Professional Documents

Culture Documents

0 Shahzaib Usman Process Engineer

Uploaded by

ShahzaibUsman0 ratings0% found this document useful (0 votes)

8 views1 page0

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document0

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 page0 Shahzaib Usman Process Engineer

Uploaded by

ShahzaibUsman0

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Shahzaib Usman

Skilled Operations Engineer

engr.shahzaibpp@gmail.com https://goo.gl/Afgu9c

+92(343)2747076 engr.shahzaibpp

January 08, 1990 @engr_cap

Why Shahzaib Usman?

Highly dedicated and motivated professional with more than 3 years of experience as a Operation and Process engineer

with proven expertise in plant & console operations, DCS systems and gas compressors. Experienced professional,

displays high rate knowledge and expertise in improvement and developmental process

Seasoned engineer with strong management capabilities with a consistent track record of foreseeing potential issues,

initiating solutions and completing projects to specification on time. Detail-oriented with proven track record for

implementing strategies that enhance productivity and profitability

Process oriented individual effective in reorganizing, streamlining and strengthening engineering operations to

maximize performance; consistently develops and sustains cooperative working relationships as well as encourages and

facilitates cooperation within the organization

CORE STRENGTHS & ENABLING SKILLS

Process Engineering Plant Operations Reactor Troubleshoot

Gas Compressors DCS Systems Fuel Gas Production

Technical Report Environment, Health & Safety Planning

Writing

PROFESSIONAL EXPERIENCE

AuVitroniscs (pvt) Limited, Karachi, Pakistan

Working as “Process Engineer”, Nov 2016 - Present

Byco Oil Pakistan Limited, Hub Balochistan, Pakistan

Worked as “Trainee Operations Engineer”, February 2014 – February 2016

Responsibilities/Accomplishments:

Worked on Isomerization Unit 12.9 MBPD; performed Commissioning of unit thoroughly (chemical cleaning of all

process lines, catalyst loading and punch listing and evaluation of every equipment of the unit), optimization

operations along with increasing energy efficiency. Monitored reactor temperature RIT, troubleshooting and safety;

troubleshoot hydrogen ingress issues to downstream of Isomerization.

Monitored gas fuel & LPG production of gas plant. Administered handling of light & heavy Naphtha feed to Isom and

reformer respectively. Analyzed column profiles & lab results along with observing temperature & pressure levels of

deisohexanizer to ensure moisture level of light Naphtha is less than 1 ppm

Performed commissioning of Penex section of isomerization unit 12.9 MBPD by punch listing, hydro testing and air

blowing process lines. Performed molecular sieve loading in liquid and gas dryers, and master startup.

Prepared production reports along with results, and presentations on process upsets under the supervision of Shift

Engineer.

Conduct and prepare test papers and training of process of isomerization unit for operators.

PROFESSIONAL TRAININGS

Training on “DCS Systems”

Training on “Health, Safety & Environment”

PROFESSIONAL QUALIFICATION

NEBOSH IGC ( International General Certificate in Health, Safety and Environment )

NED University of Engineering & Technology, Karachi, Pakistan (April 2015)

Maintenance, Operation & Control of Industrial Plants - Certified Course

NED University of Engineering & Technology, Karachi, Pakistan (2010 – 2013)

B.E Chemical Engineering

628, Area 3-A, Landhi, Karachi, Pakistan

You might also like

- Road SafetyDocument1 pageRoad SafetyShahzaibUsmanNo ratings yet

- National Immunization Management System: Tracking ID: 100001468Document1 pageNational Immunization Management System: Tracking ID: 100001468aaaaaaaliNo ratings yet

- SC Exploration & ExpolitationDocument4 pagesSC Exploration & ExpolitationShahzaibUsmanNo ratings yet

- Business LetterDocument1 pageBusiness LetterShahzaibUsmanNo ratings yet

- Stock Control 16-05-2022 ChromeDocument2 pagesStock Control 16-05-2022 ChromeShahzaibUsmanNo ratings yet

