Professional Documents

Culture Documents

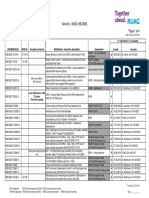

Hydraulic Cylinders

Uploaded by

mohamedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Cylinders

Uploaded by

mohamedCopyright:

Available Formats

DELHOUMI

N. ISLEM

Hydraulic Cylinders

A hydraulic cylinder converts the energy stored in the hydraulic

fluid into a force used to move the cylinder in a linear direction.

Operation Of A Hydraulic Cylinder:

The hydraulic pressure in these cylinders is in the form of hydraulic

fuels that are stored under pressure in these cylinders. The energy

stored in these oils is converted into motion. In a complete hydraulic

system, a hydraulic motor consists of one or more hydraulic cylinders.

A pump regulates the oil-flow in the hydraulic system. The pump is a

part of the generator of a hydraulic system. The hydraulic cylinders

initiate the pressure of the oil, which cannot be more than that

required by the load.

A hydraulic cylinder consists of a cylindrical barrel, piston, and a

piston rod. The piston that is placed within the barrel is connected to

the piston rod. The cylinder bottom, and the cylinder head, closes the

bottom and the head of the barrel respectively. The cylinder head is

the side from where the piston rod exits the cylinder.

The cylinder bottom and the piston rod

are mounted with mounting brackets or

clevises. The piston in the hydraulic

cylinder consists of sliding rings and

DELHOUMI

N. ISLEM

seals. The piston rod chamber and the bottom chamber are the two

chambers within the cylinder. The piston rod starts moving outwards,

as the hydraulic fluid is pumped into the bottom side of the hydraulic

cylinder. In the reverse process, the hydraulic fluid is pushed back into

the reservoir by the piston. The pressure in the cylinder is the ratio of

unit force per unit piston area.

The pressure generated in the piston rod chamber is the ratio of the

unit load per the difference in the unit piston area and unit piston rod

area. This calculation is used when the hydraulic fluid is let into the

piston rod chamber as well as the fluid flows smoothly (without

pressure) from the piston area to the reservoir. In this way, the

expansion and retraction (push and pull) action of the hydraulic

cylinder is generated.

Classification Of Hydraulic Cylinders According To Function:

Single Acting Cylinders:

In single acting cylinders the fluid is pressurized from only one side of

the cylinder during both the expansion as well as the retraction

process. A spring or an external load is used to return the cylinder top

to its original position i.e. when pressure of the fluid is cut off.

Double Acting Cylinders

In the double acting cylinders, the pressure from the fluid is applied

in both the directions. Single cylinders that consist of springs are not

used in large stroke applications because there are inherent

mechanical problems associated with the spring. The double acting

rods could be of two types:

• Single rod ended

• Double rod ended

DELHOUMI

N. ISLEM

You might also like

- 1nz FeDocument3 pages1nz FeBilal Khan100% (4)

- Bearings: IndexDocument9 pagesBearings: IndextanmayNo ratings yet

- Surface Finish and Surface Integrity (Compatibility Mode)Document23 pagesSurface Finish and Surface Integrity (Compatibility Mode)thakurkalidass100% (1)

- 330CL Cooling System - Check - OverheatingDocument4 pages330CL Cooling System - Check - OverheatingOscar VargasNo ratings yet

- Manual Focus Rs 2016Document61 pagesManual Focus Rs 2016Garikoitz FranciscoeneNo ratings yet

- Washing Machine: Case Study: Embedded SystemDocument16 pagesWashing Machine: Case Study: Embedded SystemPreetam KarmakarNo ratings yet

- Fundamentals of Bearings & Seals CourseDocument26 pagesFundamentals of Bearings & Seals CoursecarlHoughNo ratings yet

- Design of Mechanical Press PDFDocument8 pagesDesign of Mechanical Press PDFArsl RanaNo ratings yet

- Types of GearsDocument22 pagesTypes of GearsAnonymous 2RbW9dNo ratings yet

- Types of PumpDocument32 pagesTypes of Pumpkapun kumar nayakNo ratings yet

- 3.thread ManufacturingDocument29 pages3.thread ManufacturingVikrant Sharma100% (1)

- Hydraulic CylindersDocument7 pagesHydraulic Cylinderspacopil34No ratings yet

- Economy: Calculation Using Specific Fuel ConsumptionDocument5 pagesEconomy: Calculation Using Specific Fuel ConsumptionOakkarNo ratings yet

- Press Parts and TypesDocument10 pagesPress Parts and TypesAmar BhupaliNo ratings yet

- General Introduction of Hydraulic PressDocument2 pagesGeneral Introduction of Hydraulic PressKabil RajNo ratings yet

- M8S5 Manual TransmissionDocument47 pagesM8S5 Manual TransmissionHai VanNo ratings yet

- Power Press Tools and MachinesDocument60 pagesPower Press Tools and MachinesThulasi RamNo ratings yet

- 02 Training Program Gear 2013Document56 pages02 Training Program Gear 2013amrit002No ratings yet

