Professional Documents

Culture Documents

785C, 785D & 789C Mining Trucks

Uploaded by

eddyfredyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

785C, 785D & 789C Mining Trucks

Uploaded by

eddyfredyCopyright:

Available Formats

785C, 785D & 789C Mining Trucks

785C GMW 550,000 lbs. ( 249,480 kg)

130 -150 ton (118 – 136 metric tons)

785D GMW 550,000 lbs. ( 249,480 kg)

130 -150 ton (118 – 136 metric tons)

789C GMW 700,000 lbs. ( 317,515 kg)

170 -195 ton (154 – 177 metric tons)

2 CATERPILLAR: CONFIDENTIAL GREEN

Experienced Mining Trucks

• Strong Worldwide presence – Reliable Reputation

• Mechanical drive

– Product support = Availability = Tons Moved

– Productivity

– Payload control

• Key features & benefits deliver

– Health, Safety & Environment

– Lower Cost Per Ton / Availability

– Tires

• Serviceability

– Dealer Support

3 CATERPILLAR: CONFIDENTIAL GREEN

All Cat Mechanical Power Train

• Cat is only manufacturer with fully

integrated drive train

• Centralized design control allows Cat to

optimize performance & life

• Higher power train efficiency delivers

more power to ground, burns less fuel,

reduces cost per ton • Heavy-duty final drives withstand

• Wide application range extreme loads and forces, can be

• Automotive feel is easier to control remanufactured

• One-piece cast wheels enhance

• Cat design has fewer thermal

durability

limitations on steep grades

• No on-site high voltage power required • Differentials designed for long life, lower

cost- per-ton operation

• Control system manages engine speed

during shifts to increase clutch life and • Rear axle lube system cools and cleans

improve operator comfort continuously

• Purpose Built Integrated System

4 CATERPILLAR: CONFIDENTIAL GREEN

CATERPILLAR: CONFIDENTIAL GREEN

Features & Benefits

Premier machines in their classes, designed and built by Caterpillar using components and

systems that have evolved through years of rugged mining applications

Cost per Ton

Availability

• Safety & Operator Station

• Powertrain

• Systems Integration

• Frame

• Body

• Front Axle & Steering

• Retarding & Traction Control

• Tires

6 CATERPILLAR: CONFIDENTIAL GREEN

Standard Safety Features

Standard Features

• 4-post ROPS

• Oil-cooled brakes on 4 corners for

fade-resistant operation

• Ground level secondary engine

shutdown and machine lockouts for

added safety and security

• Three-point operator restraint

• Lighted driver-side ladder and

service deck

• 10/10/20 Payload Policy applies

7 CATERPILLAR: CONFIDENTIAL GREEN

New Optional Safety Features

New Safety Enhancements

• 600 mm (24 in) wide diagonal stairway – standard

785D.

– custom field kits for 785B/C & 789B/C

• Closed-circuit television factory ready and model

specific kits

• High intensity discharge (HID) lighting in

high beams and back-up lights improves

night time visibility

• Extended life carbon paper disc brakes provide

longer service life and increased heat resistance

than standard brakes

– Standard 785D

– Optional 785C, 789C

8 CATERPILLAR: CONFIDENTIAL GREEN

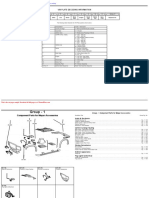

Operator Station

• Ergonomically designed

• Excellent machine control

• Exceptional all-around visibility

• Resiliently-mounted, sound suppressed cab

- Sound levels less than 80 dB (A)

4

• Air suspension seat - fully adjustable 8

10

• Operator comfort = Higher Productivity! 9

5

3

1

7

6

1. Air suspension seat 6. Storage Compartment

2. Hoist lever (left side of seat) 7. Trainer seat

3. Secondary brake pedal 8. Electric window

4. Monitoring system 9. Operator controls

5. Transmission control 10. Heating/air conditioning

6. Storage compartment

2

9 CATERPILLAR: CONFIDENTIAL GREEN

Caterpillar Engines

A proven performer for over 25 years, the 3500 series engine now has over 105,000

units working worldwide in a variety of applications

• Electronic Control Module

– Reduces smoke

– Reduces emissions.

– Improves fuel efficiency

– Optimizes performance and life

– Communicates with transmission

and retarder

– Provides information for diagnostics and management decisions.

