Professional Documents

Culture Documents

Experiment 6 Hydraulics Lab

Uploaded by

AuzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment 6 Hydraulics Lab

Uploaded by

AuzaCopyright:

Available Formats

Hydraulics Lab (ECIV 3122) Islamic University – Gaza (IUG)

Experiment (6): Flow over weirs

Introduction:

In open channel hydraulics, weirs are commonly used to either regulate or to measure the

volumetric flow rate, they are of particular use in large scale situations such as irrigation schemes,

canals and rivers. For small scale applications, weirs are often referred to as notches and invariably

are sharp edged and manufactured from thin plate material.

Purpose:

To investigate the discharge-head characteristics of a rectangular and triangular weirs.

Apparatus:

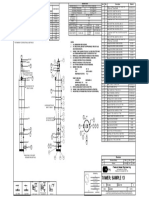

1. Rectangular and triangular notches (Figure 2).

2. Hydraulic bench.

3. Basket of glass spheres.

Figure 1: Flow over weirs apparatus

1 Instructors : Dr. Khalil M. Alastal Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122) Islamic University – Gaza (IUG)

Figure 2: Rectangular and triangular notches

Equipment set up:

1. Place the flow stilling basket of glass spheres into the left end of the weir channel and attach

the hose from the bench regulating valve to the inlet connection into the stilling basket.

2. Remove the five thumb nuts which hold the standard weir in place, remove the standard weir

and replace it with the specific weir plate which is to be tested first. Ensure that the square

edge of the weir faces upstream.

A) Flow measurement : The discharge from the weir may be measured using either the rotameter

(if fitted) or by using the volumetric measuring tank and taking the time required to collect a

quantity of water. The quantity should be chosen so that the time to collect the water is at least

120 seconds to obtain a sufficiently accurate result.

B) Measuring the weir datum : Fill the weir channel with water up to the weir plate crest level

and use the hook gauge to measure the level of the water. This will be the zero or datum level for

the weir.

C) Measuring the head : The surface of the water as it approaches the weir will fall, this is

particularly noticeable at high rates of discharge caused by high heads. To obtain an accurate

measure of the undisturbed water level above the crest of the weir it is necessary to place the

hook gauge at a distance at least three times the head.

2 Instructors : Dr. Khalil M. Alastal Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122) Islamic University – Gaza (IUG)

Figure 3: Rectangular and triangular weirs

Theory:

1. Flow through a rectangular notch

A rectangular notch in a thin square edged weir plate installed in a weir channel as shown in figure

4.

Figure 4: Rectangular notch

Consider the flow in an element of height at a depth below the surface. Assuming that the flow is

everywhere normal to the plane of the weir and that the free surface remains horizontal up to the

plane of the weir, then

Velocity through element

Theoretical discharge through element

Integrating to obtain the total discharge between and

3 Instructors : Dr. Khalil M. Alastal Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122) Islamic University – Gaza (IUG)

Total theoretical discharge

In practice the flow through the notch will not be parallel and therefore will not be normal to the

plane of the weir. The free surface is not horizontal and viscosity and surface tension will have an

effect. There will be a considerable change in the shape of the nappe as it passes through the notch

with curvature of the stream lines in both vertical and horizontal planes as indicated in figure 5, in

particular the width of the nappe is reduced by the contractions at each end.

Figure 5: Shape of a nappe

The discharge from a rectangular notch will be considerably less, approximately 60% of the

theoretical analysis due to these curvature effects. A coefficient of discharge is therefore introduced

so that:

2. Flow through a triangular notch

A sharp edged triangular notch with an included angle of is shown in figure 6.

4 Instructors : Dr. Khalil M. Alastal Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122) Islamic University – Gaza (IUG)

Figure 6: Triangular notch

Again consider an element of height at a depth

Breadth of element

Hence area of element

Velocity through element

Discharge through element

Integrating to obtain the total discharge between and

Again, a coefficient of discharge has to be introduced.

The triangular notch has advantages over the rectangular notch since the shape of the nappe does

not change with head so that the coefficient of discharge does not vary so much. A triangular notch

can also accommodate a wide range of flow rates.

5 Instructors : Dr. Khalil M. Alastal Eng. Mohammed Y. Mousa

Hydraulics Lab (ECIV 3122) Islamic University – Gaza (IUG)

Procedures:

1. Start the pump and slowly open the bench regulating valve until the water level reaches the

crest of the weir and measure the water level to determine the datum level.

