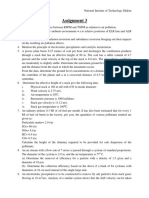

Professional Documents

Culture Documents

Stihl BG 45-85 SH 55-85 Service Manual PDF

Uploaded by

BrianCookOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stihl BG 45-85 SH 55-85 Service Manual PDF

Uploaded by

BrianCookCopyright:

Available Formats

STIH)

STIHL Series 4140 Components

BG, SH 2005-01

Contents

1. Introduction 2 8. Throttle Control 18 10. Blower and Vacuum

Attachment 35

8.1 Throttle Trigger 18

2. Safety Precautions 3 8.2 Setting Lever 10.1 Fanwheel 35

(BG 85, SH 85 only) 19 10.2 Protective Screen

8.3 Stop Switch 19 (all except BG 45) 35

3. Specifications 4 8.3.1 Version up to 2001 19 10.3 Protective Screen

8.3.2 Version from 2001 20 (BG 45 only) 35

3.1 Fuel System 4 8.4 Short Circuit Wire/ 10.4 Blower Tube

3.2 Tightening Torques 5 Ground Wire 20 (BG only) 36

8.5 Throttle Cable 21 10.5 Suction Tube

8.6 Throttle Rod 21 (SH only) 36

4. Troubleshooting 7 10.6 Elbow (SH only) 36

4.1 Rewind Starter 7 9. Fuel System 21

4.2 Fuel System 8 11. Special Servicing

4.3 Engine 10 9.1 Air Filter 21 Tools 37

9.1.1 Removing and

Installing 22

5. Housing 11 9.1.2 Choke Shutter 22 12. Servicing Aids 38

9.2 Carburetor 23

5.1 Handle Molding 11 9.2.1 Leakage Test 23

5.2 Handle and Feet 9.2.2 Removing and

(BG 85, SH 85) 11 Installing 24

9.2.3 Spacer Flange 24

9.3 Servicing

6. Engine 12 the Carburetor 25

9.3.1 Manual Fuel Pump

6.1 Removing with Oval End Cover 25

and Installing 12 9.3.2 Manual Fuel Pump

6.2 Muffler/Spark with Square

Arresting Screen 13 End Cover 26

6.2.1 Without Cat 13 9.3.3 Metering Diaphragm 26

6.2.2 Muffler with 9.3.4 Inlet Needle 27

Catalytic Converter 13 9.3.5 Fixed Jet 28

9.3.6 Pump Diaphragm

and Fuel Strainer 28

7. Rewind Starter 14 9.4 Adjusting

the Carburetor 29

7.1 General 14 9.4.1 Carburetor

7.2 Removing and with LD Screw 29

Installing 14 9.4.2 User Adjustment of

7.3 Starter Cup 15 Carburetor with H, L

7.4 Rope Rotor 15 and LA Screws 29

7.5 Replacing the 9.4.3 Basic Setting on

Rewind Spring 16 Carburetor with H, L

7.5.1 Tensioning the and LA Srews 31

Rewind Spring 17 9.5 Tank Vent 32

7.6 Starter Rope 17 9.5.1 General 32

7.7 Pawl 18 9.5.2 Replacing 33

9.6 Fuel Tank 33

9.6.1 General 33

9.6.2 Pickup Body 34

9.6.3 Fuel Hoses 34

q

© ANDREAS STIHL AG & Co. KG, 2005

Series 4140 Components BG, SH 1

1. Introduction

This service manual contains The special servicing tools Always use original STIHL

detailed descriptions of all typical mentioned in the descriptions are replacement parts.

repair and servicing procedures for listed in the chapter "Special They can be identified by the

models BG 45, 46, 55, 65, 85, Servicing Tools" of this manual. STIHL part number,

SH 55, 85, which are based on the Use the part numbers to identify the the STIH) logo and the

series 4140 powerhead. tools in the "STIHL Special Tools” STIHL parts symbol (

manual. The manual lists all special This symbol may appear alone on

You will find detailed descriptions of servicing tools currently available small parts.

procedures for servicing and from STIHL.

repairing engine components in the

service manual for the “Series 4140 Symbols are included in the text and

Powerhead“. pictures for greater clarity.

The meanings are as follows:

You should make use of the

illustrated parts lists while carrying In the descriptions:

out repair work. They show the

installed positions of the individual : = Action to be taken as

components and assemblies. shown in the illustration

(above the text)

Refer to the latest edition of the

relevant parts list to check the part – = Action to be taken that is

numbers of any replacement parts. not shown in the illustration

(above the text)

A fault on the machine may have

several causes. To help locate the b 4.2

fault, consult the chapter on Reference to another chapter, i.e.

"Troubleshooting" in this manual chapter 4.2 in this example.

and the "STIHL Service Training

System" for all assemblies. In the illustrations:

Refer to the "Technical Information" A Pointer

bulletins for engineering changes

which have been introduced since a Direction of movement

publication of this service manual.

Technical information bulletins also Service manuals and technical

supplement the parts list until a information bulletins are intended

revised edition is issued. exclusively for the use of properly

equipped repair shops. They must

not be passed to third parties.

2 Series 4140 Components BG, SH

2. Safety Precautions

If the engine is started up in the

course of repairs or maintenance

work, observe all local and country-

specific safety regulations as well

as the safety precautions and

warnings in the instruction manual.

Gasoline is an extremely flammable

fuel and can be explosive in certain

conditions.

Improper handling may result in

burns or other serious injuries.

Warning!

Do not bring any fire, flame, spark or

other source of heat near the fuel.

All work with fuel must be performed

outdoors only. Spilled fuel must be

wiped away immediately.

Series 4140 Components BG, SH 3

3. Specifications

3.1 Fuel System Carburetor: Diaphragm carburetor

Carburetor leakage test

at gauge pressure: 0.8 bar (8 kPa)

Operation of tank vent

at gauge pressure: 0.3 bar (3 kPa)

under vacuum: 0.05 bar (0.5 kPa)

Fuel: see instruction manual

Octane number: min. 90 RON

Fuel mixture: Regular brand-name gasoline and

STIHL 50:1 two-stroke engine oil or

brand-name two-stroke engine oil

Mix ratio: 50:1 with STIHL 50:1 two-stroke

engine oil

Fuel mix for units with catalytic

converter: Use only STIHL 50:1 two-

stroke engine oil with unleaded

gasoline.

4 Series 4140 Components BG, SH

3.2 Tightening Torques

DG and P (Plastoform) screws are used in polymer and light metal components. These screws form a

permanent thread when they are installed for the first time. They can be removed and installed as often as

necessary without impairing the strength of the screwed assembly, providing the specified tightening torque is

observed.

For this reason it is essential to use a torque wrench.

