Professional Documents

Culture Documents

Stop Cards Excel Sheet 30th March Status (TCPDC 4001) (Korai 2)

Uploaded by

Yaqoob IbrahimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stop Cards Excel Sheet 30th March Status (TCPDC 4001) (Korai 2)

Uploaded by

Yaqoob IbrahimCopyright:

Available Formats

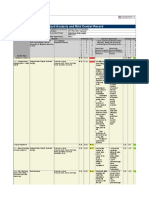

Rig: TCPDC-4001

S.No Observer Position Company

1 Tariq shiekh HOD Drilling UEPL

2 Tariq shiekh HOD Drilling UEPL

3 Tariq shiekh HOD Drilling UEPL

4 Tariq shiekh HOD Drilling UEPL

5 Tariq shiekh HOD Drilling UEPL

6 Tariq shiekh HOD Drilling UEPL

7 Tariq shiekh HOD Drilling UEPL

8 Tariq shiekh HOD Drilling UEPL

9 Tariq shiekh HOD Drilling UEPL

10 Tariq shiekh HOD Drilling UEPL

11 Tariq shiekh HOD Drilling UEPL

12 Tariq shiekh HOD Drilling UEPL

13 Tariq shiekh HOD Drilling UEPL

14 Tariq shiekh HOD Drilling UEPL

15 Tariq shiekh HOD Drilling UEPL

16 Tariq shiekh HOD Drilling UEPL

17 Tariq shiekh HOD Drilling UEPL

18 Tariq shiekh HOD Drilling UEPL

19 Tariq shiekh HOD Drilling UEPL

20 Tariq shiekh HOD Drilling UEPL

21 Tariq shiekh HOD Drilling UEPL

22 Tariq shiekh HOD Drilling UEPL

23 Tariq shiekh HOD Drilling UEPL

24 Tariq shiekh HOD Drilling UEPL

25 Tariq shiekh HOD Drilling UEPL

26 Tariq shiekh HOD Drilling UEPL

27 Tariq shiekh HOD Drilling UEPL

28 Tariq shiekh HOD Drilling UEPL

29 Tariq shiekh HOD Drilling UEPL

30 Tariq shiekh HOD Drilling UEPL

31 Tariq shiekh HOD Drilling UEPL

32 Tariq shiekh HOD Drilling UEPL

33 Tariq shiekh HOD Drilling UEPL

34 Tariq shiekh HOD Drilling UEPL

35 Tariq shiekh HOD Drilling UEPL

36 Tariq shiekh HOD Drilling UEPL

37 Tariq shiekh HOD Drilling UEPL

38 Tariq shiekh HOD Drilling UEPL

39 Tariq shiekh HOD Drilling UEPL

40 Tariq shiekh HOD Drilling UEPL

41 Tariq shiekh HOD Drilling UEPL

42 Tariq shiekh HOD Drilling UEPL

43 Tariq shiekh HOD Drilling UEPL

44 Tariq shiekh HOD Drilling UEPL

45 Tariq shiekh HOD Drilling UEPL

46 Tariq shiekh HOD Drilling UEPL

47 Tariq shiekh HOD Drilling UEPL

48 Tariq shiekh HOD Drilling UEPL

49 Tariq shiekh HOD Drilling UEPL

50 Tariq shiekh HOD Drilling UEPL

Month: 30th March 2017

Description

sling piece found near heavy weights on location

fork lift operator was not wearing seat belt

Fork lift operator was not wearing proper PPE

flexible pipes were picked up without latching sides

improper housekeeping observed near welding workshop

BHA was loaded on trailor and the supports were not sufficient

flare line anchors were not available not standard practice

sling piece was found near flare line

sling piece was found near basket

sing piece was found near baskets

sling piece was found near basket

Junk basket need to be sent to gharo yard or mazari yard

Bell Nipple was not placed in the basket laying on ground

Door of basket was lying on ground to be welded with basket

sling piece was found near basket

Rejected sling was found near basket area

improper houskeeping near basket bottles and gloves found

There is no life saving tube for the water pits

barrication strip to be used instead of Tape as due to air tape removes

chemicals at hi long area not covered

sub mersible pump lying on ground near de watering unit

Trunk of de watering crew not proper without handle and supports

pallet was placed on top of carvan for internet connerction unsafe

safety shoes were placed out side of office carvan de watering

shortage of safety signs observed diesel tank, chemical area

improper color coding de watering unit

chemicals were not covered at storage area

MSDS of chemicals was not pasted

Identification of chemcals not available at storage

chinese version sign boards not found at any place

improper house keeping at chemical mixing area

waste management procedure not followed

slip hazards due to water spillage at mixing area of chemicals

spillage of oil near oil basket and fence

found used oil in open bucket chances of spill

No signs found at storage area of oil and basket

used filters were stored at cement bund of diesel tank storage

improper housekeeping at diesel tanks

water cooler placed on ground near mechanic workshop

bolts and nuts were found on floor to be stored properly

leakage found near Mess Rig site

Junk basket of the mud Engineer need to be picked up from mini

camp

stair for the mud Engineer carvan not proper to be made

improper housekeeping found as gloves

pallet wood was found near mosque with nails

improper housekeeping found at mini camp

Rig mess water cooler out of order need to be removed if not used

shortage of safety signs at rig mess

improper housekeeping and cleaning at mess

back up sling for the guy lines to be installed at anchors

Action Taken

picked up and placed at proper place

stopped at spot and also safety violation notice given

stopped at spot and also safety violation notice given

discussed with the personel at time of picking up

