Professional Documents

Culture Documents

V Series Brochure PDF

Uploaded by

ShirkhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V Series Brochure PDF

Uploaded by

ShirkhanCopyright:

Available Formats

V - SERIES

SCREW COMPRESSOR PACKAGES

V-SERIES

SPECIFICATIONS CFM R-717 (See NOTE 1) DIMENSIONS

MODEL# Dsipl. Cap-TR Power-BHP L H W WEIGHT

160 VSD 294 109 122 121 74 44 4300

160 VMD 367 136 147 122 74 44 4500

160 VLD 441 164 174 124 74 44 4800

200 VSD 574 216 236 141 83 52 6700

200 VMD 718 272 287 143 83 52 6900

200 VLD 859 328 340 151 90 57 8300

250 VSD 1120 426 446 159 98 59 10500

250 VMD 1400 538 551 184 107 65 14400

H

250 VLD 1670 643 658 190 107 65 15200

250 VLLD 1980 762 779 199 110 65 16200

320 VSD 2250 862 899 206 124 72 20200

320 VMD 2800 1075 1111 226 127 79 25600

W L 320 VLD 3350 1291 1303 226 127 79 27300

400 SUD 4590

400 MUD 5700 PLEASE CONSULT YOUR NEAREST MYCOM OFFICE.

400 LUD 6890

400 LLUD 8120

Notes:

V SERIES COMPRESSOR FEATURES 1.Rating

Ratingbasis:

basis:R-717,

R-717,3550

3550RPM,

RPM,thermosiphon

thermosiphonoiloilcooling,

cooling,+20

+20FF(-6.7

(-6.7C)

C)

OPTIONS RANGE evaporating

evaporating temprature,95

temeprature, 95FF(35

(35C)

C)condensing

condensingtemperature,

temperature,1010FF(5.5

(5.5C)

C)

liquid

liquid

subcooling

subcoolingand

and

00FFsuction

suction

superheat.

superheat.

00Psi

Psipressure

pressuredrop,

drop,

without

without

Models from 160mm (249 CFM) to 400mm (8120 useuseofof

the

the

economizer

economizerport.

port.

REFRIGERANTS CFM)

Halocarbon refrigerant applications HOUSING 2.Physical

Physicaldata

databased

basedononoil

oilseparator,

separator,suction

suctionvalve

valvetrain

trainand

anddischarge

discharge

valve

valve

train

train

designed

designed

forfor

operation

operationatat

-50

-50

FF<<Tevap

Tevap<<+20+20

F Fand

and

8585

FF<<

Low porosity Cast Iron, ANSI/ASHRAE STD. 15, Tcond

Tcond<<105105

FF

ECONOMIZER hydraulically tested at 470 Psig after assembly

3.Each

Eachcompressor

compressorisisavailable

availablewith a shorter

at 89% rotor (89%)

of standard to meet

capacity withfit

to better

Shell and tube economizer including all BEARING motor

smaller

sizecapacity and less breaker horse power. The model becomes a

controls. Radial bearings are steel backed babbitted sleeve V*DS

ie. Model

which160VSDS

will have has

a capacity

a capacity

of 89%

of 89%

of a of

standard

160VSD compressor

with reduced

in the

BHP

type. Thrust bearings are angular contact ball * Consult

same frame

factory

size.

for*Consult

specific rating

factory with specific rating.

Economizer or Side Load control valve

bearings with oversized balanced piston.

station with back pressure regulator. 4.Consult

Consultfactory

factoryfor

forliquid

liquidinjection

injectionratings

ratingsand

anddimensions

dimensions

ROTOR PROFILE

5.All

All information

information isis subject

subject to

to change

change until

until final

final unit

unit design

design isis completed

completed for

for a

Mycom “O” profile reduces the rotor interlobe gas

OIL FILTERS blow-by and improves sealing oil film on rotor

a given application and specs.

Dual oil filters and pumps surface by use of a circular arc profile rather than

OIL FILTRATION

the conventional sealing edge.