- Me 2401 Mechatronics 1-5 Important QuestionsDocument4 pagesMe 2401 Mechatronics 1-5 Important QuestionsvasanthavananNo ratings yet

- ClutchesDocument17 pagesClutchesRanjit RajendranNo ratings yet

- SteelDocument28 pagesSteelAshfaq SaudagarNo ratings yet

- 10 Mpa Single Acting Uniform Speed Rod Action 2-Stage Telescopic CylindersDocument10 pages10 Mpa Single Acting Uniform Speed Rod Action 2-Stage Telescopic CylindersĐen BáoNo ratings yet

- Advanced Hydraulics Guide to Pumps and ComponentsDocument17 pagesAdvanced Hydraulics Guide to Pumps and ComponentsYeahkevinrocksNo ratings yet

- Mechanical Engineering Dept Lubrication System GuideDocument21 pagesMechanical Engineering Dept Lubrication System GuidedhavalNo ratings yet

- Magnetic Plug InspectDocument1 pageMagnetic Plug InspectAbner VillanuevaNo ratings yet

- Bearing PreloadDocument3 pagesBearing PreloadASHOKNo ratings yet

- Push - Rod Suspension System Used in F-1Document23 pagesPush - Rod Suspension System Used in F-1Ashish RawatNo ratings yet

- Railway Bearings 8501-Ii PDFDocument78 pagesRailway Bearings 8501-Ii PDFCarlo AguiluzNo ratings yet

- Manufacturing Technology Lab Manual Safety RulesDocument34 pagesManufacturing Technology Lab Manual Safety RulesSamuelPannierselvamShirleyNo ratings yet

- Hose & FittingDocument124 pagesHose & FittingYoga Sugi100% (1)

- Kinematics of Shaper MachineDocument30 pagesKinematics of Shaper Machinemanas mohanty100% (1)

- Self Learning Handbook SupportDocument262 pagesSelf Learning Handbook SupportRicky Pradana100% (1)

- PM Clinic D475aDocument27 pagesPM Clinic D475aHarry Wart WartNo ratings yet

- Vehicle Tribology GuideDocument29 pagesVehicle Tribology Guidejamesv52_743942786100% (1)

- 06.major Variables in Ultrasonic Inspection PDFDocument7 pages06.major Variables in Ultrasonic Inspection PDFbalajiNo ratings yet

- Condition Based Maintenance (CBM)Document2 pagesCondition Based Maintenance (CBM)BassemNo ratings yet

- 320C Vs Deere200EnglishDocument52 pages320C Vs Deere200EnglishFernando Omar ArenaNo ratings yet

- Bearing ArrangementDocument5 pagesBearing ArrangementSubbarayan SaravanakumarNo ratings yet

- Pneumatic Systems Control Engineering OverviewDocument15 pagesPneumatic Systems Control Engineering OverviewAadityaNo ratings yet

- MMAM (21ME54), Assignment-2., 2023-24Document1 pageMMAM (21ME54), Assignment-2., 2023-24pranamnathanielrajNo ratings yet

- Bearings: - What Is BearingDocument22 pagesBearings: - What Is BearingRizwan Bangash50% (2)

- Oil Pump Testing Equipment 7000Document5 pagesOil Pump Testing Equipment 7000Sakthi Sakthi VelNo ratings yet

- Everything You Need to Know About Lathe Machine ToolsDocument22 pagesEverything You Need to Know About Lathe Machine ToolsRaghavMaheshwariNo ratings yet

- Slitter Plant: Prepared By: Vedant SankheDocument20 pagesSlitter Plant: Prepared By: Vedant SankheVedant SankheNo ratings yet

- Elementary Transmission For Transforming Rotary Into Translatory MotionDocument14 pagesElementary Transmission For Transforming Rotary Into Translatory Motionshreyas jadhavNo ratings yet

- sbg2470Document41 pagessbg2470mustafa özkanNo ratings yet

- E328sea Industrial ToolsDocument296 pagesE328sea Industrial ToolsLukas EzequielNo ratings yet

- Basic Rolling Bearing TechnologyDocument75 pagesBasic Rolling Bearing TechnologyRobert Reyes100% (1)

- ME 330 Manufacturing Processes Mechanical Assembly: Joining Methods (Cont.)Document23 pagesME 330 Manufacturing Processes Mechanical Assembly: Joining Methods (Cont.)mhafizanNo ratings yet

- Shot Blasting Is A Rapid, Environment Friendly, CostDocument10 pagesShot Blasting Is A Rapid, Environment Friendly, CostSulfikar SalimNo ratings yet

- How Bearings Work and Their TypesDocument6 pagesHow Bearings Work and Their TypesabhivpcoeNo ratings yet

- Design and Calculation of Planetary Transmission WDocument8 pagesDesign and Calculation of Planetary Transmission Wkarnail singh dhimanNo ratings yet

- Calculation of Hydraulic Cylinder Design - HänchenDocument1 pageCalculation of Hydraulic Cylinder Design - Hänchenkumardas dasNo ratings yet

- Basic Hydraulic ComponentsDocument15 pagesBasic Hydraulic ComponentsmnowaqNo ratings yet