Fastener Thread size For component Torque Remarks

Nm

Screw IS-DG5x60 Muffler/cylinder 9.0

Screw IS-DG5x24 Muffler/cylinder (version with catalytic 9.0

converter)

M14x7 Stub/muffler (version with spark 10.0

arresting screen in muffler)

Screw IS-DG5x24 Spacer flange/cylinder 6.0 1)

Collar screw P6x15/49 Collar screw/inner blower housing 4.0 2)

Screw IS-DG5x24 Inner blower housing/crankcase 8.0

Screw IS-DG5x24 Inner blower housing/engine pan 8.0

Screw IS-P6x26.5 Outer/inner blower housings 5.0

Nut M8x1LH-06 Fanwheel/crankshaft 17.0

(SH with shredder blade)

Screw IS-P6x19 Handle/inner blower housing 5.0 3)

Screw IS-P6x19 Handle molding/inner blower housing 4.0 4)

Screw IS-P6x19 Fan housing/inner blower housing 6.0

Screw IS-DG5x20Z Fan housing/spiral housing 6.0

Screw IS-DG5x24 Spiral housing/crankcase 6.0

Screw IS-DG5x24 Spiral housing/engine pan 6.0

Screw IS-P6x19 Protective screen/outer blower housing 5.0 5)

M14x1.25 Spark plug 20.0

Remarks:

1) with binding head

2) SH 55, 85 only

3) BG 85, SH 85 only

4) BG 65, 85, SH 85 only

5) BG 45 only

Series 4140 Components BG, SH 5

Use the following procedure when refitting a DG or P screw in an existing thread:

– Place the screw in the hole and rotate it counterclockwise until it drops down slightly.

– Tighten the screw clockwise to the specified torque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread

and weaken the assembly.

Power screwdriver settings for Plastoform screws max. 600 rpm

polymer:

DG screws max. 500 rpm

Important:

Do not mix up screws with and without binding head

6 Series 4140 Components BG, SH

4. Troubleshooting

4.1 Rewind Starter

Condition Cause Remedy

Starter rope broken Rope pulled out too vigorously as Fit new starter rope

far as stop or over edge, i.e. not

vertically

Normal wear Fit new starter rope

Rewind spring broken Spring overtensioned – no reserve Fit new rewind spring

when rope is fully extended

Very dirty or corroded Fit new rewind spring

Starter rope can be pulled out Guide peg on pawl or pawl itself Fit new pawl

almost without resistance is worn

(crankshaft does not turn)

Spring clip fatigued Fit new spring clip

Starter rope is difficult to pull and Starter mechanism very dirty Thoroughly clean complete starter

rewinds very slowly (dusty conditions) mechanism

Lubricating oil on rewind spring Coat rewind spring with a standard

becomes viscous at very low solvent-based degreasant

outside temperatures (spring (containing no chlorinated or

windings stick together) halogenated hydrocarbons). Then

pull rope carefully as often as

necessary until normal action is

restored

Series 4140 Components BG, SH 7

4.2 Fuel System

Condition Cause Remedy

Engine stalls at idle speed Idle jet bores or ports blocked Clean jet bores and ports and blow

clear with compressed air

Idle jet too rich or too lean Reset low speed screw (L) correctly

Setting of idle speed screw (LA) Reset idle speed screw (LA)

incorrect – throttle shutter correctly

completely closed

Engine speed drops quickly under Air filter plugged Clean the air filter or replace if

load – low power necessary

Tank vent faulty Fit new tank vent

Leak in fuel line between tank and Seal or renew connections and fuel

fuel pump line

Pump diaphragm damaged or Fit new pump diaphragm

fatigued

Main jet bores or ports blocked Clean the bores and ports

Fuel pickup body dirty Install new pickup body

Setting of high speed screw (H) too Reset high speed screw (H)

rich correctly

Throttle shutter not opened fully Check linkage

8 Series 4140 Components BG, SH

Condition Cause Remedy

Poor acceleration Idle jet too lean Turn low speed screw (L) counter-

clockwise (richer), no further than

stop

Main jet too lean Turn high speed screw (H) counter-

clockwise (richer), no further than

stop

Inlet control lever too low Set inlet control lever flush with top

(relative to correct installed of carburetor body

position)

Inlet needle sticking to valve seat Remove inlet needle, clean and

refit

Connecting bore to atmosphere Clean the bore

blocked

Diaphragm gasket leaking Fit new diaphragm gasket

Metering diaphragm damaged or Fit new metering diaphragm

shrunk

Engine will not idle – Throttle shutter opened too wide by Reset idle speed screw (LA)

idle speed too high idle speed screw (LA) correctly

Carburetor floods, Inlet needle not sealing. Foreign Remove and clean or replace inlet

engine stalls matter in valve seat or cone needle, clean fuel tank, pickup

damaged body and fuel line if necessary

Inlet control lever sticking on Free off inlet control lever

spindle

Helical spring not located on nipple Remove inlet control lever and refit

of inlet control lever correctly

Perforated disc on diaphragm is Fit new metering diaphragm

deformed and presses constantly

against inlet control lever

Inlet control lever too low Fit new inlet control lever

(relative to correct installed

position)

Series 4140 Components BG, SH 9

4.3 Engine

Always check and, if necessary,

repair the following parts before

looking for faults on the engine:

– Air filter

– Fuel system

– Carburetor

– Ignition system1)

Condition Cause Remedy

Engine does not start easily, stalls Oil seals in crankcase faulty Install new oil seals 1)

at idle speed, but operates normally

at full throttle

Crankcase leaking / damaged Seal / replace the crankcase 1)

(cracks)

Muffler leaking Seal / replace the muffler

Engine does not deliver full power Piston rings worn or broken Install new piston rings 1)

or runs erratically

Muffler / spark arresting screen Clean muffler (inlet and

carbonized exhaust openings), replace

spark arresting screen

Air filter element dirty Fit new air filter element

Fuel / impulse line kinked or Fit new lines or position

cracked without kinks

Engine overheating Insufficient cylinder cooling. Thoroughly clean all cooling air

Air inlets in fan housing passages and cooling fins

blocked or cooling fins on

cylinder very dirty

1)

see "Series 4140 Powerhead" service manual

10 Series 4140 Components BG, SH

5. Housing 5.2 Handle and Feet

5.1 Handle Molding (BG 85, SH 85)

Remove fan housing with rewind

starter, b 7.2 2

– Remove the spark plug.

1

932RA172 VA

932RA262 VA

: If necessary, replace the setting : Take out the screws (arrows).

lever (1), b 8.2

– Remove the handle.

: If necessary, remove the grip

molding (2) as follows:

2 1 1

1

1

932RA170 VA

932RA261 VA

932RA263 VA

1

BG 45, 55, SH 55 only : Pull the grip molding (1) out of the : Pull the feet (1) upwards and out

guides (arrows) and lift it away. of the handle.

: Take out the screws (1) and

remove the handle molding (2). Install in the reverse sequence. Reassemble in the reverse

sequence.

2 1

1

932RA171 VA

BG 65, 85, SH 85 only

: Take out the screws (1) and

remove the handle molding (2).

Note:

BG 65 has no setting lever.

Series 4140 Components BG, SH 11

6. Engine

6.1 Removing and Installing

– Remove fan housing with rewind

starter, b 7.2

2

– Remove the fanwheel, b 10.1

1

– Remove the filter housing,

b 9.1

932RA175 VA

932RA176 VA

– Remove the handle molding, b

5.1

: On machines with a throttle : Remove the engine.

cable, disconnect the throttle

cable (1) from slotted pin (2) on

the throttle lever and push the

throttle cable out of the tensioner

(arrow). If necessary, remove the

carburetor first. Avoid kinking the

throttle cable in this process.

