Professional Documents

Culture Documents

Part-A3-Riveted Joints PDF

Uploaded by

N Dhanunjaya Rao BorraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part-A3-Riveted Joints PDF

Uploaded by

N Dhanunjaya Rao BorraCopyright:

Available Formats

Prepared By

B.N.DHANUNJAYARAO, &

Dr. K.S.RAGHURAM.

Part-A-Topic_1_CAMD_ Riveted Joints

Types of rivet heads, Single riveted lap joint, double riveted chain lap joint,

double riveted zig-zag lap joint, single riveted single strap butt joint, single

riveted double strap butt joint, double riveted double strap chain butt

joint, double riveted double strap zig-zag butt joint.

Rivets and Riveting:

Rivets are used to manufacture of boilers, storage tanks, etc., involve joining of steel sheets, by means

of riveted joints.

Figure: (a) Rivet and (b) Riveting.

Caulking and Fullering: (to produce air tight riveted joints)

(a) Outer edges of the plates used in boiler and other pressure vessels are beveled.

(b) Similar to caulking, the width of the fullering tool is equal to the width of the beveled

edges of the plates.

Figure: (a)Caulking and (b)Fullering.

Rivet Heads:

The size of the rivet, d is taken as,

where ‘t’ is the thickness of the plates to be joined in millimeters.

Various forms of rivet heads, used in general engineering works and boiler construction.

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com

2

Definitions in Riveted Joints:

If d is the diameter of the rivet then,

1. Pitch (P)=3d =distance between the

centers of the adjacent rivets in the same row,

2. Margin (m)=1.5d=distance from the

edge of the plate to the center of the nearest rivet.

3. Row Pitch (pr)= 0.8p for chain riveting &

0.6p for zig-zag riveting = distance

between two adjacent rows of rivets.

4. Diagonal Pitch (pd)=distance between the

center of a rivet in a row to the next rivet in

the adjacent row (Used in Zig-Zag Riveting).

5. Chain Riveting: rivets are used along a number of rows

such that the rivets in the adjacent rows are

placed directly opposite to each other.

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com

3

6. Zig-Zag Riveting: rivets in the adjacent rows are staggered

and are placed in between those of the previous row.

Single riveted lap joint:

Single row of rivets placed in a plate is single riveted and

plate1 overlaps over plate2 is lap joint.

Figure: Sectional front view and top view of Single

riveted lap joint

Double riveted chain lap joint:

Two rows of rivets placed in a plate is double riveted,

plate1 overlaps over plate2 is lap joint and adjacent rows

placed opposite to each other is chain riveting system.

Figure: Sectional front view and top view of the Double

riveted chain lap joint

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com

4

Double riveted zig-zag lap joint:

Two rows of rivets placed in a plate is double riveted,

plate1 overlaps over plate2 is lap joint and adjacent rows

are staggered to each other is zig-zag riveting system.

Figure: Sectional front view and top view of the Double

riveted zig-zag lap joint

Single riveted, single strap butt joint:

Single row of rivets placed in a plate is single riveted,

plate1 & plate2 placed side by side is butt joint and

Single strap is used to achieve the joint is

single strap joint.

In a single strap butt joint, the thickness of the strap

(cover plate) is given by, t1 = 1.125t

Figure: Sectional front view and top view of Single riveted,

single strap butt joint.

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com

5

Single riveted, double strap butt joint:

Single row of rivets placed in a plate is single riveted,

plate1 & plate2 placed side by side is butt joint and

double straps are used to achieve the joint is

double strap joint.

If two straps are used, the thickness of each cover plate

is given by, t2 = 0.75t

Figure: Sectional front view and top view of Single riveted,

double strap butt joint.

Double riveted, double strap chain butt joint:

Two rows of rivets placed in a plate is double riveted,

plate1 & plate2 placed side by side is butt joint,

two straps are used to achieve the joint is

double strap joint and adjacent rows placed

opposite to each other is chain riveting system.

If two straps are used, the thickness of each cover

Plate is given by, t2 = 0.75t

Figure: Sectional front view and top view of Double riveted, double strap

chain butt joint

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com

6

Double riveted, double strap zig-zag butt joint:

Two rows of rivets placed in a plate is double

riveted, plate1 & plate2 placed side by side is

butt joint, two straps are used to achieve the

joint is double strap joint and adjacent rows

are staggered to each other is zig-zag riveting

system.

