Professional Documents

Culture Documents

Effect of Crushed Quartzite On Self Compacting Concrete PDF

Uploaded by

youssefOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Crushed Quartzite On Self Compacting Concrete PDF

Uploaded by

youssefCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2014): 5.611

Effect of Crushed Quartzite on Self Compacting

Concrete

K. Surendra Babu1 , G. Nagesh Kumar2

1

PG Student, Department of Civil Engineering, G. Pulla Reddy Engineering College (Autonomous), Kurnool, Andhra Pradesh, India.

2

Sr. Assistant Professor, Department of Civil Engineering, G. Pulla Reddy Engineering College (Autonomous),Kurnool, Andhra Pradesh, India

Abstract: Self-Compacting Concrete (SCC) is one of the modern techniques in the concrete research. The SCC is able to flow and fill the

most restacked places to the form work without vibration. For SCC, super plasticizer is used in order to improve high mobility. There are

several methods for testing SCC properties in fresh state the most frequently used tests are slump flow test, L-box, V funnel test. In recent

days the demand for river sand is increasing due to lesser availability. In India the conventional concrete is produced using natural sand

obtained from river beds as fine aggregate. Decreasing natural resources poses the environmental problem and hence State Government

restrictions on sand quarrying result in scarcity and significant increase in its cost. This project presents the properties of SCC, mixed with

quartzite as fine aggregate. This project aims to focus on the possibility of using industrial by-product like crushed quartzite. The usage of

this crushed quartzite is proposed as partial replacement of fine aggregate in the production of SCC. Strengths properties such as

Compressive strength, Tensile strength, Split Tensile Strength of SCC is determined at the age of 28 days with normal curing.

Keywords: Self compacting concrete, Crushed Quartzite, Super Plasticizer

1. Introduction Therefore, use of these types of mineral additives in SCC will

make it possible, not only to decrease the cost of SCC but also

The development of self-compacting concrete (SCC) also to increase its long-term performance. To assess the

referred to as „„Self-Consolidating Concrete‟‟ has recently effectiveness of Fly ash in SCC some of the parameters like

been one of the most important developments in construction chemical composition, hydraulic reactivity, and fineness have

industry. SCC is a special concrete that can settle into the been carefully examined earlier It was seen that among these,

heavily reinforced, deep and narrow sections by its own the reactive glass content and fineness of Fly Ash alone will

weight, and can consolidate itself without necessitating influence the cementitious/pozzolanic efficiency or its

internal or external vibration, and at the same time maintaining reactivity in concrete composites significantly

its stability without leading to segregation and bleeding. SCC

demands a large amount of powder content compared to In India the conventional concrete is produced using natural

conventional vibrated concrete to produce a homogeneous and sand form river beds as fine aggregate. Decreasing natural

cohesive mix. The common practice to obtain self- resources poses the environmental problem and hence State

compactibility in SCC is to limit the coarse aggregate content Government imposing restrictions on sand quarrying, resulted

and the maximum size and to use lower water–powder ratio in scarcity and significant increase in its cost. Digging sand

together with new generation super plasticizer (SP). During from river beds in excess quantity is hazardous to the

the transportation and placement of SCC Due to flow ability environment. If deep pits are dug in river beds affect the

property of SCC it causes segregation, bleeding problems in ground water level so In order to fulfill the requirement of fine

form work placing condition to which can be overcome by aggregate, some alternative material must be found. The

providing the necessary viscosity to SCC, which is usually cheapest and the easiest way of getting substituent for natural

supplied by increasing the fine aggregate content by limiting sand is obtained from Quartzite quarry. Concrete made with

the maximum aggregate size by increasing the powder content Crushed Quartzite as replacement of natural sand in concrete

or by utilizing viscosity modifying admixtures (VMA). One of can attain more or less same compressive strength. In this

the disadvantages of SCC is its cost, associated with the use of paper the fresh and mechanical properties of SCC is evaluated

chemical admixtures and use of high volumes of Portland by partially replacing Cement with Fly ash and fine aggregate

cement. One alternative to reduce the cost of the SCC is to use with Crushed Quartzite..

