Professional Documents

Culture Documents

All-Solid-State High Performance Asymmetric Supercapacitors Based On Novel Mns Nanocrystal and Activated Carbon Materials

Uploaded by

Luis Alberto MiglioreroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

All-Solid-State High Performance Asymmetric Supercapacitors Based On Novel Mns Nanocrystal and Activated Carbon Materials

Uploaded by

Luis Alberto MiglioreroCopyright:

Available Formats

www.nature.

com/scientificreports

OPEN All-solid-state high performance

asymmetric supercapacitors based

on novel MnS nanocrystal and

received: 15 November 2015

accepted: 03 March 2016 activated carbon materials

Published: 29 March 2016

Teng Chen1, Yongfu Tang1, Yuqing Qiao1, Zhangyu Liu1, Wenfeng Guo1, Jianzheng Song1,

Shichun Mu2, Shengxue Yu1, Yufeng Zhao1 & Faming Gao1

All-solid-state high-performance asymmetric supercapacitors (ASCs) are fabricated using γ-MnS as

positive electrode and porous eggplant derived activated carbon (EDAC) as negative electrode with

saturated potassium hydroxide agar gel as the solid electrolyte. The laminar wurtzite nanostructure of

γ-MnS facilitates the insertion of hydroxyl ions into the interlayer space, and the manganese sulfide

nanowire offers electronic transportation channels. The size-uniform porous nanostructure of EDAC

provides a continuous electron pathway as well as facilitates short ionic transportation pathways. Due

to these special nanostructures of both the MnS and the EDAC, they exhibited a specific capacitance

of 573.9 and 396 F g−1 at 0.5 A g−1, respectively. The optimized MnS//EDAC asymmetric supercapacitor

shows a superior performance with specific capacitance of 110.4 F g−1 and 89.87% capacitance retention

after 5000 cycles, a high energy density of 37.6 Wh kg−1 at a power density of 181.2 W kg−1 and remains

24.9 Wh kg−1 even at 5976 W kg−1. Impressively, such two assembled all-solid-state cells in series can

light up a red LED indicator for 15 minutes after fully charged. These impressive results make these

pollution-free materials promising for practical applications in solid aqueous electrolyte-based ASCs.

Supercapacitor, as an advanced energy storage device possesses multiple desirable properties including high

power density, fast charging/discharging capability and excellent cycling stability, which hopefully meet the expo-

nentially growing demand of consumer electronics1,2. However, up to now, most commercially available super-

capacitors with a low energy density (< 10 Wh kg−1), which has restricted their application as primary power

sources to replace batteries3,4. Note that, the energy density (E), which denoted as E = CV2/2, can be improved by

increasing the specific capacitance (C) of electrode materials and/or extending the operating potential window

(V). Currently, two strategies are used to extend the operating potential window: using organic electrolytes (up to

4 V) or developing asymmetric supercapacitor (ASCs)4. As compared to aqueous electrolyte, organic electrolytes

can provide a better electrochemical stability for electrodes, which however usually suffer from limited ionic

conductivity, poor safety and toxicity5,6. Therefore, ASC design in aqueous electrolytes is an efficient approach to

extend the operating potential window and provide effective energy density. These asymmetric supercapacitors

are usually composed of a battery-type Faradaic electrode (as the energy source) and a capacitor-type electrode

(as the power source), which offering the superiorities of both the battery-type material (energy density) and

the capacitor-type material (cycle life, electron transfer rate)7,8. Meanwhile, ASCs can make full use of the dif-

ferent potential windows of the electrode materials, accordingly provide a maximum potential window in the

cell system7,9. Therefore, selecting proper materials for both positive and negative electrodes to assemble a high

performance ASCs are critical.

Hitherto, transition metal oxides/sulfides have been extensively investigated as the positive electrode materials

due to their high pseudocapacitance1,6,10,11. Among them, manganese sulfide (MnS) nanocrystals have drawn

increasing attention because of its remarkable predominance such as high theoretical specific capacitance, inex-

pensive, environmental friendliness, and higher electronic conductivity (as high as 3.2 × 103 S/cm) than their

1

Key Laboratory of Applied Chemistry, College of Environmental and Chemical Engineering, Yanshan University,

Qinhuangdao, 066004, China. 2State Key Laboratory of Advanced Technology for Materials Synthesis and

Processing, Wuhan University of Technology, Wuhan, 430070, China. Correspondence and requests for materials

should be addressed to Y.T. (email: tangyongfu@ysu.edu.cn)

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 1

www.nature.com/scientificreports/

Figure 1. (a) Structures of manganese sulfide: α -MnS (2 × 1tunnel), β -MnS (1 × 1tunnel) and γ -MnS (laminar

structure), (b) Suitable structure of γ -MnS nanocrystal and (c) polyporous EDAC for electrochemical reactions

in ASCs.

BET SSA Micropore Micropore Average pore Specific

Sample (m2 g−1) Area (m2 g−1) volume (cm3 g−1) diameter (nm) capacitance (F g−1)

EDAC 2764.3 1423.6 0.58 1.7 396.0

Black Pearl 2000 1379 934 0.22 8.6 100.7

Ketjen Black EC 600J 1439 189 0.14 6.5 45.3

Vulcan XC-72 213 114 0.06 9.4 15.2

Acetylene Black 1304 184 0.0045 3.1 4.1

Table 1. BET specific surface area, micropore Area, micropore volume, average pore diameter and specific

capacitance at 0.5 A g−1 of EDAC and other commercial activated carbons33–39.

oxides or hydroxides1,5,12. In addition, the laminar nanostructure (especially γ -phase with a wurtzite structure)

accelerates the penetration of electrolyte and the intercalation of ions, which promotes its intrinsic electrochem-

ical reactivity for the capacitive behavior vastly (Fig. 1a). For instance, we have successfully synthesized γ -phase

MnS nanocrystal by tuning the sulfide ion content with ammonia as the complex agent and precipitator, of which

the specific capacitance reached 704.5 F g−1 11, which is much higher than MnO2 (310 F g−1 at 2 mV s−1)13, Mn3O4

(314 F g−1 at 2 mV s−1)14.

It is generally known that carbonaceous materials are widely used as negative electrode materials, because of

their high surface area, excellent conductivity and low cost. However, compared to positive electrode materials

(such as transition-metal oxides, sulfides et al.)10,15,16, they usually present much lower specific capacitance (e.g.

actived carbon, carbide derived carbons, graphene, and so on)1–3,17,18, which restricts the overall performances

of ASCs largely. The capacitance of carbonaceous material depends on its structure, because of the capacitance

comes from charge accumulation at the interface of electrode material and electrolyte. It is therefore necessary for

researchers to develop a carbonaceous material with proper structure. Such as Qie et al.19 synthesized 3D hierar-

chical porous carbon, resulting in a high specific capacitance of 318.2 F g−1 was achieved.

