Professional Documents

Culture Documents

Dec 2001 - Paper 2 Question 7

Uploaded by

Jahel LootiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dec 2001 - Paper 2 Question 7

Uploaded by

Jahel LootiCopyright:

Available Formats

Dec 2001 – Paper 2 Question 7

a) Explain the principles of an interlocked machine guard. (4)

A machine cannot start up or become dangerous with the guard open

When the machine is in a dangerous condition, either the guard cannot be opened or

opening the guard causes the machine to become safe

b) Identify ways in which the following types of electrical, cam-activated position switches

(limit switches) may fail to operate as intended:

i) Negatively operated (or ‘normally open’). (3)

Guard closed – switch depressed – light off – machine circuit working

Defeated by taping up the plunger

Fail through spring failure

Welding together of the contacts due to electrical arcing

Damage or debris inside the switch

ii) Positively operated (or ‘normally closed’). (3)

Guard closed – switch released – light off – machine circuit working

Fail due to misalignment between the cam and cam follower

By being removed from its fixing point

By wear or damage to the plunger

By over-travel of the guard

c) By means of a labelled sketch, show the method of operation of an interlocked guarding

system incorporating two position switches (limit switches) operating in opposite modes

together with a simple self-monitoring arrangement utilising the ‘spare’ contacts within

each switch. (10)

Positively

operated –

normally

closed

Guard Light off –

machine

guarded

Negatively

operated –

normally open

Hazard

Machine

circuit

Positively

operated –

normally

closed

Guard Light on –

machine not

guarded

Negatively

operated –

normally open

Hazard

You might also like

- Black & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFDocument349 pagesBlack & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFHector100% (2)

- Re4f03b Re4f04bDocument756 pagesRe4f03b Re4f04bdenis100% (3)

- LiebherrDocument2,647 pagesLiebherrgosiamail100% (3)

- Risk Assessment For ExcavatorDocument4 pagesRisk Assessment For Excavatortrey milanNo ratings yet

- Fy10 Sh-20856-10 Machine GuardingDocument200 pagesFy10 Sh-20856-10 Machine GuardingKim Lien TrinhNo ratings yet

- Arming: Influence FuzeDocument1 pageArming: Influence FuzeKrizeNo ratings yet

- Working at Heights Safe Work Method Statement (SWMS)Document3 pagesWorking at Heights Safe Work Method Statement (SWMS)Toga Nainggolan100% (1)

- Drawing For Final: 45, Namhannam-Ro, Yeongdo-Gu, Busan, Korea Tel: +82 51 412 5551, Fax: +82 51 412 6660Document84 pagesDrawing For Final: 45, Namhannam-Ro, Yeongdo-Gu, Busan, Korea Tel: +82 51 412 5551, Fax: +82 51 412 6660FILIN VLADIMIRNo ratings yet

- Esquema Electrico 416DDocument4 pagesEsquema Electrico 416DMarco Antonio Esparza CastroNo ratings yet

- User Manual, Electrical - 11s000163-165 With DrawingsDocument105 pagesUser Manual, Electrical - 11s000163-165 With DrawingsMatzu StoianNo ratings yet

- Electric Distribution LinesDocument7 pagesElectric Distribution LinesluisepasNo ratings yet

- Simops SafetyDocument9 pagesSimops SafetyJahel Looti100% (2)

- Sensor Nivel cls40 BediaDocument1 pageSensor Nivel cls40 BedianovincontrolNo ratings yet

- Service Manual (NNSN9x8) PDFDocument32 pagesService Manual (NNSN9x8) PDFAlfonso NiñoNo ratings yet

- Snubber Circuits For Power Electronics - Severns PDFDocument346 pagesSnubber Circuits For Power Electronics - Severns PDFjimmyboy111No ratings yet

- Specification For VFD DrivesDocument32 pagesSpecification For VFD DrivesJAY PARIKH67% (3)

- Astm Hfe ChecklistDocument228 pagesAstm Hfe Checklistanub0025100% (2)

- Astra Convertible Roof Hints and Tips PDFDocument16 pagesAstra Convertible Roof Hints and Tips PDFLuís Diogo GomesNo ratings yet

- Instruction DRD100-200 PDFDocument51 pagesInstruction DRD100-200 PDFDeMen Nguyen100% (2)

- Khrs-598 Emergency Evacuation Plan: Well Pad Area Material Laydown AreaDocument1 pageKhrs-598 Emergency Evacuation Plan: Well Pad Area Material Laydown Areashemim2004No ratings yet

- Solar Controller User Manual - 20210729 - 0001Document2 pagesSolar Controller User Manual - 20210729 - 0001gohsaikitNo ratings yet

- Task Analysis 2017Document19 pagesTask Analysis 2017Muneeb QayyumNo ratings yet