3 – On machines with a throttle rod,

remove the throttle rod, b 8.6

1

2

932RA177 VA

932RA173 VA

: Disconnect the short circuit Install in the reverse sequence.

wire (1) and ground wire (2) from Observe correct tightening torques,

the ignition module. b 3.2.

: Remove the retainers (3). : When installing the engine in the

inner fan housing, check that the

gasket (arrow) is in front of the

inner fan housing.

2

1

932RA174 VA

932RA092 VA

: Take engine mounting screws

: Pull the fuel hoses (1 and 2) off (arrows) out of inner fan housing.

the elbow connectors on the

carburetor.

12 Series 4140 Components BG, SH

6.2 Muffler/Spark Arresting 6.2.2 Muffler with Catalytic

Screen Converter

6.2.1 Without Cat

Troubleshooting, b 4.3 Install in the reverse sequence. Troubleshooting, b 4.3

– Remove the fan housing with – Clean the sealing faces before The catalytic converter integrated in

rewind starter, b 7.2 installation. the muffler is a device that helps

reduce the amount of noxious

– Install a new exhaust gasket. emissions in the exhaust gas by

initiating chemical reactions without

– Apply sealant to the underside of being consumed in the process.

the screw head, b 12. The catalytic converter is

maintenance-free. Never attempt to

– Tighten down the screws firmly, carry out repairs on the catalytic

b 3.2 converter.

1 1

932RA207 VA

932RA205 VA

932RA208 VA

1

Muffler Spark arresting screen Muffler

: Take out the screws (1). : On machines with a removable – Remove the fan housing with the

stub (1) (with and without spark rewind starter, b 7.2

arresting screen), use a 15 mm

wrench to unscrew the stub. : Take the screws (1) out of the

muffler.

– Clean the spark arresting screen

or install a new stub if necessary.

2 2

– Clean the thread of the stub and

coat it with sealant, b 12.

1

Follow the sealant manufacturer’s

instructions.

932RA201 VA

932RA209 VA

– Screw home the stub and tighten

it down firmly, b 3.2

1 3

: Remove the muffler (1) and : Remove the muffler (1) with

exhaust gasket (2). exhaust gaskets (2) and

flange (3).

Series 4140 Components BG, SH 13

7. Rewind Starter 7.2 Removing and Installing

7.1 General

Install in the reverse sequence. Troubleshooting, b 4.1

– Clean the sealing faces before If the action of the starter rope

installation. becomes very stiff and the rope

rewinds very slowly or not

– Install new exhaust gaskets. completely, it can be assumed that

the starter mechanism is in order

but plugged with dirt. At very low

outside temperatures the lubricating

oil on the rewind spring may thicken

and cause the spring windings to

stick together. This has a

detrimental effect on the function of : Take out the screws (1+2).

the starter mechanism. In such a

case it is sufficient to apply a few – Remove the fan housing with

drops of a standard solvent-based rewind starter.

degreasant (containing no

chlorinated or halogenated : If necessary, remove the

hydrocarbons) to the rewind spring. antistatic wire (arrow).

Carefully pull out the starter rope

several times and allow it to rewind

1 until its normal smooth action is

restored.

If clogged with dirt or pitch, the

entire starter mechanism, including

the rewind spring, must be removed

2 and disassembled. Take particular

932RA210 VA

care when removing the spring.

Clean all parts, b 12.

Spark arresting screen Lubricate the rewind spring and

starter post with STIHL special

– Remove the fan housing with lubricant, b 12, before installing.

rewind starter, b 7.2

: Take out the screw (1).

: Pull the spark arresting

screen (2) out of the muffler.

– Clean the spark arresting screen,

replace it if necessary.

Install in the reverse sequence.

14 Series 4140 Components BG, SH

7.3 Starter Cup 7.4 Rope Rotor

Machines with starter cup Remove the rewind starter,

integrated in flywheel: For servicing b 7.2

information see the chapter on

“Flywheel” in the “Series 4140 Relieving tension of rewind 3 1

Powerhead” service manual. spring 2

The rewind spring will not be under

tension if the starter rope is broken.

932RA181 VA

– Pull out the starter rope about

10 cm and hold the rope rotor

steady.

Removing

– While still holding the rotor

steady, take three turns of the The rewind spring must not be

rope off the rotor. under tension.

– Pull out the starter rope a little : Remove the spring clip (1) from

further and then let go of the the starter post.

rotor.

: Remove the washer (2) and

The rotor spins back so that the pawl (3).

rewind spring is no longer under

tension. – Carefully pull the rope rotor off

the starter post.

– Replace the broken or worn

starter rope, b 7.6

Installing

– Coat the bore in the rope rotor

with STIHL special lubricant,

b 12.

1

2

932RA182 VA

: Fit the rotor on the starter post

so that the driver (1) on the rope

rotor slips behind the inner spring

loop (2).

Series 4140 Components BG, SH 15

7.5 Replacing the Rewind

Spring

– Check that the spring loop has – Remove the rope rotor, b 7.4

engaged by turning the rope rotor

a little and letting it go. It must – Remove the pieces of broken

spring back. spring from the rope rotor and

starter cover.

– Coat pawl with special lubricant

and install, b 12. – Before installing, lubricate the

new spring with a few drops of

STIHL special lubricant, b 12.

: Then grip the rewind spring with

pointed nose pliers about 10 mm

from the end of the outer loop and

place it in the starter.

2 1 932RA184 VA

932RA183 VA

: Fit the washer and engage the : Position the rewind spring in the : Check the distance of the inner

spring clip (1) in the groove in the starter and press the outer spring spring loop from the hub and

starter post. loop over the lug (arrow). correct if necessary. Dimension

"A" must not be more than 2 mm.

: Make sure the spring clip (1) den The rewind spring may pop out and

engages the guide peg (arrow) uncoil if the rope rotor is not – Install the rope rotor, b 7.4

on the pawl (2) and points installed very carefully.

clockwise. – Tension the rewind spring,

If the rewind spring has popped out, b 7.5.1

Handle the spring clip with care. refit it as follows:

The rewind starter may not function

properly if the spring clip is – Hold the spring in your hand and

deformed. wind from the inside outwards

and tension it to a diameter of

– Tension the rewind spring, 55 mm.

b 7.5.1

– Install the rewind starter,

b 7.2

16 Series 4140 Components BG, SH

7.5.1 Tensioning the 7.6 Starter Rope

Rewind Spring

– Remove the rewind starter,

b 7.2

– If the starter rope is broken,

remove the remaining rope from

the rope rotor and starter grip.

– If the starter rope is worn, relieve

932RA189 VA

tension of rewind spring, b 7.4.

932RA187 VA

Pull the end of the rope out of the

rotor and undo the knot. Then pull

the worn rope out of the starter

: Make a loop in the unwound The starter grip must sit firmly in the grip, housing and rotor.

starter rope. Grip the rope close rope guide bush without drooping to

to the rotor and use it to turn the one side. If this is not the case,

rotor six full turns clockwise. tension the spring by one additional

turn.

When the starter rope is fully

extended, it must still be possible to

rotate the rope rotor at least another

half turn before maximum spring

tension is reached. If this is not the

case, pull the rope out, hold the

rope rotor steady and take off one

turn of the rope.