Herein, we developed an all-solid-state high-performance ASC with agar gel as the solid electrolyte by employ-

ing novel MnS nanocrystal and porous eggplant derived activated carbon (EDAC) with high specific capacitance

as positive and negative electrodes, respectively. The rod-like structure of MnS nanocrystals provide electronic

transmission channels (Fig. 1a); meanwhile, the higher BET specific surface area, micropore area and pore vol-

ume of the EDAC (Table 1) can promote the reversible adsorption/desorption of electrolyte ions on the surface

of the carbonaceous materials, accordingly providing not only an enhanced power/energy density but also a high

rate capability20. Because of these specific nanostructures, the MnS nanocrystal and the EDAC electrodes showed

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 2

www.nature.com/scientificreports/

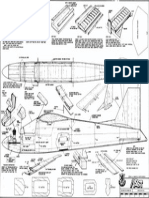

Figure 2. (a) XRD pattern of MnS nanocrystal, (b) low-magnification, (c) high-magnification FESEM images

and (d) high-magnification (inset is selected area diffraction), (e) low-magnification TEM images of MnS

nanocrystal, (f,g) HRTEM image of MnS nanocrystal (insets is its FFT plots).

high specific capacitances of 573.9 and 396 F g−1 at 0.5 A g−1 in 2.0 M KOH electrolyte with a conventional three

electrode system, respectively. In asymmetric supercapacitor, MnS//EDAC shows a superior device performance

with specific capacitance of 110.4 F g−1 and 89.87% specific capacitance retained after 5000 cycles. Importantly,

the device exhibits a high energy density of 37.6 Wh kg−1 at a power density of 181.2 W kg−1 and remains 24.9 Wh

kg−1 at 5976 W kg−1.

Results and Discussion

The composition and phase structure of MnS nanocrystal were characterized by the X-ray diffraction (XRD)

patterns, as shown in Fig. 2a. Characteristic peaks of MnS showed a highly crystalline character, which were

composed mainly of γ - and small amount of α - and β -phases1,11. As shown in Fig. 1a, manganese sulfides have

very diverse structures via sharing corners or edges. Rock salt-type α -MnS (2 × 1) and zinc blende-type β -MnS

(1 × 1) composed by edge- and corner-sharing Mn octahedra with tunneled structures, which were unsuita-

ble for the transportation of molecules and ions. Wurtzite-type γ -MnS mainly composed of edge-sharing Mn

octahedra, possesses a laminar structure. This structure permits water molecules or hydroxyl anions to easily

transfer into/out of the interlayer region, thus more accessing to the total number of Mn ions and exhibiting

higher capacitance11,21,22. The γ phase, predominantly caused by the metastable forms (β - and γ -), can be easily

precipitated from an aqueous solution in a low-temperature range23. Once the temperature or pressure rise to a

point or reaction in the reductive condition, the metastable phases will transform irreversibly into stable form.

The transformation follows the order: zinc blende (β -)rock salt and wurtzite (α -, γ -)rock salt (α -)24. Here, the

MnS nanocrystal was obtained at 120 °C in 100 mL Teflon-lined stainless-steel autoclave without reductive agent

(Experimental Section in SI). Under this reaction condition, the aqueous solution will evaporate partly, caus-

ing the increase of pressure and leading to the transformation accordingly, and then forming MnS nanocrystals

contains α -, γ -MnS and little β -MnS. Figure 2b,c show the FESEM images of MnS nanocrystal at different mag-

nifications. It can be seen that, the MnS nanocrystals were mainly composed of nanowires with the lengths of

0.5~3 μm and the diameters of 10~20 nm, with partly nanoparticles (10~20 nm in size) sticking on them. The

wire-like MnS nanocrystal (Fig. 1b) provides an electronic transfer channel, which is expected to improve the

conductivity and rate capacity of the obtained MnS nanocrystal. Based on this special structure and the similar

size of nanowires and nanoparticles, we propose the growth mechanism for MnS nanocrystal, which is shown in

Fig. 3. When the thiourea decomposed by heating in alkaline environment, the generated sulfide ions combine

with the manganese ions and the MnS precipitation is formed accordingly (Eqs S1~3). With increasing reaction

time, the chemical etching will result in dissolution and recrystallization of MnS precipitation, and the wire-like

structures are obtained under the action of a orientation force. As the reaction time increased to 5 h or longer

(Fig. S1), the MnS nanowires would decompose into nanoparticles. The mechanism of the decomposition can be

described as follow: because of the high surface free energy of wire-like MnS, it would combine with the hydroxyl

in solution and transform into MnSOH. Due to the larger lattice size of MnSOH than MnS, the decomposition

caused by the expansion of the lattice will occur with the increasing of reaction time. The TEM images (Fig. 2d,e)

also revealed the wire-like structure of MnS and its excellent dispersibility. In addition, the selected-area elec-

tron diffraction (inset of Fig. 2d) indicates the poly-crystalline characteristic of the MnS nanocrystal, which is

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 3

www.nature.com/scientificreports/

Figure 3. Schematic illustration of the as-fabricated asymmetric supercapacitor (ASCs) device based on

MnS nanocrystal as the positive electrode and EDAC as the negative electrode and the preparation process

of MnS and EDAC.

Figure 4. (a) XRD pattern of the samples for comparison and the EDS spectrum of EDAC (inset), (b) XPS

survey spectra of EDAC, (c) low-magnification, (d) high-magnification TEM images, (e) FESEM image of

EDAC, (f) HRTEM image of EDAC (and its FFT plots inset).

consistent with the XRD results. Along the direction of the nanowires, the lattice fringe distance is ~0.23 nm in

high resolution TEM (HRTEM) image (Fig. 2f), which is corresponding to the (102) planes of γ -MnS. The lattice

fringe distances in MnS nanoparticles are 0.16, 0.25, and 0.35 nm, close to that of the γ (004), γ (220), and α (100),

respectively. Meanwhile, the FFT plots (insets of Fig. 2f,g) further confirm the poly-crystalline characteristic of

MnS nanocrystals.

The XRD patterns of the graphitized EDAC carbons are shown in Fig. 4a. The characteristic peaks at around

26° and 43° corresponds to the (002) and (100) reflections of a graphite-type carbon structure, demonstrating

the graphitic structures were formed as consequence of heat treatment via high-temperature polymerization

method25,26. In addition, the broader Bragg reflection peaks on activated carbon with secondary carbide process-

ing (EDAC) than without (EDACuntreated) reveal that the carbonization process at high temperature is conducive to

the formation of amorphous carbon, corresponding to the formation of porous structure27. The X-ray photoelec-

tron spectroscopy (XPS) was used to investigate the surface states of the activated carbons. As shown in Fig. 4b,

the atom ratio of C and O in EDAC is about 88.04:11.96. The oxygen is mainly assigned to the oxygen-containing

groups on the surface of EDAC. The FTIR analysis was performed and shown in Fig. S2a to confirm their exist-

ence. The intensive characteristic peak at 3435 cm−1 originated from the stretching vibration of the O-H bond28.

The characteristic peaks around 1380, 1623, 2840 and 2917 cm−1 correspond to the stretching vibration of C-O

bond, C-H bond, and C= C bond, respectively29.