If two straps are used, the thickness of each cover

Plate is given by, t2 = 0.75t

Figure: Sectional front view and top view of Double riveted, double strap zig-

zag butt joint

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com

7

DRAWING EXERCISES

1. Draw the different types of rivet heads and take the thickness of the plates as 9 mm.

2. Draw the sectional front view and top view of the Single riveted lap joint and the thickness of

the plates is 9 mm.

3. Draw the sectional front view and top view of the Double riveted chain lap joint and the

thickness of the plates is 9 mm.

4. Draw the sectional front view and top view of the Double riveted zig-zag lap joint and the

thickness of the plates is 9 mm.

5. Draw the sectional front view and top view of the Single riveted single strap butt joint and the

thickness of the plates is 9 mm.

6. Draw the sectional front view and top view of the Single riveted double strap butt joint and the

thickness of the plates is 9 mm.

7. Draw the sectional front view and top view of the double riveted double strap chain butt joint

and the thickness of the plates is 9 mm.

8. Draw the sectional front view and top view of the double riveted double strap zig-zag butt joint

and the thickness of the plates is 9 mm.

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com

8

You might also like

- Part A5 Cotter JointsDocument6 pagesPart A5 Cotter JointsN Dhanunjaya Rao BorraNo ratings yet

- Design of Rivets & Welded JointsDocument52 pagesDesign of Rivets & Welded JointsKrishna VamsiNo ratings yet

- Cad & Component DrawingDocument36 pagesCad & Component DrawingkousikkumaarNo ratings yet

- Riveted JointsDocument16 pagesRiveted JointsAditya RaoNo ratings yet

- ACD LabDocument48 pagesACD LabBasith AbbasNo ratings yet

- Introduction to Riveted JointsDocument52 pagesIntroduction to Riveted Jointsaparunpravin079579No ratings yet

- Machine Design Lec3Document75 pagesMachine Design Lec3sam0415No ratings yet

- Rivets and Welded JointDocument37 pagesRivets and Welded JointJohn Kris San LuisNo ratings yet

- Machine Design-I and II Lecture NotesDocument37 pagesMachine Design-I and II Lecture NotesAzeem MohammadNo ratings yet

- Unit2 - BT 205 - AFDocument22 pagesUnit2 - BT 205 - AFyobingewatcher06No ratings yet

- DOS II PPT 2Document40 pagesDOS II PPT 2revathisasikumar5420No ratings yet

- 3.DME - ME3RD - UNIT-3.2 - Design of JointsDocument70 pages3.DME - ME3RD - UNIT-3.2 - Design of JointsCHITYALA YASHWANTH KRISHNA ,ECE18 Vel Tech, ChennaiNo ratings yet

- Knots for Rappelling and MountaineeringDocument24 pagesKnots for Rappelling and MountaineeringRyan RuffcornNo ratings yet

- Machine Design Lecture on Riveted JointsDocument39 pagesMachine Design Lecture on Riveted JointsHari NaniNo ratings yet

- Chapter Nine Gauze and Leno WeavesDocument20 pagesChapter Nine Gauze and Leno Weavesshobsundar100% (2)

- Zabavny_olenDocument3 pagesZabavny_olenNadja ReizNo ratings yet

- Lecture 6 Riviting DesignDocument17 pagesLecture 6 Riviting DesignAbdelrahman yasser ZaghloulNo ratings yet

- Design of Rivets (Part 1)Document46 pagesDesign of Rivets (Part 1)Dhruv PancholiNo ratings yet

- Chapter III-V Types of Joint and Torque Transmitting JointDocument18 pagesChapter III-V Types of Joint and Torque Transmitting JointfetenaNo ratings yet

- Strength Calculation and Dimensioning of Joints: Prepared By: Samson Yohannes Assistant ProfessorDocument45 pagesStrength Calculation and Dimensioning of Joints: Prepared By: Samson Yohannes Assistant ProfessorBK MKNo ratings yet

- Design of Fastners - Screwed JointsDocument25 pagesDesign of Fastners - Screwed JointsKunal AhiwaleNo ratings yet