Do not overtension the rewind

932RA190 VA

932RA188 VA

spring as this will cause it to

break.

– Place the rewind starter in

: Hold the rope rotor steady. position, insert the screws and : Thread one end of the new rope

tighten them down firmly, b 3.2 through the rotor and housing.

: Pull out the rope with the starter Tie a simple overhand knot in the

grip and straighten it out. end of the rope.

– Hold the starter grip firmly to keep – Pull the rope back into the rotor

the rope tensioned. until the knot locates in the

recess.

– Let go of the rope rotor and

slowly release the starter grip so – Thread the other end of the rope

that the rope winds itself onto the through the starter grip. Tie a

rotor. simple overhand knot in the end

of the rope.

Series 4140 Components BG, SH 17

7.7 Pawl 8. Throttle Control

8.1 Throttle Trigger

2 1

380RA065 VA

932RA183 VA

1 2

: On machines with "ElastoStart": – Remove the rewind starter, – Remove the handle molding,

Thread end of new starter rope b 7.2 b 5.1

through the grip (1) and the

spring element (2). Tie a simple : Ease the spring clip (1) off the : On machines with a throttle

overhand knot in the end of the starter post and pull the pawl (2) cable, remove the throttle

rope. Pull the rope and spring out of the rope rotor. trigger (1) and disconnect it from

element into the grip and then fit the throttle cable.

the cap (3). Do not pull the rope rotor off the

starter post.

– Tension the rewind spring,

b 7.5.1 – Coat the new pawl with special 2

lubricant, b 12, and fit it in

– Install the rewind starter, position.

b 7.2

: Push the spring clip (1) into the 1

groove in the starter post.

932RA268 VA

: Make sure the spring clip (1)

engages the guide peg (arrow)

on the pawl (2).

: On machines with a throttle

The spring clip must point rod (1), remove the throttle

clockwise. trigger (2) and disconnect it from

the throttle rod.

Handle the spring clip with care.

The rewind starter may not function Install in the reverse sequence.

properly if the spring clip is

deformed.

– Install the rewind starter,

b 7.2

18 Series 4140 Components BG, SH

8.2 Setting Lever (BG 85, 8.3 Stop Switch

SH 85 only) 8.3.1 Version up to 2001

8 7 6 1

4 3

1

2

2

932RA226 VA

932RA227 VA

932RA073 VA

54 3 2 1

– Remove the handle molding, : Fit the cam (1) on the setting : Use a flat screwdriver to ease the

b 5.1 lever’s stub so that it lines up with stop switch (1) out of the handle

the marking on the handle molding.

: Ease the E-clip (8) off the setting housing.

lever’s stub. : Pull the connectors (2) (short

: Push the E-clip (2) in the groove circuit and ground wires) off the

: Remove the cam (7). on the setting lever’s stub. stop switch.

: Pull the setting lever (1) with Assemble all other parts in the Install in the reverse sequence.

washers (2, 5) and cup springs reverse sequence.

(3, 4) out of the handle Check correct positions of wires.

molding (6).

Reassemble in the reverse

sequence.

– Slip the washers (2, 5) and cup

springs (3, 4) over the stub of the

setting lever (1) and push it into

the handle molding (6).

Note the correct installed position of

the two cup springs (3 and 4).

Series 4140 Components BG, SH 19

8.3.2 Version from 2001 8.4 Short Circuit Wire/

Ground Wire

1

2

1

3

1

932RA223 VA

2

932RA101 VA

932RA225 VA

– Remove the handle molding, – Remove the handle molding, b BG 65, 85, SH 85 from 2001 only

b 5.1 5.1

: Remove the wire (1) from the

: Use a flat screwdriver to ease the – Remove the stop switch, housing peg.

stop switch (1) and protective b 8.3

cap (2) out of the handle molding.

: Pull the connectors of the short

: Pull the connectors (3) (short circuit wire (1) and ground

circuit and ground wires) off the wire (2) off the ignition module.

stop switch.

Install in the reverse sequence.

Check correct positions of wires.

932RA075 VA

1

All BG/SH units

: Pull the retainers (1) off the

ignition lead.

: Take the wires out of the guides

(arrows) in the inner fan housing.

Reassemble in the reverse

1 sequence.

– Push home the wires so that they

are properly seated in the guides

in the inner fan housing.

2

932RA224 VA

BG 45, 55, SH 55 only, from 2001

– Remove the throttle trigger,

b 8.1

: Remove the wire (1) from the

throttle trigger’s pivot pin (2).

20 Series 4140 Components BG, SH

8.5 Throttle Cable 8.6 Throttle Rod 9. Fuel System

9.1 Air Filter

Dirty air filters reduce engine power,

increase fuel consumption and

2 make starting more difficult.

If there is a noticeable loss of

engine power, check to see if the

1 air filter is plugged with dirt.

932RA268 VA

– Before removing the air filter,

close the choke shutter and

remove all loose dirt from around

the filter.

– Remove the handle molding, – Remove the handle molding,

b 5.1 b 5.1 – Wash the foam filter in a standard

solvent-based degreasant

: Disconnect the throttle cable (1) : Remove the throttle trigger (2) containing no chlorinated or

from the throttle trigger (2), and disconnect the throttle halogenated hydrocarbons and

b 8.1 rod (1). then dry. Replace if necessary.

: Take the throttle cable out of the : Disconnect the throttle rod (1) – Replace the felt filter. As a

guides (arrows) in the inner fan from the carburetor. temporary measure, knock the

housing. filter out on the palm of your hand

Install in the reverse sequence. or blow clear with compressed

– Remove the carburetor, b 9.2.2 air. Do not wash.

– Replace multi-ply felt filter. As a

temporary measure, knock the

filter out on the palm of your hand

or blow clear with compressed

air. Do not wash

If a felt filter is replaced by a multi-

ply filter, do not re-install the foam

filter.

Always replace a damaged air filter

immediately.

: Push the throttle cable (1) out of

the tensioner (2). Remove the

throttle cable.

Install in the reverse sequence.

Series 4140 Components BG, SH 21

9.1.1 Removing and Installing 9.1.2 Choke Shutter

– Knock the filter out on the palm of

your hand or blow clear with 3

compressed air. Do not wash.

Replace if heavily loaded. 1

2

Always replace a damaged air filter

immediately.

932RA211 VA

932RA229 VA

: Squeeze retainers together. – Remove the air filter, b 9.1.1

: Remove the push nut (1).

: Pull the choke shutter (2) out of

the lever (3).

– When installing, make sure the

choke shutter is properly located

in the lever’s guide.

1 Use a new push nut.

2

Install in the reverse sequence.

932RA212 VA

932RA216 VA

: Swing the filter cover (1) to the Machines with catalytic converter

side and pull the lugs out of the

guides (arrows). : Remove the gasket (1) and heat

shield (2).

Use new gaskets.

Install in the reverse sequence.

2

1

932RA217 VA

: Pull the filter (1) out of the filter

housing (3).

: Unscrew the nuts (2) and remove

the filter housing.