- Osama Hussain COVID - CertificateDocument1 pageOsama Hussain COVID - CertificateShahzaibUsmanNo ratings yet

- Sadia Anwar: PHARM D (Doctor of Pharmacy)Document4 pagesSadia Anwar: PHARM D (Doctor of Pharmacy)ShahzaibUsmanNo ratings yet

- Task 1 Invitation LetterDocument1 pageTask 1 Invitation LetterShahzaibUsmanNo ratings yet

- High Lexis Words For Writing Task 2Document2 pagesHigh Lexis Words For Writing Task 2ShahzaibUsman100% (2)

- Vulgarity, A Grave Concern in Pakistan PDFDocument1 pageVulgarity, A Grave Concern in Pakistan PDFShahzaibUsmanNo ratings yet

- Formula 6 PDFDocument2 pagesFormula 6 PDFShahzaibUsmanNo ratings yet

- Discussin + Opinion, 12, Test 7Document1 pageDiscussin + Opinion, 12, Test 7ShahzaibUsmanNo ratings yet

- Task 1 Invite A Friend To New HomeDocument1 pageTask 1 Invite A Friend To New HomeShahzaibUsmanNo ratings yet

- Adventurous Trip To Mysterious Island PDFDocument1 pageAdventurous Trip To Mysterious Island PDFShahzaibUsmanNo ratings yet

- Trouble HistoryDocument7 pagesTrouble HistoryShahzaibUsmanNo ratings yet

- Sahil Verma, Problem Solution, TechnologyDocument1 pageSahil Verma, Problem Solution, TechnologyShahzaibUsmanNo ratings yet

- Formula 6 What Do You Like Most About X?Document2 pagesFormula 6 What Do You Like Most About X?ShahzaibUsmanNo ratings yet

- Quotation 3Document2 pagesQuotation 3ShahzaibUsmanNo ratings yet

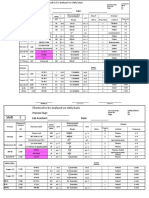

- Shift A: Process Engr: Lab Assistant: DateDocument3 pagesShift A: Process Engr: Lab Assistant: DateShahzaibUsmanNo ratings yet

- Sample Candidate Writing Scripts and Examiner Comments: Lexical ResourceDocument7 pagesSample Candidate Writing Scripts and Examiner Comments: Lexical ResourceShahzaibUsmanNo ratings yet

- Task 1 Request InfoDocument1 pageTask 1 Request InfoShahzaibUsmanNo ratings yet

- Task 1 Apology For Not Attending MeeringDocument1 pageTask 1 Apology For Not Attending MeeringShahzaibUsmanNo ratings yet

- Advantage Disadvantage Essay 12,1Document1 pageAdvantage Disadvantage Essay 12,1ShahzaibUsman100% (1)

- Sahil Double Question Large CitiesDocument1 pageSahil Double Question Large CitiesShahzaibUsmanNo ratings yet

- Ammar Enterprises - : Debit NoteDocument1 pageAmmar Enterprises - : Debit NoteShahzaibUsmanNo ratings yet

- Prize You Would Like To WinDocument1 pagePrize You Would Like To WinShahzaibUsmanNo ratings yet

- TFNG Test 6Document4 pagesTFNG Test 6ShahzaibUsmanNo ratings yet

- Shahzaib Usman Process Engineer Chrome Plating Date 05/01/2019Document4 pagesShahzaib Usman Process Engineer Chrome Plating Date 05/01/2019ShahzaibUsmanNo ratings yet

- O 2 2019 2Document1 pageO 2 2019 2ShahzaibUsmanNo ratings yet

- Career Opportunities: Senior Medical Officer (SPS-9)Document2 pagesCareer Opportunities: Senior Medical Officer (SPS-9)Aamir AbbasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document28 pagesSelf-Instructional Manual (SIM) For Self-Directed Learning (SDL)Monique Dianne Dela VegaNo ratings yet

- Two 2 Page Quality ManualDocument2 pagesTwo 2 Page Quality Manualtony sNo ratings yet