The morphology and the nanostructure of EDAC were investigated by TEM, FESEM and HRTEM technolo-

gies. Figure 4c,d show the TEM images at different magnification. Numerous crossed holes with a honeycomb-like

structure are observed in the obtained EDAC. Note that, the precursor (eggplant, Fig. S2b) and the intermediate

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 4

www.nature.com/scientificreports/

Figure 5. (a) Nitrogen adsorption/desorption isotherms and (b) BJH pore size distribution of EDAC carbon.

material (EDACuntreated, Fig. S2c,d) are nonporous. The pore network in carbons should be formed during KOH

activation process via the reactions in Eqs (1–5)30,31.

6KOH + 2C → 2K + 3H 2 + 2K 2CO3 (1)

K 2CO3 → K 2O + CO2 (2)

K 2CO3 + 2C → 2K + 3CO (3)

CO2 + C → 2CO (4)

C + K 2O → 2K + CO (5)

The size of holes is ranged from 0.35~70 nm, which is substantially larger than twice the size of the solvated

ions (K+ and OH−), contributing capacitance from compact layers of ions residing on both adjacent hole walls32.

The FESEM image in Fig. 4e demonstrates the uniform dispersity of the activated carbons. Figure 4f shows the

HRTEM image and the FFT plots. In HRTEM image, the lattice fringe spacing was measured to be ~0.21 nm,

corresponding to (100) planes of graphite-type carbon, which is consistent with the XRD result. The pore size

distribution of the as-prepared activated carbon are studied by nitrogen adsorption-desorption measurement at

77 K. The I-type isotherm plots shown in Fig. 5a indicate that the microporous (≤ 2 nm) structure is predominant

in EDAC25. According to t-Plot analysis, the micropore area is up to 1423.6 m2 g−1, accounting for around 51.5%

of its BET surface area (2764.3 m2 g−1). Moreover, the micropore volume is as high as 0.58 cm3 g−1 (total pore vol-

ume of 1.09 cm3 g−1), which is much higher than commercial activated carbons, as shown in Table 1. Meanwhile,

besides high surface area from micropores, mesopores are also observed in the EDAC (Fig. 5b). The sluggish

isotherm and the high surface area derived from the pores larger than 2 nm (1340.7 m2 g−1 and 0.51 cm3 g−1 for

mesopores) demonstrate the mesoporous structure of the EDAC.

The electrochemical properties of the as-prepared MnS nanocrystals and EDAC were measured as working

electrodes in a three-electrode system. As shown in Figure 6a,b, the quasi-rectangular CV curves of EDAC elec-

trode at different scan rates demonstrate its ideal double-layer capacitive behaviour. When the scan rate reached

up to 200 mV s−1, the remained typical rectangular shape should be ascribed to the porous structure of EDAC.

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 5

www.nature.com/scientificreports/

Figure 6. (a) CV curves of MnS and EDAC electrodes 5 mV s−1, (b) CV curves of EDAC electrode at different

scan rates, (c) charge-discharge curves of MnS electrodes at different current densities, (d) charge-discharge

curves of EDAC electrodes at different current densities, (e) specific capacitance calculated at different current

densities, and (f) EIS Nyquist plots of MnS and EDAC electrodes. The insets are the corresponding equivalent

circuit.

The obvious redox peaks shown in CV (Fig. 6a) and charge-discharge curves (Fig. 6c) of MnS electrode can be

attributed to the Faradaic redox reactions described as Eqs 6 and 7 40,41.

MnS + OH − ⇔ MnSOH + e− (6)

MnSOH + OH − ⇔ MnSO + H 2O + e− (7)

The excellent linear slope (close to equicrural triangle) from the various galvanostatic charge-discharge curves

of EDAC (Fig. 6d) indicate its typical capacitive behavior42. The specific capacitances of the electrodes, which cal-

culated from the charge-discharge process based on Eq. S4, are shown in Fig. 4e. Based on the laminar structure

and high electronic conductivity of the MnS nanocrystal, it delivers the specific capacitance of 573.9, 471.6, 431.4,

415.0, and 372.9 F g−1 at 0.5, 1, 2, 5, and 10 A g−1, respectively. Meanwhile, benefited from the high specific surface

area and high total pore volume, EDAC reveals a much high specific capacitance of 396.0, 368.6, 339.4, 329.7, and

315.3 F g−1 at 0.5, 1, 2, 5, and 10 A g−1, with a capacitance retention of 79.63%. The specific capacitance at 0.5 A g−1

is slightly less than the highest reported value (411 F g−1)43. The outstanding charging-discharging performance of

EDAC should be ascribed to its porous nanostructure, which can not only provide a continuous electron pathway,

but also facilitate short ionic transportation pathways44–46.

To further investigate the electrochemical performance of the electrodes, electrochemical impedance spec-

troscopy (EIS) analysis was used in the frequency range of 0.1~105 Hz. The Nyquist plot of the electrodes were

illustrated in Fig 6f, with a fitted equivalent circuit (inset) and the values of Rs, Rct, Cp, and CPE were calculated

using the ZSimpWin software and the calculated values are listed in Table S1 47,48. The Rs is the total ohmic resist-

ance of electrolyte resistance, intrinsic resistance of material, and contact resistance at the active material/current

collector interface49. The Rct of MnS electrode represents charge-transfer resistance, whereas the Rct of EDAC is

responsible for the self-discharge process. The time constant of the self-discharge is equal to Rct·CPE47. The low

R(s+ct) values of MnS (4.13 + 5.31) and EDAC (3.29 + 1.55) demonstrate their high electronic conductivity and

electrochemical reactivity50.

Based on the excellent performances of positive and negative materials, an asymmetric supercapacitor was

assembled and denoted as MnS//EDAC supercapacitor. The mass balance between electrodes was calculated on

the basis of the equivalence of charges passing across the positive or the negative electrode (q+ = q−)51. Therefore,

the mass ratio of positive and negative electrodes (m+/m−) can be calculated by Eq. 8:

m+ C − × ∆V −

=

m− C + × ∆V + (8)

The loading amount of positive/negative materials in this ASCs is 2.0/2.61 mg cm , respectively. As shown in

−2

Fig. 7a, the MnS//EDAC asymmetric supercapacitor shows an ideal capacitive behavior with quasi-rectangular

CV curves, even at a scan rate of 100 mV s−1, indicating its desirable high rate charging/discharging property for

power devices. The galvanostatic charge/discharge curves (inset of Fig. 7b) show equicrural triangle shapes and

are considerably symmetrical, demonstrating the good reversible performance of MnS//EDAC supercapacitor.

The specific capacitance calculated by Eq. S4 and the coulombic efficiency based on Eq. S5 are shown in Fig. 7b.

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 6

www.nature.com/scientificreports/

Figure 7. (a) CV curves of MnS//EDAC at different scan rates, (b) specific capacitance and coulombic

efficiency calculated by charge-discharge curves (inset) of MnS//EDAC, (c) cycle performance at a current

density of 1 A g−1, and (d) Ragones plots of asymmetric supercapacitors (calculated by the total active

materials), (e,f) A red LED powered by two assembled ASC devices in series.