2. Adjust the bench regulating valve to give the first required head level of approximately 10mm.

Measure the flow rate using the volumetric tank or the rotameter. Observe the shape of the

nappe.

3. Increase the flow by opening the bench regulating valve to set up heads above the datum level

in steps of approximately 10mm until the regulating valve is fully open. At each condition

measure the flow rate and observe the shape of the nappe.

4. Close the regulating valve, stop the pump and then replace the weir with the next weir to be

tested. Repeat the test procedure.

Results:

1. Record the results on a copy of the results sheet. Record any observations of the shape and type

of nappe paying particular attention to whether the nappe was clinging or sprung clear, and of

the end contraction and general change in shape.

2. Plot a graph of against for each weir. Measure the slopes and the intercepts. Calculate the

coefficient of discharge from the intercept and confirm that the slope is approximately 2.5 for

the rectangular notch and 1.5 for the triangular notch.

Trials 1 2 3

(mm)

(L)

(sec)

(m3/s)

6 Instructors : Dr. Khalil M. Alastal Eng. Mohammed Y. Mousa

You might also like

- Experiment 6 Hydraulics LabDocument6 pagesExperiment 6 Hydraulics LabTinaNo ratings yet

- Experiment 5 PDFDocument8 pagesExperiment 5 PDFTatendaNo ratings yet

- Measure Flow Using Venturi, Orifice & RotameterDocument10 pagesMeasure Flow Using Venturi, Orifice & Rotameterحاتم الشمرانيNo ratings yet

- Flow Over WeirsDocument13 pagesFlow Over WeirsAkmalhakim Zakaria100% (4)

- Lab HandoutDocument9 pagesLab HandoutlitrakhanNo ratings yet

- Flow of Water by Notch and WeirsDocument17 pagesFlow of Water by Notch and WeirsMuhammad Zulhusni Che RazaliNo ratings yet

- OrificeDocument7 pagesOrificePrasillaPrisiNo ratings yet

- Open Channel Flow 3711Document3 pagesOpen Channel Flow 3711Fearless HeroNo ratings yet

- Tilting Bed Type Hydraulic Flume (Closed Circuit) Adjustable ChannelDocument20 pagesTilting Bed Type Hydraulic Flume (Closed Circuit) Adjustable ChannelJoy BhattacharyaNo ratings yet

- FLOW OVER WEIRS EXPERIMENTDocument13 pagesFLOW OVER WEIRS EXPERIMENTIwuoha Maxrofuzo ChibuezeNo ratings yet

- Weir Experiments.02Document14 pagesWeir Experiments.02alex100% (2)

- Flow of Water by Notch and WeirsDocument15 pagesFlow of Water by Notch and WeirsCik Tiem Ngagiman93% (29)

- Doe Hydraulics EngineeringDocument30 pagesDoe Hydraulics EngineeringMaster Pits100% (1)

- ExperimentDocument7 pagesExperimentShekharNo ratings yet

- Hydraulics Laboratory ManualDocument37 pagesHydraulics Laboratory ManualHarold Taylor100% (2)

- Fluid Mechanics Sessional CE 262Document28 pagesFluid Mechanics Sessional CE 262মোঃমেহেদী হাসান শরীফNo ratings yet

- BLANKADocument15 pagesBLANKADev jibreenNo ratings yet

- Free and Forced VortexDocument8 pagesFree and Forced Vortexsmh khanNo ratings yet

- Department of Mechanical and Industrial TechnologyDocument20 pagesDepartment of Mechanical and Industrial TechnologyMPHILWENHLE JELENo ratings yet

- FM Lab ManualDocument76 pagesFM Lab ManualsidharthNo ratings yet

- Flow of Water by Notch and WeirsDocument15 pagesFlow of Water by Notch and WeirsAngelica Joyce BenitoNo ratings yet

- Falling Head Permeability Lab TestDocument6 pagesFalling Head Permeability Lab TestHamierul MohamadNo ratings yet

- Lab Expt 04 - Investigation of Forced VorticesDocument5 pagesLab Expt 04 - Investigation of Forced VorticesGIANNE MARIE AZURINNo ratings yet

- Study Surface Shape Forced Vortex FlowDocument12 pagesStudy Surface Shape Forced Vortex FlowSaravin SelhvaduraiNo ratings yet

