENTS SKETCH TITLE PAGE GENERAL NOTES 3 TANK VENTING 4-6 AP-1 General Details (1/ 3) Typical Details (2 / 3) Vent Head Detail (3

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

735 views31 pagesPiping Construction

Uploaded by

Anonymous dSFbLxc9MICLYN SHIPBUILDING and ENGINEERING PTE LTD DRAWN HULL NO : MSE 101 and MSE 102 DWG. NO. REV. CHECKED NOTED TOTAL 31 SHEETS PIPING CONSTRUCTION STANDARDS CONTENTS SKETCH TITLE PAGE GENERAL NOTES 3 TANK VENTING 4-6 AP-1 General Details (1/ 3) Typical Details (2 / 3) Vent Head Detail (3

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 31

NO MODIFICATIONS sy_| pate

APPROVED BY:

DATE

ied on the understanding that they are

the exclusive property of Shiptech Pte Ltd. They

must not be used of reproduced in whole or

This drawing and information contained herein

n- part, without permission in writing,

SHIPTECH

NAVAL ARCHITECTS

180 Paya Lebar Road, #08—06,

Yi-Guang Building, Singapore 409032

Telefax: 67465871 E-MAIL: shiptech@singnet.com.sg Tel 67486422

PROJECT

SHOR HANDLING UTILITY BOAT

TLE

-ING

NSTRUCTION

BUILDER : MICLYN SHIPBUILDING & ENGINEERING PTE LTD HULL NO: MSE 101 & MSE 102

DRAW

HUANG 12/04/2007 |SCALE DWG. NO REV.

CHECKED HAZALI 08/05/; sT1515-Ss1 | 0

NTS

NOTED TOTAL 31 SHEETS

SKETCH

APA

OF

DF-3

FP4

FP2

Es

Pit

Pu2

Ped

PLS

PP

PP-2

PP-4

SFA

SF-2

SP+4

SP-2

SP-3

bp-1

pp-2

PIPING CONSTRUCTION STANDARDS.

CONTENTS

TITLE PAGE

GENERAL NOTES 3

TANK VENTING 46

General Details (1/3)

Typical Details (2/3)

Vent Head Detail (3/3)

DECK FACILITIES 78

International Shore Connection

‘Sewage Discharge Connection

TANK FILLING ott

General Pipe Layout & Detail

Filing Pipe Head Detail

EXTENDED SPINDLE

Valve Attachment for R.S Valve (1/3)

Universal Joint (2/3)

Stuffing Box with Water-tight Gland (3/3)

PIPE JOINT 1245,

Pipe & Pipe (Butt Weld)

Pipe & Pipe (Stub-in)

Pipe & Flange

Pipe & Filting (Socket weld)

PENETRATION 16-23

For Hull W.T Deck/Bhd

For Hull W.T Bhd or Tank

Penetration for Overboard Discharge

‘SUCTION FITTING 24-26

‘Mud Box

Rose Box (Type A)

TANK SOUNDING 27-30

General Pipe Layout & Detail

Sounding Head Details

Pipe Bottom Detail

DRAINAGE 34

Deck Scupper without Water-seal

Deck Scupper with Water-seal

)

2)

3)

4)

5)

PIPING CONSTRUCTION STANDARDS,

GENERAL NOTES

‘THIS NOTES APPLIES TO ALL PIPING DRAWING UNLESS OTHERWISE

NOTED ON ITS RESPECTIVE DRAWING.

‘ALL PIPE WORK SHALL HAVE ADEQUATE NUMBER OF JOINTS TO

FACILITATE FURTHER MAINTENANCE,

ALL PIPE RUN SHALL BE STRAIGHT AND DIRECT WITH MINIMUM,

NUMBER OF BENDS.

‘ALL PIPE WORK SHALL BE ADEQUATE SUPPORTED BY HANGERS/

GUIDES AGAINST MAIN STRUCTURE,

SHIPYARD SHALL DECIDE ON SITE.

ALL VALVES SHALL BE POSITIONED SUCH THAT THEY ARE READILY

‘ACCESSIBLE AT ALL TIMES,

LEGIBLE NAME-PLATES SHALL BE FITTED ON HAND-WHEEL.