22 Series 4140 Components BG, SH

9.2 Carburetor

9.2.1 Leakage Test

If you suspect a fault in the fuel If this pressure remains constant,

system, see b 4.2. the carburetor is airtight. However, if

In the case of problems with the it drops, there are two possible

carburetor or fuel supply system, causes:

also check or clean the tank vent,

b 9.5 1. The inlet needle is not sealing

The carburetor can be tested for (foreign matter in valve seat or

leaks with the carburetor and sealing cone of inlet needle is

232RA082 VA

crankcase tester 1106 850 2905. damaged or inlet control lever

sticking).

– Remove the air filter, b 9.1.1

2. Metering diaphragm is damaged.

: Push the fuel line with nipple onto

the carburetor’s elbow connector In either of these cases the

(arrow). carburetor has to be serviced.

– After completing the test, open

the vent screw and pull the fuel

line off the carburetor.

– Push the fuel hose onto the

carburetor’s elbow connector.

Assemble all other parts in the

reverse sequence.

Always install a new gasket.

232RA083 VA

932RA215 VA

: Disconnect the fuel hose from the : Connect the tester's pressure

carburetor’s elbow connector. hose to the nipple.

2 1

2

143RA172 VA

232RA084 VA

: Push the fuel line (1) : Close the vent screw (1) on the

1110 141 8600 onto the rubber bulb (2) and pump air into

nipple (2) 0000 855 9200. the carburetor until the pressure

gauge (3) shows a reading of

approx. 0.8 bar.

Series 4140 Components BG, SH 23

9.2.2 Removing and Installing 9.2.3 Spacer Flange

Remove the air filter, b 9.1.1

1

2

932RA234 VA

: Remove the carburetor (1) and – Remove the carburetor, b 9.1.1

gasket (2).

: On machines with throttle cable,

Install in the reverse sequence. pull the throttle cable (1) out of

the spacer flange (2).

Always install the carburetor with

new gaskets.

Position the fuel hoses so that they

are not kinked.

Observe tightening torques, b 3.2

1

2

932RA253 VA

932RA233 VA

: Disconnect the fuel hoses from : On machines with throttle cable,

from the elbow connectors on the take out the screws (1) and

carburetor. remove the spacer flange

together with the hex head

screws (2).

2

2

1

1

932RA239 VA

932RA252 VA

: On machines with throttle : On machines with throttle rod,

cable (1), disconnect throttle take out the screws (1) and

cable from slotted pin (2) on remove the spacer flange

carburetor’s throttle lever. together with the hex head

screws (2).

– On machines with throttle rod,

remove the throttle rod, b 8.6

24 Series 4140 Components BG, SH

9.3 Servicing the Carburetor

9.3.1 Manual Fuel Pump with Oval End Cover

– Carry out leakage test, b 9.2

– Remove the carburetor, b 9.2.2

932RA254 VA

936RA258 VA

: Pull the gasket (1) out of the : Take the cap out of the end cover.

guides (arrows) on the spiral

housing.

Install in the reverse sequence.

Always install new gaskets.

Observe tightening torques,

b 3.2 1

936RA223 VA

936RA025 VA

: Take out the M3x12 screws (1). : Inspect the metering diaphragm

and gasket and replace if

: Remove the end cover with necessary, b 9.3.3

cap (2).

Reassemble in the reverse

sequence.

Additional holes in the gasket and

diaphragm (if there are any) must

1 line up with those in the carburetor

and flange.

2

936RA224 VA

: Take out the M3x8 screws (1).

: Remove the flange (2).

Series 4140 Components BG, SH 25

9.3.2 Manual Fuel Pump with Square End Cover 9.3.3 Metering Diaphragm

1

1

936RA023 VA

936RA025 VA

936RA026 VA

: Take out the screws (1). : Inspect the metering diaphragm – Remove flange from manual fuel

and gasket and replace if pump with oval end cover,

– Remove the end cover with cap. necessary, b 9.3.3 b 9.3.1

Reassemble in the reverse – Remove flange from manual fuel

sequence. pump with square end cover,

b 9.3.2

: Remove the metering

diaphragm (1) and gasket (2)

from the carburetor body.

If the gasket and diaphragm are

stuck together, remove and

separate them very carefully.

932RA285 VA

: Inspect the diaphragm and

gasket and replace if necessary.

The diaphragm is a very delicate

: Take the cap out of the end cover. component. As a result of the

alternating stresses the material

eventually shows signs of fatigue,

i.e. the diaphragm distorts and

swells and has to be replaced.

Reassemble in the reverse

sequence.

936RA024 VA

: Remove the flange.

26 Series 4140 Components BG, SH

9.3.4 Inlet Needle

Reassemble in the reverse

1 1 sequence.

– Engage clevis in annular groove

2 on head of the inlet needle.

Make sure the helical spring locates

on the control lever’s nipple.

936RA027 VA

936RA029 VA

– Check that inlet control lever

moves freely.

: Fit the gasket (1) on the – Remove the metering Important:

carburetor body. diaphragm, b 9.3.3 The upper edge of the inlet control

lever must be flush with the top of

Line up the hole in the gasket (2) : Take out the screw (1). the carburetor body.

with the compensating bore in the

carburetor. – Install the metering diaphragm,

b 9.3.3

1 4 3

1

936RA028 VA

932RA260 VA

: Place metering diaphragm (1) on : Remove the inlet control

the gasket. lever (4), spindle (3), spring (2)

and inlet needle (1).

Line up the hole in the metering

diaphragm (1) with the Take care with the spring (2)

compensating bore in the because it may pop out during

carburetor and gasket. disassembly.

Assemble all other parts,

b 9.3.1 and 9.3.2.

372RA120 VA

: If there is an annular indentation

(arrow) on the sealing cone of the

inlet needle, it will be necessary

to replace the inlet needle

because it will no longer seal

properly.

Series 4140 Components BG, SH 27

9.3.5 Fixed Jet 9.3.6 Pump Diaphragm and

Fuel Strainer

Take care not to damage the fixed The diaphragm is a very delicate

jet when removing. 1 component. As a result of the

alternating stresses the material

– Remove the metering eventually shows signs of fatigue,

diaphragm, b 9.3.3 2 i.e. the diaphragm distorts and

swells and has to be replaced.

– Inspect the diaphragm and

936RA032 VA

gasket and replace if necessary.

– Remove the carburetor, b 9.2.2

: Take out the screw (1).

: Remove the end cover (2).

1 1

1

936RA225 VA

936RA033 VA

936RA086 VA

C1Q-S48, C1Q-S50, C1Q-S55 : Remove the gasket (1). : Examine the fuel strainer (1) for

carburetors only contamination and damage and

replace if necessary.

: Unscrew the fixed jet (1).

1 1

2

936RA034 VA

936RA031 VA

932RA259 VA

C1Q-S64, C1Q-S73 carburetors : Remove the pump Reassemble in the reverse

only diaphragm (1). sequence.

: Unscrew the fixed jet (1). If the gasket and pump diaphragm : The pump diaphragm (1) and

are stuck together, remove and gasket (2) are held in position by

Reassemble in the reverse separate them very carefully. the pegs (arrows) on the end

sequence. cover (3).

28 Series 4140 Components BG, SH

9.4 Adjusting the Carburetor 9.4.2 User Adjustment of

9.4.1 Carburetor with LD Carburetor with H, L and

Screw LA Screws

The carburetor with idle speed

screw (LD) has no adjusting screws L

for maximum engine (H screw) or

idle mixture (L screw).