The calculated specific capacitances at the current densities of 1.0, 2.0, 4.0, 8.0, 20.0, and 50.0 mA are 110.4, 104.0,

101.2, 97.74, 97.09, and 97.09 F g−1, respectively. The high capacitance retention of 87.94% should be attributed to

their higher electronic conductivity and the particular pore structure of EDAC. The lower coulombic efficiency

(slightly higher than 90%) at low current density should be attributed to that the ratio of the side reactions at low

current density is higher than that at high current density. The capacitance decay for the cell mainly because of the

broken up of manganese sulfide nanowires, as shown in Fig. S3b~d. The original wire-like nanostructure provides

transfer paths for electron, as shown in Fig. 1b. With the process of charging and discharging, the MnS nanowires

broken up, which affected the electronic conduction seriously and caused the decay of capacitance. Note that, all

of the coulomb efficiencies in different charge-discharge current densities are higher than 90%. In term of the

cycle life, the MnS//EDAC cell shows capacitance retention of 89.87% over 5000 cycles (Fig. 7c), which should

be attributed to the following respects: (1) the layered wurtzite structure of γ -MnS nanocrystal is much better

accessible for the reactant molecules and cations through the interlayer space, which can be observed visually

from XRD patterns at different state of charges (Fig. S3a)52; (2) the ideal stability of MnS nanocrystal. After 1000

charge/discharge cycles, the crystal structure is reserved even though the manganese sulfide nanowires broken up

into nanoparticles (Fig. S3b~d); (3) the particular pore structure of EDAC. When holes were substantially larger

than twice the size of the solvated ions (OH−), there was a contribution to capacitance from compact layers of

ions residing on both adjacent hole walls31. Ragone plots, depicting the relationship of power densities (P) and

energy densities (E), which were calculated by Eqs S6 and S7 are shown in Fig. 7d. The energy density reaches up

to 37.6 Wh kg−1 at a power density of 181.2 W kg−1. Even at the high power density of 5976 W kg−1, the energy

density remains as high as 24.9 Wh kg−1. The energy densities are much higher than other asymmetric super-

capacitors in aqueous electrolyte, such as AC//AC (< 10 Wh kg−1)53, CNT//CNT (< 10 Wh kg−1)54, FeOOH//

MnO2 (24 Wh kg−1)55, activated carbon//MnO2 (17.3 Wh kg−1)56. Furthermore, we assembled two ASCs in series

(the loading amount of MnS/EDAC are 5.74/5.81 and 5.96/5.89 mg cm−2, respectively) with saturated potassium

hydroxide agar gel as separator and electrolyte and lighted up a red LED indicator for 15 minutes, as shown in

Fig. 7e,f. All these results demonstrated their practical application merit intuitively.

Conclusions

In summary, a low-cost high-performance asymmetric supercapacitors (ASCs) has been assembled using γ -MnS

as positive electrode and EDAC as negative electrode with saturated potassium hydroxide agar gel as the separator

and electrolyte. Because of the special nanostructure of MnS and EDAC, the MnS//EDAC asymmetric superca-

pacitor shows high specific capacitance, outstanding energy density, excellent cycling stability at an operating

voltage of about 1.60 V. Impressively, such two assembled all-solid-state cells in series can light up a red round

LED indicator for 15 minutes after fully charged. The inexpensive and pollution-free materials and the remarka-

ble electrochemical performances will enable them a good practical application prospect.

References

1. Tang, Y. F. et al. Synthesis of graphene oxide anchored porous manganese sulfide nanocrystals via the nanoscale Kirkendall effect for

supercapacitors. J. Mater. Chem. A. 3, 12913 (2015).

2. Wang, J. G. et al. A high-performance asymmetric supercapacitor based on carbon and carbon–MnO2 nanofiber electrodes. Carbon.

61, 190 (2013).

3. Frackowiak, E. et al. Carbon materials for supercapacitor application. Phys Chem Chem Phys. 9, 1774 (2007).

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 7

www.nature.com/scientificreports/

4. Gao, H. et al. High-performance asymmetric supercapacitor based on graphene hydrogel and nanostructured MnO2. ACS Appl

Mater Interfaces. 4, 2801 (2012).

5. Zhao, Y. et al. High-Performance Asymmetric Supercapacitors Based on Multilayer MnO2/Graphene Oxide Nanoflakes and

Hierarchical Porous Carbon with Enhanced Cycling Stability. Small. 11, 1310 (2015).

6. Chen, P. C. et al. Preparation and characterization of flexible asymmetric supercapacitors based on transition-metal-oxide nanowire/

single-walled carbon nanotube hybrid thin-film electrodes. ACS Nano. 4, 4403 (2010).

7. Yan, J. et al. Advanced Asymmetric Supercapacitors Based on Ni(OH)2/Graphene and Porous Graphene Electrodes with High

Energy Density. Adv Funct Mater. 22, 2632 (2012).

8. Wu, Z. S. et al. High-energy MnO2 nanowire/graphene and graphene asymmetric electrochemical capacitors. ACS nano. 4. 5835

(2010).

9. Zhao, X. et al. Incorporation of manganese dioxide within ultraporous activated graphene for high-performance electrochemical

capacitors. ACS nano. 6. 5404 (2012).

10. Tang, Y. et al. A highly electronic conductive cobalt nickel sulphide dendrite/quasispherical nanocomposite for a supercapacitor

electrode with ultrahigh areal specific capacitance. J. Power Sources. 314, 295 (2015).

11. Tang, Y. et al. Morphology controlled synthesis of monodispersed manganese sulfide nanocrystals and their primary application in

supercapacitors with high performances. Chem Commun. 51, 9018 (2015).

12. Ma, D. et al. One-pot synthesis and magnetic, electrical properties of single-crystalline α -MnS nanobelts. Chem Phys Lett. 462, 96

(2008).

13. Yan, J. et al. Fast and reversible surface redox reaction of graphene–MnO2 composites as supercapacitor electrodes. Carbon. 13, 48

(2010).

14. Dubal, D. P. et al. A novel chemical synthesis and characterization of Mn3O4 thin films for supercapacitor application. Applied

Surface Science. 14, 256 (2010).

15. Li, X. et al. Fabrication of γ -MnS/rGO composite by facile one-pot solvothermal approach for supercapacitor applications. J. Power

Sources. 282, 194 (2015).

16. Tang, Y. et al. Highly Oxidized Graphene Anchored Ni (OH)2 Nanoflakes as Pseudocapacitor Materials for Ultrahigh Loading

Electrode with High Areal Specific Capacitance. J. Phys. Chem. C. 43, 118 (2014).

17. Huang, W. T. et al. Hierarchical Porous Carbon Obtained from Animal Bone and Evaluation in Electric Double-Layer Capacitors.

Carbon. 49, 838 (2011).

18. Lv, Y. K. et al. A Self-Template Synthesis of Hierarchical Porous Carbon Foams Based on Banana Peel for Supercapacitor Electrodes.

J. Power Sources. 209, 152 (2012).

19. Qie, L. et al. Synthesis of Functionalized 3D Hierarchical Porous Carbon for High-Performance Supercapacitors. Energy Environ.

Sci. 6, 2497 (2013).

20. Fan, Z. et al. Asymmetric supercapacitors based on graphene/MnO2 and activated carbon nanofiber electrodes with high power and

energy density. Adv. Fun Mater. 21, 2366 (2011).