PIPING CONSTRUCTION STANDARDS] Pace @ oF

SHIPTECH |= pre v0

WAVAC ARCHITECTS AIR PIPE pores

jsveer_1 oF 3

‘A’ TYPE

FLOAT

WIRE_GAUGE

(SEE NOTE)

x x

i 1

FREEBOARO/SUPE!

STRUCTURE. DECK

NOTE: Wire gauze must be flame arresting type ond

of corrosion resistant material

Wee [LANE BPE al

ie W/o WE GAIZE[W/ WiRE CAUze|

TANK seueor | o re]

Oil_ Tank x

Sea~water_/ Ballast Tonk x

[Fresh—water / Potable Water Tonk oz

Cofferdam 7 Void Tonk v

‘Seo Chest_& Rudder Trunk vA

Bi Nominal

TANK Pre ere

(Oi! Tank 50.

Minimum |Seo—water 7 Ballast Tonk 50

Pipe Bore VFresh—water 7 Potable Water Tonk 50

[Cofferdam / Void Tonk 50

Height, H [On Freeboard Deck 760

(rom) "|abv Superstructure Ok, Deckhouse 450

Minimum Pipe Woll Thickness (mm) 65 | 60

Pipes thot are efficiently protected against in| $3

corrosion, may reduced the wall thickness 18 | 78

by not more thon 1.0mm. Oa iso [eae | 0 ips external tee

Ratio of Air / Over—flow pipe cross-sectional area to

the Filling / ‘Pump suction pipe cross-sectional area | 1-25

PIPING CONSTRUCTION STANDARDS race _S oF

SHIPTECH [= pe

‘WAVAL _AwewITECTS AIR PIPE —

AP-1

TYPICAL DETAIL weet 2 oF 3

FOR GENERAL USE £OR OWL TANK

TSx6F.B

COAMING,

75x6F.8

COAMING

4

[L- DECK PENETRATION

SLEEVE

SLEEVE

7

A) FLANGE

L sueeve

SLEEVE 1

TANK Top TANK Top ‘DECK PENETRATION

DOUBLE BOTTOM TANK

PIPING CONSTRUCTION STANDARDS| Pace G oF

SHIPTECH [= pe

AR PIPE —

VAL _AREWITESTS AP-1

VENT HEAD

jsHeet_3 oF 3

at re

pos ©

(i Fy yl

ft Y =| q

eee |

/ |

SE -4 5|

2

. =

a 1

?

elo !

zl a)

2 ch 7

2 ‘ it 1-1 © L,

8] |

= 4)

iE 2

a “ 4

1 ;—1!

S10 FF PPE FL.

wwe (Skg/ern?)

wou sze—™ | oo fur 2 fas [ ow Fn Tm foo] ef w]e | s page|

5 50 | 70 [103] 75 [Tao|ize [718] 50 [a7 [sts pss

65 65 | 60 ]120| 85 [205/139] 130] 6022 [i55[-5 [12 | —s

80 ‘80 | 90 [153 [100] 245] 160] 150] 70 | 27 [190] 6 [1a | 13

100 100105] 160 [110 [270/179 [69] 75 | 36 [225|-6 [16 | 18

125 125125185 [130] 310|204]i94[ 80 | 44 [2e5[-7 [16 [27

150 150185225 |150[350|223]212| 90] 53 [soo] 8 [16 | ~a7

200. 200 [200 298 | a0 [440] 275] 264] Yoo] 70-|4co| 9 | 20 | 67]

[HOOD Si sie [1 SUS30¢

| FLOAT, STL STEEL [1 SUSSO4

7 [SCREEN Si steeL | SUS304 SO"SF

&_[SPRING WASHER [StL sree [1 ~—}susso0

5 [Bout Siee,_—[— S841 GAW.

[pour Sh. sweet [= SUSSO4

“3 [star eRASS [1 36048 a |

2 [cover CAST IRON [1 FC.20

1 ]éoor CAST IRON | 1 F620

‘OnE TOTAL

TEM) NAME. MATERIAL | QTY | CALCULATEQ. NOTE

wes Yea}

[PIPING CONSTRUCTION STANDARD:

SHIPTECH [=

‘AVAL aReuITECTS.