picked up and placed at proper place

discussed with the driver replaced at time

not available to be made

picked up and placed at proper place

picked up and placed at proper place

picked up and placed at proper place

picked up and placed at proper place

will discuss with rig management to make action plan

picked up and placed in basket

welding will be carried out tommorow

picked up and placed properly

cutted down and placed in junk basket

area was cleaned by the persons

already demanded from head office yet not received

will discuss with rig management to make action plan

covered by the hi long team

picked up by them and placed at proper place

handle would be made by welder and support rod will be fixed

picked from roof top and placed a side

fixed all available sign boards

covered by the labor

MSDS not available to be provided by Mud Engineer

to be provided by the head office discussed with HSE M

discussed in meeting training required

spillage was cleaned out

spillage was cleaned out

removed and put back in drum

signs were pasted

put back in junk basket

cleaned out the area

picked and placed at proper place

picked all of them and placed in box by mechanic

leakage was fixed and dry sand placed over slippery area

discussed with the mud Engineer to plan

new stairs to be made by welder discussed with management

detail housekeeping carried out

picked and trashed

cleaned out the mini camp

water cooler is out of order discussed with management to send to

gharo yard

signs were pasted

deep cleaning carried out

sling was fixed

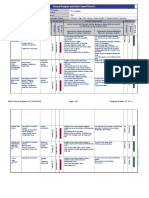

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

Rig: TCPDC-4001 Month:March 2017

S.No Observer Position Company Description Category

1 Adeel welder TCPDC Observed Forklift Operator was driving too fast, Driving Safety

Observed Safety Signs on Rig Floor were Tide with Wire Rope which

Asad Improper

2 Ashfaq

HSEO TCPDC was unsafe, so I removed the safety signs and Put them on Panel Procedure

with Nuts and Bolts and installed them back at Rig Floor Hand Rails

Observed one crew member Cleaning DP Thread without Using

3 Muzaffar A.D TCPDC PPE Violation

Gloves , stopped him and discussed the hazard with him,

Asad

Ashfaq

HSEO TCPDC Observed that Floor of Rig Mess was Broken welfare

Asad

Ashfaq

HSEO TCPDC UEPL Store have flame cut lifting eyes which are deshaped Lifting Operation

Power Cable beside Caravan was a tripping hazard, Discussed the

4 Atif A.D TCPDC Slip & Trip

Hazard with Electrition to Bury it Underground,

Observed Crew Member Doing Maintenance on Shale Shaker,

6 Muzaffar A.D TCPDC Discussed the Hazard of Rust and Dust with him and Advised him to PPE Violation

wear Mask.

Observed Crew Member crossing near High Pressure Line, Stopped Improper

7 Mobeen R.A TCPDC

Procedure

him and discussed the Hazard with Crew member

Crew Members on Rig Floor were Maintaining the Power tong in free

8 Muzaffar A.D TCPDC Apprication

time which is a good practice

Observed one crew member was crossing below lifted load by Wheel Dropping/Falling

9 Muzaffar A.D TCPDC

Object

Loader, Stopped him and discussed the hazard with him.

Asad Pallets in front of Radio Room was posing Tripping Hazard, informed

10 Ashfaq

HSEO TCPDC Slip & Trip

the hazard with labors to arrange proper platform.

Asad Observed a person handling garbage without wearing Gloves,

11 Ashfaq

HSEO TCPDC PPE Violation

stopped himi and discussed the hazard with him.

Asad while inspecting Fire Hose, Observed one Fire Hose was leaking,

12 Ashfaq

HSEO TCPDC Fire Safety

changed the Leaking Fire Hose,

Observed During Camp Food and Hygiene Inspection that House

Asad

13 Ashfaq

HSEO TCPDC Keeping of Vegetable store was unsatisfactory Discussed the hazard Health & Hygiene

with the Camp Boss and Arranged the Deep Cleaning.

Asad Observed one person smoking near living caravans stopped him and

14 Ashfaq

HSEO TCPDC Fire Safety

discussed the hazard with him.

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

Lanyard with Crown Block Fall Arrester was in too much dirty and in

Asad Dropping/Falling

15 Ashfaq

HSEO TCPDC bad shape, arranged the new lanyard and discussed with crew Object

regular cleaning of safety equipment.

Asad

16 Ashfaq

HSEO TCPDC main camp fire pumo is not working properly Fire Safety

Asad

17 HSEO TCPDC fork lift radiator is leak need repairing may cause serious damage Driving Safety

Ashfaq

Asad Found one Service Company crew member working without Safety

18 Ashfaq

HSEO TCPDC PPE Violation

Glasses , stopped him and discussed the hazard

Asad observed one person was going upstairs without three point contact, Improper

19 Ashfaq

HSEO TCPDC

Procedure

discussed the hazard with him,

Asad while doing work at Rig Floor Floor Mans were wearing all PPE;s

20 Ashfaq

HSEO TCPDC Apprication

which is a good practice.