21. Bergmann, A. et al. Electrochemical water splitting by layered and 3D cross-linked manganese oxides: correlating structural motifs

and catalytic activity. Energy Environ. Sci. 6, 2745 (2013).

22. Meng, Y. et al. Structure− Property Relationship of Bifunctional MnO 2 Nanostructures: Highly Efficient, Ultra-Stable

Electrochemical Water Oxidation and Oxygen Reduction Reaction Catalysts Identified in Alkaline Media. J Am Chem Soc. 32, 136

(2014).

23. Lu, J. et al. Metastable MnS Crystallites through Solvothermal Synthesis. Chem. Mater. 13, 2169 (2001).

24. Kennedy, S. W. et al. Mechanisms of Thermal Transformation of Zinc Blende to [NaCl] in MnS Crystals. J Solid State Chem. 31, 355

(1980).

25. Zhao, Y. et al. Oxygen-Rich Hierarchical Porous Carbon Derived from Artemia Cyst Shells with Superior Electrochemical

Performance. ACS Appl Mater Interfaces. 7, 1132 (2015).

26. Sevilla, M. et al. Catalytic graphitization of templated mesoporous carbons. Carbon, 44, 468 (2006).

27. Sajitha, E. P. et al. Synthesis and characteristics of iron nanoparticles in a carbon matrix along with the catalytic graphitization of

amorphous carbon. Carbon. 42, 2815 (2004).

28. Wang, D. et al. Facile synthesis of porous Mn3O4 nanocrystal–graphene nanocomposites for electrochemical supercapacitors. Eur J.

Inorg Chem. 4, 628 (2012).

29. Zhang, H. et al. Synthesis of bacteria promoted reduced graphene oxide-nickel sulfide networks for advanced supercapacitors. ACS

Appl Mater Interfaces. 5, 7335 (2013).

30. Wang, J. et al. KOH activation of carbon-based materials for energy storage. J. Mater. Chem. 45, 22 (2012).

31. Raymundo-Pinero, E. et al. KOH and NaOH activation mechanisms of multiwalled carbon nanotubes with different structural

organisation. Carbon. 43, 786 (2005).

32. Chmiola, J. et al. Anomalous increase in carbon capacitance at pore sizes less than 1 nanometer. Science. 313, 1760 (2006).

33. Lefèvre, M. et al. Iron-based catalysts with improved oxygen reduction activity in polymer electrolyte fuel cells. science, 324, 5923

(2009).

34. Wang, X. et al. A bi-functional micro-porous layer with composite carbon black for PEM fuel cells. J. Power Sources. 1, 162 (2006).

35. Tang, Y. et al. Comparative Study on Three Commercial Carbons for Supercapacitor Applications. Russ J Electrochem. 1, 51 (2015).

36. Osaka, T. et al. Acetylene black/poly(vinylidene fluoride) gel electrolyte composite electrode for an electric double-layer capacitor.

J. Power Sources. 1, 74 (1998).

37. Wu, C. et al. Hydrogen generation from catalytic hydrolysis of sodium borohydride for proton exchange membrane fuel cells. Catal

Today. 93, 477 (2004).

38. Leonard, N. D. et al. Carbon Supports for Non-precious Metal Proton Exchange Membrane Fuel Cells. ECS Transactions. 41, 1

(2011).

39. Kang, J. et al. Hierarchical meso-macro structure porous carbon black as electrode materials in Li-air battery. J. Power Sources. 261,

156 (2014).

40. Messaoudi, B. et al. Anodic behaviour of manganese in alkaline medium. Electrochim. Acta, 46, 2487 (2001).

41. Jiang, J. et al. Electrochemical supercapacitor material based on manganese oxide: preparation and characterization .Electrochim.

Acta. 47, 2381 (2002).

42. Sun, X. et al. Morphology controlled high performance supercapacitor behaviour of the Ni-Co binary hydroxide system. J. Power

Sources. 238, 150 (2013).

43. Liu, M. et al. Core-shell ultramicroporous@microporous carbon nanospheres as advanced supercapacitor electrodes. J. Mater.

Chem. A. 3, 11517 (2015).

44. Wang, D. W. et al. Synthesis and dye separation performance of ferromagnetic hierarchical porous carbon. Carbon. 46 ,1593 (2008).

45. Chen, Z. P. et al. Three-dimensional flexible and conductive interconnected graphene networks grown by chemical vapour

deposition. Nat. Mater. 10, 424 (2011).

46. Rakhi, R. B. et al. Nanostructured Ternary Electrodes for Energy-Storage Applications. Adv. Energy Mater. 2, 381 (2012).

47. Frackowiak, E. et al. Carbon materials for the electrochemical storage of energy in capacitors. Carbon. 39, 937 (2001).

48. Li, Y. et al. Ni-Co sulfide nanowires on nickel foam with ultrahigh capacitance for asymmetric supercapacitors. J. Mater. Chem. A. 2,

6540 (2014).

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 8

www.nature.com/scientificreports/

49. Xiao, J. et al. Design hierarchical electrodes with highly conductive NiCo2S4 nanotube arrays grown on carbon fiber paper for high-

performance pseudocapacitors. Nano lett, 14, 831 (2014).

50. Liu, M. C. et al. Facile synthesis of NiMoO4·x H2O nanorods as a positive electrode material for supercapacitors. RSC Adv. 3, 6472

(2013).

51. Khomenko, V. et al. High-voltage asymmetric supercapacitors operating in aqueous electrolyte. Appl. Phy A, 82, 567 (2006).

52. Arno, B. et al. Electrochemical water splitting by layered and 3D cross-linked manganese oxides: correlating structural motifs and

catalytic activity. Energy. Environ. Sci. 6, 2745 (2013).

53. Guo, Y. G. et al. Nanostructured materials for electrochemical energy conversion and storage devices. Adv. Mater. 20, 2878 (2008).

54. Kaempgen, M. et al. Printable thin film supercapacitors using single-walled carbon nanotubes. Nano Lett, 9, 1872 (2009).

55. Jin, W. H. et al. Hybrid supercapacitor based on MnO2 and columned FeOOH using Li2SO4 electrolyte solution. J. Power Sources.

175, 686 (2008).

56. Cottineau, T. et al. Nanostructured transition metal oxides for aqueous hybrid electrochemical supercapacitors. Appl. Phys. A. 82,

599 (2006).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 21406191, 61275100),

the China Postdoctoral Science Special Foundation (2015T80232), the Natural Science Foundation of Hebei

Province (No. B2013203199), the Specialized Research Fund for the Doctoral Program of Higher Education

(No. 20131333120011), and the Key Technology Research and Development Program of Qinhuangdao (No.

2012021A072, 201401A042, 201401A019).

Author Contributions

The research was planned by Y.F.T., Y.Q.Q., S.C.M. and F.M.G. Experiments were performed by T.C., Y.F.T., Z.Y.L.,

W.F.G. and J.Z.S., T.C., Y.F.T., Y.Q.Q., S.X.Y. and Y.F.Z. prepared the manuscript. Y.Q.Q., S.C.M., S.X.Y., Y.F.Z. and

F.M.G. contributed with feedback and comments on the manuscript. All the authors participated in discussing

and reviewing of the manuscript.

