Professional Documents

Culture Documents

PT Casting Unit 1 and 2 MCQ

Uploaded by

Srimanthula Srikanth0 ratings0% found this document useful (0 votes)

220 views11 pageshi

Original Title

Pt Casting Unit 1 and 2 Mcq

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

220 views11 pagesPT Casting Unit 1 and 2 MCQ

Uploaded by

Srimanthula Srikanthhi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

PRACTICE QUESTIONS

1. Consider the following ingredients used in molding.

1. Drysilica sand 2 Clay

3, Phenol formaldehyde 4. Sodium silicate

Those used for shell mould casting include

@ 1,2and4 (&) 2,3and4

45) tand3 (OF 1,2,3and4

2. A sand casting mould assembly is shown in the given figure. The elements marked A and E

respectively. |

(@) Sprue and riser (b) , Ingate and riser “A

(©) Drag and runner AG) Riser and runner

3. Hardness of green sand mould increases with

(a)_ Increase in moisture content beyond 6 percent. 8

(b) Increase in permeability

se} Decrease in permeability

(d) Increase in both moisture content and permeability.

4. In solidification of metal during casting, compensation during solid contraction is:

48) Provided by the oversize pattern

(b) Achieved by properly placed risers

(©) Obtained by promoting directions solidifications

(4) Made by providing chills

5. Match List (Moulding process) with List-ll (Binding agent) and select the correct answer u

the codes given below the lists:

List Lis

A. Greensand — 1. Silicate _

B. Cores sand 2. Organic ™.

©. Shell moulding —__ ™3, Clay *

D. Carbondioxide process ~ 4. Plaster of paris “0 hy

« 5. Plastic

Codes: \

A B CGC DN

@®@ 3 2 6 14 .

$Bja8 57125 ase 3 N

GP Biel gs str te

d@ 2 3 4 5 3

6. In which of the following are metal moulds used? \

(a) Green sand mould (bo) Dry sand mould =

(& Die casting process (d) Loam moulding

7. Gray cast iron blocks 200 x 100 x 10 mm are to be cast in sand moulds. Shrinkage allowance

pattern making is 1% . The ratio of the volume of pattern to that of the casting will be

@ 097 (b) 0.99

(©) 1.01 (@) 1.03

168 | Production Engineering

‘Ys 8. Which one of the following is the correct statements? Gate is provided in moulds to

g feed the casting at constant rate (b) give passage to gases

(c)_ compensate for shrinkage (0) avoid cavities

9. Volume of a cube of side ‘i’ and volume of a sphere of radius ‘r’ are equal. Both the

sphere are solid and of same material. They are being cast. The ratio of the solidi

the cube to the same of sphere is

x

3 7,46 2

4n) (1 4n)(¢ é

# (J oF ty,

2 3 2 4 Ox, JZ

any (tr an) (r

CG) s# (3) (i)

gq 10. The pattern adopted for those casting where there are some portions which are structura

and are likely to break by the force of ramming are called:

(@)_ Loose piece pattern r) Follow board pattern —

(©) Skeleton pattern (d)_ Single piece Pattern

413)In a sand casting operation, the total liquid head is maintained constant such that itis equ

mould height. The time taken to fil the mould with a top gates is t,. If the same mould is fi

a bottom gate, then the time taken is t, Ignore the time required to fill the runner and {

effects. Assume atmospheric pressure at the top molten metal surfaces. The relation be

and tis Zz

@) tp=v2ty Apy tz = 2b, a S

(0) ty = Jey

Y

12, Plastic bottles are made using We Sake?

(ef Blow moulding (b)_ Injection moutding, os

(©) Preform moulding (d) Slush casting 2 Ag

@ While cooling, a cubical casting of side 40 mm undergoes 3%, 4% and 5% volume

during the liquid state, phase transition and solid state, respectively. The volume «

compensated from the riser is

(@) 2% 8) 7%

(c) 8% (d) 9%

G44) it the metting ratio of a copula is 10:1, then the coke requirement for one ton met will be

“ (@ 0.1 ton (b) 10 tons

©, (©) tten (@) 11 tons

GB. Consider the following statements:

Assertion(A): Steel can be melted in hot blast cupola.