- Manuals He Lab ManalsDocument146 pagesManuals He Lab ManalsNIKHIL DHIMANNo ratings yet

- 10.open ChannelDocument23 pages10.open ChannelNani DeramanNo ratings yet

- Experimental Investigation of Pressure Distribution On A Rectangular Tank Due To The Liquid SloshingDocument14 pagesExperimental Investigation of Pressure Distribution On A Rectangular Tank Due To The Liquid Sloshingtravail compteNo ratings yet

- Assignment-2: Aee244-Fluid Mechanics Aerospace Engineering DepartmentDocument9 pagesAssignment-2: Aee244-Fluid Mechanics Aerospace Engineering DepartmentMuhammed Furkan SOYLUNo ratings yet

- Fluid Mechanics Sessional CE 262Document28 pagesFluid Mechanics Sessional CE 262মোঃমেহেদী হাসান শরীফNo ratings yet

- Cec 107 Practical - Introduction To Fluid MechanicsDocument28 pagesCec 107 Practical - Introduction To Fluid MechanicsVietHungCao100% (1)

- Lab 3-FREE N FORCE VORTEXDocument18 pagesLab 3-FREE N FORCE VORTEXfahmirased100% (1)

- Flow Over A Broad-Crested Weir Exp4Document10 pagesFlow Over A Broad-Crested Weir Exp4Ahmad Ismail90% (10)

- Forced-Vortex-Flow PDFDocument6 pagesForced-Vortex-Flow PDFAnonymous uVmIIuE9hNo ratings yet

- Fluid Mechanics Lab Record of Government Engineering College JagdalpurDocument35 pagesFluid Mechanics Lab Record of Government Engineering College JagdalpurMd. Sahinur RahmanNo ratings yet

- Report 7 CE231 Real OneDocument10 pagesReport 7 CE231 Real OneMohammed KhalidNo ratings yet

- Force and Vortex ExperimentDocument11 pagesForce and Vortex ExperimentPauSomerhalderNo ratings yet

- Flow Lab Experiments Boundary Layers & Pressure ProfilesDocument4 pagesFlow Lab Experiments Boundary Layers & Pressure ProfilesgetsweetNo ratings yet

- Flow Over WeirsDocument15 pagesFlow Over Weirsfarahhanamejeni0% (1)

- Numerical Analysis of Vortices Behavior in A PumpDocument11 pagesNumerical Analysis of Vortices Behavior in A PumpsoukaNo ratings yet

- Flow Through An OrificeDocument8 pagesFlow Through An OrificeKevin VillaNo ratings yet

- Fluid Mechanics Lab ManualDocument53 pagesFluid Mechanics Lab ManualprashanthreddyhNo ratings yet

- Flow Through Small Orifices Lab ReportDocument10 pagesFlow Through Small Orifices Lab ReportYasser AlshantiNo ratings yet

- Discharge Characteristics of Curved Weir PlansDocument5 pagesDischarge Characteristics of Curved Weir PlansThaer HashemNo ratings yet

- Hydraulics Experiment 7Document9 pagesHydraulics Experiment 7Allen Jesse Alfonso AtanacioNo ratings yet

- Falling Head PermeabilityDocument7 pagesFalling Head PermeabilityArjun Kumar100% (1)

- Constant Head Permeability TestDocument12 pagesConstant Head Permeability Testanis098No ratings yet

- Me301 Fluid Mechanics I - Lab1Document6 pagesMe301 Fluid Mechanics I - Lab1GÖLGE GolgeNo ratings yet

- Laboratory Manual For ME231Document28 pagesLaboratory Manual For ME231Varun TandonNo ratings yet

- Measuring Water Flow with Different Metering DevicesDocument38 pagesMeasuring Water Flow with Different Metering DevicesThe GCNo ratings yet

- Experiment - Fre and Forced Vortex UitmDocument22 pagesExperiment - Fre and Forced Vortex UitmAdil Rahman100% (1)

- MM301 Deney I FöyüDocument6 pagesMM301 Deney I FöyüSavaş Koparal DündarNo ratings yet

- Lab ManualDocument15 pagesLab ManualokbhaNo ratings yet

- Relationship Between Fluid Pressure, Velocity & Pipe DiameterDocument12 pagesRelationship Between Fluid Pressure, Velocity & Pipe DiameterNavinRajSakaranNo ratings yet