Asad Grinding Machine in Welding Machine had not the Plexi Glass

21 Ashfaq

HSEO TCPDC Electrical Safety

Protector Installed which have been procured and is being installed.

Asad Auger Emergency Switches were not installed which have been

22 Ashfaq

HSEO TCPDC Electrical Safety

procured by Hilong now and being installed.

there was one lifting belt being used which had cuts in it, observed

Asad the hazard and stopped the crew members from using it and

23 Ashfaq

HSEO TCPDC Lifting Operation

arranged a new lifting belt for them, discussed the hazard of using

worn out Lifting Belts with crew.

Asad Observed one Person without wearing Covered shoes in Main camp,

24 Ashfaq

HSEO TCPDC PPE Violation

Stopped him and discussed the hazard and Snake Bite Prevention

Asad Observed that Logging unit was properly baricaded which is a good

25 Ashfaq

HSEO TCPDC Apprication

practice.

Asad

26 Ashfaq

HSEO TCPDC 3 Ton Air Winch line damaged and should be changed Lifting Operation

Asad observed that there is no proper barication around the pits, Discussed Improper

27 Ashfaq

HSEO TCPDC

Procedure

the Hazard with the UEP Labor

Asad Observed that Barication around Logging unit was improper, arranged Improper

28 Ashfaq

HSEO TCPDC

Procedure

proper barication around logging unit

Asad observed a crew member working near katwalk without Safety

29 Ashfaq

HSEO TCPDC PPE Violation

Glasses stopped him and discussed the hazard

Asad observed a dog inside the fence informed the security to escort the Improper

30 Ashfaq

HSEO TCPDC

dog out of location. Procedure

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

cementing operation was being carried out and High Pressure lines

Asad

31 Ashfaq

HSEO TCPDC were baricaded and all the crew were wearing all the PPE's which is a Apprication

good practice

Observed One Crew Member standing on BOP and Cleaning it

Asad Dropping/Falling

32 Ashfaq

HSEO TCPDC without using fall protection which could have resulted in fall incident, Object

stopped him and discussed the hazard

Asad Desander and Desilter on Mud tanks were rig down and that area

33 HSEO TCPDC Apprication

Ashfaq was baricaded

Asad Observed one person working near cementing unit without wearing

34 Ashfaq

HSEO TCPDC PPE Violation

mask, discussed the hazards with him,

Asad Observed one person was using wire brush without wearing Mask,

35 Ashfaq

HSEO TCPDC PPE Violation

stopped him and discussed the hazard with him

Asad Observed that rig floor is slippery Discussed with Floor Man to Keep

36 Ashfaq

HSEO TCPDC Slip & Trip

Rig Floor Clean to prevent slip injuries.

Asad Rig Floor Rack Back Area rubber was damaged and needs to be

37 Ashfaq

HSEO TCPDC Slip & Trip

replaced

observed a crew member performing lifting operation using old worn

Asad

38 Ashfaq

HSEO TCPDC out lifting belts which stopped the operation and Discussed the Lifting Operation

hazard and Discard the Old Lifting Belt

Observed poor House Keeping Causing Slip Hazard at Rig Floor

Asad

39 Ashfaq

HSEO TCPDC Discussed with Rig Crew and Arranged to clean Rig Floor Prior Health & Hygiene

Starting new operation

drill pipe was being layed down and Roustabout was on Kat walk.

Asad Dropping/Falling

40 Ashfaq

HSEO TCPDC Stopped him and discussed the hazard of standing below the lifted Object

load with him,

Asad Observed one person passing under lifted load stopped him and Improper

41 Ashfaq

HSEO TCPDC

Procedure

discussed the hazard with him

during rig up operation observed one person doing manual handling

Asad

42 Ashfaq

HSEO TCPDC lifting heavy load, stopped him and discussed the hazard of Manual Lifting Operation

Handling

observed Fork Lift Operator was driving fast inside Rig Area , stopped

Asad

43 Ashfaq

HSEO TCPDC him and discussed the hazard with him and informed him of Inside Driving Safety

location speed limit.

Asad observed one senior crew member working without glasses stopped

44 Ashfaq

HSEO TCPDC PPE Violation

him and discussed the hazard and importance of PPE's

observed lifting operation was being carried out using improper lifting

Asad

45 Ashfaq

HSEO TCPDC technique, stopped them and discussed the hazards associated with Lifting Operation

the lifting operations

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

Asad Lifting Operation was being carried out using Tag Lines and Signal

46 Ashfaq

HSEO TCPDC Lifting Operation

Man wearing reflective vest appreciated the crew on their safe act.

Asad Observed that one crew member was working with grinding brush

47 Ashfaq

HSEO TCPDC PPE Violation

without using the Mask, Stopped him and discussed the hazard.

Asad Safety Harness was found dirty and full of tar, arranged proper

48 Ashfaq

HSEO TCPDC PPE Violation

cleaning of the safety harness

Asad at Main Camp some areas were dark, informed the Electrition to

49 Ashfaq

HSEO TCPDC welfare

install more lights to better the illuminance

observed tripping hazard due to improper placement of tools ,

Asad

50 Ashfaq

HSEO TCPDC discussed with crew about the proper arrangement of the tools to Slip & Trip

avoid trip hazard

Asad found personale in sleepers sent him to change immediately his

51 Ashfaq

HSEO TCPDC PPE Violation

shoes

Observed that Safety Chain on High Pressure line was missing,

Asad Improper

52 Ashfaq

HSEO TCPDC Informed the crew member about the hazard and arranged Procedure

installation of Safety Chain

Observed Cellar Cover was not available and cree member was

Asad Dropping/Falling

53 Ashfaq

HSEO TCPDC working on it, Stopped the operation and Arranged the Cellar Cover Object

Placed on it.