- Hazard Identification and Risk Assessment: Risk Rating Matrix SeverityDocument7 pagesHazard Identification and Risk Assessment: Risk Rating Matrix SeverityRipson Jose T JNo ratings yet

- 2018 Emergency Evacuation - Khrs 554Document1 page2018 Emergency Evacuation - Khrs 554shemim2004No ratings yet

- User Manual Philips MG7750 (English - 5 Pages)Document2 pagesUser Manual Philips MG7750 (English - 5 Pages)calin.ct14No ratings yet

- User Manual Solar (Abacus) 110vDocument1 pageUser Manual Solar (Abacus) 110vMaria Fernanda Sivirs CastilloNo ratings yet

- 2018 Emergency Evacuation - khrs1023Document1 page2018 Emergency Evacuation - khrs1023shemim2004No ratings yet

- Call Toll Free: I-800-BUY-AIWADocument56 pagesCall Toll Free: I-800-BUY-AIWAigbiiNo ratings yet

- PTW Demolish Paint Shop (PPS Area)Document34 pagesPTW Demolish Paint Shop (PPS Area)Soul EaterNo ratings yet

- Machine Guards Wa RD Off Danger: Safety Meeting ReprosDocument2 pagesMachine Guards Wa RD Off Danger: Safety Meeting ReprosSyeikur RoviNo ratings yet

- JVC KD-R516Document92 pagesJVC KD-R516Joe ChirayathNo ratings yet

- Gm7mainunit SheetDocument2 pagesGm7mainunit Sheetmark luigi SarmientoNo ratings yet

- 4 Tag-Out SDRRMDocument3 pages4 Tag-Out SDRRMsharmaneNo ratings yet

- Johan - Cap SolarDocument56 pagesJohan - Cap Solarfidel100% (1)

- Risk Assessment FormDocument5 pagesRisk Assessment FormAly Sherif AhmedNo ratings yet

- Manual de Usuario Peugeot 307 (2008) (184 Páginas)Document2 pagesManual de Usuario Peugeot 307 (2008) (184 Páginas)Sheila Ramírez AlfaroNo ratings yet

- FILE 51 Use of Grinder or Angle GrinderDocument1 pageFILE 51 Use of Grinder or Angle GrinderJonathan BobadillaNo ratings yet

- Khrs-267 Emergency Evacuation Plan: Well Pad 267Document1 pageKhrs-267 Emergency Evacuation Plan: Well Pad 267shemim2004No ratings yet

- Technical Notice ASAP LOCK ANSI 1Document17 pagesTechnical Notice ASAP LOCK ANSI 1fabioNo ratings yet

- Warning: 5-In-1 Grooming SystemDocument2 pagesWarning: 5-In-1 Grooming SystemOrvelNo ratings yet

- Swj802e Manual Eng Mr9 08112020 FinalDocument20 pagesSwj802e Manual Eng Mr9 08112020 FinalRose CosenStudioNo ratings yet

- Karcher 5050 C BP ClassicDocument36 pagesKarcher 5050 C BP ClassicVorpal BladesNo ratings yet

- Machine Guarding PowerPoint PresintationDocument38 pagesMachine Guarding PowerPoint PresintationGopinathbabuNo ratings yet

- E492N (Eq Al E439)Document5 pagesE492N (Eq Al E439)Juan Sánchez LópezNo ratings yet

- Iron Works and Welding CuttingDocument3 pagesIron Works and Welding CuttingIbrahim EsmatNo ratings yet

- Dremei Moto-Tool Manual: o ° Owner'sDocument8 pagesDremei Moto-Tool Manual: o ° Owner'scarlos avilésNo ratings yet

- xrh66mdDocument124 pagesxrh66mdrovelo3405475No ratings yet

- CRX7 ManualDocument1 pageCRX7 Manualjose thiagoNo ratings yet

- WKS 6 Forest Harvesting Lockout Sawmill IsolationDocument4 pagesWKS 6 Forest Harvesting Lockout Sawmill IsolationJuan Ismael Carmona RodríguezNo ratings yet

- Oi FEATUREDocument6 pagesOi FEATUREcescNo ratings yet

- Solar Charger User Manual - 20210729 - 0001Document2 pagesSolar Charger User Manual - 20210729 - 0001gohsaikitNo ratings yet

- Control of Hazardous Energies-3bDocument35 pagesControl of Hazardous Energies-3bMakotoNo ratings yet

- KYK CatalogueDocument5 pagesKYK CatalogueSợi Nhà MáyNo ratings yet

- Five Min Machine GuardingDocument1 pageFive Min Machine Guardingppimaintenance23No ratings yet

- Danger Analysis / Safety Verification: WarningDocument4 pagesDanger Analysis / Safety Verification: Warninglwwwl2No ratings yet