DECK FACILITIES —

INTERNATIONAL SHORE

CONNECTION

Eee

jsueer 1 oF 1

The shore connection piece made of brass sholl be kept aboard neor

the deck facilities on either side of the vessel.

Wt sholl be kept together with

= 1 no, of gasket for 10.5kq/em® (150psi) service

4 sets ~ M16(5/8") x 50(2") tong bolts, ond

= 8 ~ M16(5/8") woshers

[|

LDR ee

¢

145 | 19.0 | 64.0 | S08

057 | 0.75 | 252 | 20

PIPING CONSTRUCTION STANDARDS Pace § or

SHIPTECH [=

We NO.

AVAL _ARGHT = | OECK FACILITIES — OF-3

‘SEWAGE DISCHARGE CONNECTION

jsueer_ 1 oF 1

L |

J

PIPE 0.0.

NOTE:

The flonge is adopted from the morine pollution Annex IV regulation 11

(Morpol standard discharge connection facilities).

2. The flonge is designed to accept pipes up to 0 max. internal

dio. of 100mm (sin) ond sholl be of steel or other equivalent

materiol having o flat foce.

3. The flonge shall come with 4 sets of M16 x 6Omm long steel bolt ond

fut together with o gasket of oil proof moterial, suitable for service

pressure of Gkg/em? (compressed non-asbestos goskel ~ full foce —

10kg/em2 x 1.5mm thk)

marx] oa [ op | c | o

(mm) | 210.0 | 170.0 | 160 | 18.0

Gn)_| 8.26 | 6.69 | 063 | 0.71

[PIPING CONSTRUCTION STANDARDS race 9 oF

SHIPTECH [= xenoco spnoe — pus 0

NAVAL _AwenITECTS VALVE ATTACHMENT FOR ES-1

RISING STEM VALVE lower 1 of 5

Extended spindle Thk

1 (Polished steel) Steer nite

f L— stem cover

8| 1

1E--R— vave stem Pipe to suit

_ 8 based on @D

g Y— stem nut

w ‘|| Observotign

\ slot 25mm

z Stem cover plate wie ©

s S E Both Side

q

z vote it

4 4 dil TEM (STEEL)

sey,

‘eat

\=— Valve yoke

1 \ Dri! 614mm

' \ for M12 hex hd

' bolt & nut.

165mm P.C.0.

Cut to suit

valve stem

EM COVER PLATE (STEEL)

yoKs STEEL

mark] a | 8 | ¢ | eo

(mm)} 12.5 | 205 | 115 [TO SUIT

(in) | 0.50 | 8.00 | 4.50 | ofOKE,

[PIPING CONSTRUCTION STANDARDS rc 10 oF

SHIPTECH (2 25 Se ‘

NAVAL KRoWirects: =

MAVAL ARGHTTESTS UNIVERSAL JOINT ES"

Jsveer 2 oF 3

(7 Selt-ain (stcinessstee)

M10 hex hd bolt ond nut

(stoinless stee!)

Universal joint

To Valve Attachment

Extended spinaie

(Polished-stee! rod)

SHIPTECH

Wavat Awowirects.

PIPING CONSTRUCTION STANDARDS| me 1) o

HE EXTENDED SPINDLE — pas 8°

STUFFING 80X_WITH —S-1

WATER-TIGHT GLAND aca

A

TT

Bross Gland

(Hex. rod)

Packing (J) —Y

(3 Rung)

tel Sleeve —e|

(Round rod) rf

werk] RB | on | oe] oo] el] Fl ol # | aio

20: (25s) eyo a 2oaleso lea s/o) sate ge

25) 28 | 75 | 28] 30] 12} 10 | 28} 12 | 75

30 | 34] 75 | 34] 30] 12} 10 | 28 | 10 | 75

40 | 44 | 75 | 44] 30] 12 | 10 | 28] 6 | 75

PIPING CONSTRUCTION STANDARDS Pct 12 oF

SHIPTECH [=~

WAVAL_awowirects

PIPE AND PIPE (BUTT-WELD) |e toa

lowe nO,

Py-1

Grind to

30" mox.