The filter prior to the oil pump is a cleanable, 300

OIL CHARGING VARIABLE Vi mesh, stainless steel strainer. The pumped oil filter

Mycom synthetic lubricant MYCOLD The internal volume ratio (Vi) may be manually protecting the compressor bearings is a 20 micron

SCREW COMPRESSOR PACKAGES

AB-68. adjusted from 2.6 to 5.8 (2.2 to 5.0 as an option) to replaceable cartridge filter.

provide the lowest power consumption for any given

Oil charge valve with 20 mesh strainer. OIL COOLING

application.

Three methods are available as standard:

CAPACITY CONTROL thermosiphon, water cooled and liquid injection.

OIL COOLER

A hydraulically operated slide valve regulates the Other cooling methods are available as an option.

PHE oil cooler

V - SERIES

compressor capacity from 30% to 100% of full load

Stainless steel tubes in oil cooler OIL TEMPERATURE CONTROL

with improved part load performance.

Thermosiphon and water cooled units include a self

Air cooled oil cooler

V SERIES UNIT FEATURES actuated oil temperature control valve. Liquid

Glycol oil cooling system LUBRICATION SYSTEM injection units include an electric control valve

Force feed lube system with a full time pump for actuated by the Mycom MYPRO CP-IV panel to

OIL SEPARATOR bearing lubrication and capacity control actuation. control discharge temperature across the entire

Vertical oil separator Oil injection for cooling and sealing is accomplished operating range.

350 Psig DWP oil separator without the use of the oil pump, except for low SUCTION STRAINER

pressure differential conditions. 100 MESH, 3 layer design for protection against

Short length unit for trailer mounting

OIL SEPARATOR collapsing, self cleaning, cone type.

ARRANGEMENT

Horizontal, three stage oil separation system with CONTROL PANEL

serviceable coalescing type elements in the final Mycom MYPRO CP-IV, NEMA 4, UL listed control

Low temperature suction valve train stage. Designed, fabricated and tested to ASME panel with graphical color display, user friendly

(below -50 F) Sct. VIII for 300 Psig DWP. Each unit is supplied keypad and RS-485 communication port for use with

Dual screw compressor arrangement with ASME pressure relief valves rated per MODBUS ASCII or RTU protocol.

Remote control panel ANSI/ASHRAE 15.

ECONOMIZER

PLC control panel OIL PUMP Factory mounted economizer with all controls or just

Mycom double helical, direct drive, screw oil pump the economizer control valve station are available

with integral pressure regulator for reliable, efficient options.

and quiet operation.

NORTH AMERICAN GROUP

www.mycomus.com / www.mycomcanada.com

Torrance, CA Tel: (310) 328-1362 Fax: (310) 782-6759 (Canada)

Modesto, CA Tel: (209) 545-9752 Fax: (209) 545-3654 Vancouver, BC Tel: (604) 270-1544 Fax: (604) 270-9870

San Antonio, TX Tel: (210) 599-4536 Fax: (210) 599-4538 Toronto, ON Tel: (905) 564-0664 Fax: (905) 564-7614

York, PA Tel: (717) 779-0138 Fax: (717) 779-0109

Montvale, NJ Tel: (201) 307-9199 Fax: (201) 307-1566

Seattle, WA Tel: (206) 284-9280 Fax: (206) 284-7230

You might also like

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- KWBF186 V 2 RecoscrewcompspecsDocument2 pagesKWBF186 V 2 RecoscrewcompspecsTIENDINHNo ratings yet

- Gate Valve: (Waterworks and Waste Water)Document2 pagesGate Valve: (Waterworks and Waste Water)Naing TunNo ratings yet

- ZDLP、M电动调节阀 DLC 中英文Document4 pagesZDLP、M电动调节阀 DLC 中英文delux5824No ratings yet

- Range: Af CompressorsDocument2 pagesRange: Af CompressorsMatthew MhlongoNo ratings yet

- SIMCo Valve PDFDocument8 pagesSIMCo Valve PDFPedro EscarráNo ratings yet

- Deogiri-583112, Sandur, Bellary, Karnataka.: (ML No. 2580 & ML No. 2581)Document30 pagesDeogiri-583112, Sandur, Bellary, Karnataka.: (ML No. 2580 & ML No. 2581)Biju SebastianNo ratings yet

- Technical Data: Main Features and MaterialsDocument2 pagesTechnical Data: Main Features and MaterialsZeeshanNo ratings yet