of mineral additives such as limestone powder, natural

pozzolans, fly ash and slag, which are finely divided materials 2. Review of Literature

added to concrete as separate ingredients either before or

during mixing . As these mineral additives replace part of the Halit Yazici[2]had studied the effect of silica fume(SF), fly ash

portland cement, the cost of SCC will be reduced especially if on properties of concrete. Cement has replaced with a Class C

mineral additive is an industrial by-product or waste. It is well fly ash (FA) in various proportions from 30% to 60%. Test

established that the mineral additives, such as fly ash and slag, results indicate that SCC could be obtained with a high-

may increase the workability, durability and long-term volume FA. Ten percent SF additions to the system positively

properties of concrete.

Volume 4 Issue 10, October 2015

www.ijsr.net

Paper ID: SUB158891 782

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2014): 5.611

affected both the fresh and hardened properties of high- 2. Fly Ash as partial replacement to cement

performance high-volume FA SCC. 3. Crushed Quartzite as partial replacement to Fine

Aggregate.

Prajapatikrishnapal, Chandak Rajeev[6] had studied the 4. Naturally available River sand as fine aggregate

properties of self compacting concrete, mixed with fly ash. 5. Crushed Granite as coarse aggregate of size not greater

The test results for acceptance characteristics of self- than 12.5 mm

compacting concrete such as slump flow; V-funnel and L-Box 6. Master Glenium Sky super plasticizer(poly carboxylate

are presented. Further, compressive strength at the ages of 7, based)

28 days was also determined. They concluded that addition of 7. Water

fly-ash in SCC increases filling and passing ability of

concrete, Increase in fly ash, super plasticizer content in SCC 4. Material Properties

reduced water demand and increased/reduced compressive

strength of concrete. (1) Ordinary Portland Cement (OPC) 53 grade

[3]

conformingtoIS12269:1987 is used in this work. The properties

J.Guru Jawahar had studied the effect of coarse aggregate of used cement were

blending on short term mechanical properties of concrete. TYPE Ordinary Portland Cement

Their investigation mainly focused on finding the unit weight, Normal consistency 32%

compressive strength, modulus of elasticity(MOE) and split Specific Gravity 3.13

tensile strength(STS) of SCC mixes with different coarse Compressive strength 55.6 Mpa

aggregate blending(20mm and 10mm)(60:40 and 40:60) and

coarse aggregate content (28% and 32%). They concluded that (2) Fly Ash brought from Rayalaseema Thermal Power

the coarse aggregate blending did not affect the compressive Plant having specific gravity 2.2

strength of SCC mixes, but it affected the unit weight, MOE (3) Thephysical propertiesoffineaggregate (riversand) were.

and STS of SCC mixes. Specific gravity – 2.65 Water absorption – 1%

Fineness modulus – 2.68 Maximum nominal size – 4.75 mm

J.Guru Jawahar[4] had studied the micro and macro level

properties of Class F fly ash blended SCC after 28,56,112 (5)Thephysical propertiesofCoarseaggregate (Crushed granite)

days of curing. SEM analysis and X-RAY analysis were were

carried out to study the micro properties .Results revealed that Specific gravity - 2.72 Water absorption(%) – 0.3%

the pozzolanic action of class F fly ash improved the micro Fineness modulus - 4.6 Maximum nominal size – 12.5 mm

level properties with age and reducing the micro cracking

width and also enhanced the macro level properties. (6) Thephysical propertiesofreplaced fineaggregate (Crushed

Quartzite) were.