LD

The carburetor is tuned so that the

engine receives an optimum fuel-air H

mixture under all operating

232RA090 VA

932RA303 VA

conditions.

LA

Standard setting

When adjusting from scratch, first Adjusting idle speed Standard setting

carry out the standard setting.

– Carry out standard setting. The limiter cap must not be

removed from the high speed screw

– Start the engine and warm it up. (H) to carry out the standard setting.

With this carburetor it is only

Engine stops while idling: possible to correct the setting of the

high speed screw (H) within fine

: Turn the idle speed screw (LD) limits.

(arrow) slowly clockwise until the

engine runs smoothly. – Check the air filter and replace if

LD necessary, b 9.1.1

Erratic idling behavior, poor

acceleration: – Check the spark arresting

screen, clean or replace it if

232RA090 VA

: Turn the idle speed screw (LD) necessary, b 6.2

slowly no more than half a turn

counterclockwise.

: Carefully turn the idle speed

screw (LD) (arrow)

counterclockwise (left-hand

thread) down onto its seat.

: Then turn the idle speed

screw (LD) two full turns

clockwise.

– Check the air filter and replace if

necessary, b 9.1

– Check the spark arresting

screen, clean or replace as

necessary, b 7.2

Series 4140 Components BG, SH 29

– At high altitude (mountains): Turn Erratic idling behavior

L the high speed screw (H)

clockwise (leaner), but no further – Idle setting is too rich. Turn the

than stop, until there is no low speed screw (L) clockwise

noticeable increase in engine (about a quarter turn) until the

speed. engine runs and accelerates

H smoothly.

– At sea level: Turn the high speed

932RA303 VA

screw (H) counterclockwise It is usually necessary to change the

LA (richer), but no further than stop, setting of the idle speed screw (LA)

until there is no noticeable after every correction to the low

increase in engine speed. speed screw (L).

Now make the following

adjustments: It is possible that the standard

setting produces the highest engine

: Turn the high speed screw (H) rpm in both the above cases.

counterclockwise as far as stop

(no more than 3/4 turn)

Adjusting idle speed

: Carefully turn the low speed

screw (L) clockwise until it is – Open the low speed screw (L)

against its seat, then open it one one full turn.

full turn counterclockwise.

– Allow the engine to warm up.

– Start the engine and allow it to

warm up.

Engine stops while idling

Fine tuning – Turn the idle speed screw (LA)

slowly clockwise until the engine

A minor correction may be runs smoothly.

necessary when operating at high

altitude or at sea level. Note that

even very slight corrections to the Erratic idling behavior, poor

high speed screw (H) produce a acceleration

noticeable change in engine

running behavior. – Idle setting is too lean. Turn the

low speed screw (L) counter-

– Carry out the standard setting. clockwise (about a quarter turn)

until the engine runs and

– Start the engine and allow it to accelerates smoothly.

warm up.

– Open the throttle wide.

30 Series 4140 Components BG, SH

9.4.3 Basic Setting on

Carburetor with H, L

and LA Srews

The limiter cap has to be removed Adjusting idle speed

from the high speed screw (H) only

if it is necessary to replace the high – Check the air filter and clean or

speed screw (H), clean the replace as necessary.

carburetor or adjust it from scratch.

– Warm up the engine.

After removing the limiter cap it is

1

necessary to carry out the basic Adjust idle speed with a tachometer.

932RA315 VA

setting. Adjust specified engine speeds

within a tolerance of +/- 200 rpm.

1. Adjust engine speed with idle

: On carburetors with a long limiter speed screw (LA) to 3,300 rpm.

cap (1):

Use suitable pliers to pull off the 2.Turn low speed screw (L)

limiter cap. clockwise or counterclockwise

to obtain maximum engine

– Screw down both adjusting screw speed.

(H and L) clockwise until they are

against their seats. If this speed is higher than

3,700 rpm, abort the procedure and

Now make the following start again with step 1.

adjustments:

3. Use the idle speed screw (LA)

to set engine speed again to

3,300 rpm

4. Set the engine speed to

932RA316 VA

2,800 rpm with the low speed

screw (L).

2 1

5. Set maximum engine speed to

: On carburetors with a short 10,500 rpm with the high speed

limiter cap (1): Push the puller (2) screw (H).

5910 890 4501, with the groove

facing you, between the limiter Do not re-install used caps because

cap (1) and carburetor body and they may be damaged during the

pry the cap off. If the limiter cap is removal process. Always install a

stuck on the screw, turn the puller new limiter cap.

over so that its groove faces the

carburetor body. Pry off the

limiter cap.

H L

932RA317 VA

– Open the high speed screw (H)

1 1/2 turns counterclockwise.

– Open the low speed screw (L)

one full turn counterclockwise.

Series 4140 Components BG, SH 31

9.5 Tank Vent

9.5.1 General

Correct operation of the carburetor

is only possible if atmospheric

pressure and internal fuel tank

pressure are equal at all times. This

is ensured by the tank vent.

270° 270 In the event of trouble with the

carburetor or the fuel supply

system, always check the tank vent

249RA129 VA

392RA318 VA

and replace it if necessary.

Testing the tank vent

: On carburetors with a short : On carburetors with a long

limiter cap: limiter cap: – Open the tank cap slowly and

Line up the new cap for the high Line up the new cap for the high drain the tank. Refit the tank cap,

speed screw (H) against the rich speed screw (H) against the rich making sure it is tight.

stop and press it on only as far as stop so that the high speed

the second noticeable detent screw (H) can only be rotated a – Disconnect the fuel hoses from

position. 3/4 turn clockwise. the carburetor, b 9.2.2

The stop limits the adjustment : Push on the limiter cap until it – Seal one of the fuel hoses with a

range of the high speed screw (H) to butts against the carburetor body. suitable plug.

a 3/4 turn. Do not press the cap

against the carburetor body as it will Carry out standard setting, b 9.4.2 – Connect vacuum pump

otherwise be damage. 0000 850 3501 to the other fuel

hose and produce a vacuum in

– Carry out standard setting, the fuel tank by operating the

b 9.4.2 pump quickly.

– If the vacuum remains

unchanged, install a new tank

vent, b 9.5.2

If the vacuum slowly disappears,

the tank vent is in order.

32 Series 4140 Components BG, SH

9.5.2 Replacing 9.6 Fuel Tank

9.6.1 General

If no equalization of pressures takes Always use a new sealing ring. Fuel tank

place, replace the tank vent.

Install in the reverse sequence. The fuel tank is part of the inner fan

– Remove the filter housing, housing and cannot be replaced

b 9.1.1 separately.

If the fuel tank is damaged, replace

Note installed position of tank vent. the complete inner fan housing.

The diaphragm pump draws fuel out

of the tank and into the carburetor

via the fuel hose. Any impurities

mixed with the fuel are retained by

the pickup body (filter). The fine

pores of the filter eventually become

clogged with minute particles of dirt.

This restricts the passage of fuel

and results in fuel starvation.

Always observe all safety

precautions when working on the

fuel system, b 2.

In the event of trouble with the fuel

supply system, always check the

fuel tank and the pickup body first.

Clean the fuel tank if necessary.