– Diagnoses own health and status

– Controls Oil Renewal System

• Cat engines operate at lower BMEP than competition -- improving

availability, extending life, reducing costs

• Purpose Built Integrated System

10 CATERPILLAR: CONFIDENTIAL GREEN

Lock-up Torque Converter

Combines the advantages of direct drive and converter drive to achieve high component

reliability and maximum output performance

Lock-up clutch

• Increased power train

efficiency Torque

converter output

• High reliability from proven

design components Input

• 28% stall torque

• Broad converter performance

band

• Lock-up clutch engages at 6.4

Flow of power

km/h (4.0 mph)

Flow of oil

Torque converter drive mode

11 CATERPILLAR: CONFIDENTIAL GREEN

Six-Speed Planetary Transmission

Large diameter clutch packs are controlled to provide smooth shifting and to limit

clutch energy input for extended component life

• Torque converter lock-up in first

gear

• Downshift inhibitor prevents

engine overspeed

• Clutch packs mounted outside of

gear sets

for ease of service

• Directional shift management

automatically reduces engine

throttle before shifting

12 CATERPILLAR: CONFIDENTIAL GREEN

Controlled Throttle Shift

Reduces driveline torque stress for smoother shifts, extended component life,

and improved operator comfort

Controlled Throttle Shift (CTS)

Transmission Output Torque

• Regulates engine rpm during Shift without CTS

shifts

• Reduces torque spikes and

extends Shift with CTS

transmission life

• Smoother ride and less spillage

• Lowers operator fatigue

• Possible only through electronic

Clutch Power

integration of components Shift without CTS

Shift with CTS

Time

13 CATERPILLAR: CONFIDENTIAL GREEN

Rear Wheel Group

Heavy duty components and ease of service combine to deliver long life and reduced

downtime in the most rugged conditions

• Laser-hardened spindle in the

wheel bearing journal area

• Integrated wheel and hub

reduces removal

and installation time

• Rotated and flushed with oil at

factory, then filled with filtered oil

before shipping

• Duo-Cone ™ seals are air and

oil checked after assembly as

part of quality control

14 CATERPILLAR: CONFIDENTIAL GREEN

Ecology Drains

Easily accessible drain plugs are installed in components to provide an environmentally

safe and effective method to drain fluids

1

• Ecology drains are standard equipment

and located throughout the 785C &

789C

– Engine (1)

– Radiator (2)

– Transmission

– Torque converter

– Hydraulic tank

– Fuel tank 2

• Alongside the fuel tank is the optional

Wiggins service center that has quick

fill and drains for the truck fluids

15 CATERPILLAR: CONFIDENTIAL GREEN

Front Axle Steering Components

The 785C & 789C front suspension is field-proven design with dual tie-rods for

optimum steering geometry to help extend tire life

• Separate steering hydraulic system

prevents cross contamination

• Secondary steering meets ISO 5010 up

to 120% of target payload

• Twin double-acting cylinders

• Steering arm pin retention plate

provides redundant pin retention

• Front suspension cylinders serve

as kingpins

• Serviceable bracket assembly on

steering box casting saves time at

rebuild

• Two tie-rods allow optimum steering

geometry

16 CATERPILLAR: CONFIDENTIAL GREEN

Brakes and Retarding

Oil-cooled multiple disc brakes on all four wheels provide exceptional braking and retarding

• Integrated systems deliver optimum

performance 2

• Non-fade, oil cooled design offers

reliable performance, long life

• Spring-applied secondary and parking 1

systems

enhance safety

• Four-wheel braking improves control

• 40/60 brake torque split improves

control, minimizes wheel lock-up 1. Parking/secondary piston

7

• Traction Control System improves 2. Service/retarding piston

performance in poor underfoot 3

• Automated Retarder Control allows 3. Friction discs

faster, 4 4. Steel plates

safer downhill travel

• Sealed system prevents contamination

5. Actuating springs

• Brake wear measurements completed 5 6 6. Cooling oil in

quickly 7. Cooling oil out

• Purpose Built Integrated System

17 CATERPILLAR: CONFIDENTIAL GREEN

785 Specifications

785D (MSY) 785C (APX)

Target GMW – kg (lb) 249 480 (550,000) 249 480 (550,000)

Operating Machine Weight –kg (lb.) 111 618 (246,084) 111 008 (244,704)

Nominal Payload 136 tonnes (150 tons) 136 tonnes (150 tons)

3512B EUI

Engine model 3512C HD-EUI

Displacement – L (in3) 58,56 (3,573) 51,8 (3,158)

Gross power – kW (hp) 1082 (1,450) 1082 (1,450)

Engine derates above altitude – m (ft) 4267 (14,000) 3050 (10,000)

Top speed, loaded – km/h (mph) 56.0 (35.0) 56.0 (35.0)