Mucteba Uysal[5]had studied the effectiveness of various Specific gravity – 2.71 Water absorption – 1%

mineral admixtures in producing SCC. For this purpose, fly Fineness modulus – 3.12 Maximum nominal size – 4.75 mm

ash (FA), granulated blast furnace slag (GBFS), limestone

powder (LP), basalt powder (BP) and marble powder (MP) (7) Master Glenium Sky Super plasticizer (poly carboxylate

were used. It was concluded that among the mineral based) having specific gravity 1.03

admixtures used, FA and GBSF significantly increased the

workability of SCC. 5. Mix Proportioning

Anthony Nkem Ede[1]They had made attempts enhance the The mix proportion is a key factor to be considered to achieve

flow-ability of SCC by replacement of cement with varying SCC. Though the SCC was first developed in 1980‟s there is no

dosage of limestone and super-plasticizer. To validate the standard mix design adopted or developed to achieve SCC. The

improvement of SCC fresh properties, slump test is used to European Federation Of Specialist Construction Chemicals and

assess workability, L-box test for passing ability and V-funnel Concrete systems (EFNARC) provide the guideline for

test for filling ability. Test results analyzed with statistical development of SCC. But no method of mix design specifies the

tools confirmed that the workability and rheological properties grade of concrete in SCC except Nan Su et al method. In this

of SCC can be improved through the adoption of various work mix design is developed based on the EFNARC guidelines.

dosages of limestone powder. In this work Fly Ash used as a mineral additives which replaces

cement and water-powder ratio of 0.4 is maintained constant

3. Materials Used throughout the experiment. First cement is replaced with Fly ash

in proportions of 10,20,30& 40 fresh and hardened properties

In the present investigation materials used are were checked.

1. Ordinary Portland cement 53 Grade

with Crushed Quartzite is done in proportions of 10.20,30,40 &

By taking the optimum mix from the results and keeping that 50. In present work at 30% replacement with Fly ash gives the

percentage of Fly Ash constant, partially replacing Fine aggregate optimum results and for a mix with 30% Fly Ash and partially

Volume 4 Issue 10, October 2015

www.ijsr.net

Paper ID: SUB158891 783

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2014): 5.611

replacing River sand with Crushed Quartzite Gives below.

Comparatively Better Strength. The mix proportions are tabulated

MIX PROPORTION FOR 1 m3 OF SCC

Mix Mix Proportions CEMENT Fly Ash WATER F.A River F.A Crushed Quartzite C.A S.P

Designation (kg) (kg) (litres) Sand(kg) (Kg) (kg) (litres)

M0 100% C 500 - 200 897 - 733 4.6

M1 90% C + 10% FA 450 50 200 894 - 723 4.6

M2 80% C + 20% FA 400 100 200 884 - 715 4.6

M3 70% C + 30% FA 350 150 200 875 - 707 4.6

M4 60% C + 40% FA 300 200 200 864 - 700 4.6

M5 70% C+30% FA + 10% CQ 350 150 200 787.7 87.5 707 4.6

M6 70% C +30% FA+ 20% CQ 350 150 200 700 175 707 4.6

M7 70% C +30% FA + 30% CQ 350 150 200 612.1 268.29 707 4.6

M8 70% C+30% FA+ 40% CQ 350 150 200 524.7 357.72 707 4.6

M9 70% C+30% FA + 50% CQ 350 150 200 437.5 437.5 707 4.6

(C- Cement, FA – Fly ash, CQ – Crushed Quartzite)

6. Testing Procedures mm height cylinder specimens at 28 days. The splitting tensile

strength reported in the study was the average of two

6.1 Fresh properties cylinders. Flexural strength of the SCC wae determined on

500 mm x 100 mm x100 mm beam specimens. The test was

Slump flow, V-funnel, L-box, were used to test the conducted on one beam specimen after 28 days of normal

workability and passing ability, of SCC. Workability of the water curing. Test results were tabulated below

SCC was controlled through the slump flow test such that

slump flow diameters of all of the mixtures were designed to Hardened properties of SCC

be in the range of 650-800 mm as to satisfy the EFNARC MIX Compressive Split tensile Flexural

limitation . For this, trial batches were produced for each ID strength (MPa) strength (MPa) strength (MPa)