Reason(R): In hot blast cupola, the flue gases are used to preheat the air blast to the c

that the temperature in the furnace is considerably higher than that in a conventional cur

(8) Both A and R are individually true and R is the correct explanation of A.

(b) Both A and R are individually true and R is not the correct explanation of A.

©) Ais true but Ris false

(@) Ais false but Ris true

Casting | 16

6. Which of the following are in the requirements of an ideal gating system?

1. The molten metal should enter the mould cavity with as high a velocity as possible,

2. It should facilitate complete filling of the mould cavity

3. Itshould be able to prevent the absorption of air or gases from the surroundings on the molte

metal while flowing through it.

Select the correct answer using the codes given below:

(@ 1,2and3 (b) 1and3

_4e) 2and3 (a) tand3

7. Assertion(A): The rate of flow metal through sprue is NOT a function of the cross-sectional area

~ sprue, runner and gate.

Reason(R): If respective cross-sectional areas of sprue , runner and gate are in the ratio of 1:

the system is known as unpressurised gating system.

(@) Both A and R are individually true and R is the correct explanation of A.

(b) Both A and R are true and R is not the correct explanation of A.

(©) Ais true but Ris false

(@¥ Ais false but R is true

18. In gating system design, which one of the following is the correct sequence in which choke are:

pouring time, pouring basin and sprue sizes are calculated?

4@) Choke area- pouring time-pouring basin- sprue

(b) Pouring basin-sprue-choke area-pouring time

(©) Choke area- sprue-pouring basin- pouring time

(d) Pouring basin- pouring time-Choke area-sprue,

19. A gating ratio of 1:2:4 is used to design the gating system for magnesium alloy casting. Th

gating ratio refers to the cross- section areas of the various gating elements as given below:

1, Downsprue

2. Runner bar

3. Ingates

‘The correct sequence of the above elements in the ratio 1:2:4 is:

@) 1,2and3 (o) 1,3and2

(©) 2,3and1 (d) 3,1and2

20. A mould has down sprue whose length is 20 cm and the cross sectional area at the base of t

down sprue is tom?. The down sprue feeds a horizontal runner leading into the mould cavity

volume 1000cm®. The time required to fill the mould cavity will be

+ @) 405s (b) 5.058

(©) 6.05s (@) 7.258

21. Bottom gating system is some times preferred in casting because

(a) Itenables rapid filling of mould cavity (b) It is easier to provide in the mould

(c)_Itprovides cleaner metal (@_ Itreduces splashing and turbulence

22, A 200mm long down sprue has an area of cross-section of 650 mm? where the pouring bas

meets the down sprue (i.e. at the beginning of the down sprue). A constant head of molten me!

flow rate is 6.5 x 10 mms, considering the end of down sprue to be open to atmosphere and

acceleration due to gravity of 10mm/s?, the area of the down sprue in mmPat its end (avoidit

aspiration effect) should be

(a) 650.0 (b) 350.0

(0) 2907 @ 1900

You might also like

- 2011SouzaArencibiaCostaPiratelli_Acontributiontothemeasurement_COBEM2011 (1)Document11 pages2011SouzaArencibiaCostaPiratelli_Acontributiontothemeasurement_COBEM2011 (1)Srimanthula SrikanthNo ratings yet

- 2011SouzaArencibiaCostaPiratelli_Acontributiontothemeasurement_COBEM2011 (1)Document11 pages2011SouzaArencibiaCostaPiratelli_Acontributiontothemeasurement_COBEM2011 (1)Srimanthula SrikanthNo ratings yet

- Sheet No:02 Roll No: Title of The Drawing Sheet:: Conventional Representation of Machine ComponentsDocument3 pagesSheet No:02 Roll No: Title of The Drawing Sheet:: Conventional Representation of Machine ComponentsSrimanthula SrikanthNo ratings yet

- "Soft Skills: A Prerequisite For Phenomenal Growth": Pragati Engineering CollegeDocument1 page"Soft Skills: A Prerequisite For Phenomenal Growth": Pragati Engineering CollegeSrimanthula SrikanthNo ratings yet

- LAMPA_MM_2020_MAREAUDocument33 pagesLAMPA_MM_2020_MAREAUSrimanthula SrikanthNo ratings yet

- BS Sample (R) QPDocument6 pagesBS Sample (R) QPSrimanthula SrikanthNo ratings yet