- Wedge Belts Veco 200 Dynam System: ST - API - ISO 4184 - DIN 7753 - BS 3790Document2 pagesWedge Belts Veco 200 Dynam System: ST - API - ISO 4184 - DIN 7753 - BS 3790Alexandre GelsiNo ratings yet

- Gas BurnersDocument313 pagesGas Burnersferagur11No ratings yet

- JUNE OdsDocument165 pagesJUNE OdsRellyne SeradNo ratings yet

- Sprocket For Forged Chains (Drive End)Document1 pageSprocket For Forged Chains (Drive End)Irfan MahyunisNo ratings yet

- 10 - Accesorios de Los Transformadores (Parte2)Document63 pages10 - Accesorios de Los Transformadores (Parte2)LOURDES JANNETH LIMON ROMERONo ratings yet

- 6BTA5.9 133 HP CumminsDocument2 pages6BTA5.9 133 HP CumminsHendra Syalala100% (1)

- Pontoon E60306 AssemblyDocument4 pagesPontoon E60306 AssemblyVal Dimla100% (1)

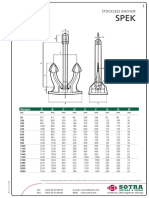

- Stockless Anchor: Weight A B C D E F G H ØDocument2 pagesStockless Anchor: Weight A B C D E F G H ØBagusNo ratings yet

- Comparacion de CentrifugasDocument1 pageComparacion de CentrifugasRicardo VillarNo ratings yet

- Bucket Elevator - Lachenmeier MonsunDocument2 pagesBucket Elevator - Lachenmeier MonsunAnonymous lu0Bn8WXNo ratings yet

- Monthly ReportDocument16 pagesMonthly ReportAnudeep KumarNo ratings yet

- Anchor Chain Eqpt NoDocument2 pagesAnchor Chain Eqpt NoSusmita SahaNo ratings yet

- Model: HANDWHEEL (Non-Rising Stem)Document2 pagesModel: HANDWHEEL (Non-Rising Stem)shyamNo ratings yet

- Fenner Wedge Belts PDFDocument2 pagesFenner Wedge Belts PDFNagendira PrabuNo ratings yet

- RMD For EmaarDocument61 pagesRMD For Emaaraliengineer953No ratings yet

- Engine Controls and Fuel - 4.3LDocument168 pagesEngine Controls and Fuel - 4.3Lluis eduardo corzo enriquezNo ratings yet

- 7-44-0022 Rev 1Document1 page7-44-0022 Rev 1Appandai SureshNo ratings yet

- 6B5.9-C (CPR252)Document2 pages6B5.9-C (CPR252)Dennis K ThomasNo ratings yet

- Downloadfile 18Document1 pageDownloadfile 18dhimozaNo ratings yet

- Aveo 2009 PDFDocument121 pagesAveo 2009 PDFEdwin Peña Pinto100% (1)

- VODCDocument2 pagesVODCVineet Maheshwari100% (1)

- Transformer Applications PDFDocument18 pagesTransformer Applications PDFtoots guiaoNo ratings yet

- Specifications: Limitorque MX Selection DataDocument18 pagesSpecifications: Limitorque MX Selection DatamarklaforestNo ratings yet

- Impulse Voltage Generators 500 KV Up To 2400 KV - Series M: Data Sheet 3.13/3Document4 pagesImpulse Voltage Generators 500 KV Up To 2400 KV - Series M: Data Sheet 3.13/3sazidzubaerNo ratings yet

- Draft Press Part CMPVDocument9 pagesDraft Press Part CMPVSutan PasaribuNo ratings yet

- Pulley DetailsDocument2 pagesPulley DetailsKristin FitzpatrickNo ratings yet

- KEC - Price List CablesDocument8 pagesKEC - Price List CablesSCM ASA BHANUNo ratings yet

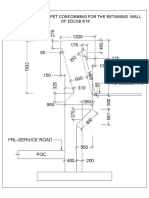

- Dimension of Parapet Conforming For The Retaining Wall of Edcsb R18Document1 pageDimension of Parapet Conforming For The Retaining Wall of Edcsb R18Rachit AgrawalNo ratings yet