M0 33.00 2.57 7.6

mixture till the desired slump flow was obtained by adjusting

M1 34.66 2.8 7.73

the dosage of the superplasticizer. Flowability of the mixtures

M2 36.88 2.97 7.95

was inspected through the V-Funnel test. L-box test was M3 38.96 3.225 8.25

carried out as an indication of passing ability, or the degree to M4 34.22 2.54 7.95

which the passage of concrete through the bars is restricted. M5 39.87 3.22 8.25

Slump flow, L-box, and V-funnel tests were performed M6 40.56 3.24 8.27

according to the procedure recommended by EFNARC M7 41.18 3.25 8.28

committee. The results of fresh properties for each mix were M8 41.77 3.30 8.30

tabulated below M9 42.07 3.38 8.34

Fresh properties of SCC

MIX Slump (mm) T500 (sec) V- T5 (sec) L-box

ID (650-800 (2-5 sec) Funnel(sec) (0.8-1.0)

mm) (6-12 sec)

M0 640 5 13 15 0.75

M1 670 4 9 11 0.82

M2 690 3.5 8 12 0.86

M3 720 2.8 7 10 0.86

M4 740 2.3 7 8 0.89

M5 720 3.0 8.5 10 0.86

M6 730 3.8 8 11 0.86

M7 730 3.5 7.3 9 0.92

M8 740 3.0 6.8 9 0.96

M9 780 2.O 5.0 7.0 1.2

6.2 Hardened Properties

Compressive strength of SCC were measured by means of a

compression testing machine. The test was conducted on three

150 mm cubes at the ages of 28 days normal water curing and

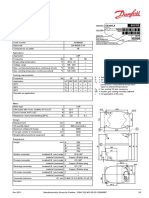

the average of them was reported herein. Splitting tensile Figure 1: Mix ID vs Compressive Strength

strength of the SCCs was determined on 150 mm dia and300

Volume 4 Issue 10, October 2015

www.ijsr.net

Paper ID: SUB158891 784

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2014): 5.611

4) The Hardened Properties shows with the replacement of

30% of Fly ash as mineral admixture and 10% to 50%

Crushed Quartzite as Fine Aggregate does not affect the

Strength Properties.

5) The Strength Properties are slightly increased, except Mix

M4when compared with the M0 mix.

References

[1] Anthony Nkem Ede.et.al “Study of effect of limestone

powder and super plasticizer dosage on properties of self

compacting concrete”, Civil and Environmental Research

ISSN 2224-5790 ISSN 2225-0514 ,Vol.6, No.2, 2014.

[2] HalitYazıcı ” The effect of silica fume and high-volume

Class C fly ash on mechanical properties, chloride

penetration and freeze–thaw resistance of self- compacting

concrete”, Construction and Building Materials 22 (2008)

456–462, Elsevier

Figure 2: Mix ID vs Split Tensile Strength [3] J.GuruJawahar,et.al.” Effect of Coarse aggregate blending

on short term properties of SCC”

[4] J.GuruJawahar, et.al “ Study of properties of class F fly ash

blended self compacting concrete”

[5] Mucteba Uysal.et.al “The effect of mineral admixtures on

mechanical properties, chloride ion permeability and

impermeability of self-compacting concrete”, Construction

and Building Materials 28; (2012); 321–326, Elsevier

[6] Prajapati Krishnapal, Chandak Rajeev “ Development and

Properties of Self Compacting Concrete Mixed with Fly

Ash”,ISSN 2278 – 9472; Vol. 1(3), 11-14, Sept. (2012).