- Design of Riveted JointDocument12 pagesDesign of Riveted JointYogesh DandekarNo ratings yet

- ALFAbeto MOVIL PDFDocument18 pagesALFAbeto MOVIL PDFCarolina HerreraNo ratings yet

- Chapter - 3 - Strength Calculation and Dimensioning of JointsDocument24 pagesChapter - 3 - Strength Calculation and Dimensioning of Jointsfedila jemalNo ratings yet

- MACHINE ELEMENT DESIGn 2Document13 pagesMACHINE ELEMENT DESIGn 2Oma AttamahNo ratings yet

- Lecture 2. Riveted Joints PDFDocument20 pagesLecture 2. Riveted Joints PDFhasanNo ratings yet

- V-Machine Design 1Document37 pagesV-Machine Design 1roamer10No ratings yet

- Riveted Welded Joints PDFDocument16 pagesRiveted Welded Joints PDFKarthikKavuriNo ratings yet

- Riveted JointsDocument7 pagesRiveted Jointsjimmy mlelwaNo ratings yet

- Trebuchet Plans 2006 10 11Document7 pagesTrebuchet Plans 2006 10 11Sue MurphyNo ratings yet

- Dar Lee WrapDocument8 pagesDar Lee WrapAlexandrina Lara WierzynskiNo ratings yet

- Oct09 CustomCool OnlineDocument2 pagesOct09 CustomCool OnlineVivian M. Rosario Santos50% (2)

- Blanking Die Parts GuideDocument28 pagesBlanking Die Parts Guideravi shankarNo ratings yet

- Module 3 - Joint Types in Machine DesignDocument28 pagesModule 3 - Joint Types in Machine DesignMahmud HassanNo ratings yet

- Types of Riveted Joints and Joint EfficiencyDocument1 pageTypes of Riveted Joints and Joint EfficiencymorolosusNo ratings yet

- Flowering Necklace: KTV2015CDocument2 pagesFlowering Necklace: KTV2015CCristina KepteaNo ratings yet

- Embroidery Thread Tension Guide for Flawless StitchesDocument4 pagesEmbroidery Thread Tension Guide for Flawless StitchesCandle thread TurkeyNo ratings yet

- Som Lecture-2Document3 pagesSom Lecture-2Albaar MehdiNo ratings yet

- Riveted JointsDocument9 pagesRiveted JointsRani_Nabil_4934100% (2)

- Frosty Penguin Cushion: Designed by Ilaria Caliri - Airali DesignDocument3 pagesFrosty Penguin Cushion: Designed by Ilaria Caliri - Airali DesignEli Mimosa100% (1)

- Riveted Connections ExplainedDocument38 pagesRiveted Connections ExplainedKeerthana PNo ratings yet

- Bolsa em CrocheDocument14 pagesBolsa em CrocheGabriella Amorim100% (1)

- Deep DrawingDocument4 pagesDeep DrawingADITYA GATTANINo ratings yet

- Bolted ConnectionsDocument23 pagesBolted ConnectionsNaresh ReddyNo ratings yet

- Chapter 3 - Design of Tension and Compression Members PDFDocument84 pagesChapter 3 - Design of Tension and Compression Members PDFNiyibizi PromesseNo ratings yet

- Q2WK2 EIM 11 BitanhuanDocument20 pagesQ2WK2 EIM 11 BitanhuanCirilo SumabalNo ratings yet

- Development SM TECHDocument24 pagesDevelopment SM TECHFreby Tony ENo ratings yet

- Steel Unit 1 QBDocument30 pagesSteel Unit 1 QBKarnakar ReddyNo ratings yet

- Joint DetailDocument4 pagesJoint DetailRamesh PrajapatiNo ratings yet

- Stress Analysis of Riveted Lap JointDocument7 pagesStress Analysis of Riveted Lap JointMeck LotfiNo ratings yet

- Outstanding Crochet Natalia Kononova Queen Bee Bag and Pillow CLDocument31 pagesOutstanding Crochet Natalia Kononova Queen Bee Bag and Pillow CLcristinagallegobarraganNo ratings yet