- AVK Butterfly Valves Centric 820 - TADocument2 pagesAVK Butterfly Valves Centric 820 - TANam Nguyễn ĐứcNo ratings yet

- ZhvsiDocument2 pagesZhvsiJose PirulliNo ratings yet

- Captiva - Engine Controls and Fuel - 2.4LDocument177 pagesCaptiva - Engine Controls and Fuel - 2.4Lhskv20025525100% (1)

- 9.0-8 Fuses-Medium Voltage: Technical Ratings (Continued)Document3 pages9.0-8 Fuses-Medium Voltage: Technical Ratings (Continued)Ruben PachoNo ratings yet

- SW 1003398 NEC Article 311 Medium Voltage Conductors and Cables White Paper LODocument8 pagesSW 1003398 NEC Article 311 Medium Voltage Conductors and Cables White Paper LOwmkaneNo ratings yet

- Data SheetDocument1 pageData SheetaxelfredyNo ratings yet

- DAMEA FWW-VC TechnicalDocument1 pageDAMEA FWW-VC TechnicalRawingNo ratings yet

- Abb - Comem - Crs - Bucha SecaDocument2 pagesAbb - Comem - Crs - Bucha SecaPedro CoelhoNo ratings yet

- Lgh-Rvx-E - Pi 2022Document3 pagesLgh-Rvx-E - Pi 2022dineshverma.dce1No ratings yet

- Temperature Versus Resistance: °C °F OhmsDocument177 pagesTemperature Versus Resistance: °C °F OhmsMilton EncaladaNo ratings yet

- AVK Butterfly Valves Centric 75 - TADocument1 pageAVK Butterfly Valves Centric 75 - TANam Nguyễn ĐứcNo ratings yet

- Allowable Nozzle LoadsDocument5 pagesAllowable Nozzle LoadsPradeepaNo ratings yet

- Voltage Peak Limiter Load Vs Power Tables FP+ Series: Dedicated Touring AmplifiersDocument2 pagesVoltage Peak Limiter Load Vs Power Tables FP+ Series: Dedicated Touring AmplifiersDimosthenis MarinidisNo ratings yet

- Crown Shackle Type-RDocument1 pageCrown Shackle Type-RPRAJESH TVNo ratings yet

- Catalog 5Document7 pagesCatalog 5Ashirvad RathNo ratings yet

- Dongmi Catalog 03.04.20Document29 pagesDongmi Catalog 03.04.20Adonis TabiosNo ratings yet

- 152 en 1Document15 pages152 en 1Стефан БогдановићNo ratings yet

- MATIERE Unibridge Technical SpecificationsDocument2 pagesMATIERE Unibridge Technical SpecificationsFadel MuhammadNo ratings yet

- Denyo DCA 150-600kva Specification TableDocument1 pageDenyo DCA 150-600kva Specification TablejerryNo ratings yet

- Technical Datasheet: Brands You TrustDocument6 pagesTechnical Datasheet: Brands You TrustLuis Daniel ContrerasNo ratings yet

- Pages From LVPED308005EN-4Document7 pagesPages From LVPED308005EN-4Ashirvad RathNo ratings yet

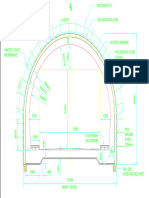

- Tunnel Cross SectionDocument1 pageTunnel Cross SectionYasir RahmanNo ratings yet

- AFK & AFQ-Series: Axial FanDocument12 pagesAFK & AFQ-Series: Axial FanAngga SenjayaNo ratings yet

- S 15 PDFDocument1 pageS 15 PDFShirkhanNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- API 610 BrochureDocument2 pagesAPI 610 Brochuredave381dNo ratings yet

- Codes & Standards For Natural GasDocument13 pagesCodes & Standards For Natural Gasharikrishnanpd3327No ratings yet

- Ip 68Document1 pageIp 68mrhomNo ratings yet

- FMP Rev 1 (G1-NT-PLNX0000272Document86 pagesFMP Rev 1 (G1-NT-PLNX0000272ShirkhanNo ratings yet

- FMP Rev 1 (G1-NT-PLNX0000272Document86 pagesFMP Rev 1 (G1-NT-PLNX0000272ShirkhanNo ratings yet