Additional Information

Supplementary information accompanies this paper at http://www.nature.com/srep

Competing financial interests: The authors declare no competing financial interests.

How to cite this article: Chen, T. et al. All-solid-state high performance asymmetric supercapacitors based on

novel MnS nanocrystal and activated carbon materials. Sci. Rep. 6, 23289; doi: 10.1038/srep23289 (2016).

This work is licensed under a Creative Commons Attribution 4.0 International License. The images

or other third party material in this article are included in the article’s Creative Commons license,

unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license,

users will need to obtain permission from the license holder to reproduce the material. To view a copy of this

license, visit http://creativecommons.org/licenses/by/4.0/

Scientific Reports | 6:23289 | DOI: 10.1038/srep23289 9

You might also like

- 2022 - Dazhi ZhangDocument11 pages2022 - Dazhi ZhangThong NguyenNo ratings yet

- 2019 - Meng LiDocument7 pages2019 - Meng Lithong.dataphdNo ratings yet

- Significant Performance Enhancement in Aqueous Asymmetric SupercapacitorsDocument12 pagesSignificant Performance Enhancement in Aqueous Asymmetric SupercapacitorsRahul RNo ratings yet

- Puplish PaperDocument11 pagesPuplish PaperBatool TaherNo ratings yet

- Flexible Solid-State Cu X O-Based - Pseudo-Supercapacitor by Thermal Oxidation - of Copper FoilsDocument9 pagesFlexible Solid-State Cu X O-Based - Pseudo-Supercapacitor by Thermal Oxidation - of Copper FoilsEdgar Fabian Pinzon NietoNo ratings yet

- 2022 - Pengcheng DuDocument16 pages2022 - Pengcheng DuThong NguyenNo ratings yet

- Carbon-Based Supercapacitors Produced by Activation of GrapheneDocument6 pagesCarbon-Based Supercapacitors Produced by Activation of Graphenefadelomar28_gmail_coNo ratings yet

- MnCo2S4 NPs For Energy Storage ApplicationDocument10 pagesMnCo2S4 NPs For Energy Storage ApplicationJolie AnnaNo ratings yet

- Facile Preparation of h-WO /carbon Cloth Nanocomposite and Its Electrochemical Properties For SupercapacitorsDocument10 pagesFacile Preparation of h-WO /carbon Cloth Nanocomposite and Its Electrochemical Properties For SupercapacitorsAkif MunirNo ratings yet

- Hierarchical MnO2/Activated Carbon Cloth Electrode for Flexible Asymmetric SupercapacitorsDocument34 pagesHierarchical MnO2/Activated Carbon Cloth Electrode for Flexible Asymmetric SupercapacitorsNamNo ratings yet

- 2017 ZhiguoYeDocument7 pages2017 ZhiguoYethong.dataphdNo ratings yet

- Ag NW-PPy Nanocomp For SCsDocument34 pagesAg NW-PPy Nanocomp For SCsanamurboyNo ratings yet

- Capacitance of Two-Dimensional Titanium Carbide (MXene) and MXenecarbon Nanotube Composites in Organic ElectrolytesDocument6 pagesCapacitance of Two-Dimensional Titanium Carbide (MXene) and MXenecarbon Nanotube Composites in Organic Electrolytessj hNo ratings yet

- Molybdenum Selenide Nanotubes Decorated Carbon Net For A High Performance SupercapacitorDocument12 pagesMolybdenum Selenide Nanotubes Decorated Carbon Net For A High Performance Supercapacitormano9042No ratings yet

- Zinc Ferrite Anchored Multiwalled Carbon Nanotubes For High-Performance Supercapacitor ApplicationsDocument6 pagesZinc Ferrite Anchored Multiwalled Carbon Nanotubes For High-Performance Supercapacitor Applicationsvijayamathubalan pandyNo ratings yet

- Hierarchical Al-Doped and Hydrogenated Zno Nanowire@Mno Ultra-Thin Nanosheet Core/Shell Arrays For High-Performance Supercapacitor ElectrodeDocument17 pagesHierarchical Al-Doped and Hydrogenated Zno Nanowire@Mno Ultra-Thin Nanosheet Core/Shell Arrays For High-Performance Supercapacitor ElectrodeSyed Anas HussaniNo ratings yet

- Synthetic Metals: Enyuan Li, Rong Liu, Shu Huang, Jia Mei, Jun Xu, Guohui YuanDocument9 pagesSynthetic Metals: Enyuan Li, Rong Liu, Shu Huang, Jia Mei, Jun Xu, Guohui YuanNida SeptariniNo ratings yet

- Co Doped With Ni-MOFDocument8 pagesCo Doped With Ni-MOFBilal KhalidNo ratings yet

- Single Wall Carbon Nanotubes/Polypyrrole Composite Thin Film Electrodes: Investigation of Interfacial Ion Exchange BehaviorDocument14 pagesSingle Wall Carbon Nanotubes/Polypyrrole Composite Thin Film Electrodes: Investigation of Interfacial Ion Exchange BehaviormiguelNo ratings yet

- Journal of Alloys and Compounds: 2 3 Fi, Erjun Liang, Baojun LiDocument10 pagesJournal of Alloys and Compounds: 2 3 Fi, Erjun Liang, Baojun LiNaseem chNo ratings yet

- Supercondensador de EnergíaDocument6 pagesSupercondensador de EnergíaAlifhers Salim Mestra AcostaNo ratings yet

- Narendra Seminar NewDocument21 pagesNarendra Seminar NewnagarjunareddyNo ratings yet

- Efficient Interconnection in Perovskite Tandem Solar CellsDocument19 pagesEfficient Interconnection in Perovskite Tandem Solar CellshijerNo ratings yet

- Scintific Reports-Aravinder Singh 2Document13 pagesScintific Reports-Aravinder Singh 2Rahul RNo ratings yet

- All-Flexible Lithium Ion Battery Based On Thermally-Etched Porous Carbon Cloth Anode and CathodeDocument10 pagesAll-Flexible Lithium Ion Battery Based On Thermally-Etched Porous Carbon Cloth Anode and CathodeDécio FreitasNo ratings yet

- Yao 2017Document31 pagesYao 2017vijayamathubalan pandyNo ratings yet

- Rational Designing of Porous Structured Nickel Manganese SulfidesDocument34 pagesRational Designing of Porous Structured Nickel Manganese Sulfidesnida shahbazNo ratings yet

- Correlative Electrochemical Acoustic Time-Of-Flight Spectroscopy and X-Rayimaging To Monitor The Performance of Single-Crystal Lithium-Ion BatteriesDocument13 pagesCorrelative Electrochemical Acoustic Time-Of-Flight Spectroscopy and X-Rayimaging To Monitor The Performance of Single-Crystal Lithium-Ion BatteriesSANTHAKUMAR SNo ratings yet

- 1st Research ArticleDocument14 pages1st Research ArticleMuhammad RomanNo ratings yet

- Feb.2019 Core Shell MoS2 GrapheneDocument28 pagesFeb.2019 Core Shell MoS2 Grapheneantony2288No ratings yet