- metals-12-01787-v2Document15 pagesmetals-12-01787-v2Srimanthula SrikanthNo ratings yet

- Zerilli–Armstrong constitutive 1-s2.0-S0167663615002550-mainDocument8 pagesZerilli–Armstrong constitutive 1-s2.0-S0167663615002550-mainSrimanthula SrikanthNo ratings yet

- A-combined-experimental-and-numerical-approach-that-eliminatesDocument12 pagesA-combined-experimental-and-numerical-approach-that-eliminatesSrimanthula SrikanthNo ratings yet

- III B.Tech I & II Semester Academic Calendar 2022-2023Document1 pageIII B.Tech I & II Semester Academic Calendar 2022-2023Srimanthula SrikanthNo ratings yet

- Locking Arrangements For Nuts: Set ScrewsDocument6 pagesLocking Arrangements For Nuts: Set ScrewsSrimanthula SrikanthNo ratings yet

- Other Forms of Bolts and Nuts: Diameter D 30mm Square Headed Bolt With Square NeckDocument5 pagesOther Forms of Bolts and Nuts: Diameter D 30mm Square Headed Bolt With Square NeckSrimanthula SrikanthNo ratings yet

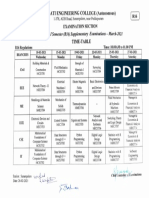

- Iii-I Mid-Ii Time Table Feb-2021Document1 pageIii-I Mid-Ii Time Table Feb-2021Srimanthula SrikanthNo ratings yet

- LAB Master SetDocument7 pagesLAB Master SetSrimanthula SrikanthNo ratings yet

- II-I (R16) Supple Examinations March-2021Document1 pageII-I (R16) Supple Examinations March-2021Srimanthula SrikanthNo ratings yet

- FCI Recruitment 2021 for 89 VacanciesDocument33 pagesFCI Recruitment 2021 for 89 VacanciesvijaythealmightyNo ratings yet

- IV-i Regular Supple Examinations March 2021Document2 pagesIV-i Regular Supple Examinations March 2021Srimanthula SrikanthNo ratings yet

- Iii-I Mid-Ii Time Table Feb-2021Document1 pageIii-I Mid-Ii Time Table Feb-2021Srimanthula SrikanthNo ratings yet

- II I (R19) Regular Examinations March 2021Document1 pageII I (R19) Regular Examinations March 2021Srimanthula SrikanthNo ratings yet

- III-I (R16) Regular Supple Examinations March 2021Document1 pageIII-I (R16) Regular Supple Examinations March 2021Srimanthula SrikanthNo ratings yet

- Guide LinesDocument6 pagesGuide LinesDevaraju ThangellamudiNo ratings yet

- Name Change Correction Form PDFDocument1 pageName Change Correction Form PDFSrimanthula SrikanthNo ratings yet

- Combined Geo-Scientist Examination, 2020Document35 pagesCombined Geo-Scientist Examination, 2020Srimanthula SrikanthNo ratings yet

- Learn Python Programming Basics in 12 StepsDocument3 pagesLearn Python Programming Basics in 12 StepsSrimanthula SrikanthNo ratings yet

- Mechanical Engineering Conference Abstracts and EventsDocument10 pagesMechanical Engineering Conference Abstracts and EventsSrimanthula SrikanthNo ratings yet

- M.tech I Sem Time Table Jan - 2019Document2 pagesM.tech I Sem Time Table Jan - 2019Srimanthula SrikanthNo ratings yet

- Learn Python Programming Basics in 12 StepsDocument3 pagesLearn Python Programming Basics in 12 StepsSrimanthula SrikanthNo ratings yet

- Combined Geo-Scientist Examination, 2020Document35 pagesCombined Geo-Scientist Examination, 2020Srimanthula SrikanthNo ratings yet

- GRAMA/WARD SACHIVALAYAM RECRUITMENT MERITLISTDocument109 pagesGRAMA/WARD SACHIVALAYAM RECRUITMENT MERITLISTSrimanthula SrikanthNo ratings yet

- FEA Questions & Answers: Everything about Finite Element AnalysisDocument20 pagesFEA Questions & Answers: Everything about Finite Element AnalysisJoseph BurnettNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)