[7] EFNARC (European Federation of National Trade

Associations Representing Producers and Applicators of

Specialist building Products), Specification and guide lines

for Self Compacting Concrete, 2002, Hampshire, U.K

Author Profile

Figure 3: Mix ID vs Flexural Strength

K.SurendraBabuholds a B. Tech degree

(CivilEngineering) JNTU A, Anantapur, India. He is

7. Conclusions currently Pursuing his PG degree in Structural

Engineering under the guidance of G. Nagesh Kumar

This paper had presented experimental results of an Andhra Pradesh, India. His present area ofresearch

investigation on feasible use of Fly ash as mineral admixture interest is in Material sciences.

and replacement of Crushed Quartzite as Fine aggregate in

SCC. Based on the results of this present study, the following G. Nagesh Kumar He has received hisM. Tech degree

Conclusions can be drawn (Structural Engineering) from JNTU, Anantapur, Andhra

Pradesh, India. He is currently pursuing his research

1) In preliminary stage, replacement of Fly Ash as Mineral

under the guidance of Dr. CH. Sudharani at SVU,

Admixture gives good results in Fresh Properties of Tirupati, Andhra Pradesh, India. Presently, he is working as Sr. Asst.

Concrete (i.e Satisfy the fresh Properties limits prescribed Prof in the CED of G. Pulla Reddy Engineering College

in EFNARC) (Autonomous) and has 28 years of experience in teaching. His

2) The Compressive strength, Split Tensile Strength and research interest includes Material Sciences.

Flexural Strength shows with the replacement of 30% Fly

ash as Mineral admixture gives the maximum strength

among 10%,20%30% and 40 % of Fly ash Mixtures.

3) While replacement of 10%,20%.30% & 40% Crushed

Quartzite as Fine Aggregate had Positive Effect on Fresh

Properties. 50% replacement of Crushed Quartzite had

Negative Effect on Fresh properties.

Volume 4 Issue 10, October 2015

www.ijsr.net

Paper ID: SUB158891 785

Licensed Under Creative Commons Attribution CC BY

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Effect of Dune Sand On The Properties of Flowing Sand-Concrete (FSC) PDFDocument6 pagesEffect of Dune Sand On The Properties of Flowing Sand-Concrete (FSC) PDFyoussefNo ratings yet

- Early Age Properties of Self-Compacting Concrete - Effects of Fine Aggregate and Limestone Filler - ThesisDocument206 pagesEarly Age Properties of Self-Compacting Concrete - Effects of Fine Aggregate and Limestone Filler - ThesisyoussefNo ratings yet

- Effect of Chemical and Mineral Admixtures OnDocument77 pagesEffect of Chemical and Mineral Admixtures OnAsif HameedNo ratings yet

- Effect of Coarse Aggregate Blending On Fresh Properties of Self Compacting Concrete PDFDocument11 pagesEffect of Coarse Aggregate Blending On Fresh Properties of Self Compacting Concrete PDFyoussefNo ratings yet

- Deviations in Standard Aggregate Gradation and Its Affects On TheDocument157 pagesDeviations in Standard Aggregate Gradation and Its Affects On TheyoussefNo ratings yet

- 1 s2.0 S0950061814002256 MainDocument9 pages1 s2.0 S0950061814002256 MainAboalmaail AlaminNo ratings yet

- Effect of Different Sand Grading On Strength Properties of Cement Grout PDFDocument8 pagesEffect of Different Sand Grading On Strength Properties of Cement Grout PDFyoussefNo ratings yet

- Effect of Fine Aggregate Replacement With Desert Dune Sand On Fresh Properties and Strength of Selfcompacting Mortars PDFDocument16 pagesEffect of Fine Aggregate Replacement With Desert Dune Sand On Fresh Properties and Strength of Selfcompacting Mortars PDFyoussefNo ratings yet

- ZX 212437440Document4 pagesZX 212437440AJER JOURNALNo ratings yet

- Effect of Coarse Aggregate Size on Properties of NCC and SCCDocument7 pagesEffect of Coarse Aggregate Size on Properties of NCC and SCCBala SubramanianNo ratings yet

- Correlating Aggregate Properties and Concrete Rheology To Dynamic Segregation of Self-Consolidating ConcreteDocument9 pagesCorrelating Aggregate Properties and Concrete Rheology To Dynamic Segregation of Self-Consolidating ConcreteyoussefNo ratings yet

- Effect of Coarse Aggregate Characteristics On Concrete Rheology PDFDocument9 pagesEffect of Coarse Aggregate Characteristics On Concrete Rheology PDFyoussefNo ratings yet