- ARISE 2023: Bharati Vidyapeeth College of Engineering, Navi MumbaiDocument5 pagesARISE 2023: Bharati Vidyapeeth College of Engineering, Navi MumbaiGAURAV DANGARNo ratings yet

- Nasoya FoodsDocument2 pagesNasoya Foodsanamta100% (1)

- Manulife Health Flex Cancer Plus Benefit IllustrationDocument2 pagesManulife Health Flex Cancer Plus Benefit Illustrationroschi dayritNo ratings yet

- Hyundai Himap BcsDocument22 pagesHyundai Himap BcsLim Fung ChienNo ratings yet

- Sena BrochureDocument5 pagesSena BrochureNICOLAS GUERRERO ARANGONo ratings yet

- M70-700 4th or 5th Axis Install ProcedureDocument5 pagesM70-700 4th or 5th Axis Install ProcedureNickNo ratings yet

- 8524Document8 pages8524Ghulam MurtazaNo ratings yet

- Management Interface For SFP+: Published SFF-8472 Rev 12.4Document43 pagesManagement Interface For SFP+: Published SFF-8472 Rev 12.4Антон ЛузгинNo ratings yet

- Analysis of Brand Activation and Digital Media On The Existence of Local Product Based On Korean Fashion (Case Study On Online Clothing Byeol - Thebrand)Document11 pagesAnalysis of Brand Activation and Digital Media On The Existence of Local Product Based On Korean Fashion (Case Study On Online Clothing Byeol - Thebrand)AJHSSR JournalNo ratings yet

- Pharmaceutical Microbiology NewsletterDocument12 pagesPharmaceutical Microbiology NewsletterTim SandleNo ratings yet

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentDocument7 pagesA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiNo ratings yet

- Brand Guidelines Oracle PDFDocument39 pagesBrand Guidelines Oracle PDFMarco CanoNo ratings yet

- Options Trading For Beginners Aug15 v1Document187 pagesOptions Trading For Beginners Aug15 v1Glo BerriNo ratings yet

- Giuliani Letter To Sen. GrahamDocument4 pagesGiuliani Letter To Sen. GrahamFox News83% (12)

- Mathematics 2 First Quarter - Module 5 "Recognizing Money and Counting The Value of Money"Document6 pagesMathematics 2 First Quarter - Module 5 "Recognizing Money and Counting The Value of Money"Kenneth NuñezNo ratings yet

- On Applied EthicsDocument34 pagesOn Applied Ethicsamanpatel78667% (3)

- Oddball NichesDocument43 pagesOddball NichesRey Fuego100% (1)

- Certification DSWD Educational AssistanceDocument3 pagesCertification DSWD Educational AssistancePatoc Stand Alone Senior High School (Region VIII - Leyte)No ratings yet

- Payment Plan 3-C-3Document2 pagesPayment Plan 3-C-3Zeeshan RasoolNo ratings yet

- To Syed Ubed - For UpdationDocument1 pageTo Syed Ubed - For Updationshrikanth5singhNo ratings yet

- Bench VortexDocument3 pagesBench VortexRio FebriantoNo ratings yet

- Ewellery Ndustry: Presentation OnDocument26 pagesEwellery Ndustry: Presentation Onharishgnr0% (1)

- Completed NGC3 ReportDocument4 pagesCompleted NGC3 ReportTiCu Constantin100% (1)

- Common OPCRF Contents For 2021 2022 FINALE 2Document21 pagesCommon OPCRF Contents For 2021 2022 FINALE 2JENNIFER FONTANILLA100% (30)

- Typical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpDocument2 pagesTypical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpSabrinadeFeraNo ratings yet

- Planas V Comelec - FinalDocument2 pagesPlanas V Comelec - FinalEdwino Nudo Barbosa Jr.100% (1)

- Sigma Valve 2-WayDocument2 pagesSigma Valve 2-WayRahimNo ratings yet

- Harga H2H Pula-Paket Data - Saldo EWallet v31012022Document10 pagesHarga H2H Pula-Paket Data - Saldo EWallet v31012022lala cemiNo ratings yet