Before’ welding

IT=WELD JOINT (DIFFERENT THICKNI

THICKNESS

65mm (2.5in) DIA. & ABOVE

‘SYMBOL, SOmm (2in) DIA. & BELOW

ROOT FACE (H) 1.6mm (1/16in) 1.6mm (1/16in)

ANGLE (A) S75 42.5" S75 42.5)

AP 1) 3.2mm (1/8in) 4.8mm (3/16in)

GAP (G2)

3.2mm (1/8in)

3.2mm (1/8in)

JOINT -

PIPE AND PIPE (STUB-IN)

PIPING CONSTRUCTION STANDARD:

SHIPTECH [=

WAVAtaRewiTeSTS.

SYMBOL | SOmm (Zin) DIA. & BELOW | 65mm (2.5in) DIA. & ABOVE

ROOT FACE (H) 3.2mm (1/8in) 3.2mm (1/8in)

ANGLE (A) 30 30"

GAP (G) 3.2mm (1/8in) 3.2mm (1/8in)

THROAT (7) (7 xt)

(07 x)

PIPING CONSTRUCTION STANDARDS| Pace | y oF

SHIPTECH Tice: [OWS NO.

WAVAt—awewitects JOINT — PJ-4

PIPE AND FLANGE sucer 1 oF 1

1st

(2 5 MM) bs

SLIP-ON TYPE

1st

(5 MM) Rs

AT LEAST 9.5 me,

SOCK!

TP,

NOTE:

1. GAP = 1.5mm (MIN.)

REQUIRED BETWEEN END

OF PIPE AND BOTTOM OF

SOCKET BEFORE WELDING.

2. DIAMETRICAL CLEARENCE < 0.8 mm.

[PIPING CONSTRUCTION STANDARDS| pat 16 oF

SHIPTECH |"=,,, ao

NAVAL awowirects, : eS

AnGHITES PIPE & FITTING (Socket-wetp)| _ PY~5

weer 1 of 1

mY

1

TYPICAL 1.09t.

MAIN PIPE.

1.5mm REQUIRED BETWEEN END OF PIPE AND

BOTTOM OF SOCKET BEFORE WELDING — TYPICAL

2. SIZE LIMITED TO 2” NB PIPE.

3. DIAMETRICAL CLEARENCE < 0.8 mm

[PIPING CONSTRUCTION STANDARDS| pxce 16 oF

SHIPTECH [= po

PENETRATION —

NAVAL AR CHITES FOR HULL W.T DECK/BHO Co

Jower_1 oF 2

gl

Sh S10, suP-on

SID. SuP-ON § FLANGE.

FLANGE SI (CARBON STEEL)

(CARBON STEEL) a

a|4- - -@- - 2 -

| SEAMLESS CARBON

STEEL PIPE

‘

| t

L a fase

eee aa

NOTE: Type “A

FOR PIPE LINE OF SCH. 160 THICK,

PENETRATION PIPE SCHEDULE TO BE SIMILAR

WORKING PRESSURE (KG/CM?)

fa es a ee

#0 [oi] #0 [ei] #0 [abi] #0 [soi] #0 | 001

28__|“80_[80.| 70 [100] 160]130] 190] 130] 190|130] 190] 135] 195

32 30 | 10 | 20] 180] 140] 200} 140200] 140] 200] 145 [205

40 90 | 10 [125] 185] 145 [205] 145 | 205] 145 [205] 165] 225

50 100 +0 |135[185] 160] 220] 160220] 160] 220} 170] 230

100| 10 | ¥60| 220] 180 [240] 1a0| 240 180| 240] 205] 265

30 100] 10 | 185 [245] 190] 250] 205 | 265| 205] 265215] 275

00 100 10 |205| 265] 215]275| 230] 290] 230] 290| 245| 305

125 120| 42 | 210] 280| 255| 325] 275] s45| 275| 345] 260| 350

150 120 12 |270| 340] 285[ 355] 310] se0] 310| 3e0| 330| 400

200_[~40_[120] 12 | 325] 408] 335] «15| 355] «35] 355] 435 [375] 455

250 150] 12 [390[ 470} 405] 485] 435] 515] — | — =

300 150] 12 [435| 515] #80] 530| 485] 565 — | — =

350 150 15 | 485|565| 495 575[545[625| - | - | - | -

400) 150] 15 [545] 635 [565] 645 [610] 650 — | — =

450 | St0_[200| 15 [610] 700] 625]715] 680] 70| = | — :