- Lab Manual 3.3 - LEVEL 1 - Measurement of Flow Over Broad Crestedsharp Crested Weir.Document4 pagesLab Manual 3.3 - LEVEL 1 - Measurement of Flow Over Broad Crestedsharp Crested Weir.Muhamad IzzanNo ratings yet

- Modelling Sedimentation TanksDocument45 pagesModelling Sedimentation TanksJeremy DudleyNo ratings yet

- Flow Over WeirDocument23 pagesFlow Over Weirahmad pidotNo ratings yet

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyFrom EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyNo ratings yet

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- Free and Forced Vortex Experiment AnalysisDocument27 pagesFree and Forced Vortex Experiment AnalysisAuzaNo ratings yet

- Free N Forced Vortex ReportDocument18 pagesFree N Forced Vortex ReportAuza100% (1)

- Isentropic ExpansionDocument22 pagesIsentropic ExpansionVivek Panchal0% (1)

- 4 FlowmeterDocument33 pages4 FlowmeterAuzaNo ratings yet

- Jun 2013Document7 pagesJun 2013AuzaNo ratings yet

- Flow Over Weir Lab Experiment ResultsDocument12 pagesFlow Over Weir Lab Experiment ResultsHafizNotey100% (1)

- Result & Calc Exp BernoulliDocument4 pagesResult & Calc Exp BernoulliAuzaNo ratings yet

- Boyle's law experiment and gas laws relationshipDocument3 pagesBoyle's law experiment and gas laws relationshipAuzaNo ratings yet

- Thermofluids Lab: Fluid MixingDocument25 pagesThermofluids Lab: Fluid Mixingfatenamira50% (2)

- Experiment 2 (Free and Forced Vortex)Document22 pagesExperiment 2 (Free and Forced Vortex)paan78% (9)

- EtiquetteDocument1 pageEtiquetteAuzaNo ratings yet

- Lab Report ContohDocument19 pagesLab Report ContohAuzaNo ratings yet

- Result and CalculationDocument3 pagesResult and CalculationAuzaNo ratings yet

- Marlin Ch07Document28 pagesMarlin Ch07Preciously OmnesNo ratings yet

- Discussion Bernoullis Theorem DemonstrationDocument3 pagesDiscussion Bernoullis Theorem DemonstrationAuzaNo ratings yet

- Table of Content PrintDocument1 pageTable of Content PrintAuzaNo ratings yet

- Extraction of collagen from red snapper skinDocument40 pagesExtraction of collagen from red snapper skinAuzaNo ratings yet

- Shell and Tube Heat ExchangerDocument25 pagesShell and Tube Heat ExchangerbaymaxxxxxNo ratings yet

- What Name Would I Choose For Yourself If You Had A Choice?Document1 pageWhat Name Would I Choose For Yourself If You Had A Choice?AuzaNo ratings yet

- Marine drugs hydrolysates provide antioxidantsDocument6 pagesMarine drugs hydrolysates provide antioxidantsAuzaNo ratings yet

- Lab 2-Water Cooling TowerDocument31 pagesLab 2-Water Cooling Towerriniz92100% (4)

- Lab 2 Water Cooling TowerDocument1 pageLab 2 Water Cooling TowerAuzaNo ratings yet

- Lec 1Document6 pagesLec 1chikukotwalNo ratings yet

- Lec 1Document11 pagesLec 1AuzaNo ratings yet

- Jurnal 5Document160 pagesJurnal 5AuzaNo ratings yet

- Graph of Q Against Head Above Bottom of Notch, HDocument2 pagesGraph of Q Against Head Above Bottom of Notch, HAuzaNo ratings yet

- W2 L1 Accurate Drawing Sept2017Document16 pagesW2 L1 Accurate Drawing Sept2017AuzaNo ratings yet

- W1 L2 AutoCAD Basics March 2017Document22 pagesW1 L2 AutoCAD Basics March 2017AuzaNo ratings yet

- Tutorial NPV and Scoring ModelDocument1 pageTutorial NPV and Scoring ModelMy EverythingNo ratings yet

- Settling Velocity (Deposition) Stokes' Law: - Stokes' Solution With The AssumptionsDocument4 pagesSettling Velocity (Deposition) Stokes' Law: - Stokes' Solution With The AssumptionsGireesh Gowda GiriNo ratings yet