- Electrochimica Acta: Recep Yuksel, Sahin Coskun, Husnu Emrah UnalanDocument6 pagesElectrochimica Acta: Recep Yuksel, Sahin Coskun, Husnu Emrah UnalanSahin CoskunNo ratings yet

- Silicon Oxycarbide-Tin Nanocomposite As A High-Power-Density Anode For Li-Ion BatteriesDocument9 pagesSilicon Oxycarbide-Tin Nanocomposite As A High-Power-Density Anode For Li-Ion BatteriesPratyush AnandNo ratings yet

- Li 2020Document8 pagesLi 2020Shohan GaziNo ratings yet

- Nano Energy: Xiang Wu, Shunyu YaoDocument8 pagesNano Energy: Xiang Wu, Shunyu YaoHamza QureshiNo ratings yet

- Quantum Dot Solar Cell: PH.D Course 2 Semester / 2019-2020Document7 pagesQuantum Dot Solar Cell: PH.D Course 2 Semester / 2019-2020mokhaladNo ratings yet

- Applied Surface Science: Chen Hao, Xiaokun Wang, Xingli Wu, Yaning Guo, Linli Zhu, Xiaohong WangDocument11 pagesApplied Surface Science: Chen Hao, Xiaokun Wang, Xingli Wu, Yaning Guo, Linli Zhu, Xiaohong Wangreca adiyanti rahmanNo ratings yet

- Applied Surface Science: Chen Hao, Xiaokun Wang, Xingli Wu, Yaning Guo, Linli Zhu, Xiaohong WangDocument3 pagesApplied Surface Science: Chen Hao, Xiaokun Wang, Xingli Wu, Yaning Guo, Linli Zhu, Xiaohong Wangreca adiyanti rahmanNo ratings yet

- 2016 - Yu-Hsuan LiuDocument9 pages2016 - Yu-Hsuan Liuthong.dataphdNo ratings yet

- Controlled Air Etching Synthesis of Porous Carbon Nanotube Aerogels With Ultrafast Charging at 1000 ADocument10 pagesControlled Air Etching Synthesis of Porous Carbon Nanotube Aerogels With Ultrafast Charging at 1000 ADiani MuhandiramNo ratings yet

- Rohil Kumar 17M713Document13 pagesRohil Kumar 17M713mokhaladNo ratings yet

- Electrochimica Acta: M. Balasubramaniam, S. BalakumarDocument12 pagesElectrochimica Acta: M. Balasubramaniam, S. BalakumarSiva RamNo ratings yet

- 1 s2.0 S2352152X22013500 MainDocument10 pages1 s2.0 S2352152X22013500 MainQamir Ullah Khan NiaziNo ratings yet

- Zhang 2020Document7 pagesZhang 2020AZ AnimalNo ratings yet

- Kale 2021Document12 pagesKale 2021tram nguyenNo ratings yet

- Electrochemical Preparation of CuBi2O4 Nanoparticles On Nanoporous Stainless Steel As A Binder-Free Supercapacitor ElectrodeDocument9 pagesElectrochemical Preparation of CuBi2O4 Nanoparticles On Nanoporous Stainless Steel As A Binder-Free Supercapacitor ElectrodemuhammadNo ratings yet

- Estc 2018 8546493Document5 pagesEstc 2018 8546493MSGNo ratings yet

- Journal of Alloys and CompoundsDocument8 pagesJournal of Alloys and Compoundsjeffry122333No ratings yet

- Chemical Engineering Journal: Murat Cakici, Kakarla Raghava Reddy, Fernando Alonso-MarroquinDocument8 pagesChemical Engineering Journal: Murat Cakici, Kakarla Raghava Reddy, Fernando Alonso-Marroquinjos20No ratings yet

- Seminar Report On Graphene Supercapacitor's High Energy DensityDocument12 pagesSeminar Report On Graphene Supercapacitor's High Energy DensityAshwini PatilNo ratings yet

- Carbon Nanowalls A New Material For Resistive Switching Memory Devices PDFDocument9 pagesCarbon Nanowalls A New Material For Resistive Switching Memory Devices PDFBogdanNo ratings yet

- Super CapacitorDocument7 pagesSuper Capacitorpreeven singNo ratings yet

- Applied Surface Science JournalDocument8 pagesApplied Surface Science Journalrosine.ahishakiyeNo ratings yet

- Carbon Nanotube-Based Supercapacitors: Chunsheng Du and Ning PanDocument8 pagesCarbon Nanotube-Based Supercapacitors: Chunsheng Du and Ning PanTitus LeeNo ratings yet

- Materials and Design: Khairul Amilin Ibrahim, Billy Wu, Nigel P. BrandonDocument9 pagesMaterials and Design: Khairul Amilin Ibrahim, Billy Wu, Nigel P. BrandonjohnNo ratings yet

- Electrochimica ActaDocument11 pagesElectrochimica ActaSahin CoskunNo ratings yet

- Published FormDocument11 pagesPublished FormSreekumar Rajappan AcharyNo ratings yet

- ECSA Formula Cs From CV ECSDocument5 pagesECSA Formula Cs From CV ECSgengan saravananNo ratings yet

- Achieving Superior Energy Storage and Microwave Absorption byDocument12 pagesAchieving Superior Energy Storage and Microwave Absorption bynoumanNo ratings yet

- 2022 Jasna, Polyaniline Wrapped Carbon Nanotube-Exfoliated MoS2 Nanosheet Composite As A PromDocument12 pages2022 Jasna, Polyaniline Wrapped Carbon Nanotube-Exfoliated MoS2 Nanosheet Composite As A Promheri rustamajiNo ratings yet

- Limiteteoricodeproplsorcuantico PDFDocument7 pagesLimiteteoricodeproplsorcuantico PDFLuis Alberto MiglioreroNo ratings yet

- Capacitores SimetricosDocument15 pagesCapacitores SimetricosLuis Alberto MiglioreroNo ratings yet

- Mastering Chess and Shogi by Self-Play With A General Reinforcement Learning AlgorithmDocument19 pagesMastering Chess and Shogi by Self-Play With A General Reinforcement Learning Algorithmeldelmoño luciNo ratings yet

- SST 33inDocument1 pageSST 33inLuis Alberto MiglioreroNo ratings yet

- B2 SpiritDocument4 pagesB2 SpiritLuis Alberto Migliorero100% (2)

- 4033Document11 pages4033shivangikhatana90No ratings yet

- Us 20070170798 A 1 Levitron 2Document17 pagesUs 20070170798 A 1 Levitron 2Luis Alberto MiglioreroNo ratings yet

- Quantum Vacuum ThrusterDocument5 pagesQuantum Vacuum ThrusterLuis Alberto MiglioreroNo ratings yet

- Chapter 4Document35 pagesChapter 4Luis Alberto MiglioreroNo ratings yet

- Experiment of The Biefield-Brown Effect Using Symmetric Plate Capacitors Charged Below 35kVDocument8 pagesExperiment of The Biefield-Brown Effect Using Symmetric Plate Capacitors Charged Below 35kVLuis Alberto MiglioreroNo ratings yet

- P-51D Mustang 36inDocument1 pageP-51D Mustang 36inLuis Alberto MiglioreroNo ratings yet