500 200| 15 [660] 70] 680|770| 735825] - | - | =| —

| 550 200] 18 |725|825| 750|850| a00| 900) - |= [= | -

| 600 200] 15 [775] 875] 800] 900] soo[ 950] — [| - [- | —

PIPING CONSTRUCTION STANDARDS| Pace 17} oF

EEE PERCH BW HO.

SHIPTECH PENETRATION ~ pe

FOR HULL W.T DECK/BHD

sueer_2 oF 2

O

3 ney al

i

WT BHD, ! -

Tk. Fook

W,_BHO/oECK

x i s v a8

i \4

Tew WANE WATERAL

a

2 [__SEeve | CARBON STEEL

3 PIPE STPO38_SCH.60

Pipe Sleeve NOTE:

ND size Lye e2

od xt 1 Working pressure up to 10kg/cm? only.

25, 48.6x7.1 150) 5 | 150 2 For pipe line of sch. 160 thick,

32 | 605x8.7 |150| 8 [150] penetration ‘pipe Schedule lo be similr.

40_[ 605.55 [150] 8 |150

50 76.3x7.0 150] 5 | 150

65 89.1x5.5 150] 8 |150

80 1078 [150] 8 [150

100 132x8 _(150| 8 [150

125 1588 [150] 8 [150

150_[ 18710 [150] 10 [150

200 241x10 150] 10 |150

250 | 29510 |150| 10 [150

300 350x12 150] 10 | 150

350 382x12_ 150] 10 | 150

400 [43212 [150] 15 [150

450 |" 4a3x12 [200] 15 | 200

500 | 540x15 | 200] 15 [200

550_| 591415 | 200] 15 [200

600 | 642x15 [200] 15 | 200

PIPING CONSTRUCTION STANDARD:

SHIPTEC mle: PENETRATION —

AVAL ARCHITECTS. FOR HULL W.T DECK/BHD

(Tat AR PIPE OF VENT PIPE

FOR_COMPARTWENT)

Lor 3.

STD. SUP-ON

FLANGE

|

SEAMLESS. :

CARBON Stee. ———-}

PIPE

DBLR PLATE

WT v€CK/aI sand

eS

eo

TYPE A

Note:

FOR WORKING PRESSURE

UP TO 10kg/ern? only

[Ee [mp er

eee

S| ao [oes [iss [ae 37

to [a0 06" | eof 3

so [eo [ais [7-0 fa

ss [oof as [tes [toes

= 80, 40 | 220 | 10 69

ce OAT

ae ieee gee

150 [80 380 | 08 [a2 [ea

|_200_| 40 |~2e0 | 360 | 12 | 224

mo_[ cao ses [eae

soo | 40 385 [| 465 12 395,

SHIPTECH

‘EAVAL_amewiTects.

PIPING CONSTRUCTION STANDARDS| Pace 14 oF

Tite:

PENETRATION — pee

FOR HULL W.T DECK

PP-2

(ane aR PES) eee

STD. SuP-oN

FLANGE

SEAMLESS

CARBON STEEL

Petia

'

— SLEEVE

wT

ob

Ae | Sees foo] of an | ne

28_| 48.6x7.1 | 25 [150| 75 | 25

32__[60.5x8.7 | 33 [150] 75 | 25

40 [60.5x5.5 | 38 [150] 75 | 25

50_|76.3x7.0 | 60 [150] 75 | 25

| 65 _|89.1x5.5 | 63 [150] 75 | 25

a0_| 1078 | 75 [150] 75] 25

100 | 132x8 100} 150] 75 | 25

125_| 158.8 [125] 150| 75 | 25

150_| 18710 |150]150| 75 | 25

200 | 241x10 | 200 150] 75 | 25

250_| 295x10 [250] 150| 75 | 25

300 | 350«12 [300] 150] 75 | 25

TYPE - 8

NOTE:

1 For working pressure up to 10kg/em?

only.