Asad Observed Rig Floor Eye washer was found dirty arranged cleaning of

54 Ashfaq

HSEO TCPDC Health & Hygiene

the Eye Washer and filled with Mineral Water

Asad Observed poor housekeeping in mud lab informed the crew member

55 Ashfaq

HSEO TCPDC Health & Hygiene

to arrange good house keeping

UEPL Basket Supports are broken and can cause an accident during

56 Atif CO TCPDC Lifting Operation

rig move

observed that the trip tank switch should be on the trip tank and not in Improper

57 Atif CO TCPDC

Procedure

the driller console

observed near water pit no have tube or tagline in case somebody Improper

58 Atif CO TCPDC

Procedure

falls into the pit

Improper

59 Atif Co TCPDC observed that pit area was not baricaded properly which is unsafe Procedure

observed some service company people don’t use proper PPE during

60 Atif Co TCPDC PPE Violation

work

Substructure support beams Safety Pins were missing so arranged

61 yasir FO TCPDC Lifting Operation

safety pins and installed

62 yasir FO TCPDC

Rig Floor Kat Heads Safety Pins were missing I put the safety pins Lifting Operation

Pull Line of Make out and break Out tong was damaged and should

63 yasir FO TCPDC

be changed Lifting Operation

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

64 yasir FO TCPDC Fly catcher in Rig Mess is out of order and should be replaced welfare

Asad

65 HSEO TCPDC

Ashfaq Main Camp Junior Mess Floor is broken and can cause injury welfare

66 pervaiz Mechanic TCPDC there should be gap between SCR for ventilation and cooling Electrical Safety

67 zahid HSEO TCPDC insect catcher of junior mess was out of order fixed it back Health & Hygiene

camp layout disturbes as there is no numbering put number on Improper

68 Zahid HSEO TCPDC

Procedure

carvans

Improper

69 Zahid HSEO TCPDC water in eyewash station was low put water inside and refilled Procedure

Improper

70 Zahid HSEO TCPDC main camp lighting was not good instructed the electricain to provide Procedure

Improper

71 Awais translator TCPDC the stand under flow line not placed to be fixed as earliest Procedure

shortage of water can cause heat stress to any body should be

72 Zahid HSEO TCPDC Health & Hygiene

provided all the time enough stock

73 Zahid HSEO TCPDC overspeeding by fork lift operator stopped and explained the limit Driving Safety

74 zahid HSEO TCPDC lines are not burried under ground at camp site Electrical Safety

75 zahid HSEO TCPDC water leakage observed at general washroom informed fitter to fix welfare

Improper

76 zahid HSEO TCPDC T card system not followed properly Procedure

78 Zahid HSEO TCPDC over seating limit was observed stopped the driver and person Driving Safety

79 zahid HSEO TCPDC recreation room TV is out of order need to be repaired welfare