1

932RA096 VA

Cleaning the fuel tank

2 – Unscrew the fuel filler cap and

drain the tank.

Machines up to 2002

– Pour a small amount of clean

: Pull out the tank vent (1). gasoline into the tank.

: Pull out the grommet (2). – Close the tank and shake the

machine vigorously.

Install in the reverse sequence.

– Open the tank again and drain it.

Dispose of fuel properly.

1

932RA321 VA

Machines from 2002

: Carefully pry out the tank vent (1)

with sealing ring (2).

Series 4140 Components BG, SH 33

9.6.2 Pickup Body 9.6.3 Fuel Hoses

– Unscrew the fuel filler cap and – Unscrew the spark plug.

drain the tank.

– Use locking strip 4221 893 5900

– Remove the fan housing with to block the piston.

rewind starter,

b 7.2 – Remove the blower tube and

elbow, b 10.4 and

– Remove the carburetor, b 9.2.2 b 10.6

– Remove the pickup body.

– Pull off the tank vent,

– Unscrew the fuel filler cap and b 9.5.2

drain the tank.

: Use hook (1) 5910 893 8800 to

pull the pickup body out of the

fuel tank.

932RA164 VA

: Pull the pickup body (1) off the : Pull out the fuel hoses (arrow). BG 55, 65, 85 only

fuel hose and check it for

contamination, replace if Note installed position. : Take out the screws and lift away

necessary. the outer fan housing.

Install in the reverse sequence.

Install in the reverse sequence. 932RA162 VA

: On BG 45, take out the screws

and lift away the outer fan

housing.

34 Series 4140 Components BG, SH

10. Blower and Vacuum 10.2 Protective Screen 10.3 Protective Screen

Attachment (all except BG 45) (BG 45 only)

10.1 Fanwheel

1 1 1

932RA163 VA

932RA161 VA

932RA166 VA

SH 55, 85 only SH units only : Take out the screws (1).

: Unscrew the star nut (1), take out – Remove suction tube, b 10.5 : Lift the right-hand side of the

the screws and lift away the outer protective screen so that it comes

fan housing. : Press down the retaining tab (1) out of the guide (2)

on the protective screen and

swing the screen open.

1 1

2

3

4

932RA165 VA

932RA167 VA

: Unscrew the nut (1) clockwise : Use a screwdriver or similar tool – Remove the protective screen.

(left-hand thread). to press down the retaining

tabs (1) on the outer fan housing : Before reinstalling, check the

: On SH 55, 85, remove the and lift away the protective seal (1) for damage and make

shredder blade (2). screen (2). sure it is properly seated.

: Remove the washer (3), Install in the reverse sequence.

fanwheel (4) and the washer

behind it. – Make sure the protective screen

engages in the guide.

– Inspect all blades and replace

fanwheel if necessary.

Install in the reverse sequence.

: Remove the torsion spring

(arrow).

Install in the reverse sequence.

Series 4140 Components BG, SH 35

10.4 Blower Tube (BG only) 10.5 Suction Tube (SH only) 10.6 Elbow (SH only)

932RA168 VA

932RA094 VA

: Insert a screwdriver or similar tool : Turn the suction tube : Loosen the star nut (1).

in the recess (arrow) on the counterclockwise as far as stop

blower stub and push the (1/4 turn). : Insert a screwdriver or similar tool

retaining tab up. in the recess (arrow) on the

– Pull the suction tube off the stub. blower stub and push the

– At the same time, turn the blower retaining tab up.

tube counterclockwise as far as To fit, open the protective screen.

stop (1/4 turn). – At the same time, turn the elbow

counterclockwise as far as stop

– Pull the blower tube off the stub. (1/4 turn).

– Fit by inserting blower tube with – Pull the elbow off the stub.

lug in the stub.

– Fit by inserting blower tube with

– Rotate the blower tube clockwise lug in the stub.

until the bayonet coupling

engages.

932RA169 VA

: Insert suction tube so that its : Check that rubber sealing ring

guide slots (arrow) engage the (arrow) is properly seated.

lugs (arrow) on the stub.

– Rotate elbow clockwise until the

– Rotate the suction tube clockwise bayonet coupling engages.

until the bayonet coupling

engages.

36 Series 4140 Components BG, SH

11. Special Servicing Tools

No. Part Name Part No. Application Rem.

1 Locking strip 4221 893 5900 Blocking crankshaft

2 Socket 0812 540 1112 Installing and removing spline socket

head screws with electric or pneumatic

screwdrivers

3 Vacuum pump 0000 850 3501 Testing crankcase and carburetor for

leaks, testing tank vent

4 Carburetor and crankcase tester 1106 850 2905 Testing crankcase and carburetor for

leaks

5 Nipple 0000 855 9200 Testing carburetor for leaks

6 Hose for leakage test 1110 141 8600 Testing carburetor for leaks

7 Screwdriver 5910 890 2420 Carburetor nuts

Q-SW 8 x 200

8 Crimping tool 5910 890 8210 Attaching connectors to electrical wires

9 Torque wrench 5910 890 0301 0.5 to 18 Nm 1) 2)

10 Torque wrench 5910 890 0311 6 to 80 Nm 1) 3)

11 Socket, T 27 x 125 0812 524 2104 Installing and removing spline socket

head screws with electric or pneumatic

screwdrivers, tightening with torque

wrench

12 T-handle screwdriver 5910 890 2400 IS screws 4)

Q - T 27 x 150

13 Hook 5910 893 8800 Removing pickup body

Remarks:

1) Always use torque wrench for tightening DG or P screws.

2) Alternative: Torque wrench 5910 890 0302 with optical/acoustic signal.

3) Alternative: Torque wrench 5910 890 0312 with optical/acoustic signal.

4) Only use for releasing/removing DG or P screws.

Series 4140 Components BG, SH 37

12. Servicing Aids

No. Part Name Part No. Application

1 Dirko gray sealant (100 g tube) 0783 830 2120 Guard on muffler

2 STIHL special lubricating oil 0781 417 1315 Bearing bore in rope rotor, rewind spring

3 Standard commercial, solvent- Cleaning sealing faces

based degreasant containing no

chlorinated or halogenated

hydrocarbons

38 Series 4140 Components BG, SH

Series 4140 Components BG, SH 39

40 Series 4140 Components BG, SH

englisch / English

0455 295 0123. M7. A5. Sä. Printed in Germany

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Stihl BG 45-85 SH 55-85 Service Manual PDFDocument42 pagesStihl BG 45-85 SH 55-85 Service Manual PDFBrianCook50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2002 Magnum 325 500 Service Manual 9917198Document429 pages2002 Magnum 325 500 Service Manual 9917198BrianCook100% (8)

- MS201T-Service Manual PDFDocument126 pagesMS201T-Service Manual PDFAfton Robert50% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Stihl MS 460 Chainsaw Service Manual PDFDocument94 pagesStihl MS 460 Chainsaw Service Manual PDFBrianCookNo ratings yet

- Keihin Carburetor TuningDocument2 pagesKeihin Carburetor TuningBrianCook0% (2)

