Professional Documents

Culture Documents

Process Costing Theory

Uploaded by

bando007Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Costing Theory

Uploaded by

bando007Copyright:

Available Formats

Process costing

Process costing is a method of costing used mainly in manufacturing

where units are continuously mass-produced through one or more

processes.

Examples of this include the manufacture of erasers, chemicals or

processed food.

In process costing it is the process that is costed (unlike job costing where

each job is costed separately). The method used is to take the total cost of

the process and average it over the units of production.

Cost per unit = Cost of inputs

Expected output in units

Important terms to understand

In a manufacturing process the number of units of output may not

necessarily be the same as the number of units of inputs. There may be a

loss.

Normal loss

This is the term used to describe normal expected wastage under usual

operating conditions. This may be due to reasons such as evaporation,

testing or rejects.

Abnormal loss

This is when a loss occurs over and above the normal expected loss. This

may be due to reasons such as faulty machinery or errors by labourers.

Abnormal gain

This occurs when the actual loss is lower than the normal loss. This could, for

example, be due to greater efficiency from newly-purchased machinery.

Work in progress (WIP)

This is the term used to describe units that are not yet complete at the end

of the period. Opening WIP is the number of incomplete units at the start of

a process and closing WIP is the number at the end of the process.

Scrap value

Sometimes the outcome of a loss can be sold for a small value. For

example, in the production of screws there may be a loss such as metal

wastage. This may be sold to a scrap merchant for a fee.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mdim - Icbit Brochure 2020Document6 pagesMdim - Icbit Brochure 2020bando007No ratings yet

- Introduction To ValuationDocument3 pagesIntroduction To Valuationbando007No ratings yet

- Mait Mba - FDP - July 2021Document7 pagesMait Mba - FDP - July 2021bando007No ratings yet

- Understanding The Concept of Corporate Social ResponsibilityDocument18 pagesUnderstanding The Concept of Corporate Social Responsibilitybando007No ratings yet

- Test 3Document1 pageTest 3bando007No ratings yet

- 1Document4 pages1bando007No ratings yet

- Question SetDocument2 pagesQuestion Setbando007No ratings yet

- International Webinar: Resurgence of Business Growth Post Covid-19: Challenges and StrategiesDocument1 pageInternational Webinar: Resurgence of Business Growth Post Covid-19: Challenges and Strategiesbando007No ratings yet

- Class 19Document5 pagesClass 19bando007No ratings yet

- Ir Fy 2017 18 PDFDocument412 pagesIr Fy 2017 18 PDFbando007No ratings yet

- List of Funding Agencies For Research Proposals: Department of Science and Technology (DST)Document13 pagesList of Funding Agencies For Research Proposals: Department of Science and Technology (DST)ParamasivamKuppusamyNo ratings yet

- Time Value of MoneyDocument11 pagesTime Value of Moneybando007No ratings yet

- Japan Funds Fillip To East-West Metro - Agency Inspects Sites Where Work Has Started After Years of DelayDocument2 pagesJapan Funds Fillip To East-West Metro - Agency Inspects Sites Where Work Has Started After Years of Delaybando007No ratings yet

- IBA Journal July Dec 2016Document104 pagesIBA Journal July Dec 2016bando007No ratings yet

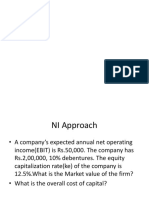

- NI NOI ApproachDocument14 pagesNI NOI Approachbando007No ratings yet

- Dividend Discount ModelDocument12 pagesDividend Discount Modelbando007No ratings yet

- XimeDocument24 pagesXimebando007No ratings yet

- Registration FormDocument1 pageRegistration Formbando007No ratings yet

- Bhruti NewDocument2 pagesBhruti Newbando007No ratings yet