Dropping/Falling

80 Zahid HSEO TCPDC observed one person throwing protector from rig floor Object

81 Raza WSE UEPL there was a hole near mosque informed HSE which was closed Health & Hygiene

82 Zahid HSEO TCPDC ice machine out of order need to repaired or replaced welfare

improper technique was used by roustabout guided him proper way

83 Zahid HSEO TCPDC manual handling

for manual handling step wise

Improper

84 Zahid HSEO TCPDC Muster Point B access is not clear mosque and water tank in front Procedure

General

85 Zahid HSEO TCPDC improper housekeeping observed chemical mixing area and rig fl0or Housekeeping

spillage of cement and mud near mud tanks and cellar area can

86 Zahid HSEO TCPDC Spillage

cause slip and trip to avoid slipery surface pallets to be placed

87 Zahid HSEO TCPDC improper and no timely maintainence is leading to equipment losses Equipment Loss

88 Zahid HSEO TCPDC starting switch of forklifter is not working sent for repairing Equipment Loss

90

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

CATEGORY

18 Dropping/Falling

Object

PPE Violation

16 Dropping/Falling Object Slip & Trip

PPE Violation Manual Handling

14 Slip & Trip Fire Safety

Manual Handling Electrical Safety

12 Fire Safety General

Electrical Safety Housekeeping

General Housekeeping Improper

10

Improper Procedure Procedure

Driving Safety Driving Safety

8 Spillage

Spillage

Health & Hygiene

6 Welfare Health & Hygiene

Equipment Loss Welfare

4 Lifting Operation Equipment Loss

Apprication Lifting Operation

2 Other Apprication

Other

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

Prepared and Updated By: Asad Ashfaq

Suggestion Target Date Status Action Taken

closed

arranged the installation of panel CLOSED

closed

To be Repaired Closed

should be replaced with a machine cut

open

lifting eyes and MPI'ed

CLOSED

CLOSED

are should be kept barricaded closed

CLOSED

CLOSED

CLOSED

CLOSED

fire hoses should be kept clean and

CLOSED

leaked fire hoses should be replaced

weekly deep cleaning schedule should

CLOSED

be stricly followed

CLOSED

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

CLOSED

Should be Repaired and Maintained cllosed

Radiater should be changed as

OPEN

soon as possible

CLOSED

CLOSED

CLOSED

CLOSED

CLOSED

Lifting belts should be inspected prior

CLOSED

lifting oeprations

CLOSED

CLOSED

Winch line should be changed with the

new one and should be regulalry CLOSED

inspected to see any damage

CLOSED

CLOSED

CLOSED

closed

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

closed

work at height should be subject to

closed

100%fall protection

closed

close

close

close

New Rubber should be procured close

closed

close

close

close

close

installed speed limit warning sign close

close

close

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

close

close

close

close

tool boxes should only be used to

close

store the tools and equipment

close

Work should not be started unless

make sure that all high pressure close

lines are secure

Cellar should always be kept

close

covered

closed

close

close

close

Tube and Tag Line shouldbe provided open

close

closed

closed

closed

closed

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

closed

Floor should be repaired Open

open

closed

closed

closed

closed

open

OPEN

closed

open

closed

open

open

open

closed

closed

OPEN

closed

open

closed

open

open

closed

Consultation and Communication Management Procedures Version No.: 1.2

TCPDC-04-02 STOP CARDS SHEET ANDTREND ANALYSIS

NUMBERS

6

13

5

1

3

4

1

17

5

1

7

7

2

11

5

0

0

0

Consultation and Communication Management Procedures Version No.: 1.2

S.No DATE Observer Position Company Description Category

I OBSERVED A PERSON DURING DRUM SHIFTING HE STAND

MAZHER STORE Improper

1 ### IQBAL

TCPDC BETWEEN TWO DRUMS I STOP HIM AND ASKED HIM DO NOT

KEEPER Procedure

STAND BETWEEN TWO OBJECT AND HE AGRRED.

Observed that escape slide donot have any sand at the base its

Improper

2 ### ASIF F/M TCPDC dangrous to slide without sand at landing area.i told fork operator to Procedure

put some sand at the base.

I See that wash gun plastic cover to protect from water is

damaged , and person cleaning with wash gun is working right

MUBASHIR above wash gun and cleaning water is droping on wash gun Electrical

3 ### AMIN

ELECTRICAN TCPDC

Safety

electric system where plastic cover is damaged, I find new plastic

cover and fix it on wash gun to protect it from water, this could had

done electricuation.

I SEE THAT Mud pump no 1 SPM senser is on the ground, some

body open the sensor and forget to fix it back where it was,its not

MUBASHIR safe if driller starts pump then there is no way to check spm of mud Electrical

4 ### AMIN

ELECTRICAN TCPDC

Safety

pump.Any time repair mud pump must take care about sensor than

call electrican. he will remove and fix the sensor.after this i fix that

sensor which was at ground.

On rig floor to mast rising line was hitting electrical cables it can

FARAZ damage cables very badly and can be happened a accident keep it Equipment

5 ### HASSAN

F/M TCPDC

Loss

tight with rope with sirde must beem now it is safe and no risk of

damage.

I Check at the mud pump no 1,2,3 the OGDCL sensor cable Joint

Conection in open condition no Electric tape,its dangrous because

now we in production zone any time gas can come at mud tank and Electrical

25 ### Imran ELECTRICAN TCPDC

Safety

mud pump area so if wires are short they can creat a spark , and

cause a fire incident.i properly secure the joint and put electric tape

on joint.

Target

Suggestion

Date

SHOULD STAND A SIDE

DURING LIFTING ###

OPERATION

PUTT SAND AT THE

BASE OF SLIDE SO NO

###

BODY HIRT IN

EMERGINCY SITUATION

should not put wash gun

down side while cleaning

up side put that a side ###

where cleaning water

cannot reach

After Repair Mud Pump ,

Tell Electrican to fix the ###

SPM Sensor

SHOULD BE TIED WITH

THE MAST BEEM , THE ###

RISING LINE

SHOULD BE PROPERLY

###

INSOLATED

You might also like

- Inspection Checklist Drill Rig PDFDocument2 pagesInspection Checklist Drill Rig PDFAbdo Ojaimy100% (2)

- Fire Extinguisher ChecklistDocument1 pageFire Extinguisher ChecklistSafety Man ShopNo ratings yet

- HSE-026.Pre-entry Hydra CraneDocument2 pagesHSE-026.Pre-entry Hydra CraneMithlesh Singh80% (5)

- Daily Drilling Stop Card AnalysisDocument6 pagesDaily Drilling Stop Card Analysisislam atif100% (4)

- JSA Table C - Job SheetsDocument80 pagesJSA Table C - Job SheetsMohamad Mazoon100% (3)

- Concrete Pipe Installation Guide-CPMDocument17 pagesConcrete Pipe Installation Guide-CPMSankar CdmNo ratings yet

- # Rig Move Procedure 2018.1.1Document38 pages# Rig Move Procedure 2018.1.1Jennifer Wang100% (2)

- Well Handover DocumentDocument1 pageWell Handover DocumentCadiffNo ratings yet

- Hazard Hunt Report TCPDC-2001 (Halipota-5)Document8 pagesHazard Hunt Report TCPDC-2001 (Halipota-5)Yaqoob Ibrahim0% (1)