- Mason Baby Shoes: Finished Size: Us Baby Shoe Size 1-5Document11 pagesMason Baby Shoes: Finished Size: Us Baby Shoe Size 1-5Maria Lúcia PereiraNo ratings yet

- Question For Cotter and Knuckle JointDocument3 pagesQuestion For Cotter and Knuckle JointRahul PatilNo ratings yet

- Afghans & Bed Runners for Knitting Looms: A Step-by-Step Guide for Creating 12 Stunning Projects on a Knitting LoomFrom EverandAfghans & Bed Runners for Knitting Looms: A Step-by-Step Guide for Creating 12 Stunning Projects on a Knitting LoomNo ratings yet

- MCMT Unit-2 PPQDocument2 pagesMCMT Unit-2 PPQN Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-2 Mech 3-1 R13Document1 pageMCMT Mid-2 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- Fundamentals of Machining TechniquesDocument2 pagesFundamentals of Machining TechniquesN Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-2 Mech 3-1 R13Document1 pageMCMT Mid-2 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-1 Mech 3-1 R13Document1 pageMCMT Mid-1 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- Mid 2Document6 pagesMid 2N Dhanunjaya Rao BorraNo ratings yet

- Supplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingDocument5 pagesSupplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingN Dhanunjaya Rao BorraNo ratings yet

- Supplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingDocument5 pagesSupplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingN Dhanunjaya Rao BorraNo ratings yet

- New Microsoft Excel WorksheetDocument3 pagesNew Microsoft Excel WorksheetN Dhanunjaya Rao BorraNo ratings yet

- Robotics Course Objectives and ApplicationsDocument5 pagesRobotics Course Objectives and ApplicationsN Dhanunjaya Rao BorraNo ratings yet

- Mid 2Document6 pagesMid 2N Dhanunjaya Rao BorraNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentN Dhanunjaya Rao BorraNo ratings yet

- Study of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionDocument1 pageStudy of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionN Dhanunjaya Rao BorraNo ratings yet

- Ucmp QBDocument1 pageUcmp QBN Dhanunjaya Rao BorraNo ratings yet

- Study of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionDocument1 pageStudy of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionN Dhanunjaya Rao BorraNo ratings yet

- Part A5 Cotter JointsDocument8 pagesPart A5 Cotter JointsN Dhanunjaya Rao BorraNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentN Dhanunjaya Rao BorraNo ratings yet

- Composite Materials QuotationDocument1 pageComposite Materials QuotationN Dhanunjaya Rao BorraNo ratings yet

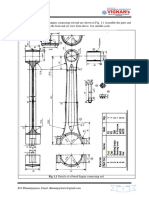

- Part-B1-Petrol Engine Connecting RodDocument5 pagesPart-B1-Petrol Engine Connecting RodN Dhanunjaya Rao BorraNo ratings yet

- CAMD QuestionsDocument3 pagesCAMD QuestionsN Dhanunjaya Rao Borra100% (1)

- Assembly DrawingsDocument15 pagesAssembly DrawingsN Dhanunjaya Rao BorraNo ratings yet

- Advanced NDE Lesson 1Document190 pagesAdvanced NDE Lesson 1N Dhanunjaya Rao BorraNo ratings yet

- Part-A5-Cotter Joints PDFDocument6 pagesPart-A5-Cotter Joints PDFN Dhanunjaya Rao BorraNo ratings yet

- Assembly DrawingsDocument15 pagesAssembly DrawingsN Dhanunjaya Rao BorraNo ratings yet

- Part A4 Keyed JointsDocument8 pagesPart A4 Keyed JointsN Dhanunjaya Rao BorraNo ratings yet

- Part A4 Keyed JointsDocument8 pagesPart A4 Keyed JointsN Dhanunjaya Rao BorraNo ratings yet

- Part-B-Topic AB 1 CAMD Petrol Engine Connecting - RodDocument8 pagesPart-B-Topic AB 1 CAMD Petrol Engine Connecting - RodN Dhanunjaya Rao BorraNo ratings yet