- Effect of Addition The Dune Sand Powder On Development of Compressive Strength and Hydration of Cement PastesDocument7 pagesEffect of Addition The Dune Sand Powder On Development of Compressive Strength and Hydration of Cement PastesyoussefNo ratings yet

- Effect of Aggregate Size Distribution On Concrete Compressive StrengthDocument5 pagesEffect of Aggregate Size Distribution On Concrete Compressive StrengthyoussefNo ratings yet

- Durability Study of Self-Compacting Concrete Using Manufactured SandDocument6 pagesDurability Study of Self-Compacting Concrete Using Manufactured SandyoussefNo ratings yet

- Construction and Building Materials: Tayeb BouzianiDocument7 pagesConstruction and Building Materials: Tayeb BouzianiyoussefNo ratings yet

- Durability Properties of Concrete With Natural Sand and Manufactured SandDocument5 pagesDurability Properties of Concrete With Natural Sand and Manufactured SandArun KumarNo ratings yet

- Durability Study of Self-Compacting Concrete Using Manufactured SandDocument6 pagesDurability Study of Self-Compacting Concrete Using Manufactured SandyoussefNo ratings yet

- Comparative Study On The Strength and Durability Properties of Concrete With Manufactured SandDocument7 pagesComparative Study On The Strength and Durability Properties of Concrete With Manufactured SandyoussefNo ratings yet

- A Study On Concrete Properties by Partial Replacement of Sand by Pond AshDocument13 pagesA Study On Concrete Properties by Partial Replacement of Sand by Pond Ashyoussef100% (1)

- Application of "The Water Layer Model" To Self-Compacting Mortar With Different Size Distributions of Fine AggregateDocument28 pagesApplication of "The Water Layer Model" To Self-Compacting Mortar With Different Size Distributions of Fine AggregateyoussefNo ratings yet

- 5.effect of Sand Content On The Properties of Self Consolidating High Performance Cementitious MortarDocument17 pages5.effect of Sand Content On The Properties of Self Consolidating High Performance Cementitious Mortaryoussef100% (1)

- Bentham Open Open Access Effects of Aggregate Grading and AdmixtureFiller On Self-Consolidating ConcreteDocument7 pagesBentham Open Open Access Effects of Aggregate Grading and AdmixtureFiller On Self-Consolidating ConcreteyoussefNo ratings yet

- Comparative Study of Self-Compacting Concrete With Manufactured and Dune SandDocument6 pagesComparative Study of Self-Compacting Concrete With Manufactured and Dune SandyoussefNo ratings yet

- Civil 31Document4 pagesCivil 31suranatanuj007No ratings yet

- 3.effect of Sand Ratio On The ElasticDocument6 pages3.effect of Sand Ratio On The ElasticyoussefNo ratings yet

- Combined Effect of Fineness Modulus and Grading Zones of Fine Aggregate On Fresh Properties and Compressive Strength of Self Compacted ConcreteDocument12 pagesCombined Effect of Fineness Modulus and Grading Zones of Fine Aggregate On Fresh Properties and Compressive Strength of Self Compacted ConcreteyoussefNo ratings yet

- 4.influence of Chemical Admixture Content Particle and Grade On Viscosity ofDocument10 pages4.influence of Chemical Admixture Content Particle and Grade On Viscosity ofyoussefNo ratings yet

- A Comparative Study of Concretes Containing Crushed Limostone Sand and Natural SandDocument6 pagesA Comparative Study of Concretes Containing Crushed Limostone Sand and Natural SandyoussefNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Background: The Duct Tape BookDocument5 pagesBackground: The Duct Tape BookCloudine IzonNo ratings yet

- Pengekstrakan besi dalam industriDocument5 pagesPengekstrakan besi dalam industriNajwa Ghazali100% (1)

- Gs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralDocument2 pagesGs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralmustafaNo ratings yet