- HSE Precheck List 1611927511Document22 pagesHSE Precheck List 1611927511sharathNo ratings yet

- JSA - Drilling ActivitiesDocument4 pagesJSA - Drilling ActivitiesAMIN100% (1)

- Drilling Engineering Crew RolesDocument37 pagesDrilling Engineering Crew RolesEga Puspita Leriana100% (1)

- Deep Well Drilling PPE and Safety RequirementsDocument4 pagesDeep Well Drilling PPE and Safety Requirementsjay RNo ratings yet

- 01 JTSPL WEEKLY CHECK LIST Crane F-15 PDFDocument5 pages01 JTSPL WEEKLY CHECK LIST Crane F-15 PDFsanjivan tawdeNo ratings yet

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- 4.01 IOEC Rigs Commisioning Project HSE PlanDocument59 pages4.01 IOEC Rigs Commisioning Project HSE Planhshobeyri100% (2)

- SOC Cards Oct-2016Document20 pagesSOC Cards Oct-2016Yaqoob IbrahimNo ratings yet

- Daily SOC Report RIG Name: Hilong 05 S# Date Name Position Company DescriptionDocument6 pagesDaily SOC Report RIG Name: Hilong 05 S# Date Name Position Company DescriptionYaqoob IbrahimNo ratings yet

- JSA Working at Heights Fixed LadderDocument3 pagesJSA Working at Heights Fixed LadderCristina Rican100% (1)

- Hse in Drilling OperationsDocument13 pagesHse in Drilling OperationsSamad Ali Siddiqui100% (2)

- Drilling Rig Safety Inspection Check ListDocument17 pagesDrilling Rig Safety Inspection Check ListKiryaki Francis100% (1)

- Oil Field Drill Rig Safety (HSE)Document34 pagesOil Field Drill Rig Safety (HSE)omer dafallahNo ratings yet

- Precision Drilling Risk AssessmentDocument2 pagesPrecision Drilling Risk AssessmentAbdul Hameed Omar100% (1)

- EDC-61 Rig SurveyDocument14 pagesEDC-61 Rig SurveyMostafa Elghifary100% (1)

- Drilling Rig Inspection ChecklistDocument29 pagesDrilling Rig Inspection ChecklistOmaira Sánchez OrtizNo ratings yet

- Observation Reg Feb 2016Document10 pagesObservation Reg Feb 2016Sarmad Hussain100% (1)

- Rig OrientationDocument35 pagesRig OrientationaymenmoatazNo ratings yet

- RIG Name: Hi-Long-05 S# Name Date Position Company DescriptionDocument7 pagesRIG Name: Hi-Long-05 S# Name Date Position Company DescriptionMuhammad Shahrukh100% (6)

- UEP-HL Stop Cards Jan - 2017Document54 pagesUEP-HL Stop Cards Jan - 2017Yaqoob IbrahimNo ratings yet

- OSHA Standard For Fixed Ladders SummaryDocument12 pagesOSHA Standard For Fixed Ladders SummarysesabcdNo ratings yet

- Job Safety Analysis and Risk AssessmentDocument1 pageJob Safety Analysis and Risk Assessmentghada gattouchNo ratings yet

- Inspection Checklist - Drill RigDocument2 pagesInspection Checklist - Drill RigDuvan Bence83% (30)

- #12 Rig Up and Run CasingDocument1 page#12 Rig Up and Run Casingkhurram100% (1)

- SYNOPSIS For Job PortalDocument6 pagesSYNOPSIS For Job PortalAkanksha Verma90% (10)

- Visible Safety and Induction: Hse Management Visit ChecklistDocument6 pagesVisible Safety and Induction: Hse Management Visit ChecklistHARSHALNo ratings yet

- Bop Ram ChangeDocument2 pagesBop Ram ChangeAbdul Hameed OmarNo ratings yet

- HSE Drilling and Well Control ProcedureDocument5 pagesHSE Drilling and Well Control ProcedureKhuda Buksh100% (2)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Rig Safety Officer Sample CVDocument2 pagesRig Safety Officer Sample CVAlekhya100% (3)

- Daily Production Report OMVDocument1 pageDaily Production Report OMVYaqoob IbrahimNo ratings yet

- Checklist (For Any Land Rig)Document13 pagesChecklist (For Any Land Rig)Kachur AlekseyNo ratings yet

- SOP - 12 Loading & Unloading - LKP by ProductsDocument10 pagesSOP - 12 Loading & Unloading - LKP by Productsfaraz ahmed100% (1)

- Rig Move Safety AnalysisDocument3 pagesRig Move Safety AnalysisShahid Alam100% (4)

- Contractor Observation Log - TAM 2020Document12 pagesContractor Observation Log - TAM 2020usman4428No ratings yet

- Stop Cards 1Document136 pagesStop Cards 1Fazal HabibNo ratings yet

- HARC Record for Standard Well Test OperationsDocument8 pagesHARC Record for Standard Well Test OperationsYaqoob IbrahimNo ratings yet

- Daily SOC ReportDocument59 pagesDaily SOC ReportYaqoob Ibrahim100% (1)

- SOC Cards Oct-2016Document22 pagesSOC Cards Oct-2016Yaqoob Ibrahim100% (1)