JPIPING CONSTRUCTION STANDARDS] Pact 26 oF

SHIPTECH i:

NG No.

WAVAL_awewitects RENETRATION TS pp-2

FOR HULL W.T BHO OR TANK [o's os

BULKHEAD

TANK WALL, BULKHEAD /

STD. BOLT TANK WALL

HEX, NUT,

stuo

ne [

40 80

80 120 “|

100_| 140

150 200

V1

=< PIPE

B80 XE } Sour vous

"enor THROUGH HO ie NOT TROUGH HAE

NOTE.

STUD AND NUT MATERIAL TO BE OF

STAINLESS STEEL MATERIAL FOR

PENETRATION ON S.W & CARGO TANK.

SHIPTE

‘EAVAT—anewirects.

CH

PIPING CONSTRUCTION STANDARDS] PAce 27 oF

THE:

PENETRATION —

WG NO.

FOR HULL W.T DECK/BHD Cha.

jsveer_ tor 1

STD, SUP-ON

FLANGE

SHORT-RADIUS ELBOW

FOR WORKING PRESSURE UP TO 10KG/cM?

“foy- FLANGED JOINT OR BUTT WELD

NOTE:

ONLY

o [eof 1] eo

130_[90_| 76

80 |-140_[ 200 [10 1

40 [ 80 [us | 205 [10]

— seo [60 [a0 [0 |

5 | 80 | v0 | 20 | 10 |

eo [80 [180 | 250 | 10 | 9

wo [a0_[ 215 | 275] 10 1

wzs_[ a0 | 285 | 395 [12 17

150 | 60 | 285 | 355 | 12 1]

200 | 40_| sss [ais [121]

250_|40_| 405 | as | 2_|7

300 | 49

“50

330

12

SHIPTECH

AVAL ARCHITECTS:

PIPING CONSTRUCTION STANDARDS] Pace 22 oF

THLE:

PENETRATION — oe Wo.

FOR OVERBOARD DISCHARGE pp-4

(TYPE = A)

sueet_1 oF 2

STORM VALVE

(FoR SCUPPER AND SOIL

Kt

2-OFF 75%75x6 THK. (25~65NB)

4-OFF 125412506 THK. (€0-150N8)

OKT: 4=OFF 250325046 THK. (200-3008

aa pe i

Seti oa te s

sone, vase gost & 4

ae aaa, Ed a

8 ora 25

IN A

3

2

rime sree. we

a

|| Es

sm sup-o

Me

a} |10

WORKING PRESSURE < 1040/2

save arena:

CAST-SEEL BRONZE OR MALLABLE OW

iS seeeran a Pen Se Bm)

FLANGE (uIS_10KG/CM2)

Pre Tipe Ta BOLT HOLE ao

NO lwo sibe ‘se

Sa | ol 1 |. beep a ar

B70 [ies | bese Ee

se] 70 [iss [16 Pros | too [eae

fo “70— piss [te [ras tae sf

os [ one brrs iw [ras | ioe foe

eo| “re [vas [we Piss {seep

Too] aa [aio we piss | vst ie [spe

vas [ar [aso a6 [ise ae] ae [eae

iso too [een oe [se | ae [ as ef ae

zoo | 125 [sso] ae fase ao as [ef a

250[125 [400 | aL | see as] Pa

ool ias Las par [aso wae fas [ef ee

PIPING CONSTRUCTION STANDARD:

PAGE D3 OF

SHEPTECH [= pencrranon - eae

‘WAVAt_awenTrecTS FOR OVERBOARD DISCHARGE PP-4

(TYPE _~ B) sueer_2 oF 2.