- P-51D Mustang 36inDocument1 pageP-51D Mustang 36inLuis Alberto MiglioreroNo ratings yet

- Charged Supercapacitor PDFDocument4 pagesCharged Supercapacitor PDFLuciano DicksonNo ratings yet

- P Saab ViggenDocument10 pagesP Saab ViggenLuis Alberto MiglioreroNo ratings yet

- The Role of Intelligence For Performance in The Prototypical Expertise Domain of Chess (2013) by Roland H. GrabnerDocument8 pagesThe Role of Intelligence For Performance in The Prototypical Expertise Domain of Chess (2013) by Roland H. GrabnerLuis Alberto MiglioreroNo ratings yet

- EFtyphoonDocument1 pageEFtyphoonamedraayNo ratings yet

- Glue & Cut Red Numbered PartsDocument1 pageGlue & Cut Red Numbered PartsLuis Alberto MiglioreroNo ratings yet

- Experiments W Spiral Magnet Motors Wankel WholeDocument46 pagesExperiments W Spiral Magnet Motors Wankel Wholetony74193100% (1)

- Us 4064442 Motor Ke PpeDocument8 pagesUs 4064442 Motor Ke PpeLuis Alberto MiglioreroNo ratings yet

- Teoria Del TodoDocument428 pagesTeoria Del TodoLuis Alberto MiglioreroNo ratings yet

- Kin Ect I Ccu An Tum Gravity TheoryDocument11 pagesKin Ect I Ccu An Tum Gravity TheoryLuis Alberto MiglioreroNo ratings yet

- A Word To Third World War: A Clarification by Billy MeierDocument2 pagesA Word To Third World War: A Clarification by Billy MeierLuis Alberto MiglioreroNo ratings yet

- Us 4064442 Motor Ke PpeDocument8 pagesUs 4064442 Motor Ke PpeLuis Alberto MiglioreroNo ratings yet

- Mig 144 de Sen Cripta DoDocument4 pagesMig 144 de Sen Cripta DoLuis Alberto MiglioreroNo ratings yet

- EFtyphoonDocument1 pageEFtyphoonamedraayNo ratings yet

- Developing An Adaptive Chess Program PDFDocument66 pagesDeveloping An Adaptive Chess Program PDFLuis Alberto MiglioreroNo ratings yet

- B2 SpiritDocument4 pagesB2 SpiritLuis Alberto Migliorero100% (2)

- P Saab ViggenDocument10 pagesP Saab ViggenLuis Alberto MiglioreroNo ratings yet

- Mari 1.4v2 GettingStartedGuide PDFDocument57 pagesMari 1.4v2 GettingStartedGuide PDFCarlos Vladimir Roa LunaNo ratings yet

- Markle 1999 Shield VeriaDocument37 pagesMarkle 1999 Shield VeriaMads Sondre PrøitzNo ratings yet

- Astrology - House SignificationDocument4 pagesAstrology - House SignificationsunilkumardubeyNo ratings yet

- Tax Q and A 1Document2 pagesTax Q and A 1Marivie UyNo ratings yet

- IB Theatre: The Ilussion of InclusionDocument15 pagesIB Theatre: The Ilussion of InclusionLazar LukacNo ratings yet

- FPR 10 1.lectDocument638 pagesFPR 10 1.lectshishuNo ratings yet

- Md. Raju Ahmed RonyDocument13 pagesMd. Raju Ahmed RonyCar UseNo ratings yet

- Toxicology: General Aspects, Types, Routes of Exposure & AnalysisDocument76 pagesToxicology: General Aspects, Types, Routes of Exposure & AnalysisAsma SikanderNo ratings yet

- International Standard Knowledge Olympiad - Exam Syllabus Eligibility: Class 1-10 Class - 1Document10 pagesInternational Standard Knowledge Olympiad - Exam Syllabus Eligibility: Class 1-10 Class - 1V A Prem KumarNo ratings yet

- AI Capstone Project Report for Image Captioning and Digital AssistantDocument28 pagesAI Capstone Project Report for Image Captioning and Digital Assistantakg29950% (2)

- BICON Prysmian Cable Cleats Selection ChartDocument1 pageBICON Prysmian Cable Cleats Selection ChartMacobNo ratings yet

- As If/as Though/like: As If As Though Looks Sounds Feels As If As If As If As Though As Though Like LikeDocument23 pagesAs If/as Though/like: As If As Though Looks Sounds Feels As If As If As If As Though As Though Like Likemyint phyoNo ratings yet

- FOCGB4 Utest VG 5ADocument1 pageFOCGB4 Utest VG 5Asimple footballNo ratings yet

- Topic 1 in 21st CneturyDocument8 pagesTopic 1 in 21st CneturyLuwisa RamosNo ratings yet

- MVD1000 Series Catalogue PDFDocument20 pagesMVD1000 Series Catalogue PDFEvandro PavesiNo ratings yet

- Digital Movement Guide CodesDocument18 pagesDigital Movement Guide Codescgeorgiou80No ratings yet

- Communicative Competence: Noam ChomskyDocument2 pagesCommunicative Competence: Noam ChomskyKiara Denise SuarezNo ratings yet

- 14 Jet Mykles - Heaven Sent 5 - GenesisDocument124 pages14 Jet Mykles - Heaven Sent 5 - Genesiskeikey2050% (2)

- Vegan Banana Bread Pancakes With Chocolate Chunks Recipe + VideoDocument33 pagesVegan Banana Bread Pancakes With Chocolate Chunks Recipe + VideoGiuliana FloresNo ratings yet

- Preparation For Exercise1-1 CompleteDocument28 pagesPreparation For Exercise1-1 CompleteSimon GranNo ratings yet

- York Product Listing 2011Document49 pagesYork Product Listing 2011designsolutionsallNo ratings yet

- Arx Occasional Papers - Hospitaller Gunpowder MagazinesDocument76 pagesArx Occasional Papers - Hospitaller Gunpowder MagazinesJohn Spiteri GingellNo ratings yet

- TorricelliDocument35 pagesTorricelliAdinda Kayla Salsabila PutriNo ratings yet

- Battery Genset Usage 06-08pelj0910Document4 pagesBattery Genset Usage 06-08pelj0910b400013No ratings yet

- Sound! Euphonium (Light Novel)Document177 pagesSound! Euphonium (Light Novel)Uwam AnggoroNo ratings yet

- MBA Third Semester Model Question Paper - 2009: Management and Organization Development-MU0002 (2 Credits)Document11 pagesMBA Third Semester Model Question Paper - 2009: Management and Organization Development-MU0002 (2 Credits)ManindersuriNo ratings yet

- Solidworks Inspection Data SheetDocument3 pagesSolidworks Inspection Data SheetTeguh Iman RamadhanNo ratings yet

- RA 4196 University Charter of PLMDocument4 pagesRA 4196 University Charter of PLMJoan PabloNo ratings yet

- MinePlan Release NotesDocument14 pagesMinePlan Release NotesJuanJo RoblesNo ratings yet

- Consent 1095 1107Document3 pagesConsent 1095 1107Pervil BolanteNo ratings yet