- Arabian Drilling Company Rig Specific Procedure AD - 32 Pick Up Drill PipeDocument4 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Pick Up Drill Pipehosam aliNo ratings yet

- Strategic Supply Chain Management and LogisticsDocument16 pagesStrategic Supply Chain Management and LogisticsNalaka Manawadu67% (3)

- 10 Work On Mud PumpsDocument5 pages10 Work On Mud PumpsdraghiceanuNo ratings yet

- 23 Sep Safety BreifDocument4 pages23 Sep Safety Breifislam atif100% (1)

- Hazard Hunt Status 26-08-2017Document28 pagesHazard Hunt Status 26-08-2017Yaqoob IbrahimNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- Daily SOC Report Reported By: Shakeel RIG Name: Hilong 05 Well Name: Rajani-6 S# Date Position Company Description CategoryDocument6 pagesDaily SOC Report Reported By: Shakeel RIG Name: Hilong 05 Well Name: Rajani-6 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- Daily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryDocument5 pagesDaily SOC Report Reported By: Mohsin Raza Tariq RIG Name: Hilong 05 Well Name: Rajani-1 S# Date Position Company Description CategoryYaqoob IbrahimNo ratings yet

- IDC SOP # 11 POOH With DP, DC's and BitDocument3 pagesIDC SOP # 11 POOH With DP, DC's and Bitkareem100% (1)

- Safe Cards Report on Transport Operations (TCPDC-2001Document8 pagesSafe Cards Report on Transport Operations (TCPDC-2001Yaqoob IbrahimNo ratings yet

- 3263 - Transfer of Diesel JSA-R76!02!202-01Document1 page3263 - Transfer of Diesel JSA-R76!02!202-01cmrig74No ratings yet

- Daily SOC Report SummaryDocument5 pagesDaily SOC Report SummaryYaqoob IbrahimNo ratings yet

- JSA CT Drill CementDocument2 pagesJSA CT Drill CementaneshseNo ratings yet

- Harc TLC Kd-1revisiDocument2 pagesHarc TLC Kd-1revisitanjungkasri rayaNo ratings yet

- How To Ensure H2S Safety On Offshore Rigs - Drilling ContractorDocument10 pagesHow To Ensure H2S Safety On Offshore Rigs - Drilling ContractorTg TarroNo ratings yet

- AB8-ELE-73-HMO - Troubleshooting VFDDocument2 pagesAB8-ELE-73-HMO - Troubleshooting VFDvikrant911100% (1)

- MS FSK Foc 051019Document2 pagesMS FSK Foc 051019DilxazNo ratings yet

- Method Statement for Steam Duct ErectionDocument6 pagesMethod Statement for Steam Duct ErectionHsebepl NkNo ratings yet

- TLC ProceduresDocument14 pagesTLC ProceduresYaqoob IbrahimNo ratings yet

- UEPL Miano-26 POWS 2.5in Perforation 16-June-2022 000Document14 pagesUEPL Miano-26 POWS 2.5in Perforation 16-June-2022 000Yaqoob IbrahimNo ratings yet

- Proposed 6 Hole Logging StringDocument4 pagesProposed 6 Hole Logging StringYaqoob IbrahimNo ratings yet

- Color Coding Assurance at HL-09 (Qabul-2)Document13 pagesColor Coding Assurance at HL-09 (Qabul-2)Yaqoob IbrahimNo ratings yet

- Tube Move Calculation ParametersDocument1 pageTube Move Calculation ParametersYaqoob IbrahimNo ratings yet

- 2-Phase With Sand TrapDocument2 pages2-Phase With Sand TrapYaqoob IbrahimNo ratings yet

- Colour Code System Compliance UET-1 KK-DT-4Document8 pagesColour Code System Compliance UET-1 KK-DT-4Yaqoob IbrahimNo ratings yet

- Mdata Miano-26: 660256622Document14 pagesMdata Miano-26: 660256622Yaqoob IbrahimNo ratings yet

- Colour Code Assurance Hilong-5 Jugan-2Document6 pagesColour Code Assurance Hilong-5 Jugan-2Yaqoob IbrahimNo ratings yet

- Errata: Date of Issue: Affected PublicationDocument88 pagesErrata: Date of Issue: Affected PublicationYaqoob IbrahimNo ratings yet

- Color Code System For Lifting Equipment: Hilong-21Document3 pagesColor Code System For Lifting Equipment: Hilong-21Yaqoob IbrahimNo ratings yet

- PDC Drill BitsDocument22 pagesPDC Drill BitsYaqoob IbrahimNo ratings yet

- Ogdcl Updated Application Form-Feb17Document1 pageOgdcl Updated Application Form-Feb17Muhammad AbubakarNo ratings yet

- Hydraulic Jet PumpDocument2 pagesHydraulic Jet PumpYaqoob IbrahimNo ratings yet

- W4V23 - Feedstocks - Intermediates - HandoutDocument7 pagesW4V23 - Feedstocks - Intermediates - HandoutJessica KingNo ratings yet

- Du Priest 2009Document12 pagesDu Priest 2009Vita RossoNo ratings yet

- Iadc PDC BitDocument1 pageIadc PDC BitVu HoaNo ratings yet

- IADC Classification ChartDocument2 pagesIADC Classification ChartYaqoob IbrahimNo ratings yet