Target fuel consumption, engine rebuild (gallons) 575,000 525,000

BSFC g/kw-hr 210.4 211.3

18 CATERPILLAR: CONFIDENTIAL GREEN

One engine –

both LAA &

HAA capability

785D FEATURES

3512C HD

(with CPI

improvements)

Tier II Certified

Maintained or

Continuous Slightly

rear axle improved Fuel

filtration Consumption

19 CATERPILLAR: CONFIDENTIAL GREEN

Canopy X Body

Coverage

Front Frame 785D FEATURES

Extended

Handrail bump

out at cab

Wide

Toe Guards

Stairway

(Standard)

Extended Life

Brake Disc

20 CATERPILLAR: CONFIDENTIAL GREEN

Continuous Rear Axle Filtration

• Standard feature

• Continuously circulates axle

lubricant through 6 micron filter to

maintain ISO 18/15 cleanliness.

• Cleaner components equal 10 to

20% longer component life.

• Reduces kidney loop maintenance

times.

21 CATERPILLAR: CONFIDENTIAL GREEN

785D Value - Summary

• Component and parts commonality with the proven 3500

series HD engine

• Continuous Rear Axle Filtration

• Diagonal Front Access Stairway

• 3512C HD Tier II Engine

• New “X” series bodies w/extended canopy coverage

• Minimum new content change (maintenance department

proficiency, existing tooling utilization, mixed fleet transition)

22 CATERPILLAR: CONFIDENTIAL GREEN

785C, 785D & 789C Reduces Cost Per Ton

Safety

• Oil cooled brakes at 4 corners with

40/60 split,dead engine full stop Utilization

capability, ROPS/FOPS, 10/10/20 • One safe source for

payload control policy support

• Diagonal stairway, HID lighting,

extended wear brakes, and WAVS • Traction control allows

rear vision camera continued operation in

poor underfoot conditions

Production

Owning cost

• Fast cycle times – broad operating

range • Long economic life

• 2 axle retarding • Higher resale value than

• Optimize payload with MSD Bodies competition. Even though

a customer may not resell

Mechanical Availability

their truck, the high resale

• Improved reliability, higher uptime is indicative of the

• 3500 Series engine has lower remaining value in older

BMEP than competition—improving Cat trucks

availability, extending life, and

reducing costs.

23 CATERPILLAR: CONFIDENTIAL GREEN

785C, 785D & 789C Reduces Cost Per Ton

Maintenance cost per hour Operator efficiency

• Field-proven components throughout • Operator station comfort and

the truck ergonomics

• VIMS™ System capability allows • Operator confidence in braking and

diagnostics and prognostics to extend retarding optimizes downhill speed

service life

of components • Good visibility

• Dealer and factory REMAN Fuel cost per ton

Tire cost per hour • Engine fuel efficiency

• Weight distribution and low Empty • Highest power train efficiency

Machine Weight • Zero fuel consumption while retarding

• VIMS™ TKPH/TMPH Speed Manager

• Traction Control System – limited slip

24 CATERPILLAR: CONFIDENTIAL GREEN

You might also like

- P8000, P9000, P10000, P11000, P12000, PD8000, PD9000, PD10000, PD11000, PD12000 PDFDocument234 pagesP8000, P9000, P10000, P11000, P12000, PD8000, PD9000, PD10000, PD11000, PD12000 PDFeddyfredy100% (2)

- Air Inlet and Exhaust System OperationDocument5 pagesAir Inlet and Exhaust System OperationeddyfredyNo ratings yet

- Track-Type Tractor: Engine WeightsDocument16 pagesTrack-Type Tractor: Engine WeightseddyfredyNo ratings yet

- 992K With Efficiency Updates SpecalogDocument36 pages992K With Efficiency Updates SpecalogeddyfredyNo ratings yet

- Bucket Capacities 23.5 - 45.8 Yd: 0021M - AESS520-00 2/8/00 4:26 PM Page 2Document16 pagesBucket Capacities 23.5 - 45.8 Yd: 0021M - AESS520-00 2/8/00 4:26 PM Page 2eddyfredyNo ratings yet

- Track-Type Tractor: Engine Engine (Continued)Document24 pagesTrack-Type Tractor: Engine Engine (Continued)eddyfredy100% (1)

- CS3001 EManual (Pilot) SPANISH Pt1Document50 pagesCS3001 EManual (Pilot) SPANISH Pt1eddyfredy100% (2)

- 1706 SlidDocument206 pages1706 SlideddyfredyNo ratings yet

- Technical DataDocument3 pagesTechnical DataeddyfredyNo ratings yet

- 351 Pit ViperDocument6 pages351 Pit Vipereddyfredy100% (1)