- Intro To NDTDocument34 pagesIntro To NDTkbldamNo ratings yet

- jk2 JAVADocument57 pagesjk2 JAVAAndi FadhillahNo ratings yet

- COP Grease BrochureDocument4 pagesCOP Grease Brochured86299878No ratings yet

- JVW 110Document2 pagesJVW 110Miguel Leon BustosNo ratings yet

- Eurapipe ABS Pipe - Fittings ManualDocument52 pagesEurapipe ABS Pipe - Fittings ManualLê Minh ĐứcNo ratings yet

- Primary Checkpoint - Science (0846) October 2016 Paper 2 MSDocument12 pagesPrimary Checkpoint - Science (0846) October 2016 Paper 2 MSdinakarc78% (9)

- Organic Evolution (Evolutionary Biology) Revised Updated Ed by Veer Bala RastogiDocument1,212 pagesOrganic Evolution (Evolutionary Biology) Revised Updated Ed by Veer Bala RastogiTATHAGATA OJHA83% (6)

- Calculate Capacity of Room Air Conditioner: Room Detail Unit Electrical Appliances in The RoomDocument2 pagesCalculate Capacity of Room Air Conditioner: Room Detail Unit Electrical Appliances in The Roomzmei23No ratings yet

- Base Is OkDocument84 pagesBase Is OkajaydevmalikNo ratings yet

- OWASP Dependency-Check Plugin: DescriptionDocument10 pagesOWASP Dependency-Check Plugin: DescriptionFelipe BarbosaNo ratings yet

- An IDEAL FLOW Has A Non-Zero Tangential Velocity at A Solid SurfaceDocument46 pagesAn IDEAL FLOW Has A Non-Zero Tangential Velocity at A Solid SurfaceJayant SisodiaNo ratings yet

- Bron 2017Document73 pagesBron 2017Anggia BungaNo ratings yet

- The Standard 09.05.2014Document96 pagesThe Standard 09.05.2014Zachary Monroe100% (1)

- HandoutDocument4 pagesHandoutZack CullenNo ratings yet

- ListDocument4 pagesListgeralda pierrelusNo ratings yet

- Boat DesignDocument8 pagesBoat DesignporkovanNo ratings yet

- Antarctica Can Give A MonopolyDocument6 pagesAntarctica Can Give A MonopolyFilip DukicNo ratings yet

- VNACS Final Case ReportDocument9 pagesVNACS Final Case ReportVikram Singh TomarNo ratings yet

- Schedule For Semester III, Class of 2021Document7 pagesSchedule For Semester III, Class of 2021Jay PatelNo ratings yet

- Procedure For NC and CapaDocument2 pagesProcedure For NC and CapaSAKTHIVEL ANo ratings yet

- XLVI ESAN INTERNATIONAL WEEK (MBA Only - July 2023)Document38 pagesXLVI ESAN INTERNATIONAL WEEK (MBA Only - July 2023)Juan Diego Fernández CastilloNo ratings yet

- Airbus Reference Language AbbreviationsDocument66 pagesAirbus Reference Language Abbreviations862405No ratings yet

- Name: Chakshu Purohit Course: BBA LLB Subject: Legal Research and Methodology Submitted To: Utkarsh MishraDocument5 pagesName: Chakshu Purohit Course: BBA LLB Subject: Legal Research and Methodology Submitted To: Utkarsh Mishrachakshu purohitNo ratings yet

- Mass ELA Releases ORQs Grade 8Document24 pagesMass ELA Releases ORQs Grade 8scmsliteracyNo ratings yet

- Kamera Basler Aca2500-20gmDocument20 pagesKamera Basler Aca2500-20gmJan KubalaNo ratings yet

- Declarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Document13 pagesDeclarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Jair Luiz S. FilhoNo ratings yet

- Creature Loot PDF - GM BinderDocument97 pagesCreature Loot PDF - GM BinderAlec0% (1)

- Motor Operated ValveDocument6 pagesMotor Operated ValveYosses Sang NahkodaNo ratings yet

- Nigerian Romance ScamDocument10 pagesNigerian Romance ScamAnonymous Pb39klJNo ratings yet

- CONTACT DETAILS HC JUDGES LIBRARIESDocument4 pagesCONTACT DETAILS HC JUDGES LIBRARIESSHIVAM BHATTACHARYANo ratings yet

- Audit AP TestsDocument3 pagesAudit AP TestsSweet Emme100% (1)