- Manual DireccionalDocument2 pagesManual DireccionaljuansorrocheNo ratings yet

- Drillers Istructions 21 Oct 2013 - BOP Pressure TestDocument2 pagesDrillers Istructions 21 Oct 2013 - BOP Pressure TestYaqoob IbrahimNo ratings yet

- Sequence of OperationsDocument4 pagesSequence of OperationsHamdan HamzahNo ratings yet

- PDC Drill Bits: Manufacturer IADC Code Bit Name/model NumberDocument16 pagesPDC Drill Bits: Manufacturer IADC Code Bit Name/model NumberYaqoob IbrahimNo ratings yet

- IWCF Principles Procedures Test Paper QuestionsDocument13 pagesIWCF Principles Procedures Test Paper Questionsrake1981No ratings yet

- Understanding Toolface: Angus JamiesonDocument32 pagesUnderstanding Toolface: Angus JamiesonYaqoob Ibrahim100% (2)

- LLD - IN-20161222-003 Drill Pipe Elevator Failure at DFXK-1000 Rawat-2Document1 pageLLD - IN-20161222-003 Drill Pipe Elevator Failure at DFXK-1000 Rawat-2Yaqoob IbrahimNo ratings yet

- W4V27 - Oil Logistics2 - HandoutDocument7 pagesW4V27 - Oil Logistics2 - HandoutJessica KingNo ratings yet

- Anti Stall Tool For Drilling BHA by ATSDocument4 pagesAnti Stall Tool For Drilling BHA by ATSYaqoob IbrahimNo ratings yet

- W3V21 Gas Treatment V2016 HandoutDocument7 pagesW3V21 Gas Treatment V2016 HandoutJessica King100% (1)

- E380b PDFDocument12 pagesE380b PDFanaNo ratings yet

- Isolation of Caffeine from TeaDocument6 pagesIsolation of Caffeine from TeaDaisy Joyce Seroje BuslonNo ratings yet

- Comb Manual IM 106 6888QSDocument36 pagesComb Manual IM 106 6888QSsathish2829No ratings yet

- Subnetting PracticeDocument5 pagesSubnetting PracticeUncleSamNo ratings yet

- Plutnicki ResumeDocument1 pagePlutnicki ResumeAli PlutnickiNo ratings yet

- TI Oxydur PTB 206 - en PDFDocument5 pagesTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- Cap 3 CutoffDocument51 pagesCap 3 CutoffYashraj KajaveNo ratings yet

- Reliance Jio Industry AnalysisDocument45 pagesReliance Jio Industry AnalysisBhavya BhartiNo ratings yet

- FD FX Brochure Update 072020Document9 pagesFD FX Brochure Update 072020Alex PomaNo ratings yet

- Under Water WeldingDocument23 pagesUnder Water WeldingNishanth GowdaNo ratings yet

- c600 17lookinsideDocument6 pagesc600 17lookinsideИван МинчевNo ratings yet

- Structural Theory Eval Exam by SorianoDocument6 pagesStructural Theory Eval Exam by SorianoBenjie MorenoNo ratings yet

- Shiela S. Portillo Ang Specification 09112021Document9 pagesShiela S. Portillo Ang Specification 09112021JR De LeonNo ratings yet

- CS As Corporate Saviour - Oil and Gas Industry PDFDocument48 pagesCS As Corporate Saviour - Oil and Gas Industry PDFBalraj JNo ratings yet

- Verilog Interview Questions & AnswersDocument6 pagesVerilog Interview Questions & AnswersKrishna Saroja SankaNo ratings yet

- DatasheetDocument13 pagesDatasheetebertecnicoNo ratings yet

- Pump HydraulicsDocument5 pagesPump HydraulicsSiddharth Kharat100% (1)

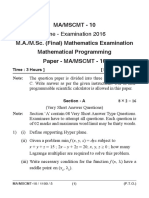

- Ma-Mscmt-10 J16Document5 pagesMa-Mscmt-10 J16Dilip BhatiNo ratings yet

- Green Aviation SeminarDocument19 pagesGreen Aviation SeminarAromalSPillaiNo ratings yet

- PilotstarD AP02-S01 Mar09Document168 pagesPilotstarD AP02-S01 Mar09Dharan NarayananNo ratings yet

- EML 4507 Spring 2017 HW11 SolutionDocument7 pagesEML 4507 Spring 2017 HW11 SolutionUnmil PatelNo ratings yet

- UDR MANUFACTURE ManufacturesDocument8 pagesUDR MANUFACTURE ManufacturesQuadri Consultancy ServicesNo ratings yet

- Hybrid or Standard?: Why The Urge To "Go Green"Document20 pagesHybrid or Standard?: Why The Urge To "Go Green"Tyler McPhersonNo ratings yet

- Ee09 704 - Electrical Machine Design Model QPDocument2 pagesEe09 704 - Electrical Machine Design Model QPGīřïşh McNo ratings yet

- PL-BRICK HP 2850 740 2X6: Product DatasheetDocument4 pagesPL-BRICK HP 2850 740 2X6: Product DatasheetAbhilash ThomasNo ratings yet

- Tek 10-03Document4 pagesTek 10-03Thai DamNo ratings yet