- Safeguarding & Complementary Protective Measures: (As Per BS EN 12100-2, Clause 5)Document1 pageSafeguarding & Complementary Protective Measures: (As Per BS EN 12100-2, Clause 5)azriNo ratings yet

- Cy 600 800gii PDFDocument92 pagesCy 600 800gii PDFArmando Rivera100% (1)

- Lock Out Tag OutDocument13 pagesLock Out Tag OutsexyrustyNo ratings yet

- Operation Instructions: Camera AdapterDocument21 pagesOperation Instructions: Camera AdapterGeorge Cristian CatunaNo ratings yet

- CQ-D1703W Operating InstructionsDocument52 pagesCQ-D1703W Operating InstructionsAlexey OnishenkoNo ratings yet

- BBS Card Summary 09 April 2021Document7 pagesBBS Card Summary 09 April 2021Monang IkhwanulNo ratings yet

- DSP 1Document40 pagesDSP 1DNo ratings yet

- Mechanical Safety Switches Standards FeatArticle 201503Document8 pagesMechanical Safety Switches Standards FeatArticle 201503apex EHSNo ratings yet

- Mechanical Safety Switches Standards FeatArticle 201503Document8 pagesMechanical Safety Switches Standards FeatArticle 201503Giovani TavaresNo ratings yet

- Stephan Reanimator F-120 - Short InstructionDocument2 pagesStephan Reanimator F-120 - Short Instructionmr_phenriqueNo ratings yet

- Project Title: Tiara Pool Villa (Phase 1) AnchorworkDocument5 pagesProject Title: Tiara Pool Villa (Phase 1) AnchorworkMohd Khairul AnwarNo ratings yet

- CRW-F1UX enDocument50 pagesCRW-F1UX enSiles SandelNo ratings yet

- Risk AssessmentDocument2 pagesRisk AssessmentRosemenjelNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- Tennant 7300 Operator ManualDocument111 pagesTennant 7300 Operator ManualUmar ShamsudinNo ratings yet

- Technical Notice OMNI 1Document13 pagesTechnical Notice OMNI 1Enaitz OtazuaNo ratings yet

- H2S Package For OffshoreDocument2 pagesH2S Package For OffshoreJahel LootiNo ratings yet

- مقاله سیستم های پویاDocument12 pagesمقاله سیستم های پویاJahel LootiNo ratings yet

- 5.0 Safety 05Document8 pages5.0 Safety 05Jahel LootiNo ratings yet

- Fire Safety: Managing Risks For Industrial Hot WorkDocument4 pagesFire Safety: Managing Risks For Industrial Hot WorkJahel LootiNo ratings yet

- NEBOSH IGC2 Past Exam Paper June 2012 PDFDocument2 pagesNEBOSH IGC2 Past Exam Paper June 2012 PDFJahel LootiNo ratings yet

- 5.0 Safety 06Document7 pages5.0 Safety 06Jahel LootiNo ratings yet

- Safety Manual: 4.0 Protective Clothing & EquipmentDocument8 pagesSafety Manual: 4.0 Protective Clothing & EquipmentJahel LootiNo ratings yet

- Safety Manual: 2.0 Safety & Environment Protection Policy and Safety OrganizationDocument6 pagesSafety Manual: 2.0 Safety & Environment Protection Policy and Safety OrganizationJahel LootiNo ratings yet

- L13a Human FactorsDocument2 pagesL13a Human FactorsJahel LootiNo ratings yet

- Safety Manual: 3.0 General Duties of Employees and Safe Working PracticesDocument19 pagesSafety Manual: 3.0 General Duties of Employees and Safe Working PracticesJahel LootiNo ratings yet

- Safety Manual: Afety Anagement YstemDocument2 pagesSafety Manual: Afety Anagement YstemJahel LootiNo ratings yet

- Safety Manual: 3.0 General Duties of Employees and Safe Working PracticesDocument19 pagesSafety Manual: 3.0 General Duties of Employees and Safe Working PracticesJahel LootiNo ratings yet

- L11a Principles of RiskDocument2 pagesL11a Principles of RiskJahel LootiNo ratings yet

- In Relation To Human Error: I) Distinguish Between Routine Situational and Exceptional ViolationsDocument1 pageIn Relation To Human Error: I) Distinguish Between Routine Situational and Exceptional ViolationsJahel LootiNo ratings yet

- L12a Principles of RiskDocument2 pagesL12a Principles of RiskJahel LootiNo ratings yet

- Dec 2001 - P1 Q8 - RepDocument1 pageDec 2001 - P1 Q8 - RepJahel LootiNo ratings yet

- Identify Measures To Improve Human Reliability in The Workplace.Document1 pageIdentify Measures To Improve Human Reliability in The Workplace.Jahel LootiNo ratings yet