STORM vatve

(FoR SCUPPER AND SOUL

DISCHARGE ONLY)

SONA. VALVE

(FOR ORDINARY DISCHARGE)

OKT: 2-OFF 75e75x6 THK (25-65N8)

KT: 4—OFF 125412515 THK (80—150N0)

BAT. 4-OFF _2501250x6 THK (200-300N8)

° 2

MB &

casker BS :

stu z a

t

oo

ome sree. Pe

1

com

ls

Poe

CAST-STEEL FOE OR MALEABLE ROL

FS Sree ee a

Tome STORET

ee ae ee sour

a sae

G2 | oo | 1 |. beep a Car

Bp 10 pes ie fest sop ef pas

32 | 70 135 | 16 [105] 100 19 4 M16

wo | 70 Die fost ose

50 7.0 155 | 16 | 105] 120 19 4 M6

eS 70[ se Peet of

oo] asp [es eT ae

vas [ vat pase oo Piss ae [ ae ete

soo fas} a [ise [sao | as [et

zoo 1a8~|s50| = [seo ase [as

350 | 128 [400 | re [seo [es] as [1a at

300 | 125 | 445 | 24 | 280| 400 |” 25, 16 ‘M22

PIPING CONSTRUCTION STANDARDS] Pace 24 oF

SHIPTECH | pre

SATE ET SUCTION FITTING — SF-1

MAVAL ARCHITECTS _

MUD BOX

ae

M16 Wing nut

with fitting

(4-off, true

position shown

fen plan

|

Flonge OD

TIS 5K Flange

‘SCH, 40

2043.2 Q

NEOPREN

flonge 00__| section an

IS 5K Flange So 3

DETAIL_X

60

* \ 7

wt /

vi

PERFORATED PLATE

AER: GALYO MAD STEEL

1 eerons in me

PIPE SIZE WeIGeT

ES | wee su] ox 8 ¢ o |e na

50, 40 160 180 100 130 10,

3 CC SE

20) 40) 285; 235 | 138 250 {20

108 nose | ten fr] tr no [sso [cz

125 eee ven] evo [eye ow |cEzo

|PIPING CONSTRUCTION STANDARDS| Pace 9 § oF

SHIPTECH [=

SUCTION FITTING— F-2

ROSE BOX (TYPE A) sl

jeer 1 oF 1

: 12

pb

Perforoted —

‘SECTION plate

“x PIECE

ene

fe)

(®

‘A’ PIECE “B' PIECE

COMBINED AREA OF >> 2 x AREA OF

errors Beever

‘@ PIECE

PLAN

stems oxo am srect

(Petrted ee)

PIPE SIZE ‘WEIGHT

NOM, OIA, 4 f ‘a fe = c (KG)

Ge |r

So a ero art os [a [aero

eer ower eer re at (eee

eee Ra ae rors poe | ea lero =

foo ara ose eet aor [coor eee ee ea z

se of ees arenes fe

a

200] 380 | “a00 | ae] ast

see esa [ara] ace [eater

a acu een fg peee|r|a

PIPING CONSTRUCTION STANDARDS| Pace 2.6 oF

SHIPTECH |=

‘WAVAL_AROMITECTS SOUNDING -

bac no

PIPE LAYOUT & DETAIL an

jsweer_1 of 1

SOUNDING HEAD

ie

LT oe

OPEN peck

\

2 Hoes —

810mm: @

5 'Puces 3

7 |

Pee ‘SLEEVE

+ i}

+} _tanic toe

yy

12 Howes ~ 1

eon

$ :

eel TANK BOTTOM

10" 10"

10° 10"

BENT SOUNDIN:

‘TYPIGAL_TANK SOUNDING DETAI

NOTE: PIPE RUN ARE TO BE STRAIGHT

AS PRACTICABLE AND IF THEY

ARE CURVED, THE CURVATURE

IS TO BE SUFFICIENTLY LARGE.

PIPING CONSTRUCTION STANDARDS| Pace 27 oF

SHIPTECH [=

Wavat aeemirects:

SOUNDING -

SOUNDING HEAD

fae No.

SP-2

PLUG

(Mat. := BRONZE)

290

975

|. _ 970

=

ser toe 3

beck

You might also like