- R 22Document22 pagesR 22Luis MartinezNo ratings yet

- Concrete Discharge Time (ASCC)Document1 pageConcrete Discharge Time (ASCC)V. ManilalNo ratings yet

- 03 20 00 - Concrete ReinforcingDocument6 pages03 20 00 - Concrete Reinforcingahmad ibrahinNo ratings yet

- Fluid FlowDocument88 pagesFluid FlowFren R.100% (2)

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Document1 pageMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (2)

- Outgoing Transmittal Log-20160422Document10 pagesOutgoing Transmittal Log-20160422Lopez GardoNo ratings yet

- Tensile Membrane Structures: Name of Project Page - of - July 9, 2013Document18 pagesTensile Membrane Structures: Name of Project Page - of - July 9, 2013jackNo ratings yet

- Heat Transfer Chapter 1 ProblemsDocument8 pagesHeat Transfer Chapter 1 ProblemsVon A. Damirez0% (1)

- Project - Bali Chambre Go: BTDC Nusa Dua - BaliDocument44 pagesProject - Bali Chambre Go: BTDC Nusa Dua - BaliYudi Ibo NlfNo ratings yet

- Table 7-3 UPC DFUDocument4 pagesTable 7-3 UPC DFUAhmed OsmanNo ratings yet

- How Plants Reduce Noise Levels Indoors - AmbiusDocument4 pagesHow Plants Reduce Noise Levels Indoors - AmbiusSakshi SahuNo ratings yet

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494No ratings yet

- How Does Contact With Aluminum Affect Concrete - Concrete Construction MagazineDocument1 pageHow Does Contact With Aluminum Affect Concrete - Concrete Construction MagazineHerdisNo ratings yet

- REX - Gland Packing (Mechanical Seal) - PTFE, Aramid, GFO, Gore, Graphite, Cotton, KelvarDocument6 pagesREX - Gland Packing (Mechanical Seal) - PTFE, Aramid, GFO, Gore, Graphite, Cotton, KelvarREX Sealing and Packing Industries Pvt. Ltd.No ratings yet

- EDI FlexAir Threaded Spec SheetDocument2 pagesEDI FlexAir Threaded Spec Sheetomega AlfaNo ratings yet

- Method Statement For AFS.15.04.19 R0 PDFDocument12 pagesMethod Statement For AFS.15.04.19 R0 PDFkrishna100% (1)

- Head loss calculation for Souq Waqif car parking projectDocument1 pageHead loss calculation for Souq Waqif car parking projectKarthy GanesanNo ratings yet

- Properties of Concrete by A M NevilleDocument2,866 pagesProperties of Concrete by A M NevilleAnthony Angeles83% (6)

- Vibrations in Steam TurbinesDocument11 pagesVibrations in Steam TurbinesAnudeep Chittluri100% (1)

- Capnut Terminations 1Document4 pagesCapnut Terminations 1ringleNo ratings yet

- Software Verification: ACI 318-14 Example 002Document4 pagesSoftware Verification: ACI 318-14 Example 002yudhi putraNo ratings yet

- Bearing Failure Inspection MethodsDocument41 pagesBearing Failure Inspection MethodsM.TayyabNo ratings yet

- Various Infill Patterns and Their Effect in 3D Printable MaterialsDocument5 pagesVarious Infill Patterns and Their Effect in 3D Printable MaterialsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Technical Manual - 2000 USG Horizontal Lined Acid TankDocument20 pagesTechnical Manual - 2000 USG Horizontal Lined Acid TankGade JyNo ratings yet

- Cementitious Underlayment (Maxxon Corp.)Document6 pagesCementitious Underlayment (Maxxon Corp.)Donald EssenNo ratings yet

- Sampson Challis Flange Insulation Kits MaterialsDocument2 pagesSampson Challis Flange Insulation Kits MaterialsCalvin WongNo ratings yet

- 74-014 Duplex-Superduplex Ss Pipe To Astm A790 2020Document13 pages74-014 Duplex-Superduplex Ss Pipe To Astm A790 2020kuttub28No ratings yet