- Toro Workman 2002-07 1100 1110 2100 2110 Service Manual PDFDocument194 pagesToro Workman 2002-07 1100 1110 2100 2110 Service Manual PDFBrianCook67% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stihl 020 T Chainsaw Service Manual PDFDocument58 pagesStihl 020 T Chainsaw Service Manual PDFBrianCookNo ratings yet

- Stihl 020 T Chainsaw Service Manual PDFDocument58 pagesStihl 020 T Chainsaw Service Manual PDFBrianCookNo ratings yet

- Fishing Tool ManualDocument152 pagesFishing Tool ManualDozie Kesieme100% (8)

- M1 Garand ManualDocument8 pagesM1 Garand Manualsutlerman100% (1)

- Arctic Cat 650 V2 BELT RESET PROCEDUREDocument1 pageArctic Cat 650 V2 BELT RESET PROCEDUREBrianCookNo ratings yet

- Aircraft Engine Rools-RoyceDocument40 pagesAircraft Engine Rools-RoyceShanmuga100% (9)

- CGDDocument2 pagesCGDPradeep AnejaNo ratings yet

- LPG Co-MinglingDocument17 pagesLPG Co-MinglingderhgawenrahulNo ratings yet

- 0001 - M25 - e KBB TC HPR6000 ModificationDocument3 pages0001 - M25 - e KBB TC HPR6000 ModificationAnshul AsthanaNo ratings yet

- Fox Podium RC3 Service ManualDocument22 pagesFox Podium RC3 Service ManualBrianCook100% (1)

- 1964-08 Z 50 Mini Trail Z 50 Service ManualDocument38 pages1964-08 Z 50 Mini Trail Z 50 Service ManualBrianCookNo ratings yet

- Fox Podium RC3 Service ManualDocument22 pagesFox Podium RC3 Service ManualBrianCook100% (1)

- Garand Bayonets PDFDocument7 pagesGarand Bayonets PDFab212amisarNo ratings yet

- Float X Evol Service ManualDocument24 pagesFloat X Evol Service ManualSohan PatelNo ratings yet

- FAST M10 Universal Mount Kit Instructions 07092008Document6 pagesFAST M10 Universal Mount Kit Instructions 07092008BrianCookNo ratings yet

- Stihl MS 460 Chainsaw Service ManualDocument10 pagesStihl MS 460 Chainsaw Service ManualBrianCookNo ratings yet

- Workshop ManualDocument52 pagesWorkshop ManualMarko ZgNo ratings yet

- Exmark Ultra Vac Operators & Parts Manual 103-4456Document40 pagesExmark Ultra Vac Operators & Parts Manual 103-4456BrianCookNo ratings yet

- Polyvance The BookDocument20 pagesPolyvance The BookBrianCookNo ratings yet

- Grasshopper Kohler Command 18 ConversionDocument9 pagesGrasshopper Kohler Command 18 ConversionBrianCookNo ratings yet

- 2007 Hawkeye Service Manual 9920795 PDFDocument432 pages2007 Hawkeye Service Manual 9920795 PDFBrianCook100% (1)

- Polyvance The BookDocument20 pagesPolyvance The BookBrianCookNo ratings yet

- Kawasaki FH451V-FH721V 2000 Service ManualDocument140 pagesKawasaki FH451V-FH721V 2000 Service ManualBrianCook100% (1)

- Kawasaki FH451V-FH721V 2003 Service Manual PDFDocument153 pagesKawasaki FH451V-FH721V 2003 Service Manual PDFBrianCookNo ratings yet

- Service Manual GN724 V-Twin PDFDocument56 pagesService Manual GN724 V-Twin PDFwassa53No ratings yet

- Everride KW2560Document122 pagesEverride KW2560BrianCookNo ratings yet

- Stihl MS 460 Chainsaw Service ManualDocument10 pagesStihl MS 460 Chainsaw Service ManualBrianCookNo ratings yet

- Stihl MS 460 Chainsaw Service ManualDocument10 pagesStihl MS 460 Chainsaw Service ManualBrianCookNo ratings yet

- 35 Electrical Safety SamanDocument32 pages35 Electrical Safety SamanSaman Sri Ananda RajapaksaNo ratings yet

- KOHASA ENGINEERING LINE SIZING CALCULATIONSDocument9 pagesKOHASA ENGINEERING LINE SIZING CALCULATIONSEkundayo JohnNo ratings yet

- Heavy Oil Drag Reducing Agent PDFDocument12 pagesHeavy Oil Drag Reducing Agent PDFMichael MedinaNo ratings yet

- Maxsym 400iDocument34 pagesMaxsym 400iadelelkadyNo ratings yet

- 01 Dedusting EquipmentDocument40 pages01 Dedusting Equipmentrudye kardunNo ratings yet

- Fire Safety SeminarDocument95 pagesFire Safety SeminarRalph CastilloNo ratings yet

- Om3 65 PDFDocument81 pagesOm3 65 PDFibrahemNo ratings yet

- DBM Service Vehicle CircularDocument5 pagesDBM Service Vehicle CircularAra Gayares GalloNo ratings yet

- IC Engine Notes Petrol Injection SystemDocument38 pagesIC Engine Notes Petrol Injection SystemNithinvpNo ratings yet

- Kta50-G3 0 PDFDocument3 pagesKta50-G3 0 PDFAlisabel Muñoz de Morales0% (1)

- Volvo ManualDocument141 pagesVolvo Manualrichieg7777No ratings yet

- Shriram PistonDocument46 pagesShriram Pistondeepak GuptaNo ratings yet

- GMC Motorhome Service BulletinsDocument363 pagesGMC Motorhome Service Bulletinsbilly_gfroerer100% (1)

- J616V01 enDocument4 pagesJ616V01 enMartin KratkyNo ratings yet

- EOR Methods GuideDocument109 pagesEOR Methods GuideKarwan DilmanyNo ratings yet

- Emulsion Fuel Technology in Combustion FurnacesDocument3 pagesEmulsion Fuel Technology in Combustion Furnacesvuongcoi102No ratings yet

- Questions CombustionDocument3 pagesQuestions CombustionKristian TarucNo ratings yet

- Sulphur Market Outlook: Is the 2017 Price Rally Here to StayDocument23 pagesSulphur Market Outlook: Is the 2017 Price Rally Here to StaysaeidNo ratings yet

- Determinant of Global Crude Oil Pricing Theoretical ReviewDocument10 pagesDeterminant of Global Crude Oil Pricing Theoretical ReviewibidaboNo ratings yet

- Multiphase Method For Converting WHP To BHPDocument7 pagesMultiphase Method For Converting WHP To BHPHichem FakhfekhNo ratings yet

- Introduction to Oil & Gas: Energy Sources and Future ProspectsDocument44 pagesIntroduction to Oil & Gas: Energy Sources and Future ProspectsRabiathul EleenaNo ratings yet

- John Deere Combine Belts - 7700Document4 pagesJohn Deere Combine Belts - 7700Volodymyr KuruchNo ratings yet

- Assignment 3Document3 pagesAssignment 3HARINo ratings yet

- Brochure Disp Century-Na Na enDocument8 pagesBrochure Disp Century-Na Na enJuan Gabriel Barbosa CepedaNo ratings yet

- Chapter 1-Basic Energy Concepts-HulscherDocument17 pagesChapter 1-Basic Energy Concepts-HulscherdgiagkouNo ratings yet