- PC-Bedienungsanleitung Heater enDocument33 pagesPC-Bedienungsanleitung Heater enZoran Tanja JarakovićNo ratings yet

- Development of SandDocument53 pagesDevelopment of Sandwondifraw girmaNo ratings yet

- Composites enDocument20 pagesComposites enpolymer_foam100% (1)

- C10129004 PDFDocument20 pagesC10129004 PDFChristopherNo ratings yet

- Nuova Fima MGS18 - 63mmDocument2 pagesNuova Fima MGS18 - 63mmPaweł HejmowskiNo ratings yet

- Chapter 11 - Industry and ManufacturingDocument36 pagesChapter 11 - Industry and ManufacturingNolan NelsonNo ratings yet

- Iso 2528Document8 pagesIso 2528nisa nurhidayatiNo ratings yet

- Appleton Sellos VerticalesDocument2 pagesAppleton Sellos VerticalesArq. Giovanni LopezNo ratings yet

- ATG System Introducton DetailDocument6 pagesATG System Introducton DetailNenad NikolićNo ratings yet

- Amercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsDocument4 pagesAmercoat 37-B-1 / 37-G-1: Product Data/ Application InstructionsTony KhouryNo ratings yet

- Emd NotesDocument182 pagesEmd Notesvpzfaris0% (1)

- Drveni Zidovi PDFDocument35 pagesDrveni Zidovi PDFMartinJankovićNo ratings yet

- M606 CAD Module 3Document6 pagesM606 CAD Module 3jobingpNo ratings yet

- Vice President Operations in Somerville NJ Resume Vasu MohanDocument3 pagesVice President Operations in Somerville NJ Resume Vasu MohanVasumohanNo ratings yet

- Methodology For Design Process of A Snap-Fit JointDocument6 pagesMethodology For Design Process of A Snap-Fit JointGhenal RiveraNo ratings yet

- Aplikasi Teknologi Pengolahan Air Asin Desa Tarupa Kecamatan Taka Bonerate Kabupaten SelayarDocument15 pagesAplikasi Teknologi Pengolahan Air Asin Desa Tarupa Kecamatan Taka Bonerate Kabupaten SelayarChrist ManapaNo ratings yet

- Ce04014 QaDocument49 pagesCe04014 QaekaamfNo ratings yet

- Whirlpool Arg 773 Service ManualDocument9 pagesWhirlpool Arg 773 Service ManualkrisgoNo ratings yet

- W7 Smith CapacitorsDocument31 pagesW7 Smith CapacitorsyjandeNo ratings yet

- Fiberfrax Ceramic Fiber Paper: Product Information SheetDocument4 pagesFiberfrax Ceramic Fiber Paper: Product Information SheetbowoNo ratings yet

- Stress Strain ModelDocument3 pagesStress Strain ModelKtk ZadNo ratings yet

- Curriculum Vitae: John AyengahDocument3 pagesCurriculum Vitae: John Ayengahjohn ayengahNo ratings yet

- ChE 103 Syllabus PDFDocument2 pagesChE 103 Syllabus PDFnadimNo ratings yet

- Synthesis and Analysis of A Coordination CompoundDocument3 pagesSynthesis and Analysis of A Coordination CompoundDozdi67% (6)

- Four Stroke Diesel EngineDocument17 pagesFour Stroke Diesel Engineamirsyawal87No ratings yet

- Slurry Pump The KproDocument11 pagesSlurry Pump The Kpro4lk0nNo ratings yet

- Dept of Chemistry 18CHE12/22 Sai Vidya Institute of TechnologyDocument22 pagesDept of Chemistry 18CHE12/22 Sai Vidya Institute of TechnologyshreyaNo ratings yet

- Owner's Manual: Downloaded From Manuals Search EngineDocument12 pagesOwner's Manual: Downloaded From Manuals Search EnginegragrNo ratings yet

- Astm D323 - 1999Document10 pagesAstm D323 - 1999Teymur RegenmaisterNo ratings yet

- Composites Knowledge Competition AnswersDocument13 pagesComposites Knowledge Competition AnswersAhmed Akram AlkhashabNo ratings yet