- 5) Bearing Fundamentals PDFDocument123 pages5) Bearing Fundamentals PDFRizal Gunawan100% (1)

- Automobile - Full Notes - 6TH PDFDocument179 pagesAutomobile - Full Notes - 6TH PDFShailesh RajuNo ratings yet

- Hydraulic Fluid Functions & ComponentsDocument33 pagesHydraulic Fluid Functions & ComponentsIbnu Awalla100% (1)

- 301 Basic Mechanics Course DescriptionDocument2 pages301 Basic Mechanics Course DescriptionAnonymous q9eCZHMuSNo ratings yet

- HYDRAULIC Presntation 1Document27 pagesHYDRAULIC Presntation 1Takudzwa MatangiraNo ratings yet

- Hydraulic Pump: Made By: Arsheen and Shweta DEPARTMENT: F.P.TECH (2019-23) Submitted To: Ms. RuchitaDocument11 pagesHydraulic Pump: Made By: Arsheen and Shweta DEPARTMENT: F.P.TECH (2019-23) Submitted To: Ms. RuchitaDis ShwetaNo ratings yet

- Linear ActuatorsDocument4 pagesLinear ActuatorsAndres Felipe Ospino CatañoNo ratings yet

- Basic Hydraulic Circuits - AnalysisDocument49 pagesBasic Hydraulic Circuits - AnalysisMohamed ZahranNo ratings yet

- P 1300 Toyota Automatic TransmissionDocument6 pagesP 1300 Toyota Automatic TransmissionSuksan Sananmuang100% (1)

- ACEA Oil Sequences Light Duty Engines Rev1 2022Document10 pagesACEA Oil Sequences Light Duty Engines Rev1 2022AfdhalNo ratings yet

- Perubahan Harga Nov 2017Document4 pagesPerubahan Harga Nov 2017m26404093No ratings yet

- Kohler Study GuideDocument443 pagesKohler Study GuideJohn Gee100% (2)

- The Diagnostic Process VVDocument29 pagesThe Diagnostic Process VVahmad razaNo ratings yet

- Quotation: Pt. Norgantara Surya PerkasaDocument1 pageQuotation: Pt. Norgantara Surya PerkasabagasNo ratings yet

- Parts Docs D65 px17Document838 pagesParts Docs D65 px17alexandr75% (4)

- Balance Shaft RemovalDocument6 pagesBalance Shaft RemovalMartinho RangelNo ratings yet

- enDocument2 pagesenSören Christopher LaxNo ratings yet

- Compressors and Gensets: An OverviewDocument38 pagesCompressors and Gensets: An OverviewShanza AsifNo ratings yet

- PIM130B1 - Turbomeca Makila TI Archived NOV PDFDocument5 pagesPIM130B1 - Turbomeca Makila TI Archived NOV PDFValBMSNo ratings yet

- 1HD, KZ Timing Belt Lc42tdDocument4 pages1HD, KZ Timing Belt Lc42tdavm53No ratings yet

- EngineModification Status HB-ZMB PDFDocument4 pagesEngineModification Status HB-ZMB PDFJuan de Dios Chivalan RojasNo ratings yet

- Lister Alpha LPW Spec Sheet IndustrialDocument4 pagesLister Alpha LPW Spec Sheet IndustrialMartyn PitmanNo ratings yet

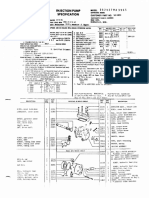

- Injection Pump Specification SheetDocument2 pagesInjection Pump Specification Sheetjohnny sabinNo ratings yet

- c15 Parts Manual Vol IIDocument731 pagesc15 Parts Manual Vol IIBernardo Leor75% (4)

- 17ME655-Module 4 PDFDocument40 pages17ME655-Module 4 PDFVinayakNo ratings yet

- 3054470316F1Document55 pages3054470316F1เสกสรรค์ จันทร์สุขปลูกNo ratings yet

- ATV 250 ManualDocument223 pagesATV 250 ManualDavid PootNo ratings yet

- Taurus 60: Gas Turbine Compressor SetDocument2 pagesTaurus 60: Gas Turbine Compressor SetIsabel PaixaoNo ratings yet

- Spare Parts Catalogue: 180 UG4 180 UG4Document76 pagesSpare Parts Catalogue: 180 UG4 180 UG4Walter Adin100% (1)

- PC - Print - 9-34-28 AmDocument3 pagesPC - Print - 9-34-28 AmandraNo ratings yet

- October 2023 INCALDVD CoverLetterDocument4 pagesOctober 2023 INCALDVD CoverLetterJoséNo ratings yet

- Mobilgard 570Document1 pageMobilgard 570Anonymous F2TxS3YoaNo ratings yet

- This Study Resource Was: Engineering:: Turbo MachinesDocument3 pagesThis Study Resource Was: Engineering:: Turbo MachinesrishitNo ratings yet

- Air Compressor XAS 186 CDocument2 pagesAir Compressor XAS 186 CAsad AijazNo ratings yet

- H5204 To H5213 Air-Cooled BrochureDocument2 pagesH5204 To H5213 Air-Cooled Brochurescrollock0428No ratings yet