- AP 800d FolletoDocument12 pagesAP 800d FolletoeddyfredyNo ratings yet

- Drill Stability Charts: Bucyrus International, IncDocument2 pagesDrill Stability Charts: Bucyrus International, InceddyfredyNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Service FRDocument86 pagesService FRmohahossam1992No ratings yet

- 2Document2 pages2shohratNo ratings yet

- 2017 Chevrolet City Express Owners ManualDocument279 pages2017 Chevrolet City Express Owners Manualmfruge5No ratings yet

- (京都府)きょうと留学生ハウス Kyoto Ryugakusei House: Hyakumanben Int'l HouseDocument2 pages(京都府)きょうと留学生ハウス Kyoto Ryugakusei House: Hyakumanben Int'l HouseATHAYANo ratings yet

- PressRelease 012020 40103-IFS-KitbDocument4 pagesPressRelease 012020 40103-IFS-KitbM2a ProductionNo ratings yet

- Motor Trend - March 2016Document122 pagesMotor Trend - March 2016neep100% (1)

- Analysis of Marketing Mix of Honda Cars in IndiaDocument25 pagesAnalysis of Marketing Mix of Honda Cars in Indiaamitkumar_npg7857100% (5)

- Colorado High Country LeafletDocument2 pagesColorado High Country LeafletDanangAjiPrasetiaNo ratings yet

- Go-Kart Engineering ProjectDocument18 pagesGo-Kart Engineering ProjectSaajid MumtazNo ratings yet

- ORTIZ CatalogDocument60 pagesORTIZ CatalogJairo GodoyNo ratings yet

- Wiring Diagram Handbook: For LHD and RHD TrucksDocument168 pagesWiring Diagram Handbook: For LHD and RHD Trucksluis meza100% (3)

- A Chinese Brand That Leads With Quality: Great Wall Motor Company LimitedDocument8 pagesA Chinese Brand That Leads With Quality: Great Wall Motor Company LimitedDana Ross Capcha MaximilianoNo ratings yet

- LTO Car Registration Fees PDFDocument4 pagesLTO Car Registration Fees PDFCiti PinoyNo ratings yet

- 2006 Radical Sr8 Owners ManualDocument11 pages2006 Radical Sr8 Owners ManualOscar PenteadoNo ratings yet

- EWD - Electrical Wiring Diagrams PDFDocument278 pagesEWD - Electrical Wiring Diagrams PDFintejamNo ratings yet

- Bajaj GPDocument298 pagesBajaj GPHarpreet Sethi0% (1)

- Volkswagen Passat (B4)Document2 pagesVolkswagen Passat (B4)Arūnas GiraitisNo ratings yet

- Stock Opname BulananDocument12 pagesStock Opname BulanandeboraNo ratings yet

- Autos OctubreDocument217 pagesAutos OctubreUlises GarciaNo ratings yet

- Last Herb 204 FlowDocument3 pagesLast Herb 204 FlowlastbikesNo ratings yet

- Wheel Steering System PDFDocument6 pagesWheel Steering System PDFvivek ghoriNo ratings yet

- Car Case StudyDocument9 pagesCar Case StudyAnnapurna PurohitNo ratings yet

- BMW Car Radio-Bavaria C Buisiness RDSDocument28 pagesBMW Car Radio-Bavaria C Buisiness RDSAncla SordiaNo ratings yet

- Available Colours: Technical Specifications+Document2 pagesAvailable Colours: Technical Specifications+Vishal PoulNo ratings yet

- Chrysler Pacifica 2007 Cs Parts CatalogDocument20 pagesChrysler Pacifica 2007 Cs Parts Catalogandrew100% (55)

- Hino Truck Bus Parts CatalogueDocument12 pagesHino Truck Bus Parts CatalogueDavina80% (5)

- Airbag Cushion or Stew - Logbook Peugeot 607 Controls Both The Cards 2002 DRIVE2Document10 pagesAirbag Cushion or Stew - Logbook Peugeot 607 Controls Both The Cards 2002 DRIVE2Blashko GjorgjievNo ratings yet

- 2001 Polaris Sportsman 500 H.O. Owners Info 3Document2 pages2001 Polaris Sportsman 500 H.O. Owners Info 3Mandy HarmonNo ratings yet

- E61 Technical Manual 2005Document72 pagesE61 Technical Manual 2005mmitev80% (5)

- Operator Manual: RR RD RSDocument20 pagesOperator Manual: RR RD RSDody SetiawanNo ratings yet