- ESP CentriliftDocument102 pagesESP CentriliftJB BalcacerNo ratings yet

- VDP Series: Dynamic Differential Pressure Control Valves (DPCV)Document3 pagesVDP Series: Dynamic Differential Pressure Control Valves (DPCV)Muhammad MuslimNo ratings yet

- Sewer Hydraulics Calculations Using Manning EquationDocument13 pagesSewer Hydraulics Calculations Using Manning EquationshamashergyNo ratings yet

- Water Hammer. Water and Slurry HammerDocument57 pagesWater Hammer. Water and Slurry HammerDdNak Ydk SubangNo ratings yet

- Notes in Fluid MachineryDocument36 pagesNotes in Fluid MachineryIvanNo ratings yet

- Progress Billing No 17 FPDocument82 pagesProgress Billing No 17 FPLuzon ThorinNo ratings yet

- NOZZLE AND MANWAY SCHEDULEDocument1 pageNOZZLE AND MANWAY SCHEDULEdhaktodesatyajitNo ratings yet

- 07-FO Flow Control Valves CatalogDocument54 pages07-FO Flow Control Valves CatalogFederico TomiNo ratings yet

- Level and Flow Measurement - AdnanDocument83 pagesLevel and Flow Measurement - AdnanMuzamilNo ratings yet

- Laminar Drag Reduction: Prof. Keizo WATANABE Tokyo Metropolitan UniversityDocument73 pagesLaminar Drag Reduction: Prof. Keizo WATANABE Tokyo Metropolitan UniversityVita PuspitaNo ratings yet

- BFC21103 Assignment No. 6Document3 pagesBFC21103 Assignment No. 6Zuety Ikhsan0% (2)

- MYHT Hydraulic Flow MeterDocument12 pagesMYHT Hydraulic Flow MeterW Morales100% (1)

- Lecture 8. Centrifugal PumpDocument68 pagesLecture 8. Centrifugal Pumpmatrix1x100% (1)

- Kuwait BOQ FORMATDocument167 pagesKuwait BOQ FORMATAutoCrankNo ratings yet

- VFA Pricelist PDFDocument119 pagesVFA Pricelist PDFnatashaNo ratings yet

- Fluid Flow (Laminar) Practice Sheet - SolutionsDocument2 pagesFluid Flow (Laminar) Practice Sheet - SolutionsHercules ArgyNo ratings yet

- Pumps (Questions & Answers)Document14 pagesPumps (Questions & Answers)SriRaman Pathakgaru100% (4)

- Hydraulic Machinery PDFDocument1 pageHydraulic Machinery PDFSusanta Biswas0% (3)

- Chapter 3 Flow ComputationDocument16 pagesChapter 3 Flow ComputationRefisa Jiru100% (1)

- Pavientadora CAT AP500E and BG500EDocument10 pagesPavientadora CAT AP500E and BG500Ealexander_1985100% (1)

- Civn7016 Hydraulic Structures: 2. Underflow GatesDocument11 pagesCivn7016 Hydraulic Structures: 2. Underflow GatesAlexander MakaringNo ratings yet

- Modeling A Pump Start-Up Transient Event in HAMMER - OpenFlowsDocument22 pagesModeling A Pump Start-Up Transient Event in HAMMER - OpenFlowsmailmaverick8167No ratings yet

- Blowdown Orifice Sizing CalculationDocument2 pagesBlowdown Orifice Sizing CalculationOmprakaash MokideNo ratings yet

- Chapter1&2 2023 - 2024Document85 pagesChapter1&2 2023 - 2024Sulaiman ObaidNo ratings yet

- Plambing Mg-9. Sistem Pembuangan & Vent-3Document16 pagesPlambing Mg-9. Sistem Pembuangan & Vent-3Tyas SeptiaraniNo ratings yet

- Spring Support Used in PipingDocument7 pagesSpring Support Used in Pipingashish.mathur1No ratings yet

- Tarif Agricole 2013Document68 pagesTarif Agricole 2013FLONo ratings yet

- E&P-Jabsco-Rule 2020 Customer Price ListDocument31 pagesE&P-Jabsco-Rule 2020 Customer Price ListpaulaNo ratings yet

- Testing and Commissioning of Water Supply Piping System Network PDFDocument4 pagesTesting and Commissioning of Water Supply Piping System Network PDFHumaid ShaikhNo ratings yet