- Dec 2001 - Paper 2 Question 4Document2 pagesDec 2001 - Paper 2 Question 4Jahel LootiNo ratings yet

- Dec 2001 - P1 Q8 - RepDocument31 pagesDec 2001 - P1 Q8 - RepJahel LootiNo ratings yet

- Dec 2001 - Paper 1 Question 9Document1 pageDec 2001 - Paper 1 Question 9Jahel LootiNo ratings yet

- Dec 2001 - Paper 2 Question 2Document1 pageDec 2001 - Paper 2 Question 2Jahel LootiNo ratings yet

- In Relation To Human Error: I) Distinguish Between Routine Situational and Exceptional ViolationsDocument1 pageIn Relation To Human Error: I) Distinguish Between Routine Situational and Exceptional ViolationsJahel LootiNo ratings yet

- Dec 2001 - P2 Q3 - RepDocument1 pageDec 2001 - P2 Q3 - RepJahel LootiNo ratings yet

- Dec 2001 - Paper 2 Question 10Document1 pageDec 2001 - Paper 2 Question 10Jahel LootiNo ratings yet

- Dec 2001 - Paper 1 Question 9Document1 pageDec 2001 - Paper 1 Question 9Jahel LootiNo ratings yet

- Dec 2001 - P2 Q6Document1 pageDec 2001 - P2 Q6Jahel LootiNo ratings yet

- Dec 2001 - Paper 2 Question 5Document2 pagesDec 2001 - Paper 2 Question 5Jahel LootiNo ratings yet

- Dec 2001 - Paper 1 Question 9Document1 pageDec 2001 - Paper 1 Question 9Jahel LootiNo ratings yet

- AD, ML-310 Phase 7 Parts Manual PN 450028 (REV-1) 051701Document74 pagesAD, ML-310 Phase 7 Parts Manual PN 450028 (REV-1) 051701naokito AkemiNo ratings yet

- Electric Actuator InstructionDocument40 pagesElectric Actuator Instructiongasm220% (1)

- Product Specifications:: Series:NEO Colour: Grey Silver With Blue LED Locator Brand: Schneider ElectricDocument3 pagesProduct Specifications:: Series:NEO Colour: Grey Silver With Blue LED Locator Brand: Schneider ElectricSayemAbusadatNo ratings yet

- Condensed Checklist F 86F 35Document6 pagesCondensed Checklist F 86F 35Juan Francisco Sanchez MassadiNo ratings yet

- App Guide EntelliGuard - G 09 - 2020 AplicacionDocument100 pagesApp Guide EntelliGuard - G 09 - 2020 AplicacionjeorginagNo ratings yet

- Installation and Safety Instruction For Gas ValveDocument4 pagesInstallation and Safety Instruction For Gas Valvespscribd1No ratings yet

- Advanced Protection System: Engineer and Architect SpecificationsDocument12 pagesAdvanced Protection System: Engineer and Architect SpecificationsCesar TunarosaNo ratings yet

- Samsung CAC (Slim 1 Way Cassette) Service ManualDocument107 pagesSamsung CAC (Slim 1 Way Cassette) Service Manualsonic865967% (3)

- Air ManagementDocument80 pagesAir ManagementarifzakirNo ratings yet

- Liquiphant M FTL51C: Technical InformationDocument40 pagesLiquiphant M FTL51C: Technical Informationdford8583No ratings yet

- Wet WeldingDocument13 pagesWet WeldingViktor ŽganecNo ratings yet

- 1.7 Relay Terms and Definitions-GlossaryDocument5 pages1.7 Relay Terms and Definitions-GlossaryRingoNo ratings yet

- RC Switch by Alan BondDocument4 pagesRC Switch by Alan BondKaisNo ratings yet

- Mapa de Sensores Caex 930EDocument7 pagesMapa de Sensores Caex 930EBASE MINECARE CERREJONNo ratings yet

- Mapping SymbolsDocument35 pagesMapping SymbolsSparkPar0% (1)

- UniGear ZS2 Catalogue V1 MEDDocument26 pagesUniGear ZS2 Catalogue V1 MEDkjkljkljlkjljlkNo ratings yet

- Honeywell AQ2000Document8 pagesHoneywell AQ2000vsilickasNo ratings yet

- Description: Wattstopper Occupancy SensorDocument1 pageDescription: Wattstopper Occupancy SensorJeffery OsvoldNo ratings yet

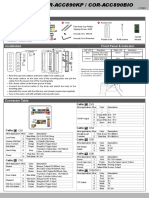

- Cor-Acc890kp Cor-Acc890bioDocument8 pagesCor-Acc890kp Cor-Acc890biojuan david mendez tellezNo ratings yet